Abstract

In the discussion on innovations for sustainable development, radical innovations are frequently called for in order to transform society into a system perceived as sustainable successfully. The reason for this is the greater environmental efficiency of these innovations. This hypothesis is, however, not supported by empirical evidence. Given the background of a global increase in coal-fired power plants and the consequent environmental impacts to be expected, the hypothesis that radical innovations are superior to incremental innovations and will thus be introduced to the market is reviewed on the basis of fossil fuel power plants. In this paper we examine the diffusion of incremental and radical innovations in the field of power plants and the basic obstacles confronting these innovations. For example, we compare Pressurized Pulverized Coal Combustion (PPCC) as a radical innovation and supercritical coal-fired power plants as an incremental innovation. PPCC failed due to technological uncertainty. We show in an ex-post analysis of the German R&D portfolio for power plants in the past three decades from an environmental viewpoint that, for radically innovative technologies, it was difficult to be accepted by possible investors. The future potential of radical innovations in the field of power plant technology is to be regarded as relatively low, especially due to technological uncertainty, market uncertainty and sunk costs. The conclusion for future R&D work in the sector of large-scale power plants is that an innovation is more likely to succeed if it follows established technological trajectories. In the context of energy market liberalization, hardly any radical innovations are expected in the technology of power plants. The findings of this paper may also be helpful to evaluate risks or probabilities of success of technologies being developed currently. We discuss for example the technological trajectories currently favored in CO2 capture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the discussion on innovations for sustainable development, radical innovations are frequently called for in order to transform society into a system perceived as sustainable successfully (Vellinga 2004). The reason for this is the expectation that these innovations will increase environmental efficiency by factor 10, compared to factor 2 for incremental innovations (Geels et al. 2004).

The literature, however, provides hardly any empirical evidence in favor of this hypothesis. Supporters of this viewpoint admit that such changes need at least one generation to become accepted, since they have to pass several stages. Radical innovations should ideally develop in small market niches first, then diffuse and finally replace existing technologies. In the literature this idea of innovation is described as transition management (Geels 2004).

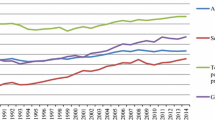

Against the backdrop of a projected global increase in the diffusion of coal-fired power plants and the environmental burden—in particular in terms of CO2 emissions—to be expected, the potential and the relevance of radical innovations in this field are of interest to researchers. As shown in Fig. 1, the International Energy Agency (IEA 2008b) assumes that the global need in electricity capacity will increase significantly in the next decade and that fossil fuel power plants will be the central basis of future electricity generation worldwide.

Predicted increase in capacity worldwide (IEA 2008b)

In this study, we use the development of power plant technology in Germany as an example to show, in an ex-post analysis, to what extent radical innovations have been successful and the obstacles they had to face. We show the relevance of these aspects for future R&D policy by applying our concept to the ongoing discussion of CO2 capture.

The paper is organized as follows. In Section 2, we describe the concepts of radical and incremental innovation and factors that may influence technology choice on the basis of theories of innovation in mainstream and evolutionary economics. In Section 3, we analyze the development of the German R&D portfolio for power plants in the last decades. We then use the examples of Pressurized Pulverized Coal Combustion (hereafter: PPCC) and supercritical coal-fired power plants in Section 4 in order to compare the development of radical and incremental innovations. This section is followed by an evaluation of risks and probabilities of success with regard to technological trajectories of CO2 capture which at present are favored globally. Section 5 draws several conclusions.

2 Incremental and radical innovations from the perspective of evolutionary economics

2.1 Definition of environmental innovations

In accordance with the OECD Guidelines for Collecting and Interpreting Technological Innovation Data (OECD 2005), we distinguish between technical and organizational innovations. Technical innovations are divided into product and process innovations:

-

Process innovations occur when a given amount of output (goods, services) can be produced with less input.

-

Product innovations require improvements to existing goods (or services) or the development of new goods. Product innovations in machinery in one company are often process innovations in another firm.

-

Organizational innovations include new forms of management, e.g. total quality management.

We use the following definition of environmental innovation in our report (Kemp and Arundel 1998; Rennings and Zwick 2002): Environmental innovations consist of new or modified processes, techniques, practices, systems and products to avoid or to reduce environmental harms. Environmental innovations may be developed with or without the explicit aim of reducing environmental harm. They may also be motivated by the usual business goals such as profitability or enhancing product quality. Many environmental innovations combine an environmental benefit with a benefit for the firm or user.

This means that, among all innovations, environmental innovations are technological, economic, institutional and/or social changes which result in an improvement in environmental quality (Klemmer et al. 1999). Regarding improvements of coal-fired power plants, it may be controversial to characterize them as environmental innovations. However, if the greenhouse gas emissions decrease significantly, or energy efficiency is improved, they can be considered environmentally innovative.

The extent to which an improvement is made may be classified according to their degree of “novelty”. According to Freemann (1992), incremental innovations are continuous improvements of existing technological systems, for instance, the optimization of an exhaust air filter, while radical innovations are discontinuous processes, e.g. the introduction of fuel cells.

2.2 Level of analysis

Before discussing the development of incremental and radical innovations in detail, we have to define these concepts further (Garcia and Calantone 2002). The terms of radical or incremental innovations may be used to refer to a technology at the component level as well as to the entire technological process. Figure 2 shows the different levels of analysis.

As we will demonstrate below, a radical innovation at the component level does not necessarily have to result in a similar innovation at the system level (Level 2). It is, however, a necessary precondition. The (further) development of technology is motivated by the innovation environment, which is determined by market conditions for operators and providers, innovation policy, energy policy, and environmental policy measures, etc. In Fig. 2, they are represented by Levels 3 and 4. The following reflections mainly concern technologies used for the conversion of coal into electricity. Thus, the analysis is carried out at a technology-based micro level (Level 2). From a technological point of view, however, the level exhibits a considerably high degree of detail, since the technological system we examine (i. e. the power plant process) is separated into components (Level 1) and then analyzed (Garcia and Calantone 2002). Against this background, an innovation is considered radical if one or more newly developed components change the power plant system, which spurs the development of a new technological trajectory in power plant technology and results in a new technological paradigm. According to Dosi (1988), a technological paradigm can be defined as a pattern “of solution of selected socioeconomic problems based on highly selected principles derived from natural science, jointly with specific rules aimed to acquire new knowledge and safeguard it, whenever possible, against rapid diffusion to the competitors.”

This new trajectory has to differ considerably from existing “activity of technological progress along the economic and technological trade-offs defined by a paradigm” (Dosi 1988, p. 1128). Or, in other words: It has to differ from existing technological trajectories and offer significant advantages, e.g. a leap in efficiency, lower emissions, lower costs, etc. This is the case with nuclear power plants, which were developed in the 1950s and 1960s and have been used commercially since the 1970s.

Figure 3 gives an overview of different technological trajectories. In this paper, we define an incremental change as the further development of a technology without leaving the chosen technological path. Thus, turbines in the field of power plants have been improved for decades, benefiting from innovations in other areas—powerful computers allowing three-dimensional simulations for instance—and thus finally creating an increase in efficiency. Another example is the development of materials enabling an increase of steam parameters and by that contributing to an increase in efficiency of fossil fuel power plants.

2.3 Determinants and barriers of the firms’ decision to adopt incremental or radical innovations: sunk costs, uncertainty, irreversibility and market structure

The added value of evolutionary economics in the context of technology choice stems from the possibility identifying that certain inferior environmental technologies which may be locked in to the economic system (Carillo-Hermosilla 2006). Kemp (1997) mentions several determinants and success factors of technological change that are able to open a socio-technical system: new scientific findings providing new technological opportunities, serious technological bottlenecks (e.g. the limits of additional emission reductions based on additive technology; high costs of improving a technological trajectory, such as cost-intensive reductions in CO2 emissions; changes in demand; scarcity of resources or industrial conflicts), entrepreneurial activities and institutional support for radical new technologies. Important factors influencing the decision on incremental vs. radical technological change at the firm level are sunk costs, uncertainty, irreversibility and market structure. In this context, it should be mentioned that, according to Pavitt (1984), the power plant sector belongs in terms of technology development to the more supplier-dominated sectors, i.e. demand and globalization are not as important as for technology developers who typically act worldwide.

R&D expenditures are often, due to their nature, sunk costs (Stiglitz 1987). Since investments in knowledge are very specific, they typically have a high depreciation rate (Manez et al. 2009). Sunk costs decrease the likelihood of technology adoption, as Astebro (2004) has shown for the adoption of Computer Aided Design and Computer Numerically Controlled technologies. Bakker (2005) analyzed the case of the strong dominance of Hollywood studios in the global film market over the past century and identified sunk costs of outlays on film production and advertising—such as money spent on exclusive contracts with famous stars, on rights to novels and theater plays, and on special effects—as the central innovation barrier for European competitors (Bakker 2005).

It should be expected that R&D investments play a central role in achieving innovation and competitive advantage in the energy sector. However, under the liberalization regulation, power investors are exposed to greater risks than before (Roques 2008). The most fundamental change regarding the value of investments is the uncertainty about electricity prices, and correspondingly the uncertainty about fossil fuel prices and CO2 emission permits in Europe. Due to market and regulatory uncertainty and the public good character of R&D, the willingness to undertake such investments may be limited. While in the long run the main source of firms’ efficiency improvement lies in technical progress induced by R&D and innovation, short-term profitability can be improved by reducing R&D expenditures.

Risk aversion is closely connected with market structure, since the uncertainty that R&D investments are at least compensated decreases in competitive markets. Jensen and Meibom (2008) have analyzed investments in liberalized power markets and came to the conclusion that there is considerable uncertainty among investors. Investors tend to postpone investments in coal-fired power plants until more certain information about future CO2-emssion permit prices is available. Thus, it is not only market uncertainty but also uncertainty about climate regulation that is reflected by this strategy (see also Held et al. 2009; Reinelt and Keith 2007). Pindyck (2000) uses, in this context, the terms economic and ecological uncertainty which may tend to delay irreversible investments. Regarding the development of innovation, the technological uncertainty regarding the availability and performance of the new technology should also be mentioned.

In general, Jamasb and Pollitt (2008) show a decline of private R&D investments in the electricity industry in a review of US, European and Japanese studies in the post-liberalization years. Despite the reduction of the R&D budget, the innovation output in terms of patents increased in many countries (Jacquier-Roux and Bourgeois 2002). This may mean that, on the one hand, firms in liberalized markets adopt new technologies faster, as, e.g., Rose and Joskow (1990) show in their analysis of US electric utilities. On the other hand, very uncertain and long term research projects are cut down. This is also confirmed by Defeuilley and Furtado (2004) who analyze the effects of energy market liberalization in the US and UK in the 1990s and draw the conclusion that long term research projects with potentially radical outcomes have become less attractive.

2.4 Political strategies for radical technological change

Typically, approaches in evolutionary economics accept that development paths are historically conditioned, enabling them to consider coincidences or path-dependence when analyzing technological change (Rennings 2000). They are more focused on exploring transition and learning processes than balances. If new technologies are to be developed alongside established technological trajectories, resistance has to be overcome. Before a lock-in situation can be overcome, a window of opportunity should be open (Sartorius and Zundel 2005). Policies pursuing this goal aim at opening (“unlocking”) a socio-technical system (Faber and Frenken 2008).

Key success factors for a change in technology are the early establishment of market niches and the use of existing knowledge and technology, i.e. a certain compatibility with existing know-how, experiential knowledge and existing infrastructure. On the basis of these success factors, Kemp (2007) (see also (Kemp and Rotmanns 2005) suggests supporting a change for more eco-friendly technologies through a policy of transition management. In the Netherlands, the approach of transition management has been met with noticeable response from policy-makers in recent years. This strategy is based on the attempt to induce system innovations facilitating sustainable development. The goals of such innovations are technical, socio-cultural, regulatory and economic systems which meet certain social requirements, such as the need for energy, housing, mobility or food. System innovations are fundamentally different technologies for meeting these needs; they also necessitate addressing the economic, legal and socio-cultural conditions which determine the relevant technology (Rennings et al. 2004). Examples of system innovations are the transitions from sailing ships to steamships or from coal-based to gas-based energy supply, etc. System innovations, and thus the approach of transition management, are long-term transitions (at least 25 years). Based on the strong commitment of all participants to long-term goals they are to be achieved and implemented in concrete projects. The creation of protected spaces for up-and-coming, but not yet fully developed, technologies is considered a promising strategy. This implies, for instance, the creation of temporary pilot markets, protected by funding programs, subsidies or other regulatory measures.

According to Berkhout et al. (2004), however, such transitions from one technological regime to the next are not imperative. They list a range of other options, including, for instance, a re-orientation of the existing technological trajectories. Such a re-orientation implies that the existing system reacts to the selective pressure of its environment by improving innovations on the existing technological path (Berkhout 2005). Continuous improvements of an “old” technology before or after the introduction of a “new“ technology, not least due to the new competitive situation, are familiar phenomena in innovation studies (Rosenberg 1972), and also for environmental innovations (Lutz et al. 2005).

3 Incremental and radical innovations in power plant technology in Germany

In the following, we use an ex-post analysis to examine the German R&D portfolio for the field of large-scale power generation, with a focus on the development of radical and incremental innovations. A particular focus is on research activities that were publicly funded during the last decades. Concomitantly, the R&D portfolio examined represents a part of the industrial R&D portfolio, since a wide range of projects were cooperatively funded by public sponsors and the industry. Unlike purely industrial research, the public portfolio contains a large number of technologies and technological trajectories, which imply a much greater diversity but also development risk. Thus, the participation of the industry may also be interpreted in terms of risk sharing.

In a first step, the course of development is scrutinized. We investigate incremental or radical innovations which received particular attention from research and development and examine whether and/or to what extent they established themselves in the market. The example of PPCC, which was considered a promising technology for the conversion of coal into electricity due to its large potential to increase efficiency, demonstrates that, in spite of assumed advantages, radical innovations are not necessarily successful.

3.1 The R&D portfolio

Table 1 depicts the development of the R&D portfolio in the field of power plant technology in Germany over several decades. We differentiate between R&D portfolio, power plant construction/demonstration and pilot plants and existing power plants.

When interpreting this table, it should be noted that, for political reasons, research focused on different issues in each decade: in the 1970s, oil crises caused the research portfolio to focus on resource conservation and a change in energy sources, whereas in the 1980s, environmental protection and, since the end of the 1990s, climate protection were guiding themes. Until 1998, the electricity market was a monopolized market (regional monopolies for generation, transmission and distribution). In this context, a wide range of pilot and demonstration plants were realized.

In Germany, unlike in most other EU countries, liberalization was instantaneous (i.e. no transition period), i.e. 100% opening of market, modified anti-trust laws and new energy laws prohibited monopolistic behavior. Prior to liberalization, tariffs had to be approved by the Federal States (Länder); before liberalization German power prices were among the highest in Europe, but they dropped dramatically; wholesale prices dropped by over 40% within 18 months after liberalization due to excess capacities and competition.

Since 1998, a clear decrease in demonstration plants and a trend towards smaller and less cost-intensive technologies can be observed. The reasons are obvious: in a monopolized market, risks could simply be passed on to the end customer, whereas this is not possible in the now deregulated market (Roques 2008). Thus, sunk costs and technological as well as market uncertainty may have become important barriers for the introduction of innovative solutions.

To establish itself successfully, a technology must pass both “R&D portfolio” and “power plant construction/demonstration and pilot plants” phases and finally become a significant element of existing power plants. Examples of particularly successful R&D activities are the works in the area of desulphurization and denitrification, which became a major basis for implementing the ordinance on large combustion plants and gas turbine plants (13. BImSchV, 13th ordinance on the implementation of the Federal Emission Control Act): within one decade, they passed the R&D phase and the demonstration phase, so that all existing German power plants could be provided with large-scale systems by the early 1980s. Another successful example of the establishment of a radical system-level innovation in the market is the construction of nuclear power plants (pressurized-water and boiling-water reactors).

In the field of fossil fuel power plants, many technologies could not establish themselves beyond the phase of demonstration and pilot plants. It must be noted that no radical innovation has succeeded at the system level during the last three decades. This applies, for instance, to technologies for the conversion of coal into electricity on the basis of coal gasification, which did not succeed on an international scale either. Thus, strong path dependency could be observed in the field of fossil fuel power systems during the last decades, despite the existence of new power plant models (e.g. Integrated Gasification Combined Cycles or Pressurized Pulverized Coal Combustion), which constitute radical innovations and stand out due to their higher degree of efficiency or eco-friendliness compared to established technologies.

At the component-level, however, we observed a few changes in technological trajectories. One example in the field of coal-fired power plants is the transition from slag-tap firing to pulverized fuel firing with dry ash removal, which was triggered by the introduction of the German ordinance of large combustion plants (13. BImSchV) prescribing strictly limited values for nitrogen oxide. Another reaction to the prescription of emission limits is the development of scrubbing technologies to remove sulphur and nitrogen oxide from flue gases, which did not exist before and thus must be considered a radical innovation at the component level. The component-level changes mentioned did, however, not fundamentally change the actual power plant process as a whole and thus cannot be considered radical innovations at the system level “power plant” (Level 2).

Other procedures, which are de facto alternatives to the above-mentioned SO2 and NO x scrubbing technologies, such as fluidized-bed combustion systems, could not establish themselves as expected, since their potential usage also entails new restrictions (e.g. lower performance) and a dramatic change in the actual power plant process (e.g. replacement or fundamental modification of the steam generator). Fluidized-bed combustion systems offer the advantage of being compatible with a broad range of fuels and therefore serve a niche market today. Apart from a few exceptions, the further development of fossil fuel power plant technology has had an incremental character. Thus, the increase in efficiency of conventional power plant technology by increasing the steam parameters, pressure and temperature, played a decisive role in all decades and occurred independently of demands and conditions created by energy- and environmental policy. Due to this development, a combination of established gas and steam cycles (CCGT plants) became possible, which significantly increased degrees of efficiency.

In the following, PPCC is used as an example in order to examine why technologies that are considered radical innovations and are assumed to offer considerable advantages compared to conventional technologies could nevertheless not establish themselves.

3.2 Pressurized Pulverized Coal Combustion as a radical innovation

An increase in efficiency, resulting in lower input use and hence cost reductions, is often the main motivation for conducting R&D projects. Based on the state of the art at the beginning of an R&D project, the efficiency potentials indicated—in comparison to established competitive technology—are generally seen from a medium- or long-term perspective. In contrast to conventional coal-fired power plants, PPCC is a combined process, in which a gas turbine receives direct pressure using pressurized flue gas from a coal firing. Unlike conventional processes, PPCC requires hot-gas filtration at highest temperatures (approx. 1400°C), which, at the beginning of R&D activities, implied venturing into uncharted territory. In addition, the boiler design had to be modified for operation under pressure. After 1985, only dry pulverized fuel firing was used in power plants due to limits on emissions required by legislation. Realizing the PPCC process would have required slag-tap firing, thus implying a trend reversal. In summary, the new model, requiring the development of completely new components (such as hot-gas cleaning) and the modification of established components (such as the steam generator), qualified the PPCC process as a radical innovation in the field of power plants.

Research and development activities started in the late 1980s in the context of a cooperative research project including many private companies (operators and constructors). In 2003, however, R&D activities were terminated and the promising power plant process, which accounted for development cost of approximately 90 million €, was never realized.

Table 2 contains information on the efficiency of state-of-the-art technology in the late 1980s, as well as efficiency projections for several power plant technologies at that time.

The significant advantages of PPCC are clearly visible. Compared to conventional power plant technology, PPCC promised an increase in efficiency by 5 to 10 percentage points, which was the actual motivation for the industry and public sponsors to participate in the project. A comparison with today’s state of the art, however, paints a different picture. It becomes clear that the potential of conventional power plant technology to increase its efficiency had been greatly underestimated. The assumed efficiency advantage of PPCC thus diminished considerably over time. Experts had not anticipated the remarkable progress in material research and in computer simulation, which particularly benefitted conventional technology. A comparison of today’s efficiency projections, also listed in Table 2, shows that PPCC has now only an efficiency advantage of 2 percentage points. Since conventional and proven technology achieves similar degrees of efficiency and high technological availability is ensured, work in the field of PPCC was terminated after 15 years of continuous R&D activities. The core problem of PPCC, high temperature ash removal, was solved at the stage of experimental plants. The next step would have been constructing a pilot plant and afterwards a demonstration plant. This was, however, not supported by public sponsors, nor by the industry, which sponsored all project phases but whose participation decreased throughout the project. The PPCC case shows that technological uncertainty is an important barrier for implementing radical innovations.

A similar picture may be painted in the case of power plants based on Integrated Gasification Combined Cycle (hereafter: IGCC). Several of such large-scale plants currently operate, for example in the Netherlands (Buggenum), Spain (Puertollano) and the USA. Since the technological availability necessary to be competitive cannot be provided with those plants, their operation is subject to high risk. This risk has a direct impact on profitability, and so global power plant operators do not include them in their plant portfolio. The few plants that were built currently serve niche markets (such as refineries).

Since sunk costs are an important determinant of R&D investments and technology choice, Table 3 shows current and expected costs to generate electricity for the different power plant technologies.

In 1995 Pressurized Fluidized-Bed Combustion (hereafter: PFBC) and IGCC were seen as the most expensive systems. It was expected that in the year 2010 the specific cost of IGCC would be significantly lower than the cost of other coal-fired power plant technologies. However, until now, IGCC has not become the cheapest option. Taking into account that technology specific mark-ups for risks and uncertainties are only partially included in the cost numbers of Table 3, there are big doubts about the future of IGCC. PFBC was seen as an interesting technological option in the past. Currently, this technology is not any longer on the agenda because other technologies, e.g. based on ultra-supercritical steam parameters, are cheaper and more reliable. No cost data is available for PPCC because the technology did not reach demonstration-level. So the commercial viability of this power technology could not be proved.

3.3 Supercritical coal-fired power plants as an incremental innovation

The results outlined above also hold true for incremental changes in technology, such as the transition to supercritical steam parameters. The development towards high steam temperatures and steam pressures directly resulted in improved efficiency and took many decades, as shown in Fig. 4.

The individual plants shown in the figure represent milestones in the development of steam parameters. Supercritical steam parameters had been realized in some power plants (“pioneers”) since the late 1950s; they were, however, marketable only 30–40 years later. On the one hand, this was due to the use of expensive austenitic steels. On the other hand, the materials used in the pioneer plants were found to have inadequate thermal properties, which significantly decreased technological availability. Only with increasing progress in the field of material research was it possible to develop materials that met thermal requirements and were more cost-efficient. While for hard-coal-fired power plants the transition to supercritical steam parameters took place in the 1980s, for lignite-fired power plants it was introduced in the 1990s. Consequently, all newly constructed lignite-fired power plants in Germany operate with supercritical steam parameters, which, along with other methods, increase net efficiency to as much as 42%. Currently, intensive research is conducted in order to further increase live-steam parameters (350 bar, 700°C). Ultra-supercritical hard-coal-fired power plants are predicted to achieve an efficiency of more than 50% (see Table 2). The efficiency advantage of competitive new trajectories of power plant technology thus continuously decreases.

Apart from an increase in efficiency by increasing temperature and pressure, other improvements must be noted. For example, the design of gas and steam turbines and their components was optimized using three-dimensional simulations, which were made possible by the introduction of more powerful computers. The same holds true for the design of other components (e.g. cooling tower) and the optimization of the whole power plant process. These individual developments accumulated to a considerable increase in efficiency of established trajectories of power plant technology (COORETEC 2003).

4 Carbon dioxide capture in power plants: radical or incremental?

In the context of a reduction in CO2 emissions from fossil fuel power plants, the use of CO2 capture and storage (hereafter: CCS) technologies is increasingly debated (IEA 2008a; IPCC 2005). However, in the economic debate, CCS is often seen as a single technology and the introduction only depends on the level of carbon prices (Otto and Reilly 2008). CO2 abatement costs are estimated to be between 35 and 50 Euro per ton of CO2 for 2020 (German Advisory Council on the Environment SRU 2008). These sunk costs do not vary much between the different technologies in question.

CCS may only be seen as an incremental innovation since it is based on fossil fuels. In fact, there are considerable differences. Three technological processes are currently favored: in post-combustion, CO2 is removed from flue gases by means of solvents and thus captured after combustion. In oxy-fuel combustion, coal is not burnt using the ambient air but rather by using pure oxygen and recycled flue gas, consisting mainly of CO2 and water vapor. The flue gas produced consists mainly of CO2. In the third process, pre-combustion, carbon is removed from the energy carrier prior to the actual combustion process in the power plant. This procedure is used in IGCC power plants.

The three technological trajectories differ in their technological proximity to existing power plant models, in their marketability, in the technological uncertainties associated with their use, and in their expected financial advantages in comparison with known technologies. In principle, power plants using CO2 capture combine a trajectory of power plant technology with a capture procedure. Thus, the following comparative assessment, as shown in Table 4, differentiates between the actual basic process and the capture procedure. Subsequently, the overall process is assessed. An assessment of uncertainties for CO2 transport and storage is not required in the following analysis, since it has no influence on the comparison of technological trajectories.

A comparison of basic processes clarifies the point that post-combustion as well as oxy-fuel combustion are added to power plant processes dominating the global market for power plant technology. They confirm the impression that this kind of CCS technology is merely an incremental improvement of coal power plants. The IGCC power plant, on the other hand, is considered a radical innovation which is commercially available, but is hardly used in power generation. Large-scale use requires further optimization and improvement of components (gasifier, gas turbine) to achieve the necessary degree of availability.

When combining basic processes with capture processes, a possible modification of the basic power plant process may be considered. With post-combustion and pre-combustion, however, modifying the basic process is generally not necessary. From a technological as well as an economic point of view, the steam generator and firing are the decisive components in a power plant process. In oxy-fuel combustion, they need to be newly dimensioned and designed, thus considerably increasing the technological uncertainties compared to both above-mentioned processes.

Components of different CCS technologies are commercially available and are currently used in the chemical industry. The air separation unit required for oxy-fuel combustion, for instance, is state of the art. CO2 scrubbing, which is based on the principle of chemical and physical absorption by means of solvents, is currently used in the chemical industry (e.g. in ammonia production or refineries). Due to the high volume flow rates of a power plant, the technological components currently available need to be scaled up in all processes. The individual CCS processes do not differ in their technological uncertainty.

Using CO2 capture processes results in substantial efficiency losses for all technological trajectories, caused by the additional use of energy for air separation (oxy-fuel combustion) and by the regeneration of the “rich” solvent containing the CO2 (post-combustion, pre-combustion). From today’s perspective, efficiency losses are largest in the overall process of post-combustion, while they are more moderate in other processes. The development of improved solvents, however, is expected to unleash remarkable efficiency potentials. The highest efficiency potential is found in the overall process of pre-combustion, since it is particularly suited to CO2 scrubbing for reasons of technology and, moreover, its basic process is regarded as having a high efficiency potential.

The individual technological trajectories exhibit several additional characteristics which may significantly influence their use. Post-combustion, for instance, is the only process suitable for retrofitting (the addition of new technology or features to existing plants). Against the backdrop of increasing efforts to mitigate greenhouse gas emissions, this characteristic may be considered an advantage. Oxy-fuel combustion is regarded as more eco-friendly, since no chemical additives are required. In pre-combustion, the hydrogen used for electricity generation may also be used for other purposes. This process may thus be used very flexibly and possibly pave the way for a hydrogen economy.

All technological trajectories are associated with significantly higher investments, exceeding those of the basic process by at least 50% (ignoring CO2 transport and storage). When comparing the necessary investments of the basic processes, those of steam power plants are, from today’s perspective, clearly higher than those of an IGCC power plant.

Since CCS technologies do not differ in uncertainties, the evaluation of the overall process is mainly determined by the basic process. Based on the results of the ex-post analysis, the risk of pre-combustion is considered the highest, as this process is added to a basic process constituting a radical innovation. Due to the modification of the steam generator, oxy-fuel combustion is thus considered to pose a somewhat higher risk than post-combustion, which is technologically closest to established power plant processes.

Figure 5 shows a comparison of different CCS technologies with regard to the associated risks and their expected advantages. Both post-combustion and oxy-fuel combustion pose relatively low risks to investors. The use of IGCC in combination with CCS, on the other hand, may involve more difficulties as regards continuous commercial operation (see for example Reinelt and Keith 2007). Yet such technologies may prove to be more profitable than others.

Since investors in the field of power plants are currently highly risk-averse, it must be anticipated that radical technologies are associated with higher uncertainties than incremental improvements. Thus, their large-scale establishment is possible only if existing risks are significantly reduced or the expected profitability can be significantly increased.

5 Conclusions

In the case of power plant technology, a classical lock-in situation can be observed – not to be equated, however, with the well-known case of the typewriter keyboard (the QWERTY example), where a system less convenient was successful in technological evolution due to its advantages in standardization (David 1985). PPCC, on the other hand, did indeed perform less well in a dynamic comparison and thus did not pass the evolutionary selection. While the new technology had some advantages at the beginning of the innovation process, the dynamic progress of the old technology - which was unforeseen - caught up. Thus technological uncertainty seems to be an important barrier for the implementation of radical technologies. Advantages ascribed to the radical innovation in comparison to incremental development have changed over time due to research and development activities. Consequently, technologies in the R&D phase should be evaluated gradually in time intervals, since every indication of, e.g. efficiency and cost potential, has to be regarded as a mere snapshot.

In other words: New technologies have to compete with “old” technologies, while the latter are not to be considered static. It has to be taken into account that the old technology is, in the light of its competition with the new technology, continually being developed. This experience gained in innovation research was confirmed using the example of power plant technology. Thus, skeptical views regarding a transition from one technological regime to the next have been confirmed in our paper. There is a range of other options; one example is a possible re-orientation of existing technological trajectories (of conventional coal-fired power plants in this case). Such a re-orientation implies that the existing system reacts to the selective pressure of its environment by incrementally developing innovations on the existing technological path (in this case, in the form of supercritical coal-fired power plants). While planning any transition, such development paths should also be taken into account.

The classical lock-in situation is supported by the deregulation of the electricity market. Many hard-coal-fired power plants built in the 1970s and 1980s are unique and tailored to the specific needs of their operators. Increasing global demand for power plants, and deregulation of the electricity market have changed the general conditions for European power plant constructors. The main goal is global competitiveness (Level 4).

This will probably not make enterprises more willing to take risks, since they are now exposed to serious competition which will not forgive wrong decisions. In a competitive market, more importance is attached to the criterion of profitability, or rather pay back time. Due to market uncertainty, investments into radical solutions are postponed into the future.

In this context, cooperative research, i.e. cooperation with competitors, becomes increasingly relevant. It ensures that development risks are pooled and may thus be understood as risk sharing in the broader sense. Furthermore, participation in cooperative research projects gives access to information, which might perhaps constitute a competitive advantage. One example is the research project COMTES700 (development of ultra-supercritical power plants), to which a number of national and international utilities (e.g. E.ON, EdF etc.) and power plant constructors contribute (Jäger 2005).

Sunk costs play also an important role as a barrier for introducing radical technologies. Power plant standardization, elimination of redundancies and reduced construction time lead to further reductions in investment costs and are expected to do so in the future. Power plant design strives to meet the needs of global (in particular, Asian) consumers. The call for increased plant availability plays a decisive role in this and constructors have to guarantee it, even though they face high financial risks and consequently are less willing to “experiment” with new technology. New or improved technologies first have to be presented and tested in their country of manufacture before being exported. A successful example is the introduction of supercritical hard-coal-fired power plants in China. Whereas Europe completely switched to supercritical power plants in the 1990s, in China only plants with subcritical steam parameters were constructed. Only since the year 2000, with a time lag of roughly 10 years, have supercritical power plants been constructed on a large-scale basis there. It can be expected that CCS technology will diffuse to China with similar delays, and perhaps only partial CCS will be realized in the near future, which may be much more cost effective. However, due to political pressure on emerging countries like China, and the abundance of coal reserves, CCS technologies are likely to be used in theses countries over the long run.

An ex-post analysis shows that—in contrast to incremental innovations—radical innovations mostly did not succeed, despite their evident advantages (more eco-friendly, more efficient). This holds particularly true in the field of power plant systems. When focusing on fossil fuel power plant technology, several radical component-level innovations were made and diffused into the market during the last three decades. Yet, no radical innovations were made at the system level in this field, which indicates its strong path-dependence. The risk that new technological trajectories cannot establish themselves is particularly high in the case of newly developed components or a trend reversal at the component level. Both might constitute a radical innovation in the power plant system. In fossil fuel power plant technologies, an innovation is more likely to succeed if it follows established technological trajectories.

The development of new technologies in the field of power plants is essentially motivated by an envisaged increase in efficiency. This holds true independently of the conditions created by energy and environmental policy. Yet, the ex-post analysis shows that this criterion is generally overestimated, whereas other characteristics (e.g. availability) significantly influencing economical power plant operation and thus profitability do not receive sufficient attention.

The results gained in the ex-post analysis also allow for an assessment of power plant technologies for future use, as we have shown in the example of carbon capture technologies. The results are inherently uncertain, since it is not possible to predict precisely the prevailing general conditions when using the technology. Highest priority must be given to path-dependence, since it has been observed in the field of coal-fired power plants for decades and carries more weight than other criteria.

From a social perspective, a reasonable strategy would be to develop further all three CCS technologies. While the incremental post combustion technology has the advantage that it can be used for retrofitting (which may be most urgent, e.g., for existing German power plants), the radical pre combustion technology is more efficient, but the window of opportunity (at least in Germany) may already be closed when the technology is in a mature phase of development. Thus, a reasonable R&D portfolio should include both post- and pre-combustion technologies, at least for international appliances. If R&D on CCS is left to energy suppliers, it is to be expected that only the incremental technology is realized and that the radical technology will not be developed further.

Deregulation of the electricity market has constituted a fundamental market uncertainty for energy suppliers. It is evident that more pilot and demonstration plants were constructed before deregulation than afterwards, since in a monopolized market, potential cost of failure could more easily be passed on to the end customer. During the past years a rise of an incremental technology, the Combined Cycle Gas Turbine as the favored technology for new entrants could be observed. The technology has critical advantages for new entrants in the liberalized markets: low capital cost, a short construction time and modularity (Roques 2008). Consequently, there will probably be less willingness in the future to take the risk of developing and implementing a radical innovation at system level. On the other hand, radical technologies such as IGCC lower regulatory uncertainty due to comparatively small costs of later carbon capture retrofits, and improve the strategic position of the firm by investing in natural gas generation (Reinelt and Keith 2007).

In the end, the stringency of the environmental regulatory framework may dictate the technological choice. If stringent environmental policy is applied, e.g. by CO2 pricing, coal would have to compete with alternative options of avoidance. Radical technologies may need strict regulation, while a laxer climate policy allows for incremental solutions. Given the abundant coal reserves in countries such as China (but, for example, also in the US and Poland), the likelihood of a strict decarbonisation policy can be however be questioned.

References

Astebro T (2004) Sunk costs and the depth and probability of technology adoption. J Ind Econ LII(3):381–399

ATLAS (1997) Main report—energy technology information base 1980-2010. European Commission, DG XVII (Energy). THERMIE Program. Brussels

Bakker G (2005) The decline and fall of the European film industry: sunk costs, market size, and market structure, 1890–1927. Econ Hist Rev LVIII 2(2005):310–351

Berkhout F (2005) Technological regimes, environmental performance and innovation systems: tracing the links. In: Weber M, Hemmelskamp J (eds) Towards environmental innovation systems. Springer, Berlin

Berkhout F, Smith A, Stirling A (2004) Socio-technical regimes and tranistion contexts. In: Elzen B, Geels FW, Green K (eds) System innovation and the transition to sustainability—theory, evidence and policy. Edward Elgar, Cheltenham

Bohn D (2008) Future developments for CO2-free power plants technologies with integrated gas turbines. VGB PowerTech 7:24–30

Carillo-Hermosilla J (2006) A policy approach to the environmental impacts of tchnological lock-in. Ecol Econ 58:717–742

Commission of the European Communities (2007) Communication from the Commission of the Commission to the European Council and the European Parliament - an energy policy for Europe. Brussels

COORETEC (2003) Forschungs- und Entwicklungskonzept für emissionsarme fossil befeuerte Kraftwerke, BMWA Dokumentation Nr. 527

David PA (1985) Clio and the economics of QWERTY. Am Econ Rev Int Polit Econ 75:332–337

Defeuilley C, Furtado AC (2004) Impacts de l’ouverture à la conucurrence sur la R&D dans le secteur électrique. Ann Public Coop Econ 71(1):5–28

Dosi G (1988) Sources, procedures, and microeconomic effects of innovation. J Econ Lit XXVI:1120–1171

Faber A, Frenken K (2008) Models in evolutionary economics and environmental policy: towards an evolutionary environmental economics. Technol Forecast Soc Change 76:462–470. doi:10.1016/j.t4echnfore.2008.04.009

Freemann C (1992) The economics of hope. London, New York

Garcia R, Calantone R (2002) A critical look at technological innovation ty-pology and innovationess terminology: a literature review. J Prod Innov Manag 2002:110–132

Geels FW (2004) Understanding system innovations: a critical literature review and a conceptual synthesis. In: Elzen B, Geels FW, Green K (eds) System innovation and the transition to sustainability - theory, evidence and policy. Edward Elgar, Cheltenham

Geels FW, Elzen B, Green K (2004) General introduction: system innovation and transitions to sustainability. In: Elzen B, Geels FW, Green K (eds) System innovation and the transition to sustainability - theory, evidence and policy. Edward Elgar, Cheltenham

Held H, Krieger E, Lessmann K, Edenhofer O (2009) Efficient climate policies under technology and climate uncertainty. Energy Econ 31:550–561

IEA (International Energy Agency) (2008a) CO2 capture and storage: a key carbon abatement option. OECD/IEA, Paris

IEA (International Energy Agency) (2008b) World energy outlook, (IEA), I. E. A. IEA/OECD, Paris

IPCC (International Panel on Climate Change) (2005) IPCC special report on carbon dioxide capture and storage. Working group III of the intergovernmental panel on climate change. Cambridge University Press, New York

Jacquier-Roux V, Bourgeois B (2002) New network of technological creation in energy industries: reassessment of the roles of equipment suppliers and operators. Technol Anal Strateg Manag 14(4):399–417

Jäger G (2005) Großversuch in Scholven. BWK 57:36–37

Jamasb T, Pollitt M (2008) Liberalisation and R&D in network industries: the case of the electricity industry. Res Policy 37:995–1008

Jensen SG, Meibom P (2008) Investments in liberalised power markets—gas turbine investment opoortunities in the Nordic power system. Electr Power Energy Syst 30:113–124

Kather A, Rafailidis S, Hermsdorf C, Klostermann M, Maschmann A, Mieske K, Oexmann J, Pfaff I, Rohloff K, Wilken J (2008) Research and development needs for clean coal deployment. IEA Clean Coal Centre, Report CCC/130, London

Kemp R (1997) Environmental policy and technical change. Edward Elgar, Cheltenham, Brookfield

Kemp R (2007) An example of “managed transition”: the transformation of the waste management subsystem in the Netherlands (1960-2000). In: Lehmann-Waffenschmidt M (ed) Innovations towards sustainability - conditions and consequences. Physica, Heidelberg

Kemp R, Arundel A (1998) Survey indicators for environmental innovation, IDEA, Indicators and Data for European Analysis) paper series 8/1998

Kemp R, Rotmanns J (2005) The management of the co-evolution of technical, environmental and social systems. In: Weber M, Hemmelskamp J (eds) Towards environmental innovation systems. Springer, Berlin

Klemmer P, Lehr U, Löbbe K (1999) Umweltinnovationen: Anreize und Hemmnisse, Berlin

Lezuo A, Riedle K, Wittchow E (1989) Entwicklungstendenzen steinkohlebefeuerter Kraftwerke. BWK 41:13–21

Lutz C, Meyer B, Nathani C, Schleich J (2005) Endogenous technological change and emissions: the case of the German steel industry. Energy Policy 33:1143–1154

Manez JA, Rochina-Barrachina ME, Sanchis A, Sanchiz JA (2009) The role of sunk costs in the decision to invest in R&D. J Ind Econ LVII(4):712–735

Martin H (1988) Steigerung des prozesswirkungsgrades kohlegefeuerter Kraftwerke. VGB Kraftwerkstechnik 68:219–225

OECD (Organisation for Economic Cooperation and Development) (2005) Guidelines for Collecting and Interpreting Technological Innovation Data – Oslo Manual, The Measurement of Scientific and Technical Activities Series, Paris

Otto VM, Reilly J (2008) Directed technical change and the adoption of CO2 abatement technology: the case of CO2 capture and storage. Energy Econ 30:2879–2898

Pavitt K (1984) Sectoral patterns of technical change: towards a taxanomy and a theory. Res Policy 13(3):343–373

Pindyck RS (2000) Irreversibilities and the timing of environmental policy. Resour Energy Econ 22:233–259

Pruschek R, Renz U, Weber E (1990) Kohlekraftwerke der Zukunft. Stand und Entwicklung, Erprobung und Planung neuer Kohlekraftwerks-Technologien, Studie im Auftrag des Ministers für Wirtschaft, Mittelstand und Technologie des Landes NRW, Düsseldorf

Reinelt PS, Keith DW (2007) Carbon capture retrofits and the cost of regulatory uncertainty. Energy J 28(4):101–127

Rennings K (2000) Redefining innovation - eco-innovation research and the contribution from ecological economics. Ecol Econ 2000:319–332

Rennings K, Zwick T (2002) The employment impact of cleaner production on the firm level - empirical evidence from a survey in five European countries. International Journal of Innovation Management (IJIM), Special Issue on. Manag Innov Environ Sustain 6:319–342

Rennings K, Kemp R, Bartolomeo M, Hemmelskamp J, Hitchens D (2004) Blueprints for an integration of science, technology and environmental policy. ZEW, Mannheim

Roques FA (2008) Technology choices for new entrants in liberaliszed markets: the value of operating flexibility and contractual arrangements. Util Policy 16:245–253

Rose NL, Joskow PL (1990) The diffusion of new technologies: evidence from the electric utility industry. RAND J Econ 21(3):354–373

Rosenberg N (1972) Factors affecting the diffusion of technology. Explor Econom Hist 10:3–33

Sartorius C, Zundel S (eds) (2005) Time strategies, innovation and environmental policy. Cheltenham

SRU (German Advisory Council on the Environment) (2008) Umweltschutz im Zeichen des des Klimawandels, Berlin

Stiglitz JE (1987) Technological change, sunk costs and competition. Brookings Pap Econ Act 3:883–937

Vellinga P (2004) Foreword. In: Elzen B, Geels FW, Green K (eds) System innovation and the transition to sustainability—theory, evidence and policy. Edward Elgar, Cheltenham

Acknowledgements

The authors would like to express their appreciation for the support in the context of the project “Decision criteria towards efficiency of strategic R&D subsidies—innovation–economic principles and applications to new energy technologies”, which was funded by the support program EDUARD (Energie-Daten und Analyse R&D—Energy Data and Analysis R&D) initiated by the German Federal Ministry of Economics and Technology (BMWi). Thanks for productive comments to our colleagues Andres Löschel and Sascha Rexhäuser, to Joachim Schleich from the Fraunhofer ISI Institute, and to anonymous referees. We would like to thank Anne-Kathrin Koch for a language check.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rennings, K., Markewitz, P. & Vögele, S. How clean is clean? Incremental versus radical technological change in coal-fired power plants. J Evol Econ 23, 331–355 (2013). https://doi.org/10.1007/s00191-010-0198-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00191-010-0198-9