Abstract

Customization and market uncertainty require increased functional and physical bandwidth in product platforms. This paper presents a platform design process in response to such future uncertainty. The process consists of seven iterative steps and is applied to an automotive body-in-white where 10 out of 21 components are identified as potential candidates for embedding flexibility. The paper shows how to systematically pinpoint and value flexible elements in platforms. This allows increased product family profit despite uncertain variant demand, and specification changes. We show how embedding flexibility suppresses change propagation and lowers switching costs, despite an increase of 34% in initial investment for equipment and tooling. Monte Carlo simulation results of 12 future scenarios reveal the value of embedding flexibility.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mass customization emerged as a paradigm in the early 1990s (Pine 1993) and focuses on serving the needs of individual customers through high product variety. This demanded a corresponding decrease in development time (Sanderson and Uzumeri 1997). Manufacturers were forced to seek more efficient and flexible product design and manufacturing strategies.

Two of the more successful strategies were the lean manufacturing strategy (Womack et al. 1991) and the product platform strategy (Meyer and Lehnerd 1997; Bremmer 1999). The lean manufacturing strategy attempts to reduce manufacturing costs by eliminating inefficiencies in the supply chain, as well as in fabrication and assembly processes. The product platform strategy attempts to save costs by sharing core elements among different products in the product family (Simpson et al. 2006). Both strategies have received significant attention in the literature, but opportunities for further research still abound. This is mainly so because new situations arise that are not handled by the traditional approaches. Lean supply chains have been shown to be excessively vulnerable due to unexpected disruptions such as terrorism and natural disasters (Sheffi 2005). Product platforms often turn out to be overly constraining in a dynamic market environment.

Figure 1 illustrates this last point by showing the percent change in aggregate demand for various types of automobiles in the United States from 2003 to 2004. While small sports utility vehicles (SUV) and crossover wagons gained in popularity, traditional large cars (sedans) and pickup trucks suffered significant losses. These market dynamics are caused by a multitude of factors such as the price of fuel, changing demographics, international competition and shifting customer preferences in terms of styling and favored functional attributes.

Changes in aggregate unit sales from 2003 to 2004 for the US car and truck market (Simmons 2005)

When new products are designed in response to or in anticipation of such changes, the manufacturing firm has essentially two alternatives: design a full up new product or derive a product by modifying an existing product to suit the changed requirements. If these modifications are done in a systematic way with sharing of common elements across multiple variants we call this a platform strategy. Figure 2 shows an example of a new vehicle derived from an existing platform. The exploded view highlights new and unique components (dark gray), carryover-modified (light grey) and carryover-common (medium grey) components. Only the last category of elements is reused without modifications and is traditionally considered a part of the product platform.

The tension between wanting to reuse as much as possible from previous products, i.e. having the platform comprise a large percentage of the product, and the desire for distinctiveness, innovation and new styling requiring many new-unique components is well documented in practice and in the academic literature (Simpson et al. 2006). What has not received a lot of attention is the second category of components in Fig. 2. The components labeled as “carryover-modified” are those that are very similar to existing components, but not exactly the same. These components are generated by redesign of existing components, and such redesigns are most often done in an expensive reactive mode. The degree of change varies, but oftentimes these components require substantial redesign as well as tooling and equipment changes in manufacturing. The purpose of this paper is to develop and demonstrate a systematic design process for treating such elements as “flexible elements” and to consider them as part of an expanded product platform. The hypothesis is that if the right subset of elements is designed with flexibility, that a platform will be more nimble in the future, therefore avoiding expensive redesigns and manufacturing switch(ing) costs. We strive to (1) demonstrate how to select flexible elements by projecting exogenous uncertainty into the platform and (2) to quantify both the additional upfront investment required to achieve this flexibility as well as the downstream benefits resulting from the investment.

After a brief literature review in Sect. 2, we present a normative flexible product platform design process in Sect. 3. This flexible platform design process (FPDP) takes exogenous uncertainties into account and incorporates the concept of flexible elements. Flexibility is defined as “the property of a system that is capable of undergoing specified classes of changes with relative ease (Moses et al. 2002)”. In this paper, flexible elements are defined as “elements that can accommodate each product variant’s different requirements through modification at lower additional investment levels, relative to other unique elements that can achieve the same purpose (Suh 2005)”. In Sect. 4 we demonstrate the process in a real world case study where three car variants are to be built from a common, but flexible platform. How much flexibility is needed? How much will flexibility cost? What are the future benefits of flexibility? We will attempt to answer these questions in Sect. 5.

2 Previous work

The state of the art in product family and platform design research has been recently summarized and broadly reviewed by Simpson et al. (2005). Instead of repeating such a broad review here, we will focus our discussion on five key papers that are most closely related to product platform design under uncertainty. They are papers by Simpson et al. (2001), Martin and Ishii (2002), Li and Azarm (2002), and Gonzalez-Zugasti et al. (2000, 2001).

Simpson et al. (2001) proposed the Product Platform Concept Exploration Method (PPCEM). In the paper, the authors state that PPCEM is a “formal method that facilitates the synthesis and exploration of a common product platform concept that can be scaled into an appropriate family of products.” The method applies to scalable product platforms and families, and consists of five steps: (1) market segmentation grid creation, (2) factor and range classification, (3) meta-model creation and validation, (4) product platform specifications aggregation, and (5) product platform and family development. The method was demonstrated through a universal motor case study, in which a family of ten motors is designed by varying the stack length.

Martin and Ishii (2002) developed the Design for Variety (DFV) method, to develop modularized product platforms. The authors used the Generational Variety Index (GVI) and Coupling Index (CI) to design platforms that can be easily changed in the future. In the paper, GVI is defined as an “indicator of the amount of redesign required for a component to meet the future market requirements.” The CI “indicates the strength of coupling between the components in a product. The stronger the coupling between components, the more likely a change in one will require a change in the other.” The method is demonstrated through a water cooler example, in which the GVI and CI for seven major components are calculated. Then, for components with high GVI and CI, flexible designs are generated to reduce GVI and CI, thus lowering future redesign cost.

Li and Azarm (2002) developed a design process for a product line (family) design under uncertainty and competition. The design process is divided into the design alternative generation stage and the design evaluation stage. During the design alternative generation stage, each design alternative is optimized through multiobjective optimization. In the design evaluation stage, each design alternative is optimized and evaluated using a Multi-Objective Genetic Algorithm (Narayanan and Azarm 1999), due to the combinatorial nature of the formulated optimization problem. In the end, the best product line (family) is chosen using a selection rule, which takes into account the designer’s utility of the product line as a whole. The proposed design process was demonstrated through a case study in which a cordless screw driver family is designed. Of the three major components (motor, gear, battery), the motor was designated as the platform component a priori. Through optimization of the other components, the authors identified best designs for several different uncertain scenarios.

Finally, Gonzalez-Zugasti et al. introduced a quantitative method to design product platforms (Gonzalez-Zugasti et al. 2000) and a framework to assess the value of the product platform-based family using a real options approach (Gonzalez-Zugasti et al. 2001). In the first paper, the proposed method was implemented for an interplanetary spacecraft family in which three candidate platform designs based on various telecommunications technologies and bandwidths (X-band, Ka-band, optical) were optimized for mass, cost, and launch margin, given a pre-determined set of future NASA missions. In the second paper, the interplanetary spacecraft family was evaluated under uncertain future mission requirements and platform development investments were valued using the real options approach.

This previous research covers several areas of product platform design which inspired our work. However, of all previously published methods, none deal with an end-to-end design process in which the uncertainty is systematically mapped to (functional) product attributes, design variables, physical components, flexible designs, and then to relevant costs for economic evaluation. Second, in most platform design processes, the notion of “flexible elements” is not explicitly apparent. This is crucial since system architects want to know where and how much flexibility to embed in a system in a specific design-under-uncertainty context. In the methods proposed by Li and Azarm, and by Gonzalez-Zugasti et al., the focus of the process was to identify common and unique elements for maximum performance and/or profit but they offered no mention of flexible elements. In the work published by Martin and Ishii, flexible design alternatives were presented in the case study, but the economic consequences and subsequent uncertainty analysis were not developed. Work by Simpson et al. deals with scalable (“flexible”) universal motors, but only optimizes them for current needs. Finally, most of the previous work deals with rather simple examples, thus not fully capturing the intricacy of designing complex products. The main difficulty in going from simple to complex products is that the product architecture is not trivial and that the effects of change propagation (see Eckert and Clarkson 2004) must be captured. In the next section, the steps and logic of a normative FPDP to address some of the challenges are presented.

3 Flexible platform design process

3.1 Overview

Figure 3 outlines the framework for designing flexible product platforms. This FPDP assumes that preliminary designs of a product platform (set of related common components) and variants (platform + unique components) have been developed by experience or by using one of the formal methods proposed in the literature (Simpson et al. 2005). At the outset, however, uncertainty has not yet been considered. The process in Fig. 3 resulted from numerous interviews and iterations with car designers and vehicle architects at a large automotive manufacturer. However, we believe the process to be general enough to be applied to other types of physical products.

The process begins by identifying target market segments, product variants, and critical uncertainties that the product platform must be able to accommodate (Step I). Subsequently, functional product attributes impacted by uncertainty and related system-level design variables are identified (Step II). The identified set of design variables for each product variant in the family is optimized to yield maximum product family revenue (Step III). In this way the required bandwidth for key product design variables in the product family is determined. Given the requirement to achieve bandwidth for uncertainty-impacted design variables, a critical set of physical elements, affected by the design variable change(s), is determined via change propagation analysis (Step IV). Using the identified physical elements and given bandwidth requirements, flexible platform design alternatives are generated (Step V). Initial investment, variable costs, and switching costs for the design alternatives are calculated in Step VI. The final step in the framework consists of uncertainty analysis (Step VII), wherein the benefit of each platform design alternative is estimated under future scenarios with varying degrees of uncertainty. Finally, the best flexible platform design alternative is selected, or one enters a loop back to Step I or Step V if a satisfactory solution has not been found.

The steps in the FPDP are mapped to and differentiated from the methods discussed in the earlier five papers in Fig. 4. It can be seen that mostly product platforms are treated at the “parametric” level, omitting Step IV which identifies the physical elements of the platform. In practice, however, commonality is always assessed via a bill of materials (BOM), which lists all physical elements and their unique part number. An important feature of FPDP is that it handles both functional attributes and design variables as well as physical components.

For each of the steps in the FPDP process a variety of methods and tools may be used, see Table 1.

The subsections that follow present the generic formulation and explain each step of the process.

3.2 Step I: Identify market, variants, and uncertainties

The first step of the process is to identify target market segments \({{\mathcal{M}}}= \left[M_1,\ldots \right],\) desired product variants \({{\mathcal{P}}}= \left[p_1 \ldots {p_{n_p}} \right] \) assigned to those segments, and a set of uncertainties \({{\mathcal{U}}}= \left[u_1 ,u_2,\ldots \right]\) that are related to \({{\mathcal{M}}}\) and \({{\mathcal{P}}}.\) Here we assume that all product variants in a product family \({{\mathcal{P}}}\) will be derived from a common product platform. A graphical representation of the assignment of the set of variants \({{\mathcal{P}}}\) to the set of market segments in \({{\mathcal{M}}}\) is shown in Fig. 5.

A set of market segments \({{\mathcal{M}}}\) for a specific type of product is typically defined through clustering analysis (Jajuga et al. 2002). Figure 5 shows how small, midsize and large sedans as well as vans cluster in terms of passenger volume [cft] versus price [2002 $]. We can see that products in the same market segment are grouped together in terms of similar product attributes. Figure 5 assumes that three variants are produced: p 1 a large sedan, p 2 a midsize sedan and p 3, another midsize sedan. All three variants are built from the same platform and differentiated via price and other attributes not shown on the plot. An individual product variant can be expressed as a vector of specific product attributes (J A ) and price (P), i.e. for the ith product variant let p i = [ J A,i P i ]T. Therefore, the product family \({{\mathcal{P}}}\) can be expressed as a matrix of specific product attributes’ values and prices, as in Eq. (1):

The last item to be defined in this step is a set of uncertainties \({{\mathcal{U}}}\) that might impact the product platform in significant ways. Figure 1 demonstrated that demand can change significantly for different market segments from year to year, whereby such fluctuations can be amplified for individual product variants. To illustrate this point, Table 2 summarizes how various quantities have evolved dynamically in the SUV market in North America in the period from 1999 to 2003 (Table 2).

The data suggests that the aggregate SUV market has grown at an average rate of 10% per year and that these types of vehicles have grown larger, more powerful and yet slightly more fuel efficient over the same 5-year period. The data shows that exogenous uncertainties and future trends cannot be ignored in engineering design of product platforms that have long lifecycles (>10 years). The main issue addressed by the FPDP (Fig. 3) is that product platforms often have a life cycle that exceeds that of the variants built from the underlying platform and that market and technological trends are difficult or impossible to predict accurately over such planning horizons. A platform must therefore be designed to accommodate several product variants at its point of inception, as well as be flexible to respond to future uncertainties.

3.3 Step II: Determine uncertainty-related key functional attributes and design variables

In the previous step, we identified market segments \({{\mathcal{M}}},\) product variants \({{\mathcal{P}}},\) and uncertainties \({{\mathcal{U}}}.\) Each market segment M j can be expressed as a range of customer-preferred attribute values and price, within which a specific product variant’s J A,i and price P i must fall (see dashed boxes in Fig. 5):Footnote 1

Depending on the number and position of competing products and the firms own current product attribute values in a specific market segment M j , the firm needs to set their ith product’s J A,i and P i values within the established range of M j in order to gain market share and a competitive position. J A is a function of a system-level design variable vector X A for each product. Examples of system-level design variables x A,i ∈ X A are height, wheelbase and engine horsepower rating (see Table 2) in automobiles. These are design variables because customers do not value these variables directly and designers can choose their instantiations freely (within bounds and subject to physical constraints). The term “system-level” implies that these variables are not directly associated with individual components such as the ones shown in Fig. 2, but instead they describe the product at an aggregate level. A product family is thus defined as:

Even though there can be many different product attributes within J A , the ones that are of special interest here are product attributes that are related to the set of uncertainties, \({{\mathcal{U}}}.\) A product attribute vector, related to a set of uncertainties \({{\mathcal{U}}},\) can be expressed as \({\bf J}_{{\mathcal{U}}},\) where \({\bf J}_{{\mathcal{U}}} \subseteq {\bf J}_A.\) These attributes are significantly affected by the uncertainties identified in Step I and must be mapped to system-level design variables. The next step is to establish the relationship between the uncertainty-specific product attributes \({\bf J}_{{\mathcal{U}}}\) and the related system-level design vector \({\bf X}_{{\mathcal{U}}},\) where \({\bf X}_{{\mathcal{U}}} \subseteq {\bf X}_A.\) This is expressed as

Given the target market segment M j assigned for each p i , the upper and lower bounds of the uncertainty specific system-level design variable vector \({\bf X}_{{{\mathcal{U}}},i}\) for a product variant p i must be within the limits of M j .

3.4 Step III: Optimize product family and platform bandwidth

For each p i , defined as a function of \({\bf X}_{{{\mathcal{U}}},i}\) and its established upper and lower bounds, all p i in the product variant set \({{\mathcal{P}}}\) need to be positioned within their respective market segment to generate maximum revenue as a product family. This can be stated as:

where \({R_{pi}}\) is the total revenue generated by the ith product variant, and h and g are equality and inequality constraints that must be satisfied. Individual product variant revenue R pi is further explained in Eq. (6):

where ms i,j is the market share for the ith product variant in its assigned market segment M j (see Fig. 5), and D T,j is the total demand in market segment M j . Market share is a function of product attribute values J A and variant price P (Cook 1997).

Estimating a reliable market share for given values of J A,i and P i is, in itself, uncertain and a large research field. It can be accomplished through conjoint analysis (1992), in which companies estimate customers’ preference sensitivities for particular products by systematically changing the product’s attribute values. Once the maximum revenue generating solution for Eq. (5) is obtained through optimization, the values of \({\bf X}_{{{\mathcal{U}}},i}\) and \({\bf J}_{{{\mathcal{U}}},i}\) for each product variant are determined, thus defining the bandwidth of the product platform in both the system-level design variable space and the customer-preferred attribute space. Figure 6 shows bandwidths of a hypothetical product platform in design variable and attribute space (grey shaded area).

Also, for each design variable in the optimization, it is important to perform a sensitivity analysis to determine how these variables affect the objective function (=product family revenue). For the most sensitive variables—even if their initially required bandwidth is zero or very small—it could be valuable to incorporate flexibility to easily influence future variants.

3.5 Step IV: Identify critical elements for flexibility

After establishing the platform bandwidth, each \(x_i \subseteq {\bf X}_{{\mathcal{U}}},\) must be mapped to a set of specific physical elements. This is an important prelude to identifying critical platform elements that must be flexible enough to achieve the desired design variable bandwidth, as suggested by the result of variant optimization in Step III. This step will be explained using a generic example.

Figure 7 shows both a graph (network) and design structure matrix (DSM) representation of a generic product system. Within the system, there are eight elements (A–H) connected to each other. Elements can be connected physically (e.g. welded together), or through information (e.g. signals), energy (e.g. electrical power) or material flow. The DSM represents the system using a matrix format with 1’s indicating connectivity between elements, see Eppinger et al. (1994). This is useful because (1) when a system-level design variable is required to be flexible, the designer needs to identify system elements affected by such change; and (2) when the identified elements are changing, the system designer must observe the change propagation to other elements (which may not be directly related to \({\bf X}_{{\mathcal{U}}})\) to estimate the effects of change.

Next, for every x i in \({\bf X}_{{\mathcal{U}}}\) that must have a non-zero bandwidth (Fig. 6), the designer must observe how a change Δx propagates throughout the system. We refer to Eckert et al.’s (2004) seminal work on change propagation in this context. There are four sources of changes for product platforms:

-

1.

Non-zero bandwidth of design variables is required by the initial revenue optimization (Step III).

-

2.

Product family revenue or market share might be very sensitive to some design variables and might benefit from flexibility in the future, even if the initially required bandwidth is zero or very small.

-

3.

Changes might be required in response to changes in other coupled elements of the system.

-

4.

New product variants might be added in the future.

Figure 8 shows how a hypothetical change Δx can propagate through the system. This figure represents the final system configuration after the change (due to Δx) has been implemented, showing the direction of change propagation.

The terms multiplier, carrier, absorber, and constant have been defined by Eckert et al. (2004) to classify elements that react to changes. We find this nomenclature compelling and adopt it here. Multipliers are elements that “generate more changes than they absorb.” Carriers are elements that “absorb a similar number of changes to those that they cause themselves.” Absorbers are elements that “can absorb more change than they themselves cause.” Finally, constants are elements “that are unaffected by change.” In Fig. 8, each element is classified, with multipliers indicated as circled elements. Then the questions are: how can these classes of elements be identified quantitatively, and how does identification of such elements provide a guide for better (flexible) product platform design?

To measure the degree of change propagation for a single element, i, we introduce the change propagation index (CPI) measuring the degree of physical change propagation caused by this element when the an external change is imposed on the system. Equation (7) is shown below:

where ΔE is a binary change propagation matrix. In Eq. (7), n is the number of elements in the system; and ΔE i,j is a binary number (0,1) indicating whether the ith element is changed because of element j. CPI helps classify elements and measures physical change propagation to other elements.

However, simply measuring the degree and number of physical change propagation instances is not enough. One must also consider the cost impact caused by Δx on the system via its affected elements. For each changed element, the change-related investment cost (switching cost K switch) needs to be identified. This provides the system designer with two quantitative measures for each element and each type of change Δx: one indicating the degree of physical change propagation (CPI), and the other indicating the economic consequence of such change (K switch).

In Fig. 8, the final state of change propagation is shown for a system after it has been altered due to the design variable change Δx. This final state can be expressed in matrix form shown in Fig. 8 (bottom). The column sum indicates the total number of changes going outward from a specific element (∑ΔE out). The row sum indicates the total number of changes coming into a specific element (∑ΔE in). Subtracting ∑ΔE in from ∑ΔE out yields the CPI value for each specific element. Depending on the value of the CPI, an element can be classified according to the terms previously defined. A positive CPI indicates that the element is a multiplier (class M); a zero CPI (with ΔE out,i = ΔE in,i ≠ 0) indicates that the element is a carrier (class Ca); a negative number indicates that the element is an absorber (class A) and an element with ΔE out,i = ΔE in,i = 0 is a constant.

The numbers added above each component in Fig. 8 (top) show the relevant switching cost, K switch (hypothetical) due to change propagation. Note that for element A (the change initiating element), total incoming change is set to 0 since there is no component sending changes to that particular component. The switching cost is the engineering cost of design changes and additional fabrication and assembly tooling and equipment investment to implement the changes. Changes could be made in hardware or software. Based on the CPI and switching cost incurred for each element, the following recommendations can be made for selecting critical elements and (re)designing them to be flexible:

-

1.

Multiplier elements are prime candidates for incorporating flexibility. These are elements that, as more changes are added, make the system harder to change.

-

2.

One must investigate elements connected to multiplier elements to understand the nature of change. These elements might require flexibility [e.g. a “buffer” to absorb the change, see Eckert et al. (2004)] to reduce or even eliminate change propagation altogether.

-

3.

Carrier elements must be examined as well. For example, a carrier element might receive changes from five elements and send out five changes, making it more expensive than a multiplier element that receives change from only one element and sends it out to two elements.

-

4.

Elements with high switching costs, even though they may not be multipliers, also require special attention. These elements, through high switching costs, make it financially unattractive to change the system in the future.

-

5.

Physical suppression of future change propagation and investment in flexibility must be carefully balanced. In some cases, physical propagation may be entirely eliminated, but it may require prohibitive investment to do so.

One practical example for the last point comes from the automotive industry. When engineers design a front motor compartment (see Sect. 4), they may have the option to design the compartment to accommodate a future V8 engine, even though it may only require a V6 engine initially. This will incur extra upfront investment, but when a future situation requires implementation of the V8 engine configuration, the built-in option can reduce or eliminate change propagation to other major parts of the vehicle.

3.6 Step V: Create flexible design alternatives

With target elements for embedding flexibility identifiedFootnote 2 in Step IV, the system designer must consider (re)designing the elements so that they propagate a smaller degree of change and/or require lower switching cost than for the inflexible design. This is accomplished by embedding flexibility into key elements—the ones that have the greatest impact. According to Hull (2002) and de Neufville et al. (2004), such flexibility is a “real option, in which we can either avoid downside risks or exploit upside opportunities.” However, this flexibility will often incur additional upfront investment and might result in additional system complexity. This raises important questions: How much flexibility is needed? How should it be embedded into these elements?

To answer the first question, we examine the platform bandwidth obtained by the revenue optimization in Step III (Fig. 6). The upper and lower limit values of X A , established through Eq. (5), set the range within which the platform must be flexible. Additionally, sensitive system design variables in \({\bf X}_{{\mathcal{U}}}\) need to be examined (see case study).

Addressing the second question the system architect must consider several factors related to the identified elements such as the demand distribution among variants, the types of physical changes required and the frequency with which those changes are expected in terms of future product releases. Embedded flexibility should be biased towards the most important variant p i in \({{\mathcal{P}}}\) to yield favorable overall cost expenditure to amortize investments in flexible parts and tooling. After considering all factors discussed, the product architect can generate a set of different platform design alternatives. One of the challenges in this step is the non-uniqueness of the design space. For a given requirement of achieving platform bandwidth, multiple flexible designs can be generated through established design principles (Pahl and Beitz 1996) and expertise of the system/subsystem designers. After flexible elements have been generated, the system is divided into two portions: (1) the product platform that consists of common elements and flexible elements that, with minor modifications, can be used for multiple product variants, and (2) the unique portion of the product that is customized for each variant.

3.7 Step VI: Determine costs of design alternatives

At the end of Step V, one or more flexible product platforms are defined. At a minimum we need to be able to compare two platform alternatives (rigid, flexible), but could include platforms with varying degrees of flexibility. To determine whether the generated platform design alternatives are flexible to change, accurate cost estimates for each alternative need to be generated. Costs are divided as follows:

-

1.

Initial investment cost K init, which includes fabrication and assembly equipment and corresponding tooling;

-

2.

Variable cost C total, which is the unit cost of each product variant multiplied by the number of product variants produced;

-

3.

Switching related capital investment cost K switch, which consist of investment costs caused by design changes. The switching cost is the total cost that results from a decision to make design changes.

To verify that the generated design alternatives are indeed more flexible than the original design, CPIs and switching costs for the same set of changes (identified in Step IV) are calculated. For a particular change, one design is more flexible if it incurs lower switching costs than other designs. However, one must consider the extra “price” paid upfront, to make the platform flexible. Whether the upfront investment is worthwhile depends on whether the flexibility (real option) is truly needed and can be amortized over the course of the product platform life cycle.

3.8 Step VII: Uncertainty analysis

Once all costs are identified, design alternatives must be evaluated under scenarios with varying degrees of uncertainty to determine their economic performance. The underlying hypothesis is that flexibility has more value as the degree of uncertainty grows. For each product platform design alternative, the expected future benefit expressed in terms of the expected net present value can be generically stated as

where the total expected benefit E[NPV] for the ith design alternative, is a function of the total product family revenue R T,i , the initial capital investment K init,i, the total variable cost C total,i, and the switching cost K switch,i incurred due to \({{\mathcal{U}}},\) as defined in Step I. After evaluating the proposed platform design alternatives under several scenarios, the system designer(s) can select the best platform design (maximum expected NPV) for a given uncertainty set \({{\mathcal{U}}}.\) In the next section, the FPDP is demonstrated through a case study in which a vehicle platform is designed with flexibility to respond to future uncertainties in demand, length and styling.

4 Case study: Automotive platform

4.1 Background

An automotive company is planning to add a new product platform to its portfolio. The new platform will accommodate three vehicle variants that were not previously built from a common platform. All three variants are midsize to large passenger sedans in different market segments (see Fig. 5) and have different requirements in terms of styling, production volume, and system-level design variables. Two variants will have a short wheelbase and one variant will be a stretched vehicle (long wheelbase). The new platform must be flexible enough to accommodate the initial vehicle variant specifications, as well as uncertain changes in the future. To achieve these objectives, we identify a critical subset of vehicle elements, incorporate flexibility into these platform elements, and then evaluate the flexible design under various uncertain scenarios.

This case study investigates in detail the body-in-white (BIW), which represents the structural portion of the product platform. At the end, the common, flexible and unique BIW platform elements will be defined along with recommendations on when to implement a flexible BIW platform versus a traditional (rigid) BIW.

4.2 Step I: Identify variants, and uncertainties

4.2.1 Market segments

For this case study, the vehicle sedan market segment is divided into smaller segments according to vehicle size and price (see Fig. 5).

4.2.2 Product variants

We define the sedan vehicle family \({{\mathcal{P}}}_{\rm veh}\) as: \({{\mathcal{P}}}_{\rm veh} = \left[ {p_1 ,p_2 ,p_3 } \right]\) where each p i in set \({{\mathcal{P}}}_{\rm veh}\) is described by specific values of J A and P, according to Eq. (1). Detailed explanations of J A and P for this automotive market are presented in the next section. The three variants are positioned in the following market segments as shown in Table 3:

4.2.3 Uncertainties

In this case study, the set of uncertainties \({{\mathcal{U}}}_{\rm veh}\) is defined as:

\(D_{{{\mathcal{P}}}_{\rm veh}}\) is the future demand of the vehicle family as a function of time t, and \(S_{{{\mathcal{P}}}_{\rm veh}}\) is a discrete sequence of required styling changes of the vehicle family as a function of time t. Note that the three variants are currently produced on different platforms and that their current (initial) yearly demand is known:

4.3 Step II: Critical attributes and design variables

4.3.1 Key attributes

For automobiles, the customer-preferred attribute set J A has several well defined attributes (Cook 1997). Some of these attributes are fuel economy, acceleration, reliability, towing capacity, and workmanship quality, to name a few. From these attributes, four attributes related to the uncertainties \({{\mathcal{U}}}_{\rm veh},\) were identified through interviews. They are

RM is customer-perceived vehicle roominess, IE is the ease of front ingress/egress, FE is fuel economy, and AC50–70 is the acceleration time interval from 50 to 70 mph. RM and IE are scores between 0 and 100 and represent the percentage of customers who are either “very satisfied” or “satisfied” with a specific vehicle. These scores are derived from past data obtained through a market survey of customers who owned their vehicle for 6 months or less. RM and IE are selected as attributes which are related to one of the uncertainties identified: styling. Vehicle styling is mostly influenced by the shape of BIW. Similarly, RM and IE are attributes which are also influenced by the BIW shape and its key dimensions. The reasons for selecting these attributes are that: (1) these four attributes are among the most important attributes for market segments where \({{\mathcal{P}}}_{\rm veh}\) is targeted; and (2) FE and AC50-70 are vehicle performance attributes affected by the vehicle size, and thus are coupled with RM and IE. Other attribute values, not included in \({\bf J}_{{{\mathcal{U}}}_{\rm veh}},\) are treated as constants in the case study.

4.3.2 Design variables for key attributes

Once the set of uncertain attributes \({\bf J}_{{{\mathcal{U}}}_{\rm veh}}\) is identified, the next step is to establish the mapping relationship between the attribute space and the system-level design variable space, as described by the system-level design variable set \({\bf X}_{{{\mathcal{U}}}_{\rm veh}}.\) For many engineering performance attributes, mapping from the functional attribute space to the system-level design space can be straightforward and analytical. However, in this case study, the two attributes RM and IE are customer perceived attributes, and so establishing the analytical relationship between the two spaces is not trivial. In order to translate customer judgments in terms of RM and IE into the vehicle-level design variables, principal component analysis (PCA) (Dunteman 1989), is used. Shown in Fig. 9 are relevant system level design variables, identified for each attribute. Dimensions in the figure are designated using standard SAE nomenclature (SAE 2001).

There exists a set of design variables that influences people’s perception of vehicle roominess (RM) and ease of front ingress/egress (IE) more than others. Using a principal components analysis based attribute translator model, RM and IE scores are estimated as functions of the design variables in Fig. 9. The following design variables were selected as a result of the PCA as independent design variables for each variant p i in the vehicle family \({{\mathcal{P}}}_{\rm veh},\) and they will be used for optimization in Step III:

-

L48: Second row knee clearance relates to RM and wheelbase differentiation.

-

W3: Front shoulder room is one of the most sensitive dimensions that affects RM.

-

W20: Seating reference point-front-Y coordinate, relates to RM.

-

H5: Distance from ground to seat for ease of IE.

-

H50: Overall BIW height affects both RM and IE.

From the dimensions shown in Fig. 9, several dependent variables are expressed as functions of independent design variables defined in Eq. (11). The dependent variables are H11, H30, H31, H61, H63, and S97. The last task is to identify constants, which are either common or unique for each vehicle variant. They are L18, W27, H112, H115, and H122. The constants L18, H112, and H115 are the same for all vehicle variants. The variables W27 and H122 are variant-unique for styling differentiation of the “greenhouse”, i.e. the part of the vehicle above the belt line, see Fig. 9 lower right. This is further discussed later.

4.4 Step III: Optimize product platform bandwidth

4.4.1 Product family optimization

The ultimate goal of the product platform is to maximize profit of the product family built from it through product variety increase and cost reduction. To begin the process of maximizing profit, the first task is to position each vehicle variant in \({{\mathcal{P}}}_{\rm veh}\) within the corresponding vehicle market segment to generate maximum revenue as a product family. Using relationships defined previously, the revenue maximization problem for the vehicle variant set \({{\mathcal{P}}}_{\rm veh}\) can be formulated as shown in Eq. (12).

In the equation, the individual vehicle market share, ms i is a critical value that is difficult to estimate. In our case study this information was obtained through a market simulation software for the North American automotive market for the 2002 model year, as a function of aforementioned vehicle attributes. Figure 10 shows the simulation and optimization framework for product family revenue optimization in Step III. Coupling equations capture the effect of RM and IE on fuel economy FE and acceleration AC (Suh 2005). Generally, an increase in vehicle dimensions leads to poorer fuel economy due to increased drag as well as longer 50–70 (mph) acceleration times due to larger structural mass, assuming a given powertrain.

Once all optimized functional attribute values and design variable values \({\bf X}_{{{\mathcal{U}}}_{\rm veh}}\) are determined, the vehicle platform bandwidth of the product family \({{\mathcal{P}}}_{\rm veh}\) is determined, both in the design space and attribute space. Tables 4 and 5 list optimized values (normalized) of \({\bf X}_{{{\mathcal{U}}}_{\rm veh}}\) and \({\bf J}_{{{\mathcal{U}}}_{\rm veh}}.\) They are normalized with respect to the maximum value of each variable among the three vehicle variants.

For some design variables, values for all vehicle variants are either the same or very close, indicating that a very small or no bandwidth is required for those design variables. Three independent variables—H5, L48, and Pw—require significant bandwidths. Variable P w (weighted price across trim levels) will be used during the uncertainty analysis (Step VII) to calculate the overall product family profit.Footnote 3 The next task is to perform a sensitivity analysis of the optimum solution, which will identify additional design variables that might benefit from flexibility, even if their initially required bandwidth is zero or very small.

4.4.2 Sensitivity analysis

The normalized sensitivity of variant p 1’s revenue with respect to the product design variable set \({\bf X}_{{{\mathcal{U}}}_{\rm veh}}\) is shown in Fig. 11.

The chart shows the percent change in the revenue of vehicle variant p 1 as a function of percent change in each design variable. Note, that with the exception of L48, the design variables have negative sensitivity value. This means that when these design variable values increase, revenue decreases. The reason is that as vehicle size increases to improve IE and RM, it degrades FE and AC50–70 values, resulting in decreased market share and variant revenue. Analysis results show that the vehicle price P is the most sensitive parameter, representing the price elasticity of demand. The most sensitive geometrical design variable is H50, the upper body opening to ground dimension. It has a significant effect on total revenue, especially for p 1. Even though this particular dimension does not require any differentiation initially (Table 4), incorporating flexibility for this particular dimension may be advantageous in the future. When the customers’ preferences change in the future (e.g. they want roomier cars or more economical cars depending on factors such as the price of gasoline), the firm may want to respond to this uncertainty with greater ease.

4.5 Step IV: Identify critical elements

4.5.1 Selecting flexibility drivers

Figure 12 shows design variables (L48, W3, W20, H5, H50) and differentiating constants (H122, W27). The figure shows two variants, p 1 and p 2 that feature differences in these values, which are most pronounced in the geometry of the body (“greenhouse”) above the belt line and the difference in wheelbase.

The upper variant in Fig. 12 shows a short wheelbase sedan (related to L48) with a box-like greenhouse (W27, H122) and higher (easier) ingress/egress, while the second variant features a longer wheelbase, sportier look and lower ingress and egress point. H50 was shown to be a very sensitive dimension, and if made flexible, can potentially add value under future uncertainty. We select the four design variables L48, W27, H122, and H50 as those that are the primary drivers of flexibility in the BIW. Some of the flexibility is dictated by the initial bandwidth between variants, while for H50 the need for flexibility arises out of sensitivity to potential changes in future requirements.

4.5.2 Bounding the physical domain

The challenge of this step is the non-uniqueness of achieving flexibility in the domain of physical elements. The identified design variables can be mapped to the physical elements space in many ways, generating many non-unique solutions. To address this problem, the system architect must decompose the physical system to bound the element space, thus constraining the physical space under consideration.

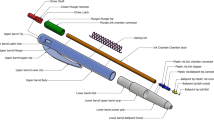

The BIW of a passenger car is shown in Fig. 13 with a high level system decomposition (motor compartment, passenger compartment, and cargo compartment). Since the key customer-preferred attributes, RM and IE, are attributes that are directly related to the passenger compartment in addition to the styling aspect, the system designer must focus on the passenger compartment to identify critical elements as candidates for incorporating flexibility.

Once the boundary of the “flexible” domain is established, components in the BIW structure need to be identified. In this study, the BIW is decomposed down to its individual component level, at which individual components are end-items supplied to the BIW assembly line directly. The architecture of the steel body is a body frame integral (BFI) structure with 21 components that are spot welded together. Next, the connective relationship between individual components is established and expressed in DSM format or as a network graph (Fig. 14) based on the DSM.

To achieve flexibility in L48, W27, H50, and H122, the product designer must (1) identify components that need to change, and (2) determine how such changes propagate through the BIW. The links between components represent physical connections, where each component is connected to another by spot welding. There are four system-level design variables, x i , mentioned in Sect. 4.4, that require differentiation for each vehicle variant. Additionally, styling uncertainty is a key factor that causes BIW changes to occur. For each specified design variable change, Δx i , one must identify multipliers and carriers that send out changes to other components when they themselves are changed. Once these components are identified, the system designer can (re)design the system (BIW platform) to reduce the degree of change propagation or switching costs by incorporating flexibility into the multiplier/carrier components directly, or into components into which secondary changes propagate.

4.5.3 Change propagation analysis: Length change

As a result of the revenue optimization in Step III, it was determined that the vehicle platform must achieve bandwidth for length, represented by L48. Such BIW changes are required because of varying needs for RM, IE or styling as shown in Fig. 12. We need to investigate cases in which length and styling requirements change in the future within the optimized L48 bandwidth.

The length change originates from the body outer panel, the outermost body component that is perceived by the customer and the most important component for vehicle styling. The change subsequently propagates throughout the BIW, and the final change propagation state is shown in the change propagation matrix ΔE in Fig. 14. This matrix and method of quantifying change propagation was explained earlier in Sect. 3.5.

The change propagation matrix shows CPI values for all components affected by the length change and classifies each component into four pre-defined classes, depending on the value of CPI. Ten components are affected by the lengthwise direction change, initiated by a change in L48. We refer to the change as ΔL. Once these components are identified, then the switching costs for making such a change need to be calculated.

Switching related investment costs for all components were calculated using a process based cost model (Kirchain 2004). The investment cost consists of blanking tool investment, stamping tool investment, and welding tool investment cost. Table 6 lists the initial investment cost and BIW length related switching costs for the ten identified components. The assumption is that—initially—these BIW components are customized for each vehicle variant. This corresponds to the components designated as “new-unique” in Fig. 2. Costs in Table 6 are normalized with respect to the initial investment cost of the body outer panel.

Figure 15 summarizes all change propagation related information into a graphical network format. Above the name of a particular component, its component class (for this particular change) and related switching cost are displayed. Change propagation paths are shown as thicker arrows, components affected by (this) change are shaded. Other change scenarios (e.g. restyling of the greenhouse only) as in Suh (2005) can also be analyzed in this fashion.

Once all critical BIW components and relevant switching costs are identified, this information is used to generate flexible BIW design alternatives in Step V.

4.6 Step V: Create flexible design alternatives

In Sect. 4.5, we identified critical BIW components that are affected by the specified uncertainties and attributes via change propagation analysis. The task now is to reduce the magnitude of change propagation through flexible component design and in turn to reduce the economic impact of future changes on the system (platform).

4.6.1 Passenger compartment decomposition strategy

We developed the following decomposition strategy to make the BIW flexible to change. The passenger compartment is decomposed into three sub-compartments, as shown by the dashed decomposition lines (DL) in Fig. 13. The lower front passenger compartment remains common for all three vehicle variants. The lower rear passenger compartment must be flexible in order to accommodate the design variable bandwidth for L48. The upper passenger compartment, also known as the “greenhouse,” will be either unique or flexible for differentiation in W27, H122, and the overall vehicle styling.

4.6.2 Single component decomposition: Body outer and inner panels

The body outer panel is a critical component that is visible to customers. It probably is the most sensitive component to styling changes. Figure 16 (top) shows how the component can be decomposed to incorporate flexibility.

The lower body outer panel is made common for all three vehicle variants. The upper body outer panel is customized for each vehicle variant for styling differentiation, as well as for the critical design variables differentiation as shown. Common and unique portions of the body outer panel are welded together to create the body outer panel for each vehicle variant. The welding interfaces for all three vehicle variants are also common.

The proposed decomposition will incur extra investment cost in blanking, stamping, and welding tools, but when the design changes, those changes will result in lower switching costs. The body inner panel is also a multiplier and incurs high switching cost whenever a change occurs. To reduce the impact of change, it is decomposed into three different pieces as shown in Fig. 16 (bottom). These pieces must be designed to meet the L48 bandwidth requirement while meeting the manufacturing, strength, crashworthiness and quality requirements as well. One way to achieve these requirements is to design the flexible piece to meet the long vehicle specification, and to trim the end (where it is welded to the common piece) to produce the short wheel base variant. A cursory analysis of teardown inspections of newer vehicles from various manufacturers revealed that flexible BIW panel buildup starting from smaller sub-panels does now indeed occur in practice, particularly for inner panel assemblies where welding lines are less of an issue.

4.6.3 Other components

Of the remaining six components identified as critical in Fig. 15—the rocker inner panel (RH and LH), floor pan, roof panel, front roof support and rear roof support—the roof panel is the only component that must be designed uniquely for each variant every time the design changes since it must comply with the styling restrictions imposed by the particular design change. In this case study, flexible designs for the rocker inner panel, floor pan, and front and rear roof support use the trimming strategy in which these components are designed for longer length specifications, and then trimmed down to meet shorter specifications (Suh et al. 2007).

4.6.4 Flexible assembly process

Assembly related investment is perhaps the biggest cost driver during the initial investment phase. In order to accommodate the flexible component designs proposed in the previous section, the BIW assembly line must also be flexible. Shown in Fig. 17 is the simplified BIW assembly process (based on the actual process) with the proposed areas for incorporating flexibility highlighted (shaded).

The motor compartment is common for all vehicle variants. However, remaining downstream processes do require flexibility in assembly tooling (such as flexible dies to hold variants of a body component for different vehicle variants) to accommodate different vehicle variants, which results in significant cost increases compared to using inflexible dies.

4.6.5 Vehicle platform element selection

As a result of the system decomposition strategy, several components and assembly processes became “flexible” elements, as parts of the vehicle platform. Table 7 shows a platform element comparison between the inflexible BIW design and the flexible BIW design.

Note that in the inflexible BIW design, components and processes are divided into either common or unique elements. In the flexible BIW design, several unique elements are redesigned to become flexible elements as part of the platform.

4.7 Step VI: Determine costs of platform alternatives

The next step is to determine the cost of the flexible BIW platform design. For this case study, a process-based cost model (Busch and Field 1988; and Han et al. 1993) is used to determine the capital investment and the unit (variable) cost of each vehicle. As mentioned in the previous section, the architecture of the BIW is BFI, using spot welded steel sheets as its material. Company-specific cost parameters were used for accurate cost calculation, and numbers are reproduced here in a normalized format.

In Sects. 4.6, we generated a flexible BIW design (other alternatives could be generated). The costs of the flexible design and the original inflexible design, customized for each vehicle, need to be determined in order to compare benefits and costs under future uncertainty. Table 8 shows, for each vehicle variant, the initial estimated annual production volume, expected volume trend and volatility, maximum expected production volume during the life of the vehicle platform, and the number of required BIW assembly lines per particular vehicle variant.

The number of required assembly lines is based on the maximum expected production volume during the lifetime of each vehicle variant built from the platform (15 years). In each assembly line, there is a maximum number of BIW units that can be assembled per year. Assembly lines with fixed tooling are dedicated to only one vehicle variant while assembly lines with flexible tooling can accommodate all vehicle variants. The following assumptions are made for determining relevant costs:

-

The life of the vehicle platform is 15 years (three generations of variants).

-

From the analysis in Steps IV and V, only ten components require differentiation while the other components remain common. For this study, only costs related to these ten components are calculated.

-

Two design alternatives are considered: the inflexible BIW design, in which ten differentiating components are uniquely customized for each vehicle variant and the flexible BIW according to Table 7. The assembly process for inflexible BIW design assumes fixed tooling, while the process for flexible design utilizes flexible tooling in the flexible (shaded) assembly sequences, as shown in Fig. 17.

-

Once the initial investment costs and unit costs are determined, they are assumed to be fixed for the remainder of the platform life.

For each design alternative, the initial capital investment cost, refurbishing cost, and switching costs are calculated. Table 9 lists normalized values of initial investment cost, refurbishing cost, and switching cost of the inflexible and flexible BIW platform designs. Values are normalized to the initial investment cost of the customized (rigid) BIW design.

The numbers indicate that the flexible BIW design, with flexible parts fabrication and assembly, requires approximately 34% more upfront investment than the inflexible BIW design. The inflexible BIW design is also more cost-efficient in terms of refurbishing costs. However, the flexible BIW design, with flexible assembly lines, outperforms the inflexible design in terms of switching cost when the styling and the length of the BIW need to be changed (within the pre-defined bandwidth) in the future. This shows the costs and benefits of the flexible BIW platform design; extra investment is required initially, but subsequent changes can be accommodated with lower investment costs. It is clear that the flexible BIW design is more expensive to implement initially, but has the potential to perform more economically when the frequency of styling changes increases. Step VII of the FPDP (recall Fig. 3)—the uncertainty analysis—will help determine those cases in which adding flexibility in the platform is worthwhile and those in which it is not.

4.8 Step VII: Uncertainty analysis

4.8.1 Problem formulation

In Step VI, all relevant costs for the inflexible and flexible BIW platform design were calculated. Costs include initial investment (K init), refurbishing cost (K ref), switching cost (K switch), and BIW unit cost (Suh 2005). Using the identified costs, uncertainty analysis can be performed to evaluate the economic performance (profit) of each platform under various degrees of uncertainty. The following assumptions are made for the uncertainty analysis:

-

All costs are normalized to the initial investment cost of the inflexible BIW design (see Sect. 4.7).

-

The time horizon is 15 years, corresponding to three generations of nominal vehicle variant redesigns.

-

Fabrication and assembly tools are refurbished every five years unless they are being replaced.

-

Geometric Brownian Motion (GBM) is used for future demand prediction.

-

The demand for individual vehicle variants cannot exceed the maximum assembly line capacity set by the number of assembly lines designated for each variant (for inflexible BIW platform design).

-

Flexible BIW platform manufacturing is also capacity limited, even though the flexible tooling in all assembly lines enables flexible capacity utilization in that case.

-

Styling changes and length changes occur within the design variable bandwidths defined from the results of revenue optimization in Step III.

-

When the styling changes, it is assumed that all three vehicle variants change together.

-

To calculate the total vehicle family lifetime profit for each design alternative, the net present value (discounted cash flow) method is used with an annual discount rate of 6%.

Table 8 lists demand forecast parameters for each variant, where α is the demand trend coefficient, and σ v is the demand volatility coefficient. These parameters are calculated from actual vehicle sales data (annual) between 1997 and 2003. Within the boundaries of the pre-stated assumptions, expected demand trends, and volatility, the two BIW design alternatives are evaluated and compared under several future scenarios (Table 10).

Scenarios I–IV are scenarios with varying degrees of uncertainty. Uncertainty analysis starts with investigation of scenarios where only the production volume of the variants is uncertain. Styling change uncertainty is added to increase the degree of uncertainty in scenarios III and IV, in addition to annual production volume uncertainty.

Scenarios V–VIII investigate instances where styling is changing above the vehicle belt line only but with a change frequency that exceeds the nominal 5-year life of individual variants, and under uncertain future demand. Scenarios IX–XII investigate instances where the styling is changing in the lengthwise direction with increasing frequency but within the L48 bandwidth defined from the optimization in Step III. Length changes result in higher switching costs since more component changes are required.

The expected net present value E[NPV] for the total product family is used to measure and compare the economic performance of each platform design alternative. The net present value is obtained by the following (well known) equation:

where

and

NPV is the total sum of time discounted cash flow over a period of 15 years; CF t is the total cash flow at time t; r is the discount rate; R i,t is the revenue generated by sales of the ith vehicle variant at time t; C total,i,t is the total variable cost incurred to produce the ith variant; K Init,t is the investment that occurs at time t; K ref,t is the refurbishing related investment that occurs at time t; K switch,t is the switching-related investment that occurs at time t; D i,t is the demand for the ith vehicle variant at time t; P w,i is the weighted average price of the ith vehicle variant, obtained from Step III; and c veh,i is the unit cost of the ith vehicle variant. In this case study, since only the BIW of the vehicle is investigated, the unit cost of the BIW will be used as the unit cost c veh. This is acceptable since our goal is not absolute profit forecasting, but a relative comparison of two platform designs, one with embedded flexibility and one without.

4.8.2 Scenario I–XII results

Monte Carlo simulation is conducted to determine the range of future vehicle demand and revenue. For each scenario (with the exception of scenario I, in which no uncertainty is present), simulation consists of 25,000 runs to represent a full range of outcomes. First, future demand uncertainty is simulated using GBM and the initial demand, mean trend and volatility from Table 8 are used for the variants in \({{\mathcal{P}}}_{\rm veh}.\) Figure 18 shows a particular instantiation of a demand scenario for variant p 2.

Depending on the scenario (I–XII) the simulation captures the effects of implementing changes to vehicle variants at varying time intervals. Scenarios III and V–VIII capture demand uncertainty (Fig. 18) plus styling changes above the belt line only at an increasing frequency. In scenario III the styling change is done every 5 years, while in scenario VIII we assume that the variant redesigns take place every year.

The second group of scenarios assumes that both vehicle length changes and styling changes occur together (see Fig. 15). In scenario IV this more invasive change is assumed to occur only every 5 years. In scenarios IX–XII the change frequency is increased by one year at a time. Under what scenarios will the inflexible or the flexible BIW yield a higher E[NPV]?

To answer this, an NPV analysis is conducted for each change scenario, BIW architecture and demand scenario. Figure 19 shows the results of the Monte Carlo simulation for scenario VI in terms of the expected difference in NPV between the flexible and inflexible BIW, E[ΔNPV]. The distribution of 25,000 runs converges to a probability density function with lower and upper bounds of 5.00 and 14.00 and a mean of E[ΔNPV] = 9.1. This means that the flexible BIW platform is superior to the rigid BIW platform in this scenario.

Table 11 summarizes the normalized NPV difference for all the scenarios described in Table 10. Table 11 also shows the total expected lifetime profit as NPV for each design over the life of the product platform.Footnote 4

In scenarios I–IV, the inflexible BIW design performed better than the flexible BIW platform. Even for scenario IV, where the uncertainty is greatest among the first four scenarios, the inflexible BIW design outperformed the flexible BIW design. Results suggest that under these circumstances, this particular flexible BIW platform should not be implemented as the higher investment in flexible elements and assembly equipment (Table 9) is never amortized over the 15-year time horizon. However, when the frequency of styling change increases, the results are different.

In Scenarios V–VIII, styling for all vehicle variants is changed more frequently. In these scenarios, styling is changed above the vehicle belt line only (no length change). The rationale for increasing styling change frequency is that there might be a situation in which, to maintain current demand levels under competition, the company must change vehicle styling more frequently to refresh the product family. Mean lifetime NPV for each platform design alternative is calculated, based on the Monte Carlo simulation described above. Results are shown in Table 11. As the frequency of styling change increases, the profit difference between the inflexible BIW design and the flexible BIW design initially decreases.

The crossover point occurs when the styling change frequency increases from every 4 years to every 3 years. When the styling changes every 3 years (Scenario VI) or more frequently, the flexible BIW design outperforms the inflexible BIW design in terms of total NPV. This is due to the switching cost incurred every time the styling of the variants—built from the shared platform—changes. Total NPV for the flexible BIW design does not decrease as rapidly as that for the inflexible BIW design as changes are made more frequently. This is due to the lower switching cost of the flexible BIW design (Table 9), making it more profitable under increasing uncertainty due to market dynamics. The presence of market dynamics was shown in Fig. 1.

Scenarios IX–XII evaluate situations in which styling changes also require a vehicle length change within the established L48 bandwidth. Since there are more components and tooling that require modifications when the vehicle length changes (ten vs. seven components when the ‘greenhouse’ only changes), switching costs for both designs—the flexible and inflexible BIW platform—are higher. However, due to its significantly lower switching cost, the flexible BIW has better economic performance once styling and length changes occur every 4 years (Scenario IX) or faster.

4.8.3 Value of flexibility for H50 dimension

During sensitivity analysis in Step III of the FPDP, we determined that product family profit is very sensitive to H50, and if rendered flexible, this dimension could influence the total product family revenue. We also found that H50 is an active constraint. If the constraint were relaxed, how long would it take to break even? Table 12 shows results for the break even analysis. The constraint on H50 is relaxed by 1% from its current lower limit. It is assumed that all three variants’ H50 are changing at the same time. Again, costs are normalized with respect to the initial investment cost of the inflexible BIW platform design.

The results show the superiority of the flexible design when H50 is changed. Given the same amount of revenue increase, the flexible design is able to break even within 6 months while the inflexible design requires approximately 2½ years to break even.

4.9 Discussion

Evaluating two different BIW platform designs under scenarios of varying uncertainty produced interesting results. When uncertainty was not considered, or was only very small, the inflexible BIW design performed better. However, as the degree of uncertainty increased, the expected NPV difference between the two designs decreased, and at a certain point, the flexible BIW platform design started to show higher expected NPV. The reason is that the magnitude of switching costs for the inflexible BIW design is much higher than for the flexible BIW design, and when the frequency of design change increased, the flexible BIW design outperformed the inflexible platform design. The results suggest that, under uncertain styling change frequency and uncertain vehicle family demand, it is beneficial to implement the flexible BIW platform design if styling must change every 3 years or less, or if styling and length change together every four years or less. While the actual particularities of future geometry changes are subject to styling trends and represent exogenous uncertainty (since vehicles are not designed 10 years ahead of their release), the frequency of the styling change is a controlled decision variable that can be decided by the firm’s management. Given this situation, Table 11 offers decision makers a useful quantitative guideline for making a decision on whether or not flexibility should be embedded into the BIW platform.

5 Summary and discussion

5.1 Summary

This paper introduces an end-to-end design process for flexible product platforms (Fig. 3). The framework is applied to a vehicle platform case study reflecting real world complexity. In the case study, the platform is designed to accommodate three vehicle variants while being flexible to uncertain future demand and specification changes.

The process is general and consists of seven steps, using a combination of quantitative analysis and expert engineering knowledge for each step. First, uncertainties are identified (Step I) and mapped to quantifiable product attributes (Step II), then to critical system-level design variables which require bandwidth and/or are sensitive to the aforementioned attributes (Step III). Once the bandwidths for the system-level design variables are determined through product family revenue optimization, critical product platform components are identified using change propagation analysis (Step IV). Flexible design alternatives are generated for critical components (Step V) in order to reduce change propagation and lower switching costs. The cost of flexible design, both in component fabrication and in the assembly processes, are calculated using a process based cost model (Step VI). Uncertainty analysis is performed to determine the economic performance of both the inflexible and flexible platform alternatives (Step VII) under a set of uncertain future scenarios.

We believe that Step IV, identifying critical platform elements as candidates for embedding flexibility, is the most critical and difficult step. This is were the main contribution of this paper lies. Much of the literature on platform design and optimization is satisfied with setting the values of design variables x i to be common (up to and including Step III). If, however the product is complex and the common design variables do not map to the same physical elements for reuse, such purely parametric commonality is of little real benefit. By decomposing the physical product in depth and performing change propagation analysis one can reveal those components that act as change multipliers (CPI > 0) and/or whose switching costs are significant. Embedding flexibility in those components requires initial investment in design, tooling and assembly equipment and is akin to taking out a “real option” on the platform design.

A cost comparison in our case study showed that the flexible platform design will cost 34% more to implement initially, but will incur significantly lower switching costs when the vehicle design changes. Higher investment also affects BIW unit costs, resulting in higher unit cost for flexible BIW design for some variants. However, other vehicle variants benefited from common component sharing, resulting in lower unit cost relative to the inflexible BIW design based variants. Creativity in embedding flexibility is important, and the best flexible designs may not increase upfront investment at all.

5.2 Critical discussion

The case study demonstrated that a specific subset of flexible BIW platform components allowed the whole BIW to become flexible to respond to the uncertainties defined at the beginning of the design process. Ten (10) out of twenty-one (21) BIW components together with the flexible assembly process (Fig. 17) made the BIW flexible to future styling and length changes, while remaining economically profitable in terms of total expected NPV.

Another important outcome of the paper is that the results quantitatively demonstrate the increasing value of flexibility as uncertainty increases. This fact is already well known in options analysis, but oftentimes designers do not have guidance in how specifically to respond to exogenous uncertainty. The FPDP is a methodology to identify (1) where in a complex, coupled system or product to embed flexibility and (2) how to value that flexibility in the context of realistic scenarios.

To do so required a number of simplifying assumptions that had a significant impact on the results:

-

In Step I we chose IE and RM as well as variant demand as the driving uncertainties for which flexibility was embedded. We substantiated this choice by empirical consideration of demand variations across market segments (Fig. 1) as well as historical trends of key product attributes (Table 2). As shown in this paper, flexibility can only be beneficial if the “right” uncertainties were selected in the first place and we acknowledge that the method developed here does not help product platforms deal with wholly unknown uncertainties or provide insurance against all future eventualities.

-

In Step III we established the “optimal” bandwidth of the product platform across a set of variants p i . In order to do so required setting lower and upper bounds of the system-level variables. The setting of these bounds was informed by the minimum and maximum occurrences in the constituent market segments (recall Fig. 5). However, market segment boundaries are always arbitrary and fluid so that setting different bounds might lead to different platform bandwidths. This relates to the question of platform extent and when it is beneficial to split a single large platform into two or more smaller platforms; a question which has been discussed elsewhere (Seepersad et al. 2000; de Weck (Chapter 12 in Simpson et al. 2005)).

-

A critical analysis of step VI reveals that the BIW only encompasses a relatively small percentage of total vehicle cost (typically <20%). So, there remains vast potential for platforming and embedding flexibility in other parts of the vehicle such as the powertrain, or the electrical equipment and software. The cost contribution of the latter subsystems has been steadily increasing in recent years.

-

Throughout the paper we have tacitely assumed that a basic product platform architecture already exists (see Fig. 13) and that flexibility is achieved by redesigning that existing platform. There might be other, more efficient ways of deriving a flexible platform architecture de novo.

-

In the change propagation analysis (Sect. 4.5) we assumed that the CPI and switching costs were independent of the amount of change (e.g. ΔL48 could be 1″, 5″, 10″…) as long as the change was within the allowed bandwidth. In reality the number of affected components and switching costs will not only depend on the type of change, but also on its magnitude.

5.3 Future work

Throughout this work we assumed that all variants would be built from a single common platform. However, this may not be true in some cases where the differences between variants are too great. In those situations, multiple platforms may be required, see work on this topic by Seepersad et al. (2000, 2002) and more recently by de Weck (Simpson et al. 2005). Future work will include determination of “splitting” criteria which will tell system designers in which cases a platform has been “stretched” too far and should therefore be split into separate platforms. One of the difficulties with this in practice is that the true bandwidth of a platform can often only be established via testing of physical prototypes.

Change propagation analysis was presented for an automotive BIW in this paper. While involved in its own right, the change propagation was relatively straightforward, given that only changes in geometry were taken into account. Future work will include analysis of change propagation in complex products were changes can potentially “jump” across subsystem boundaries and are not simply transmitted to directly neighboring components.

Notes

This does not necessarily preclude market segments from partially overlapping.