Abstract

Our aim was to identify alternative suture materials that might provide superior knot performance and equivalent ease of manipulation by means of an in vitro experimental study. Although used widely for arthroscopic shoulder stabilisation, absorbable poly(p-dioxanone) (PDS) monofilament sutures can lead to dehiscence and clinical failure due to knot slippage and/or loop elongation at low applied loads. With the objective of identifying alternative suture materials that might provide superior knot performance and equivalent ease of manipulation, an in vitro experiment was undertaken in which both Duncan and Snyder knotted loops were tied from four different suture materials using an arthroscopic knot pusher (Surgeon’s 6th Finger) and a wooden practice box (Arthrex). Three monofilament sutures, made from polypropylene (PROLENE), poly(glycolidetrimethylenecarbonate-co-dioxanone) (Biosyn) and PDS, and one braided polyester suture (SURGIDAC) were tested. Ease of manipulation was evaluated by measuring the time required to tie the knots, and the knot performance was assessed in terms of loop elongation and loop holding capacity by performing cyclic fatigue testing of the loops while they were immersed in saline on an INSTRON mechanical tester. The PROLENE and SURGIDAC sutures showed improvements in loop elongation and loop holding capacity over PDS, with the Snyder knots being consistently superior to Duncan knots. BIOSYN gave no improvement over PDS. Difficulties were encountered in advancing half-hitch throws of the braided SURGIDAC suture down the cannula, which resulted in longer knotting times. In conclusion, both the polypropylene and polyester sutures gave superior knot performance to PDS, but only the polypropylene gave equivalent ease of manipulation. As a result there may be clinical advantages in replacing PDS with monofilament polypropylene or braided polyester sutures for certain arthroscopic procedures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the clinical situation, the surgeon must choose which type of suture and which type of knot will be most appropriate for a specific task. For example, to repair a shoulder instability the length and tightness of the suture loop must remain constant following surgery, because an elongation or loose suture loop would cause loss of tissue apposition [1]. Recognizing that some clinical failures are due to the elongation of an arthroscopically tied knot [2], it is important for surgeons who use this surgical technique to select a type of suture material and type of knot that will provide high tensile strength, low elongation and minimal knot slippage.

Recent studies have indicated that current suture materials, such as monofilament made from poly (p-dioxanone) (PDS) and poly (glycolidetrimethylenecarbonate) (MAXON) show slippage and elongation even when twisted under low cycle loads [1, 3]. Consequently, demand for alternative suture materials for arthroscopic surgery remains.

With a view to resolving some aspects of this problem, we endeavored to compare four different types of suture materials and two different types of knots to compare knot performance and ease of manipulation in arthroscopic surgery.

Materials and methods

Two commonly used arthroscopic knots were used; (1) the Duncan loop plus three half hitches with a reversing post and switching throws called the Duncan knot and (2) the Snyder knot (see Fig. 1).

Four different types of suture material were used; (1) poly (p-dioxanone) (PDS), (2) poly(glycolidetrimethylene-carbonate-co-diaxanone) (BIOSYN), (3) polypropylene (PROLENE), and (4) poly(ethylene terephthate) or polyester (SURGIDAC). The Surgeon’s 6th Finger Knot Pusher (Arthrex, Naples, FL, USA) was used in tying knots for the study. Scanning electron microscopy was performed on a Cambridge Instruments Stereoscan 120 instrument, and the images were captures and digitized with an Kontron IBAS electronic image analyzer with the accompanying software.

Dependant variables

-

1.

Knot performance characteristics:

-

(a)

Loop elongation: loop elongation refers to the maximum displacement or growth in length of the knotted loop at peak load under cyclic loading [1]. A suture loop that is loose will cause loss of tissue apposition no matter how tight the knot is tied [4].

-

(b)

Knot elongation: this is the elongation of the construct due to the knot itself.

-

(c)

Loop holding capacity: this refers to the maximum force that produces a displacement or growth of 3 mm in the length of a knotted suture loop. This threshold has been used by several investigators who found in the clinical situation that this amount of displacement results in loss of tissue apposition [3, 5, 6].

-

(d)

Number of cycles.

-

(e)

Knot security: the measure of the strength of a knot. It refers to the maximum load the knot is able to support prior to breaking (fracture) or complete slippage [3]. Previous studies have shown that loop-holding capacity and knot security are influenced by the type of knot, the knot configuration, the type of suture material, and the size and coating of the suture, as well the technique used for the knot [6–8].

-

(f)

Maximum elongation: maximum elongation refers to the maximum displacement of a stressed knotted suture loop either when the suture breaks and the knot remains intact, or when the knot slips completely off the end of the suture. In a previous study, it was shown that for PDS sutures the maximum elongation was greater than 5 mm regardless of which knot configuration was tested. This degree of loop displacement is well beyond the 3 mm limit assumed to represent clinical failure by loss of apposition [3].

-

(a)

-

2.

Ease of manipulation:

-

(a)

Knotting time.

-

(a)

Knot tying techniques

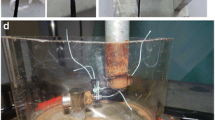

The instrument used was the Surgeon’s 6th Finger Knot Pusher with suture passer (Arthrex, Naples, FL, USA). This instrument is recommended by Burkhart for rotator-cuff repair [4]. Eugene Wolf’s hangman knot-tying technique as described by Snyder was used for tying the Duncan knot and the Snyder knot [9]. The knots were tied around a 1.6 cm-diameter rigid plastic rod (5 cm circumference) made from polytetrafluoroethylene (TEFLON) with a low friction surface and mounted in an Arthrex “wooden shoulder” arthroscopy practice box (Arthrex, Naples, FL, USA). The knot loop and additional throws were formed outside a 7 mm-diameter cannula, and then moved down the cannula using the 6th Finger Knot Pusher. Knots were tied in a standard atmosphere (21±1% and 65±2% relative humidity). After tying, the knots were carefully removed from the rod and tested immediately.

Number of specimens

A sample size of ten was selected for this study. A sample size of ten was also used in Loutzenheiser’s study [3].

Sampling

Eighty knot specimens were tied around 16 TEFLON rods. Five knots of different sutures were tied around each rod. A random selection was used to determine the order of knot tying and the type of suture used for each plastic rod. The 16 groups of knots were tied following the order generated by random selection.

Validation of knot tying technique

In order to validate the results of this study for the knots tied by the investigator, it was necessary to compare the knot performance and ease of manipulation for knots tied by the investigator with those tied by an experienced arthroscopic surgeon.

Test methods

Testing conditions

To simulate the arthroscopic environment, testing was performed in Tris buffered (pH 7.6) saline in the environmental tank at 21°C. This was to simulate the physiological liquid environment [1].

Test procedure for Loop elongation under fatigue testing (cyclic loading)

Loop elongation was defined as the average maximum displacement of a knotted suture loop at the peak load during cyclic loading [3]:

-

1.

A 7 N preload was applied at a strain rate of 40 mm/min to remove any initial slack and to provide a zeroed reference point for the knotted loop.

-

2.

After the preload was reached, a strain rate of 12 mm/min was applied in a linear ramp to a load of 30 N. The maximum displacement with respect to the zeroed position was recorded at the peak load (30 N) for each cycle up to a total of ten cycles. In addition, the number of cycles when the knotted loop reached or exceeded 3 mm extension was recorded.

A video camera was used during the knot-tying procedure to record the movement of the investigator’s hands and the instruments. During the replay of these videos, a stopwatch was used to record the time required to complete each knot.

Results

Loop elongation in terms in number of cycles needed to reach 3 mm loop elongation and at 30 N are summarized in Tables 1 and 2. Knot elongation is summarized at 30 N in Table 3. The results of loop holding capacity are demonstrated in Table 4. This shows that the mean values for loop holding capacity of the Snyder knots are greater than those for the Duncan knots. Furthermore, the braided polyester suture SURGIDAC has a superior loop holding capacity relative to the three monofilament sutures, regardless of which knot is tied. The results of knot security are summarized in Table 5. This shows that the highest average knot-security values were achieved by tying Snyder knots with BIOSYN and SURGIDAC sutures, but that similar differences were not found with the same suture materials when tied in Duncan knots. The results of maximum elongation are summarized in Table 6. This suggests that for both types of knots PDS gave the highest elongation at failure and SURGIDAC gave the lowest. Furthermore, there is the tendency for the average maximum elongation of the Duncan knot to be greater than those for the Snyder knots.

Mechanisms of loop failure

After mechanical testing the suture residues were analyzed and several observations were made by scanning electron microscopy (SEM). It was found that suture loops failed in one of two ways. One was by the knot slipping; the other was by suture breaking. From the data it is noticed that the Duncan knot was more likely to fail either by suture breaking in the knot for monofilament sutures or by knot slippage for braided sutures. On the other hand, the Snyder knot was more likely to fail by suture fracture rather than in the knot.

Ease of manipulation

The ease of manipulation was defined as the average time required to complete the tying of the particular type of knot. The results of these tests are presented in Table 7. Three observations were made from this:

-

1.

PDS and BIOSYN sutures were relatively easy to manipulate and tie with both types of knots.

-

2.

There was no problem tying PROLENE in a Duncan knot; however, when using the Snyder knot there were occasions when it was difficult to slide down the half-hitch throw.

-

3.

More severe difficulties were encountered when attempting to slide down the half-hitch throws of the SURGIDAC sutures when tying both types of knots.

Discussion

Loop elongation

These results are consistent with those reported by Mishra et al. [1], who showed that Duncan knots appeared to have a greater loop elongation than Snyder knots when tied with MAXON and TYCRON.

Knot elongation

In general, the distinct differences in performance of the four suture types as in loop elongation are not evident. Even though the knot elongation for the BIOSYN knots appears to be marginally less than the three other sutures, this difference may not be significant. There is a tendency, as with loop elongation, for the Snyder knots to be associated with less knot elongation than the Duncan knots. If this difference is significant, it may merely be a reflection on the fact that there is less suture material to stretch in a Snyder compared to a Duncan knot.

Loop holding capacity

These results are consistent with the findings reported by Mishra et al. [1], who also showed that the Snyder knots tied with polyester braided (TYCRON) or polyglycolide monofilament (MAXON) sutures have a greater loop-holding capacity than Duncan knots. Furthermore, the braided polyester suture, SURGIDAC has significantly-superior loop-holding capacity relative to the three monofilament sutures, regardless of the knot tied. The results of loop-holding capacity for both types of knots generally fall within a narrow distribution. The results confirm the higher loop-holding capacity for the SURGIDAC sutures and give an indication that the capacity of PROLENE may be higher than BIOSYN, which may be higher than PDS.

Knot security

These results support the previous observations made in earlier studies [1]. We showed that the Snyder knot had superior knot security compared to the Duncan knot, when tied with braided polyester TYCRON sutures, but no such difference was observed with absorbable monofilament MAXON sutures.

Maximum elongation

Within each suture knot group there appears to be a relatively wide distribution of maximum elongation values, and the Duncan knots appear to be more variable, i.e. less consistent that the Snyder knot. We observed maximum elongations for all types of suture loops far beyond 3 mm. Therefore, maximum elongation is considered to be a less useful indicator for evaluating the knot performance of sutures for arthroscopic surgery.

Mechanisms of loop failure

Most of the PDS knots failed because the suture broke. The main difference between the Duncan and Snyder knots was that for the Duncan loops the PDS suture broke in the knot, whereas for the Snyder loop it broke near the knot. In both cases, longitudinal cracks were observed on the curve’s external surfaces where the bent PDS suture was under maximal tensile stress. Half of the BIOSYN sutures tied in the Duncan knot failed by suture fracture. The other half failed by knot slippage. All of the BIOSYN knots tied in the Snyder knot failed by suture breakage, mostly near the knot. Most of the PROLENE knots also failed by suture fracture. The Duncan knots failed more frequently because the suture broke in the loop, whereas the Snyder knots were more prone to breakage near the knot. In all cases of PROLENE suture fracture, the fracture morphology suggested a tensile failure mechanism associated with longitudinal cracking and axial splitting. For the SURGIDAC sutures, the Duncan knots failed almost exclusively by slippage, where most of the Snyder knots failed by fracture near the knot.

Ease of manipulation

The knotting time distribution appears to be marginally wider for the Snyder group compared to the Duncan group of knots. In addition, SURGIDAC sutures appear to have a wider distribution of time compared to the three monofilament sutures, regardless of the type of knot required.

Conclusions

This study has shown that improvements in knot performance have been achieved by using PROLENE and SURGIDAC sutures instead of PDS monofilaments.

Similar improvements over PDS have been observed in the loop-holding capacity of SURGIDAC polyester braided and polypropylene monofilament sutures. PROLENE monofilament also provides improvement, with 27 N loop-holding capacity. Similar and consistent, but less dramatic, improvements have been found with the use of Duncan knots. BIOSYN monofilament sutures do not offer any improvement over PDS in terms of loop elongation for either type of knot.

In terms of ease of manipulation, no significant differences in knotting times were found for the alternative monofilament sutures, BIOSYN and PROLENE, when compared to the knots from polyester braided SURGIDAC sutures, because of the difficulties in advancing the half-hitch throws down the cannula.

From this evidence it is concluded that polypropylene monofilament sutures, with superior knot performance and equivalent ease of manipulation, may have clinical advantages over PDS in certain arthroscopic procedures. The braided polyester suture, in spite of superior mechanical properties, was found to be more difficult to handle and manipulate using arthroscopic techniques. However, this may be an acceptable trade-off for better knot properties.

References

Mishra DK, Cannon WD, Lucas DJ, Belzer JP (1997) Elongation of arthroscopic tied knots. Am J Sports Med 25:113–117

Chu CC (1983) Survey of clinically important wound closure biomaterials. In: Biocompatible polymers, metals, composites. Technomic, Lancaster, PA, pp 477–523

Loutzenheiser TD, Harryman DT, Yung SW, France MP, Sidles JA (1995) Optimizing arthroscopic knots. Arthroscopy 11:199–206

Burkhart SS, Wirth MA, Simonick M, Salem D, Lanctot D, Athanasiou K (1998) Technical note: loop security as a determinant of tissue fixation security. Arthroscopy 14:773–776

Batra EK, Franz DA, Towler MA, Rodeheaver GT, Thacker JG, Zimmer CA, Edlich RF (1992) Influence of emergency physician’s tying technique on knot security. J Emerg Med 10:309–316

James JD, Wu MM, Batra EK, Rodeheaver GT, Edlich RF (1992) Technical considerations in manual and instrument tying techniques. J Emerg Med 10:469–480

Magilligan DJ, DeWeese JA (1974) Knot security and synthetic suture materials. Am J Surg 127:355–358

Van-Rijssel EJ, Trimbos JB, Booster MH (1990) Mechanical performance of square knots and sliding knots in surgery: comparative study. Am J Obstet Gynecol 162:93–97

Fischer SP (1995) Arthroscopic knot-tying. In: Proceeding of Arthroscopy Association of North America annual meeting, pp 180–193

The United States Pharmacopeia (1995) The National Formulary, USP 23, NF 18. United States Pharmacopeial Convention, Inc., Rockville, MD

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., King, M. & MacDonald, P. Comparative study of knot performance and ease of manipulation of monofilament and braided sutures for arthroscopic applications. Knee Surg Sports Traumatol Arthrosc 12, 448–452 (2004). https://doi.org/10.1007/s00167-004-0503-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00167-004-0503-y