Abstract

A growing number of manufacturers are adopting the so-called supermarket strategy to supply components to the production system. Supermarkets are decentralized storage areas used as intermediate warehouses for parts required by the production system (typically assembly lines). Such a feeding system is widely used in the automotive industry where assembly stations in multiple mixed-model assembly lines are usually refilled by means of a systematic part replenishment driven by Kanban systems, adopting small trucking vehicles towing some wagons (tow trains). The aim of this paper is to provide a simple but robust framework in order to design the supermarket/feeding system dedicated to complex multiple mixed-model assembly lines. This framework proposes an integrated approach both for long-term (static analytical model) and short-term (dynamic simulation) problems dealing with Kanban and Supermarket systems dedicated to assembly lines, and the tow train fleet sizing and management. This proposed methodology is applied to a case study derived from the Italian automotive industry, and the results highlight the high interrelation between the long and the short term variables that can be evaluated only by an integrated approach that considers both static and dynamic aspects of the problem. The results of this study are then presented and widely discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

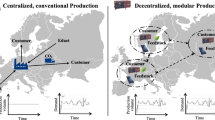

Companies, especially in the automotive sector, need to offer a wide range of different products. As a result, a typical configuration of the production system is the multiple mixed-model assembly line system. Each assembly line in the system is dedicated to a product family but is also able to produce several different models. In this context, one significant challenge is the part feeding to the assembly stations (Battini et al. 2009c; Emde and Boysen 2012a). Reliable and flexible part supply is crucial, because component shortages lead to line stops and assembly station idleness. On the other hand, enlarged stocks near the lines both increase inventory costs and obstruct the assembly process due to the lack of space within the plant (Emde and Boysen 2012b).

Following the just-in-time (JIT) approach, a growing number of manufacturers are therefore adopting the so-called supermarket concept where possible frequent small batches are delivered (Gamberi et al. 2008), permitting inventory reduction near the lines and avoiding long distance trips from a central warehouse to the production system. Supermarkets are decentralized logistics areas distributed near operative areas used as an intermediate store for the parts required by the assembly lines. In these warehouses, handling operations usually have to be ergonomic and fast. For these reasons, special storage equipment such as gravity shelves and modular pipes are used. The bins used to stock and to move parts from the supermarket to the assembly lines are also typically tailor-made for the part type.

Today the connection between the supermarket and production systems is made by adopting tow trains (vehicles towing small wagons) used to deliver the required components to assembly stations and to collect empty bins to be refilled for the next trip. In this way, supermarkets can deliver frequent but small batches of parts, hence minimizing stocks and distances travelled.

In the paper the considered feeding policy applied to the supermarket concept is the Kanban-based continuous supply where the Stock Keeping Unit (SKU) is normally associated with a Kanban card to control the production and replenishment flow (Sendil Kumar and Panneerselvam 2007).

In relation to the adopted feeding system (supermarket with Kanban supplying policy), two aspects have to be correctly designed:

-

1.

The tow train fleet size and management;

-

2.

The level of inventory for each part at each assembly station (related to the Kanban number).

The trade-off between the fleet size and the inventory stocks level in relation to the Kanban number is a known problem in operations (Emde and Boysen 2012b). From a cost point of view it is clear how the number of tow trains has a large impact of the associated capital consumption, staffing and maintenance cost. On the contrary a small fleet imposes high amounts of in-process inventories, and generally higher safety stocks, due to the higher supply lead time. As a result, large stocks near lines are required but this circumstance especially in the automotive assembly system due to the large dimensions of parts, is not feasible. Moreover, small fleet size can cause possible assembly line stops, as a result of delays of component deliveries. The stock-out risk increases with the production mix variability and decreases with the commonality between produced models (Battini et al. 2010).

Notwithstanding the extensive Kanban literature, it is interesting to observe that most Kanban models propose a design method based on empiric rules or simple formulas (Bonvik et al. 1997). Furthermore, it is important to highlight how the fleet size and management problem is strictly connected with the Kanban number sizing problem.

Let’s consider the well-known Toyota \(n\ge D\cdot L\cdot (1+\partial )/a\), where \(n\) is the number of Kanban, \(D\) is the consumption rate, \(L\) is the replenishment lead time, \(a\) is the stock-keeping unit (SKU) capacity and \(\delta \) is the positive safety factor (Sugimori et al. 1997). While in a vendor/buyer system the replenishment lead time \(L\) is (almost) fixed, in the supermarket/multiple mixed-model line assembly system this parameter is a function of the number of tow trains used (fleet size), their average load capacity, their average saturation; their tours and their schedule (fleet management).

For this reason the aim of this paper is to investigate the fleet size-inventory stocks level trade-off typical of complex multi mixed-model assembly lines fed by a supermarket warehouse.

Starting from an Italian automotive case study, the authors present a framework proposing an integrated approach for a long-term (static) and short-term (dynamic) design of such a system:

-

A first static model for the long-term fleet-Kanban number sizing problem;

-

A second dynamic multi-scenario model based on the simulation for the short-term fleet management problem.

The main contributions of the paper is to provide a structured methodology for operations managers in order to face with complex supermarket/multiple mixed-model assembly line system, dealing with an integrated approach both long term and short term problems of its fleet sizing and management.

The remainder of the paper is organised as follows. Section 2 presents a review of related literature, while Sect. 3 provides optimization framework. The following Sect. 4 presents the case study while conclusions are drawn in Sect. 5.

2 Literature review

As previously stated, this paper deals with two main topics in operations management literature: Kanban and the supermarket concept. While there are a huge number of contributions about the first topic, the second research topic is relatively new and few works are available.

The benefits of using the Kanban and other JIT techniques have allowed production systems to be optimized in recent decades (Sugimori et al. 1997; Manzini et al. 2008) also adopting new technologies (electronic Kanban and wireless traceability) for implementing these methods (Battini et al. 2009a).

A good recent JIT-Kanban literature survey has been developed by Sendil Kumar and Panneerselvam (2007). Most of the researchers were focusing on the determination of number of kanbans and determining corresponding solutions by using suitable models and tools. This kind of research has been developed according different directions, that can be classified:

-

By the layout in which the proposed procedure is set (flow shop, batch, assembly line).

-

By the mathematical different models and tools adopted (simulations model, meta-heuristics like, genetic algorithm, tabu search, simulated annealing, simulation, queuing models, costs models).

-

By the aims pursued in this problem (design of kanban system, performance behavior, sequencing and scheduling).

The proposed approach according this classification can be defined as a simulations model for the design of the kanban system considering an assembly lines production environment.

Inside the design of the kanban system different objectives can be found:

-

Maximization of average cumulative throughput rate (the ratio of total satisfied demand to total generated demand) (Vito et al. 1995; Yavuz and Satir 1995);

-

Minimization of average production lead time (the amount of time spent on a job from entering the system until the completion of all operations) (Jing-wen-Li 2003; Sharadapriyadarshini and Rajendran 1997);

-

Minimization of average work–in-progress (the mean of all in-process inventory levels for the products) (Chan 2001; Shahabudeen et al. 2003).

Other purposes such as the maximization of system saturation or minimization of part feeding delays are also used. Kanban number optimization through the minimization of the total cost function is another possible approach. Sarker and Balan (1999) study a multi-stage Kanban system for short life-cycle products in the market. A cost function was developed based on the costs incurred for the raw materials, for the work-in-progress and for the finished goods. Ohno et al. (1995) propose an algorithm to determine the optimal number of Kanban systems for each of the two kinds of Kanban (production ordering and supplier Kanban) under stochastic demand, thus minimizing the expected average cost per period. Salameh and Ghattas (2001) propose a cost analysis using a trade-off between holding cost and shortage cost.

Looking at the layout dimension Aghajani et al. (2012) study the cellular manufacturing system controlled by a Kanban mechanism, proposing a mixed-integer nonlinear programming model in order to determine the number of Kanban, batch size and number of batches using the minimization of the total cost function. Azadeh et al. (2010) present a hybrid approach as an optimization search technique and a simulation model to improve an existing JIT automotive industry production line system. Considering assembly line systems, many contributions refer to the sequencing problem solution. Xiaobo and Ohno (1997) consider the mixed-model assembly line sequencing problem and propose a branch and bound approach in order to minimize total conveyor stoppage time. Manzini et al. (2004) provide a general framework for designing a flexible cellular assembly system.

Looking at the aims pursued in this problem a very important role is played by sequencing. Drexl and Kimms (2001) introduce an assembly line sequencing mixed-model combinatorial approach for small problems. Gamberi et al. (2008) propose a multiple single-pass heuristic algorithm solving the assembly line rebalancing problem. Battini et al. (2009b) propose a linear programming model in order to minimize the buffer dimension, thereby optimizing the model’s sequencing for a mixed-model single line assembly system. Azzi et al. (2012a) introduce a linear sequencing model for workload leveling in the case of multiple mixed-model assembly line systems where the problem of workload leveling is critical (Azzi et al. (2012b)).

From the literature review of Kanban number optimization problems, and considering the scope of the present paper (i.e. multiple mixed-model assembly lines served by a supermarket warehouse) and looking at the recent survey by Sendil Kumar and Panneerselvam (2007) on the JIT-Kanban system, it is clear that the Kanban number optimization problem in such a production environment has not been studied in depth.

The supermarket concept, mentioned in the introduction, is a relatively new research topic and hence further research is certainly necessary. According to Emde and Boysen (2012b), it is possible to classify these contributions according to timeframe (from long-term strategic to short-term operational), as follows:

-

1.

Location, i.e. determining the number/locations of supermarkets, what parts each one has to manage and their assignation to the assembly lines (Battini et al. 2010; Emde and Boysen 2012a);

-

2.

Sizing, i.e. deciding on the number of tow trains assigned to the supermarket and assembly stations served by each operator, and where a route starts and ends in the supermarket (routing) (Emde and Boysen 2012b; Golz et al. 2011; Choi and Lee 2002);

-

3.

Scheduling, i.e. determining each tow train’s delivery schedule for supplying parts on its given route. (Emde and Boysen 2012b; Golz et al. 2011; Choi and Lee 2002);

-

4.

Loading, i.e., agreeing on the number and types of a part’s SKUs to be loaded per trip (Emde et al. 2012; Golz et al. 2011; Choi and Lee 2002). The loading problem aims to minimize inventory at the stations, while avoiding part stock-outs with certainty, considering that tow train capacity is finite and typically scarce.

As demonstrated in the literature review the supermarket warehouse presents some correlations with other research fields like the Kanban system optimization problem. A recent study of Faccio et al. (2013) highlighted the relations of these two research areas. On the other hand the proposed approach was static, without considering the short term dynamic variables.

Starting from an Italian automotive case study this work tries to give a contribution to scientific literature introducing a framework that integrates the long-term sizing problem to the short-term loading policy adopting a static/dynamic approach.

This paper conceptually covers the Kanban number optimization problem and the supermarket concept for points 2 and 4. It provides an optimization framework that aims to merge the impact of the long-term problems (Kanban and fleet sizing problems) with the short-term problems (fleet loading problems), giving as output their best setting in order to optimally set the supermarket design and management attributes.

3 Supermarket fleet sizing and loading optimization framework

In order to describe the procedure, the following notations are introduced:

- \(m\) :

-

set of all products produced in the system, \(m=1,{\ldots }, M\);

- \(i\) :

-

set of parts necessary for the same system; \(i=1,{\ldots }, I\);

- \(l\) :

-

assembly lines of the system, \(l=1,{\ldots }, L\);

- \(BOM_{i,m}\) :

-

bill of materials of part \(i\) related to model \(m\) [parts/product];

- \(SKU_{i}\) :

-

SKU capacity is the size of the container of parts i, [parts/Kanban];

- \(d_{m,l}\) :

-

daily expected average model demand for model \(m\) on line \(l\), [products/day];

- \(Q_{l}\) :

-

leveled daily throughput for assembly line \(l,Q_l =\sum \limits _m {d_{m,l} }\)[products/day];

- \(Q\) :

-

leveled daily throughput for the whole system, \(Q=\sum \limits _l {Q_l}\) [products/day];

- \(B\) :

-

average number of bins delivered per tow train trip;

- \(\sigma m,l\) :

-

standard deviation for model \(m\) on line \(l\), [products/day];

- \(CV_{m,l}\) :

-

coefficient of variation of model \(m\) on line \(l,CV_{m,l}\% =\sigma _{m,l}/d_{m,l}\) [%];

- \(Nop\) :

-

number of tow trains (equal to the number of handling operators who guide them);

- \(V_{run}\) :

-

average speed during the route of the handling operator [meter/minute];

- \(L_{run}\) :

-

total length of the route in order to refill all assembly stations in the system starting and ending at the supermarket, function of the tow trains expected tours, considered fixed. [meters];

- \(T_{rips}\) :

-

average number of trips per day travelled by tow trains [trips/day];

- \(T_{run}\) :

-

average run time to cover the total length \(L_{run}, T_{run} ={L_{run} } /{V_{run} }\) [minutes];

- \(T_{w}\) :

-

daily working time [min/day];

- \(T_{si}\) :

-

specific \(SKU_{i}\) time for loading/unloading operations at the supermarket [min/SKU];

- \(T_L/U_i\) :

-

specific \(SKU_{i}\) time for loading/unloading operations on the assembly lines [min/SKU];

- \({SL}_{i,l}\) :

-

service level considered in the assembly system [adimensional];

- \( k_{i,l}\) :

-

security factor for part \(i\) in assembly line \(l;\) this refers to the service level\(SL_{i,l}\) considering a normal distribution pattern of consumption [adimensional];

- \(Kanban_{i,l}\) :

-

number of Kanban for part \(i \)on line \(l;\)

- \(d_{i,l}\) :

-

expected daily average demand for part \(i\) on line \(l,d_{i,l} =\sum \limits _m (BOM_{i,m} \cdot \) \(d_{m,l} )\)[parts/day];

- \(\sigma _{i,l}\) :

-

part standard deviation [parts/day];

- \(di\) :

-

expected daily average demand for part \(i\), \(d_i =\sum \limits _l {d_{i,l} } \) [parts/day];

- \(LT\) :

-

lead time calculated as in (7) expressed in days according the daily working timeTw;

- \(C\) :

-

tow train capacity [number of bins];

- \(R\) :

-

refilling interval, i.e., the average time spent at the supermarket for the refilling [minutes].

3.1 General framework

The relation between long-term sizing and short-term management decisions in the supermarket context has also been highlighted by Emde and Boysen (2012b). On the other hand their relations with the Kanban number sizing and the impact of short-term decisions like the loading policies on system performance have not been discussed, especially for the dynamic nature of the problem.

In this context, this paper presents a framework that aims to provide decision-makers with a useful tool focused on supermarket feeding system design and management. This framework can be divided into 3 main steps (or phases):

-

1.

Static step applying an analytical simple but robust model to design and correlate the tow train fleet size and the Kanban number;

-

2.

Multi-scenario dynamic analysis (given the fleet size and the Kanban number, varying the parameters fixed in the static phase into allowed ranges), is performed to point out the best delivery frequency from the supermarket to the lines and the vehicle capacity utilization;

-

3.

Performance analysis of the long-term and short-term variables and system validation.

Thanks to the integration of the static model (step 1) with the dynamic validation (step 2) it is possible to evaluate the impact of long-term and short-term parameters on the supermarket feeding system, assessing its performance (step 3).

Figure 1 summarizes the proposed framework. In the first step the expected trips/day (T\(_{rips})\) and the related average supply lead time (LT) are determined as a function of the tow trains number Nop and the service level SL for the assembly station supply, (assumed the invariant for all parts).

Given T\(_{rips}\) an LT, the safety stock (SS) and the Kanban number are derived. In the same way the expected average bin number delivered per trip (bins/trip) is derived and a first tow train capacity check is made in order to evaluate only feasible solutions in the second step of the framework.

These results are used as inputs for the following dynamic multi-scenario analysis, together with the short-term decision variables, the tow train capacity (C) and the refilling interval (R).

Finally the system performance is evaluated in terms of different indicators (tow train utilization, T\(_{rips}\), distance travelled etc.) providing a solution for the correct design and management of the supermarket.

3.2 Assumptions

In order to formulate the problem the following assumptions are introduced:

-

The system is made up of a supermarket feeding the assembly stations belonging to different assembly lines. The layout is given.

-

Each line is a mixed-model assembly line that is capable of producing a large number models of a common base product, while the base product is different from one assembly line to the others. For this reason, each model is produced in one assembly line only. Therefore, there is a univocal correspondence between the model and the assembly line. The set-up times are negligible.

-

The JIT environment imposes a leveled production. For this reason, the total daily throughput of each line is considered to be constant, while the production mix can be variable according a certain range. The average takt time of the assembly line is considered to be constant.

-

The mix variation of a certain assembly line is considered to have a normal distribution, i.e. the daily historical demand for a model has a normal distribution.

-

A generic part can be used in different assembly lines but it cannot be used in more than one station of each line\(.\)

-

The SKU of parts is the same in every part of the system. Therefore, SKU capacity is a function only of the part. Every SKU is associated with a Kanban card.

-

The supermarket has a service level of 100 %. The inventory level at the assembly stations is a direct function of the Kanban number in the system.

-

Tow Trains have a constant speed, a constant loading and unloading time per Kanban both in the supermarket and in the assembly station and they have finite loading capacity.

-

In order to simplify the notations and the problem the security factor Ki,l for part \(i\) on line \(l\) is considered equal for all the partsi and all the line l. As consequence of this assumption the factor will be called \(K\). The proposed formulations are still valid considering Ki,l. In the same way it is considered SL instead of SLi,l. A Normal probability density distribution for the parts consumption behavior is considered, as a consequence of a normal distribution of the finite products demand.The safety factor\( K \)is calculated as function of the chosen service level LS accordingly to the Fig. 2, that shows the relation between K and SL for the Normal distribution.

3.3 The static step: tow train fleet size and Kanban number

In the proposed approach, there are just two independent parameters in the static approach: Nop and SL, while the others are derived.

Considering the supermarket feeding the mixed-model assembly lines, the replenishment lead time is firstly a function of the number of tow trains used. Secondly it is also a function of other factors like the tow train load capacity and saturation (bins loaded per trip), the tow trains tours and the tow train scheduled tours.

As a function of the number of tow trains used in the system (Nop) it is possible to obtain an expected average replenishment lead time, according to the assumption that the workload for tow trains is considered equally distributed between them, as:

Estimating the real number of tow train \(T_{rips }\)is difficult due to the dynamic nature of the problem and this circumstance obliges assumptions to be made in order to analytically solve such a problem. In particular, the following approach is based on an averaged values of the considered parameters. The real behavior of the system will be studied later during the dynamic phase.

By considering the expected average model demand, it is possible to write:

where dKi,l is the expected daily average Kanban demand for part \(i\) on line \(l\);

average expected time spent on the loading/unloading operations;

average estimated time spent on the loading/unloading operation at the supermarket.

The estimated trips/day (and as a result the average parts supply lead time) is:

where Nop is the number of tow trains, \(\eta \) is the vehicle efficiency and \(T_{w}\) is the daily working time in minutes.

Since the tow trains are guided by an handling operator, the parameter \(\eta \) defines the efficiency of the vehicle-operator system, that could be defined as the product of the operator efficiency for the vehicle efficiency. This parameter, minor than 1, defines that is not possible to saturate during the daily working time Tw the tow trains.

Once the decision variables have been defined, Nop and \(SL_{i,l}\), it is possible to derive the Kanban number Kanban\(_{i,l}\) using (1–5) the following well-known simple model:

\(SS_{i,l}\) is the safety stock on line \(l\) for part \(i\) and is calculated as:

The average number of bins loaded per trip (B) in the long-term static fleet-Kanban number sizing problem is derived as function of the number of tow trains Nop as follows:

This index is very important because it allows, also in the first static step, to compare the bins/trip value with the tow train capacity value C, in order to understand if the tow train capacity is large enough to continue with the short-term fleet loading problem solution. On the contrary, the starting values for Nop and SL have to be changed and this phase repeated.

3.4 The dynamic step: short-term simulation

A Multi-scenario dynamic analysis using simulation is very important to deal effectively with the many uncertainties that surround the assembly system (Manzini et al. 2005; Gamberi et al. 2009). In the dynamic analysis, in addition to all the previously defined average parameters, two new factors are introduced:

-

\(C\), tow train capacity. The number and types of SKU to be loaded per trip is different from B (previously mentioned) because the dynamic part consumption is random (according to a normal probability density function) a function of the tow train capacity and the parts loaded. The tow train capacity is related to the tow train specifications (that usually are not able to tow more than two wagons) and the bin volume/weight. We assume an identical average tow train capacity for all the tow trains, measured in number of loadable bins, calculated using an average weighted value on bin volumes and utilizations.

-

\(R\), refilling interval. The average level of saturation of the tow trains depends on the loading policy, and in particular we introduce a refilling interval variable, R, defined as the minimum interval between a vehicle trip and the following one. In fact is possible to set the waiting time for tow trains returned at the supermarket for the next loading. R defines different possible replenishment policies, from the instant delivery (vehicle starts as soon as a kanban request is defined) to complete tow train saturation (vehicle starts only when it is full).

Due to the dynamic nature of the problem, the authors have developed a visual interactive simulation model, using a commercial discrete events tool (Automod™, www.automod.com), modeling the real system. All the mentioned parameters, related to the case study, are implemented starting from the case study layout. The added value of such an approach is the possibility to relate both static and dynamic factors within a real system.

3.5 Performance analysis and decision variables definition

By means of the dynamic model is possible to derive a multi-scenario analysis, considering different values of the long-term decision variables Nop and SL and the short-term decision variables \(C\) and \(R \)with the aim of tuning the static design.

The performance analysis focuses on the comparison of different production factors, such as:

-

Tow train utilization (%)

-

\(T_{rips}\) the number of tours completed in the system

-

Total distance covered (meters)

-

Average number of bins loaded for trip (Bins/trip)

-

Number of delayed deliveries

-

Instant inventory level in the assembly system (number of parts)

Once the performances have been defined for each scenario, the goal is to provide a decision tool that solves the trade-off between the fleet dimension (its sizing and management) and the inventory stocks level (related to the Kanban number) with the aim of:

-

Determining the minimum fleet size Nop that permits the target service level SL to be reached (i.e., the number of delayed or missed deliveries has a maximum acceptable value) and an inventory level to be considered that preserves the assembly system productivity.

-

Optimization of the refilling interval, R, maximizing the utilization of the tow train capacity C but also satisfying the service level SL imposed as input.

The integration of the long and short-term decision variables through a multi-scenario analysis, allows the best solution to be provided for the design and management of the supermarket feeding system.

4 Italian automotive case study

The considered problem arises from an Italian automotive manufacturer located in the northern Italy. The simulation model that replace the real industrial layout of the case study is shown in Fig. 3. For the sake of brevity and privacy, the data presented constitutes an extract of the whole problem. This has also been carried out in order to simplify the problem and to understand it better.

The case study produces the wide variety of products in an assembly to order environment. Its 12 models are produced on four mixed model assembly lines fed by a single supermarket. The assembly lines are divided by the supermarket from the engine assembly area. The assembly lines are refilled using tow trains, guided by a handling operator. Their efficiency from the historical data is \(\eta \)=75 %. The total length of the route Lrun is 1,000 m and the average speed Vrun, considering queues, curves, etc., is 0.8 m/s. The loading/unloading time on the assembly line TL/Ui and in the supermarket TSi is considered to be equal for all parts, namely 1 min/SKU.

The daily working time is Tw = 8 h (480 min) and the considered period for the total cost calculation is one year with a working time \(D=200\) days. Table 1 presents the average daily production of each model from each assembly line.

The bill of materials for each model is presented in Table 2, including the SKU capacity. The SKU of part \(i\) is the same and does not change from one model to another. Therefore, SKU capacity is only a function of the part. Each SKU is associated with a Kanban card.

The average takt time of each line can be derived as takt time=1/Ql where \(Q=75 \) models/day and the average system takt time is one model every 6.4 min, while the average assembly line takt time is 25.6 min. The daily throughput Ql is considered to be fixed (leveled production) while the production mix of each line varies within a range (\(\pm \)30 %) randomly according to a normal distribution. The historical data shows that the coefficient of variation for all models is almost the same, and thus CVm,l is considered the same for all models, namely equal to CV = 30 %.

4.1 Long-term supermarket fleet-Kanban number sizing problem

The following Table 3 summarizes the results derived from the application of the proposed static analytical model. The expected number of used kanban from (2) considering the average production mix at the assembly system is 620. This number represents the average used bins that are moving from/to the supermarket. The number of kanban that will be installed in the system will be typically lower as function of (1) and (6). The daily time for load/unload these 620 bins in the system is 20.5 h. It means that a minimum number of 3 tow trains is necessary for a daily working shift of 8 h in order to complete all the deliveries. In this case study, SL is fixed at 99.7 %, as a management decision and this implies that (with a normal distribution model for parts consumption) the security factor \(k\) is equal to 3.

4.2 Short-term supermarket fleet management problem

Moving to the second step of the proposed framework, different values of long-term and short-term decision variables have been considered in the multi-scenario analysis:

-

Nop (fleet size) [3; 4; 5; 6; 7];

-

SL (service level) [99.97 %];

-

C (tow train capacity in bins/trip) [ 20; 40; 60; 80];

-

R (refilling interval in seconds) [60; 600; 1200; 1800; 2400; 3000; 3600].

Figure 3 shows the dynamic simulation environment modeling the case study. As reported in the framework (Fig. 1) different performance indicators related to the long-term and short-term decision variables are derived.

Figure 4 shows the number of delayed deliveries as a function of Nop and \( R\) varying C. This index is very important because it is a measure of the service level of the feeding system. In this case, for example, the dynamic result is in agreement with the static model (SL = 99.7 %), in fact, from Fig. 4 it can be noted that for R values ranging from 60 to 2,400 s, the number of delayed Kanbans is below 1 %.

Highlighting a case, for example Nop = 5, from Fig. 5 a rather evident upper limit for the refilling interval R can be noted (around 2,400 s) and this is the limit that avoids the increasing of delays in component supplying to assembly lines.

Figure 6 shows the tow train utilization (%) as a function of \(C\) (10–100) and R (60–3600 s) for different tow train capacity Nop. The negative influence on tow train utilization of Nop is clear: the higher the Nop, the lower the % utilization. The opposite behavior is caused by the vehicle capacity that increases % utilization in the first half of its range (C = 10 \(\div \) 50) reaching an asymptotic upper limit in the second half of the graph (C \(>\) 50). The effect of \(R\) is surprisingly very low if compared to the others parameters (Nop and \(C\)).

The average bins number loaded for trip by each tow train is shown in Fig. 7 varying R, C and Nop. This parameter bins/trip increases with C and R while it is inversely proportional if compared to Nop. It is interesting to observe that the influence of C on the bins/trip values, decreases when Nop increases, while R affects the bin/trip values independently from the number of Tow trains Nop.

The next Fig. 8 presents the average capacity saturation per trip (i.e., average bins/trip presented in Fig. 8 divided by the relative \(C\)). In this case, curves decrease with C and Nop while the proportionality with R is maintained. From Figs. 7 and 8 it is evident that \(R, C\) and Nop are strictly interrelated and the static results can be heavily affected by the dynamic behaviour of the system.

The number of trips per day, \( T_{rips}\), as a function of Nop and \(R\) for different tow train capacity (bins number, grey lines) is depicted in Fig. 10. Data show that the static model well estimates the real behaviour of the system, underestimating the real \(T_{rips}\). In fact, for Nop = 4 the static model gives approximately 33 trips/day, while the average value of the dynamic simulation model is 40 trips/day. For Nop =5 the number of trips/day obtained using the static is approximately 56 trips/day while for the dynamic model it is averagely 58.

The following Fig. 9 shows the that the number of trips/day is almost independent by the tow train capacity \(C\), but is function of of Nop and overall of the loading policy \(R\).

The total distance covered had been not reported because its behaviour is correlated to the number of trips per day.

About the inventory level, Fig. 10 depicts the instant inventory level in the whole assembly system (number of parts) for all different parts (colored lines) when Nop = 5. By means of the dynamic simulation it is possible to monitor and control buffer levels, verifying the presence of possible stock-out of components.

4.3 Performance analysis

Following the previously presented results, it is possible to observe that:

-

The number of tow trains Nop has a great impact on the system response, but also the short-term decision variables, \(C\) and \(R\) heavily affect the performance.

-

The tow train capacity \(C\) influences the feeding system only for low values of Nop. With high values the influence is not important. For this reason, if the capacity constraint is critical (as normally happens in the automotive sector, where the tow train capacity continuously changes due to the different dimensions of loaded parts) it is better to consider a number of tow trains that can eliminate any capacity restrictions.

-

The refilling interval \(R\), that defines the tow train loading policy adopted, negatively affects the results only after an upper threshold limit, causing stock-out events. In this case study, the threshold limit is approximately 2,400 s (40 min). This value can be evaluated as an upper limit for the refilling interval.

So larger \(R\) values (i.e. loading policy “deliver when it is full”), appear never optimal also considering that it implies the increasing of stocks near the line with negative effects on inventory costs and on the productivity according to Emde and Boysen (2012b).

On the other hand, the loading policy with low \(R\) values (i.e., “load the ready bins and go”) is not optimal because it increases the total travelled distance and time with wrong vehicle utilization.

Thus an optimum value of \(R\) between these two extremes has to be evaluated but this value depends on several factors like the assembly system takt times, route number and length, bin loading/unloading times and obviously on the dynamic behavior of such a system.

Applying the proposed framework, the best values of the long and short-term decision variables may be:

-

SL = 99.97 %, defined as input (K=3);

-

\(C\) = 20. In order to consider the strongest capacity constraint (i.e., 20 bins) to take into account the typical automotive sector pats typology

-

Nop = 5. It occurs with at least 5 tow trains in the system. On the other hand, a greater value would imply major capital and management costs, so it appears the best solution.

-

\(R\) = 40 min.

5 Conclusions

This paper presents a framework for the design and management of a supermarket system feeding multiple-model assembly lines. This approach starts from the automotive sector by applying kanban concepts to supply the required components to assembly lines by means of a tow train.

The proposed framework includes an integrated approach with a first static system design (long-term sizing) and a second dynamic analysis (short-term loading policy). There are several factors included in this methodology (Kanban number, service level, tow train number, safety stocks, vehicle capacity and utilization).

The results reported in the paper show that different benefits are achievable with the application of the proposed approach to a supermarket warehouse feeding multiple mixed-model assembly lines:

-

The interdependence between long-term sizing and short-term management decisions in the supermarket context has also been highlighted by Emde and Boysen (2012b). For the long-term fleet sizing problem the correlation with other decision variables like the safety stock levels, the Kanban number or the average expected tow train capacity utilization have been discussed and a static analytical formulation has been introduced in order to define the tow train fleet and the Kanban number. The result shows that there are just two long-term independent variables for the first stage of the fleet-Kanban number sizing problem: Nop and SL, while the others are derived.

-

Due to the dynamic nature of the fleet loading problem, a dynamic multi-scenario simulation model may be effective. The high impact of the short-term loading variables like the tow train capacity \(C\) and the loading policy represented by the refilling interval \(R\) demonstrates that use of an analytical approach alone may be unable to obtain reliable results.

-

The loading policy, expressed as a function of the refilling interval \(R\) has a high incidence on the system performances (service level, fleet saturation, etc.). For this reason it has to be optimized for each specific production environment.

The authors are now developing fleet sizing models considering different feeding methodologies using supermarket concepts. For example, in the automotive industry, the kitting feeding policy (i.e., when all components of an item are collected before being assembled) is very common. On the other hand, hybrid Kanban-kitting policies are also present. In this context the feeding system is crucial, enforced also by the presence of a relevant picking activity.

References

Aghajani, M., Keramati, A., Javadi, B. (2012). Determination of number of Kanban in a cellular manufacturing system with considering rework process. International Journal of Advanced Manufacturing Technology, 63(9–12), 1177.

Azadeh, A., Ebrahimipour, V., & Bavar, P. (2010). A hybrid GA-simulation approach to improve JIT systems. International Journal of Produdtion Research, 48(8), 2323–2344.

Azzi, A., Battini, D., Faccio, M., & Persona, A. (2012a). Sequencing procedure for balancing the workloads variations in case of mixed model assembly system with multiple secondary feeder lines. International Journal of Production Research, 50(21), 6081–6098.

Azzi, A., Battini, D., Faccio, M., & Persona, A. (2012b). Mixed Model Assembly System with Multiple Secondary Feeder Lines: Layout Design and Balancing Procedure for ATO Environment. International Journal of Production Research, 50(18), 5132–5151.

Battini, D., Faccio, M., Persona, A., Sgarbossa, F. (2009a). A new methodological framework to implement an RFID project and its application. International Journal of Rf Technologies: Research And Applications, 1(1), 77–94.

Battini, D., Faccio, M., Persona, A., & Sgarbossa, F. (2009b). Balancing-sequencing for a mixed model assembly system in case of finite buffer capacity. Journal of Advanced Manufacturing Technology, 44(3–4), 345–359.

Battini, D., Faccio, M., Persona, A., Sgarbossa, F. (2009c). Design of the optimal feeding policy in an assembly system. International Journal of Production Economics, 121(1), 233–254.

Battini, D., Faccio, M., Persona, A., & Sgarbossa, F. (2010). “Supermarket warehouses”:stocking policies optimization in an assembly-to-order environment. International Journal of Advanced Manufacturing Technology, 50, 775–788.

Bonvik, A. M., Couch, C. E., & Gershwin, S. B. (1997). A comparison of production-line control mechanisms. International Journal of Production Research, 35(3), 789–804.

Chan, F. T. S. (2001). Effect of Kanban size on just in time manufacturing system. Journal of Material Processing Technology, 116, 146–160.

Choi, W., & Lee, Y. (2002). A dynamic part-feeding system for an automotive assembly line. Computers and Industrial Engineering, 43, 123–134.

Drexl, A., & Kimms, A. (2001). Sequencing JIT mixed-model assembly lines under station-load and part-usage constraints. Management Science, 47(3), 480–491.

Emde, S., & Boysen, N. (2012a). Optimally locating in house logistics areas to facilitate JIT-supply of mixed-model assembly lines. International Journal of Production Economics, 135, 393–402.

Emde, S., & Boysen, N. (2012b). Optimally routing and scheduling tow trains for JIT-supply of mixed-model assembly lines. European Journal of Operational Research, 217, 287–299.

Emde, S., Fliedner, M., & Boysen, N. (2012). Optimally loading tow trains for JIT-supply of mixed-model assembly lines. IIE Transactions, 44, 121–135.

Faccio, M., Gamberi, M., Persona, A. (2013). Kanban Number optimisation in a supermarket warehouse feeding a mixed-model assembly system. International Journal Of Production Research, 51(10), 2997–3017.

Gamberi, M., Gamberini, R., Manzini, R., & Regattieri, A. (2008). An analytical model to evaluating the implementation of a batch-production-oriented line. International Journal of Production Economics, 111(2), 729–740.

Gamberi, M., Manzini, R., & Regattieri, A. (2009). A new approach to the automatic analysis and control of material handling systems: integrated layout flow analysis (ilfa). International Journal Advanced Manufacturing, Technology, 41(1), 156–167.

Golz, J., Gujjula, R., Günther, H.-O., Rinderer, S., & Ziegler, M. (2011). Part feeding at high-variant mixed-model assembly lines. Flexible Services and Manufacturing Journal, 24, 119–141.

Jing-wen, Li. (2003). Improving the performance of Job shop manufacturing with demand-pull production control by reducing setup/processing time variability. International Journal of Production Economics, 84, 255–270.

Manzini, R., Ferrari, E., Gamberi, M., Persona, A., & Regattieri, A. (2005). Simulation performance in the optimisation of the supply chain. Journal of Manufacturing Technology Management, 16(2), 127–144.

Manzini, R., Gamberi, M., Regattieri, A., & Persona, A. (2004). Framework for designing a flexible cellular assembly system. International Journal of Production Research, 42(17), 3505–3528.

Manzini, R., Gamberi, M., Gebennini, E., & Regattieri, A. (2008). An integrated approach to the design and management of a supply chain. International Journal of Advanced Manufacturing Technology, 37(5), 625–640.

Ohno, K., Nakashima, K., & Kojima, M. (1995). Optimal number of two kinds of Kanbans in a JIT production system. International Journal of Production Research, 33, 1387–1401.

Salameh, M. K., & Ghattas, R. E. (2001). Optimal just in time buffer inventory for regular preventive maintenance. International Journal of Production Economics, 74, 157–161.

Sarker, B., & Balan, C. V. (1999). Operations planning for a multi-stage Kanban system. European Journal of Operational Research, 112(2), 284–303.

Sendil Kumar, S., & Panneerselvam, R. (2007). Literature review of JIT-KANBAN system. International Journal of Advanced Manufacturing Technology, 32, 393–408.

Shahabudeen, P., Krishniah, K., & Thulasin, Narayanan M. (2003). Design of two card dynamic Kanban system using a simulated annealing algorithm. International Journal Advanced Manufacturing Technology, 21, 754–759.

Sharadapriyadarshini, R., & Rajendran, C. (1997). Scheduling in Kanban-controlled flow shop with dual blocking mechanisms and missing operations for part types. International Journal of Production Research, 35(11), 3133–3156.

Sugimori, Y., Kusunoki, K., Cho, F., & Uchikawa, S. (1977). Toyota production system and Kanban system materialization of just-in-time and respect-for-human system. International Journal of Production Research, 15(6), 553–564.

Vito, A., Dassisti, M., & Okogbaa, G. O. (1995). Approximation approach for performance analysis production lines under a Kanban discipline. International Journal of Production Economics, 40, 197–207.

Xiaobo, Z., & Ohno, K. (1997). Algorithms for sequencing mixed models on an assembly line in a JIT Production system. Computers Industrial Engineering, 32(1), 47–56.

Yavuz, I. H., & Satir, A. (1995). A Kanban based simulation study of a mixed model just in time manufacture line. International Journal of Production Research, 33(4), 1027–1048.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faccio, M., Gamberi, M., Persona, A. et al. Design and simulation of assembly line feeding systems in the automotive sector using supermarket, kanbans and tow trains: a general framework. J Manag Control 24, 187–208 (2013). https://doi.org/10.1007/s00187-013-0175-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00187-013-0175-1