Abstract

Two-dimensional explosion experiments were conducted to discuss the interaction between a blast wave and sand and show the mitigation effect of the sand on the blast wave. The explosive used was a detonating cord 1.0 m in length, which was initiated in a sand hill shaped like a triangular prism and whose cross section was an isosceles triangle with base angles of 30\(^\circ \). Sand-hill heights of 30 and 60 mm were used as parameters to discuss the effect of sand mass upon blast-wave strength. The interaction of the blast wave with the sand/air interface causes multiple peaks in the blast wave, which are induced by successive transmissions at the interface. The increase in the sand mass further mitigates the blast parameters of peak overpressure and positive impulse. The results of this experiment can be utilized to validate the numerical method of solving the problem of interaction between a compressible fluid and a particle layer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High-energy materials have been incorporated into industrial activities such as mining and blasting excavation, but an accidental detonation generates a blast wave, causing a physical hazard. The pressure increase induced by a blast wave is sufficient to destroy windows or rupture eardrums at a certain distance.

The placement of barrier materials around a high explosive has been found to be an effective means of mitigating its effects. Homae et al. [1] conducted experiments in the case of detonating 100 g of Pentolite in encircling sand to understand the sand-mass effect. A larger sand barrier was found to have a larger attenuation effect on the peak overpressure and the positive impulse. Rigby et al. [2] investigated the detonation of a buried explosive in dry sand and discussed the effect of the standoff distance between the explosive and air/sand layer interface. This study showed that the pressures and impulses are much lower in magnitude for the longer standoff distance. The mitigation of the blast wave could be induced by transportation of some of the internal and kinetic energies of the detonation products into the sand. However, the mechanism of the attenuation effect has yet to be elucidated quantitatively because factors such as the physical properties of the particle layer and an estimation of the energy transfer between materials are difficult to perform by experiment only.

Since numerical simulations can be used to explore the energy transfer mechanisms between materials quantitatively, a reliable numerical method is very important in estimating physical hazards in general and in understanding the mitigation mechanism of the blast wave in particular. To determine the complex flow behavior including the interaction of a compressible flow, a blast wave, and a particle layer, it is necessary to formulate a model that includes their physics to a sufficient degree. Some methods treat phenomena including the compressible flow and the particle layer using an Eulerian–Eulerian approach [3], a Lagrangian–Lagrangian approach such as smoothed-particle hydrodynamics [4] (SPH), or an Eulerian–Lagrangian approach such as the computational fluid dynamics/discrete-element method [5] (CFD/DEM).

To validate these methods, some simple experiments are utilized. Some researchers have used a shock tube in which a generated shock wave collides with a particle layer [6,7,8,9,10] or propagates along a particle layer [3, 11]. The former technique can be used to gage the one-dimensional reflection and transmission behavior of the shock wave at the air/particle-layer interface and the movement and inner-pressure properties of the particle layer. The latter concerns the uplift of the particle layer by propagation of the one-dimensional shock wave along it or by partial collision between the one-dimensional shock wave and a shallow particle layer. However, few studies have handled the shock-wave/particle-layer-interaction problem in multiple dimensions.

Therefore, in the present study, in order to obtain fundamental experimental data to validate numerical methods and to determine the mitigation effect of a particle layer upon the blast wave, we conduct two-dimensional explosion experiments with a sand barrier.

2 Experimental details

2.1 Sand

We used No. 4 Tohoku silica sand (Kita Nihon Sangyo Co., Ltd.) whose true density was 2620 kg/m\(^3\) and which was composed of over 98% SiO\(_2\). First, its particle-size distribution was estimated. Figure 1a shows the approximate shape of the ellipsoid whose half-lengths of major and minor axes are denoted as a and b, respectively. The radius R of a sphere having a volume equivalent to that of the ellipsoid is estimated as

Figure 1b denotes the numerical distribution of the equivalent radius R from 1000 randomly selected particles. This distribution is reasonably assumed to be Gaussian, and the average and standard deviation of the radius, R, are 0.938 and 0.141 mm, respectively. The bulk density of sand in the present study is estimated as 1650 kg/m\(^3\).

2.2 Setup

Figure 2 shows the schematics of the present experiments. A steel plate is regarded as the ground. The test explosive was a 1.0-m-long detonating cord (Kayaku Japan Co., Ltd.), allowing two-dimensional explosion experiments to be conducted. This cord was filled with pentaerythritol tetranitrate (PETN) of 10.6 g/m, and it was initiated using a No. 6 detonator (Kayaku Japan Co., Ltd.). The detonating cord was affixed to plywood using an adhesive tape in order to remove its deflection, and the assembly was put on a wooden stand as shown in Fig. 2a. The detonator was fixed at the end of the cord. The origin (O in Fig. 2a) in the present study was defined as the midpoint of the detonating cord on the steel plate. The blast-wave pressures were recorded using piezoelectric pressure sensors (PCB 113B28, 100 mV/psi) situated at 6 points as shown in Fig. 2a. Figure 2b–d denotes cross section A in Fig. 2a. In the case without a sand hill (Case 1) in Fig. 2b, the height between the steel plate and the center of the detonating cord was 34 mm. In Fig. 2c, d, a detonating cord was initiated in a sand hill.

Here, we explain how the sand hill was formed as described below. First, a leveling thread was extended where the ridge of a sand hill would be. Then, enough sand was gently poured from near the thread to make the sand hill on a steel plate. Finally, excess sand was removed with a cardboard scraper to trim slopes. Their tilt angles were adjusted and confirmed with a protractor when viewed from the direction of the ridge. Sand hills were formed in the shape of a triangular prism whose cross section is an isosceles triangle with base angles of 30\(^\circ \). The heights of sand and the sand mass per unit length were 30 mm and 2.362 kg/m for Case 2 and 60 mm and 10.079 kg/m for Case 3, as shown in Fig. 2c, d, respectively. The center of the detonating cord was located at a position where the distances between the sand/air and sand/steel-plate interfaces were equivalent. The radii, r, are 14 mm in Fig. 2c and 28 mm in Fig. 2d, respectively. A series of explosion experiments was conducted to confirm the reproducibility of the peak overpressure and positive impulse.

3 Results

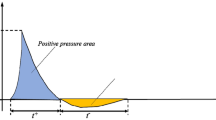

Figure 3 shows the pressure–time histories of (a) Case 1, (b) Case 2, and (c) Case 3. Their properties and the blast parameters of peak overpressure and positive impulse are estimated to show the sand effect on the blast-wave mitigation. Only one peak is observed for Case 1. Since the blast wave is so strong, Case 1 shows the high-frequency oscillation before the blast wave reaches the pressure sensors because vibration of the steel plate is observed. Multiple local and small peaks appeared for Case 3. In the present study, multiple peaks always occurred, and their observation times show good reproducibility.

These peaks arise from the complex blast-wave behavior in the sand hill and at the sand/air interface. After detonation, the blast wave cylindrically expanded from the initiation point in the sand hill. The wave was reflected as a rarefaction wave back into the sand and transmitted as a blast wave into the air at the sand/air interface. In addition, the blast wave also reflected off the steel plate. Then, multiple waves in the sand hill were generated and successively transmitted to air each time they reached the sand/air interface, thereby inducing multiple-blast-wave generation. Since these blast waves were local and weak, they could be observed, especially in Case 3 where the sand hill was larger and the blast wave was weaker. At 600 mm in Case 3, the peak overpressure was observed at the fourth peak, as shown in Fig. 3c. As the third and fourth peaks overlap, the peak overpressure recovered between 600 and 800 mm. Finally, a blast wave with one peak at 1600 mm appeared.

Figure 4a, b shows the peak overpressure and positive impulse, respectively. As the blast wave expands from the initiation point, the peak overpressure and impulse are reduced, except between 600 and 800 mm in Cases 2 and 3. Because the overlap between two peaks recovers the blast-wave strength, the peak overpressures in Cases 2 and 3 between 600 and 800 mm show different behaviors. The sand hill mitigates the peak overpressure and the positive impulse, and the increase in the sand mass causes further mitigation. The peak-overpressure ratios normalized with respect to that in Case 1 gradually increase with distance, and those at 600 and 1600 mm are 0.20 and 0.40 for Case 2 and 0.07 and 0.20 for Case 3, respectively. On the other hand, the positive-impulse ratios are independent of the distance and are constant at 0.30 for Case 2 and 0.15 for Case 3, respectively. This indicates that local physical properties such as the peak overpressure are strongly affected by the instantaneous flow field with multiple blast waves and their interference, whereas the integrated blast parameters such as the positive impulse are only determined by the initial conditions of how much sand is utilized. Further study with different positions of the pressure sensor and a different sand size could reveal the interaction between the blast wave and the sand hill, as well as enable an understanding of the effects of particle properties such as density and size upon blast-wave mitigation.

These experimental data show the physics involved in the interaction between blast waves and sand and can be utilized to validate the numerical method describing a coupled compressible fluid and particle layer in two dimensions. The interaction between the blast wave and the sand occurs within 100 \(\upmu \)s, as estimated from the radius r (\(\le 30\) mm) between the center of the detonating cord and the sand/air and sand/steel-plate interfaces divided by the speed of sound in air (340 m/s). Many mitigation mechanisms could be considered, including friction and heat transfer between sand and air, transfer of kinetic energy to the sand, and deformation and fragmentation of the sand. However, experiments are limited in their ability to show how energy transfer occurs between the blast wave, the air, and the particle layer. Thus, the blast-wave-mitigation mechanism is expected to be understandable from low-cost two-dimensional numerical simulations that model the present experiments.

4 Conclusion

Two-dimensional explosion experiments were conducted to understand the interaction between a blast wave and sand. Interaction with the sand/air interface induces multiple peaks in the blast wave, which are generated by successive transmissions at this interface. These peaks could be observed, especially for larger sand hills, where the blast wave was weaker. The sand hill mitigates the peak overpressure and the positive impulse. An increased mass of sand offered further mitigation. Data from this experiment can be used to validate numerical methods treating the interaction between a compressible fluid and a particle layer.

References

Homae, T., Wakabayashi, K., Matsumura, T., Nakayama, Y.: Attenuation of blast wave using sand around a spherical pentolite. Sci. Technol. Energ. Mater. 68, 90–93 (2007)

Rigby, S.E., Fay, S.D., Clarke, S.D., Tyas, A., Reay, J.J., Warren, J.A., Gant, M., Elgy, I.: Measuring spatial pressure distribution from explosives buried in dry Leighton Buzzard sand. Int. J. Impact Eng. 96, 89–104 (2016). https://doi.org/10.1016/j.ijimpeng.2016.05.004

Houim, R.W., Oran, E.S.: A multiphase model for compressible granular-gaseous flows: formulation and initial tests. J. Fluid Mech. 789, 166–220 (2016). https://doi.org/10.1017/jfm.2015.728

Lucy, L.B.: A numerical approach to the testing of the fission hypothesis. Astron. J. 82, 1013–1024 (1977). https://doi.org/10.1086/112164

Tsuji, Y., Kawaguchi, T., Tanaka, T.: Discrete particle simulation of two-dimensional fluidized bed. Powder Technol. 77, 79–87 (1993). https://doi.org/10.1016/0032-5910(93)85010-7

Ben-Dor, G., Britan, A., Elperin, T., Igra, O., Jiang, J.P.: Experimental investigation of the interaction between weak shock waves and granular layers. Exp. Fluids 22, 432–443 (1997). https://doi.org/10.1007/s003480050069

Ling, Y., Wagner, J.L., Beresh, S.J., Kearney, S.P., Balachandar, S.: Interaction of a planar shock wave with a dense particle curtain: modeling and experiments. Phys. Fluids 24, 113301 (2012). https://doi.org/10.1063/1.4768815

Lv, H., Wang, Z., Li, J.: Experimental study of planar shock wave interactions with dense packed sand wall. Int. J. Multiph. Flow 89, 255–265 (2017). https://doi.org/10.1016/j.ijmultiphaseflow.2016.07.019

Theofanous, T.G., Mitkin, V., Chang, C.-H.: The dynamics of dense particle clouds subjected to shock waves. Part 1. Experiments and scaling laws. J. Fluid Mech. 792, 658–681 (2016). https://doi.org/10.1017/jfm.2016.97

Wagner, J.L., Beresh, S.J., Kearney, S.P., Trott, W.M., Castaneda, J.N., Pruett, B.O., Bear, M.R.: A multiphase shock tube for shock wave interactions with dense particle fields. Exp. Fluids 52, 1507–1517 (2012). https://doi.org/10.1007/s00348-012-1272-x

Khmel, T.A., Fedorov, A.V.: Effect of collision dynamics of particles on the processes of shock wave dispersion. Combust. Explos. Shock Waves 52, 207–218 (2016). https://doi.org/10.1134/S0010508216020118

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by A. Higgins.

Rights and permissions

About this article

Cite this article

Sugiyama, Y., Izumo, M., Ando, H. et al. Two-dimensional explosion experiments examining the interaction between a blast wave and a sand hill. Shock Waves 28, 627–630 (2018). https://doi.org/10.1007/s00193-018-0813-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-018-0813-5