Abstract

In this paper, an experimental test results on silicon rubber insulator with voltage of 20 kV have been shown. Artificial aging on insulator has been done using solid layer methods according to IEC60507 standard. Leakage current waveforms during the experimental studies were measured. Normally Fast Fourier transform method used to find the harmonic spectrum in the leakage currents. Three states of analysis are considered. In the first state, it is done with nominal voltage and without arc. In the second state, it is done in the presence of dry band arcing and corona discharge and in the last case, continuous arc is investigated and in each state harmonic analysis is performed. It is observed that in second state the third harmonic components increase rather than in the first state. Artificial aging on insulator has been done using solid layer methods according to IEC60507 standard. Leakage current waveforms during the experimental studies were measured. Eventually, to distinguishing pollution intensity, equivalent salt deposit density calculations are implemented. At the end, finite element method has been investigated for the results of water droplets existing on the surface of silicone rubber materials and electric field distribution along the surface of insulator.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Where silicon rubber is used as an outdoor insulator, various environmental factors such as ultraviolet light, rain and air pollutant deteriorate the material properties. Then, tracking and erosion are caused by electrical factors such as arc and corona partial discharges, when the power system is in operation tracking and erosion of polymer sheds, chalking and crazing of sheds which lead to increased contamination, arcing and flashover, bonding failures and electrical breakdowns along the rod-shed interface and corona splitting of sheds which lead to electrical breakdown [1].

It is well known that aging, which leads either to tracking or erosion or to flashover under contaminated conditions at normal operating voltage, is still the main cause of failures for non-ceramic insulators [2]. Exposure to dirty environment easily makes insulators polluted. After the polluted layer being wetted, the insulation capacity of the contamination insulator will decrease, and flashover is often invited which seriously impacts the reliability of power supply. Pollution existence and humidity increase the leakage current and surface arc. Subsequently, it leads to insulator electrical flashover and loss of transmission lines [3].

The leakage current provides information on the amount of contamination on a polluted insulator. The relationship between the leakage current and the discharge phenomena has been investigated on the polymer material under wet condition. In general, during aging test, two kinds of discharges are observed that can evaluate the insulation performance. One of them is corona partial discharge that occurs between water droplets. The other is dry band arc discharge that occurs between dry bands on the surface of the polymeric material that may cause tracking and erosion phenomena, its cumulative charge is much larger than that of a corona discharge [4].

Therefore, the study of the pollution effects on the leakage current and avoiding of its occurrence will get much special importance and in this paper, both of leakage current and Fast Fourier transform (FFT) analysis of polymeric insulator has been investigated on artificial pollution.

Under rain and fog conditions, the presence of water droplets intensifies the electric field strength on the surface of a polymer insulator. As a result, corona discharge (weak electrical activity) that occurs between water droplets accelerates the aging of the shed material of a polymer insulator. The study of the electric field of polymer insulators under wet conditions is important for the in-depth understanding of the aging process and the pollution flashover beginning mechanism for polymer insulators. The electrical characteristics of the material have not been explained sufficiently. Hence, the diagnostic methods are strongly required. The diagnostic factors are: hydrophobicity, ESDD, flashover voltage (FOV), leakage current and surface conductivity [5, 6]. ESDD is the equivalent amount of NaCl that would yield the same conductivity at complete dilution. ESDD is used as offline method, which is used for comparison criteria with other methodologies. Due to it is a main factor to arrange contamination severity and map pollution areas, forecasting ESDD plays an important role in the safety and reliability of power system. Therefore, the main way to measure pollutions on high voltage insulators is manual measurement of ESDD at present. It is possible to develop a relationship between leakage current with respect to ESDD level for a specific non-soluble material level because of almost linear function. Nowadays, ESDD has been adopted widely as a parameter of pollution severity in the whole world.

The water droplets play several roles in the pollution flashover and aging of composite insulators, because of high permittivity and conductivity of water droplets, electric field intensity increase at the insulator surface. The surface corona discharges from water droplets age the weather shed material of the insulator [7].

Recognizing electrical field and potential distribution at the dielectric insulation has always been important as a result of the general necessity to reduce the physical size of HV systems and to ensure a high degree of reliability in operation. Improvement of HV system reliability demands progress in the design criteria as well as a better understanding of the insulation behavior [8].

At higher voltages, field can be high enough to cause damage to the insulator sheath due to the corona discharge, hence grading devices need to be used to reduce the electric field to acceptable levels [9]. Calculation of stress levels on an insulator when subjected to a high voltage provides an important insight into the safety measures pertaining to high voltage transmission lines. If the E-field magnitude in any regions exceeds critical values, excessively large magnitudes of discharge activity can ensue, and the long- or short-term performances of the insulator may be affected; there is a direct relationship between the E-field distribution and the resulting discharge activity within composite insulators. The presence, location and magnitude of discharges are a function of the magnitude and direction of the local E-field [10].

The other objectives of this paper are to study the electric field enhancement effects by water droplets on the surface of polymer insulator, and to calculate the electric field distribution along a polymer insulator under different conditions of water droplet on polluted silicon rubber insulator (SiR), because of the presence of water droplets at the surface of polymer insulator.

2 Experimental test

2.1 High voltage test set up

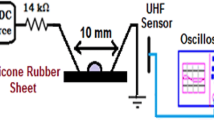

In order to execute the tests on contaminated insulators and measure leakage current and save the data, the laboratory setup was prepared as shown in Figs. 1 and 2. An experimental setup consisting of a high voltage transformer with ratio of 220 V/100 kV, output: 5 kVA, short-circuit voltage: approx. 5 %. Capacitive divider and data acquisition system is shown in Fig. 1. The transformer is employed to energize the insulators to the required voltage stress. Data acquisition system which provides the LC information, e.g., the time variations, maximum, average, etc. comprises a digital oscilloscope, back to back connected Zener diodes (15 V) for overvoltage protection and a shunt resistor for measuring LC. Also, Fig. 2 shows the experimental set up.

2.2 Insulator contamination

An smooth pollution layer is coated on the SiR insulator surface by a method of artificial contamination provided in [11]. This method can produce an approximately uniform contamination layer and can also be performed rapidly, so several insulators can be contaminated with the same slurry. Because of surface hydrophobicity of SiR insulators, contaminating is rather difficult. Therefore, the insulators should be pre-contaminated initially according to this procedure, Kaolin powder is deposited after spraying a fine mist of water droplets on the surface. Afterwards, the insulator is immersed in the slurry of contaminants and dried. Kaolin composition consists of 40 g kaolin, 1,000 g tap water and 10 g NaCl, when the volume conductivity of tap water is 0.041 S/m.

2.3 Test insulators

Room temperature volcanism (RTV) SiR insulator of rating 20 kV (L-L) was used for laboratory artificial aging study. Figure 3 illustrates the photographs of actual insulators as well as test arrangements. Table 1 shows the characteristics of tested insulators. After measuring leakage current, ESDD was measured according to IEC60507 to determine the amount of insulators’ surface contamination level.

3 Leakage current under clean surface

Initially, a clean 20 kV silicon rubber was tested with an applied voltage of 11.5 kVrms. No visual discharges were observed under this test condition. Figure 4a shows the typical waveform of LC obtained at this test condition. It is noticed that even at high relative humidity negligible amount of LC only flows on the surface of the insulator due to clean surface condition. Figure 4b shows the frequency spectrum plot of the leakage current during clean surface condition. It is observed that the LC signal under clean surface condition contains the higher order harmonic components like 4th, 5th, and 7th. Also, it was observed that in clean condition, the 5th harmonic component was always greater than the 3rd harmonic. That is, the insulator was in its normal condition. In the polluted dry condition, the harmonic content does not change, it looks like a clean condition.

4 Leakage current under pollution condition

Sometimes, transmission and distribution lines pass near the coastal, desert and industrial areas. Therefore, insulators are exposed to the outdoor environment. In this environment, different types of contaminants such as NaCl, \(\mathrm{{CuSO}}_4\) salts are coming from the different sources and deposited on the insulator surface. Salt contamination makes a drastic reduction in the breakdown insulation level of the affected insulators, which will lead to flashover.

Artificial aging tests should simulate actual field conditions as much as possible and test results should be validated by the performances in actual fields. They want to evaluate degree of aging deterioration of a polymer insulator by means of the magnitude of leakage current and/or its cumulative charge flowing on that specimen polymer insulator. It is pointed out, however, that conductive current flowing only in contaminated and wetted layer on the surface of a polymer insulator without any discharge would not deteriorate the surface so much as compared with the case of corona discharge or dry band arc currents. The typical surface leakage current pattern has been recorded on the following three levels.

4.1 Conductive current

For completely wet surfaces, which were obtained in the successive contamination tests, LC also appeared to be sinusoidal but resistive and at higher level (Fig. 5a). The cases in which the hydrophobic properties were either partially lost or a weak dry band activity started, the patterns could be resistive and non-linear. It is observed that the LC signal (Fig. 5b) shows the frequency spectrum plot of the leakage current during pollution surface condition. It is observed that the LC signal under pollution condition contains the 3rd harmonic components greater than 5th and other harmonic components. All of the results are shown in Table 2.

4.2 Dry band arcing and corona arcing

We have investigated the relationship between the leakage current and the discharge phenomenon on the polymer material under moist condition. In general, two kinds of discharges are observed during test which can evaluate the insulation performance. One of them is corona partial discharge that occurs between water droplets, in which Si–C bonding of silicon rubber is broken down by photon energy because the photon energy due to the corona discharge is larger than the bonding energy of Si–C. Corona discharge (weak electrical activity) that occurs between water droplets, in which Si–C bonding of SiR is broken down by photon energy because the photon energy due to the corona discharge is larger than the bonding energy of Si–C. The other is dry band arc discharge that occurs between dry bands on the surface of the polymeric material. Thus, the dry band arc discharge and the corona discharge influence the insulator performance and therefore it is necessary to investigate their characteristics in aging test [12].

The non-linear behavior, as the one in Fig. 6a occurred during and prior to the visible discharge activity and, therefore, the discharge currents can be considered as a spike appearing on the crest of a non-linear LC waveform. Figure 6b shows the frequency spectrum plot of the leakage current during pollution surface condition. It is observed that the LC signal under pollution condition contains the 3rd harmonic components higher than 5th and other harmonic components. All of the results are shown in Table 3.

4.3 Fully arcs with dry band arcing

The partial discharges will elongate along the surface and lead to fully arcing. This condition is the previous state of the insulator flashover. As dry band discharges continue, it can lead to degradation of the polymer material. C–H and Si–\(\mathrm{{CH}}_3\) bonds will be broken and erosion occurs. With loss of the polymer lattice, amount of silicone on insulator surface is reduced and also aluminium trihydrate (ATH) particles appear on insulator skin.

This phenomenon will cause the insulator surface to become hydrophilic. Partial discharges will elongate along the surface and lead to fully formed arcs. Figure 7a shows these phenomena. Figure 7b shows the result. All of the results about leakage current and harmonics of leakage current are shown in Table 4. The result of Table 4 shows that the surface of insulator became dry, and decrease of leakage current is inevitable, because arc was decreasing.

5 The solution and determination of the amount of pollution

The contaminants on the insulator surface can be classified into two types. One soluble conductive component and other is insoluble non-conductive components. The most common conductive components consist of ionic salts such as sodium chloride, sodium sulfate, magnesium chloride, etc. The severity of contamination on the insulator surface due to these salts are generally presented and expressed by the term equivalent salt deposit density (ESDD). In the seaside, NaCl is the main component of the insulator contamination. This contaminant is coming out from the sea and deposited on the insulator surface. After measuring leakage current, ESDD was measured according to IEC60507 to determine the amount of insulators’ surface contamination level. Initially, the insulator is cleaned properly and then contaminated by different amounts of NaCl salt solutions. The wet contaminated insulator is then put under the sunlight for 1 h to simulate the dry conditions. The dry granules of sodium chloride are wiped out from the insulator surface by the brush. The collected salts by the brush are then dissolved in 500 ml distilled water. The resulting suspension is kept stirred for at least 2 min before the measurement of its volume conductivity \(\sigma _\theta \) S/m at the temperature \(\theta \,^{\circ }\)C. \(\sigma _{20}\) is obtained from \(\sigma _\theta \) in Eq. (1):

B is the factor depending on \(\theta \) in Table 5, for other values of temperature \(\theta \), within the range of 5–30 \(^{\circ }\)C, the factor B is obtained by interpolation [11].

The salinity of the suspension is determined using Eq. (2), ESDD is then obtained by Eq. (3):

where V is the volume of the suspension \((\text{ cm}^{3})\) and A is the area of the cleaned surface \((\text{ cm}^{2})\)

Table 6 shows the results of measured electrical conductance and calculated ESDD in tested insulators.

Result of ESDD in Table 6 according to IEC or IEEE institute show that the type of pollution is heavy.

6 Procedure of simulation

In order to analyze the effects of contaminants on surface of silicon rubber insulator, 3D calculation method is applied. For the studies described in this paper, Comsol 3.5 program has been employed. Voltage, electric field distribution and maximum electric field are examined by results of calculation.

6.1 Characteristic of SiR for finite element method (FEM) analysis

Composite insulators essentially consist of a fiber glass core rod covered by weather sheds of silicone rubber and equipped with metal end fittings, the basic design of a polymer insulator is as follows: a fiber reinforced plastic (FRP) core having relative dielectric constant 6, attached with two metal fittings, is used as the load bearing structure. Weather sheds made of RTV silicone rubber having relative dielectric constant 4.5 are installed outside the FRP core. Surrounding of the insulator is air having relative dielectric constant 1; AC 11.5 kV is energized on the lower electrode while the upper electrode connected with ground.

6.2 Effect of water droplets on electric field distribution

There are three main regions of interest when considering the E-field distribution of composite insulators.

-

1.

On the surface of, and in the air surrounding, the polymer weather-shed surface and surrounding the end-fitting seal [13].

-

2.

Within the fiberglass rod and polymer rubber weather-shed material, as well as at the interfaces between these materials and the metal end fitting.

-

3.

On the surface of, and in the air surrounding the metallic end fittings and attached corona rings [14]. If the E-field magnitude in any of these three regions exceeds critical values, excessively large magnitudes of, discharge activity can ensue, and the long or short-term performance of the insulator may be affected. There is a direct relationship between the E-field distribution and the resulting discharge activity on and within composite insulators. The presence, location and magnitude of discharges are a function of the magnitude and direction of the local E-field. In this paper, we investigate the effect of droplet on the insulators in two states.

6.2.1 Water droplets on the shed

In order to examine electric field distribution by water droplets, three water droplets exposed to the shed of insulator, and electric field distribution are investigated. The distances between droplets are 1.5 mm. The placements of droplets on sheet of insulator are shown in Fig. 8.

Figures 9, 10, 11, 12, 13 and 14 show the result of electric field analysis, it can be found that the maximum of the electric field appeared at the beginning and end of polymer insulator.

The results of Figs. 9, 10, 11, 12, 13 and 14 are evident that electrical field changes along the horizontal line are due to the change in the dielectric constant of dielectric. The E-field distribution on composite insulators is non-linear with the regions close to the energized end normally being subjected to the highest magnitudes, for most transmission line applications, the dominant direction of the E-field is along the axis of the insulator. As can be seen from figures, the magnitude of the E-field close to the energized end is higher than that at the grounded end. Increasing the number of droplets on the insulator surface causes non-uniform field in insulator. Increase of electrical field and non-uniform field in long-term periods causes adverse effects on insulators.

6.2.2 Water droplets on the sheath

The placements of droplets on sheath of insulator are shown in Fig. 15.

From the results of Figs. 16, 17, 18, 19, 20, 21, adding water droplets can cause the peaks and non-uniform electrical field distribution complete. Peaks are due to the difference in the dielectric constant on core, air and shed.

7 Conclusion

Experimental results on polymer insulator to understand the pollution severity by harmonic content of leakage current signal have been presented in this paper. An experimental test result on silicone rubber insulator has been done. Third harmonic components of leakage current waveform are closely related to the pollution on the insulator. Under clean conditions, no flashover occurred during the tests, when 3rd harmonic is lower than 5th harmonic, the insulators have no or very light contamination. Therefore, harmonic analysis of leakage current will be an efficient approach to determine the pollution severity of outdoor polymer insulators. Dry band discharges are observed during test which can evaluate the insulation performance; when discharge starts, 3rd harmonic component increases obviously rather than foundation harmonic. Discharge activity was observed as spikes on the crest of the waveform due to the formation of dry bands. Result on ESDD shows that the type of pollution is heavy. In the present study, simulation of electric potential and electric field for the actual composite insulators of 20 kV has been carried out using 3D analysis in Comsol 3.5 program. The result shows that increasing the number of droplets on the insulator surface causes non-uniform field in insulator. As can be seen from the result, the magnitude of the E-field close to the energized end is higher than that at the grounded end.

References

Seifert JM, Hubl W (2001) Hydrophobicity effect of silicone housed composite insulators and its transfer to pollution layers–design and environmental parameters influencing the hydrophobic surface behavior. Iraklion symposium, Kreta (26 and 27th April)

Deng H, Cherney EA, Hackam R (1993) Effects of particles size of ATH fillers on the performance of RTV rubber coatings. In: IEEE electrical insulation and dielectric phenomena conference, pp 598–604

Liu Y, Wang JK (2002) Analysis of large area pollution flashover occurred in Shannxi power network on Dec. 18, 2000 and preventative measures for similar accidents. Power Syst Technol 26:82–85

Otsubo M, Hashiguchi T, Honda C, Takenouchi O, Sakoda T, Hashimoto Y (2003) Evaluation of insulation performance of polymeric surface using a novel separation technique of leakage current. IEEE Trans Dielectr Electr Insul 10(6)

Wang T, Ou QH, Wu JH (2004) Test and research on cleaning of high voltage transmission line based on salt density. Power Syst Technol 28:22–26

Manabe Y (1996) New measuring equipment of ESDD of transmission line insulators. In: Proeedings of joint conference Asian international conference on dielectrics and electrical 96‘AICDEl and 4th-JCCEID Xi’an

Kaana S, Nkusi PH (1988) Potential and electric field distributions at a high voltage insulator shed. IEEE Trans Electr Insul 23(2)

Kojimi S, Oyama M, Yamashita M (1988) Potential distribution of metal oxide surge arresters under various environmental conditions. IEEE Trans Power Deliv 3(3):984–989

Subba Reddy B, Kumar A, Shashikala A, Ravishankar KV (2009) Electric field modeling of composite high voltage insulators, India. In: IEEE annual conference (INDICON)

Que W, Sebo SA (2002) Typical cases of electric field and voltage distribution calculations along polymer insulators under various wet surface conditions. In: Annual report conference on electrical insulation and dielectric phenomena

IEC 60507 (1991) Artificial pollution tests on high-voltage insulators to be used on AC systems. International Electrotechnical Commission, Geneva

Bologna FF, Reynders JP, Britten AC (2003) Corona discharge activity on a string of glass cap-and-pin insulators under conditions of light wetting, light non-uniform contamination. In: IEEE Bologna PowerTech Conference, Bologna June, pp 23–26

Phillips AJ, Childs DJ, Schneider HM (1999) Aging of non-ceramic insulators due to corona from water drops. IEEE Trans Power Deliv 14(3):1081–1086

EPRI (1998) Application guide for transmission line NCI. Palo Alto, TR, pp 111–566

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joneidi, I.A., Kamarposhti, M.A., Shayegani Akmal, A.A. et al. Leakage current analysis, FFT calculation and electric field distribution under water droplet on polluted silicon rubber insulator. Electr Eng 95, 315–323 (2013). https://doi.org/10.1007/s00202-012-0260-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-012-0260-8