Abstract

Trade in high-value-added toxins for therapeutic and biological use is expanding. These toxins are generally derived from microalgae belonging to the dinoflagellate family. Due to the difficulties to grow these sensitive planktonic species and to the complexity of methods used to synthesize these molecules, which are generally complex chemical structures, biotoxin manufacturers called on artificial intelligence technologies. Manufacturing processes have been greatly improved through the development of specific learning neural networks, applied to each phases of biotoxin production: photo-bioreactors operating at optimal yied; new chemical synthesis research processes; toxin biosynthetic research pathways offering short-cut possibilities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hundreds of thousands of microalgae species are distributed on the surface of the globe in marine, freshwater or brackish.The long-lasting interest in bioactive molecules (toxins) produced by microalga has risen in recent years (Sun 2016; Khan 2018). Microalgae Market is valued at USD 54.64 million in 2018 and expected to reach USD 76.37 million by 2025 with a compound annual growth rate of 4.9% over the forecast period. (Brandessence Market Research 2019). Microalgae could be seen as “Cell mills producing recombinant commercial molecules”, which have encouraged the creation of numerous start-ups, specialized in the production of microalgae species (Green algae, Dinoflagellates, Red algae, Euglenoids) mainly in the western countries (Cadoret 2008). The reason for the growing interest of microalgae species is their ability to synthesize a wide variety of complex molecules recognized for their biological features with great potential for use as pharmaceuticals therapies and/or biological probes. Among myriads of microalgae species, the family of dinoflagellates is of particular interest since they exhibit wide varieties of natural compounds. The main known toxins extracted from dinoflagellate microalgae species with strong biological credit profiles are given in Table 1.

Most of these dinoflagellate drugs have complex chemical structures, the development of which requires efficient chemical synthesis processes through the use of new designed retrosynthetic schemes. The case of palytoxin is a significant example of high market value since its price is around 700 US $ 100 μg. This molecule has 64 stereogenic centers; its synthesis requires more than 140 steps (Hoffmann 2012; Newhouse 2009). Start-ups, whose economic business model is based on the production and sales of dinoflagellate bioactive toxins with high added value, have to face three major concerns:

-

Dinoflagellate in general grow slowly and are shear-sensitive species. It is the reason why dinoflagellate are difficult to culture in photo-bioreactors compared to other classes of microalgae. Consequently, chemical–physical conditions (temperature, pH, media composition, light, stirring conditions) to find economical and viable options regarding bioreactor design and culture strategies have to be optimized. Moreover, taking into account those drastic dinoflagellate culture conditions, scale-up biotoxin production requests the development of high-capacity bioreactors with a view to overcoming dinoflagellate biomass weight limitations (Assunçao 2017).

-

Due to the complex chemical structure of biotoxins of interest, their direct chemical synthesis through multi-steps synthesis requires design of efficient retrosynthetic schemes with focus on the most performing. Besides the possibility of their direct chemical synthesis, hemisynthetic routes can be also envisaged. Numerous examples of hemisynthesis of natural complex compounds are described in literature (Lone and Bhat 2015, Ten Lohuis 1995). To process biotoxin production through hemisynthetic technology, the most suitable metabolite involved in the metabolic pathway should be first selected, before to be included in the retrosynthetic scheme envisaged for the targeted biotoxin synthesis. Such pathway selection implies the total knowledge of the metabolic pathways involved in the metabolism of this biotoxin, besides, the possibility retrosynthetic scheme.

-

To circumvent quantities limitations of the targeted toxin, and to enhance the yields, genetic and metabolic engineering (Segler 2018) could be ways to overcome those constraints. For this purpose, the knowledge of the different metabolism pathways specific to each dinoflagellate species is required. Assuming that such pathways are not currently available, data mining have to be first undertaken before handling genomic experiments.

After having analyzed difficulties relative to the production of these high-added-value biotoxin production from dinoflagellate microalgae, one can ask the question:

“How Artificial Intelligence (AI) helps biotoxins manufacturers to overcome the whole problems raised in the previous paragraphs?”

AI is a valuable tool that can contribute to the achievement of each important phases (chemical synthetic processes, photo-bioreactor engineering, biological pathway identification) involved in the biotoxin cycle production.

2 AI in dinoflagellate culture production

A deep-learning neural network that considered the whole physical parameters (temperature, pH, irradiance, turbulence airflow, bioreactor capacity, light energy sources), as well as biological parameters (composition media, nutritional requirements) involved in the production of dinoflagellates helps to define the optimized conditions which allow to get the best dinoflagellate biomass yield for a given dinoflagellate species.

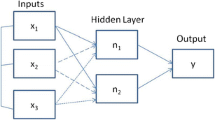

The learning neural network presented in Fig. 1 is an important step towards the goal of developing an algorithm which can help the tuning of a photo-bioreactor regarding optimized conditions for the preparation of a targeted biotoxin. This algorithm which predicts the best conditions to produce a given dinoflagellate specie is part of a learning machine, adapted to a photo-bioreactors devoted to the automatic dinoflagellate production.

Optimization of production can be achieved using a wide range of AI techniques from classical "one-factor-at-a-time" to modern statistical and mathematical techniques, viz. artificial neural network (ANN), genetic algorithm (GA), etc. Every technique comes with its own advantages and disadvantages, and despite drawbacks, some techniques are applied to obtain best results (Singh 2016).

Moreover, knowledge-based or artificial intelligence techniques are used increasingly as alternatives to more classical techniques to model environmental systems, but we believe that AI techniques could be also applied to biological systems production. These techniques can be artificial neural networks, fuzzy models, genetic algorithms, cellular automata, multi-agent systems, swarm intelligence, reinforcement learning and hybrid systems (Hamilton 2008).

3 AI and biotoxins chemical synthesis and hemisynthesis

Synthesis of molecules remains one of the most important challenges in organic chemistry. Standard approaches based on the development of specific retrosynthetic schemes are repetitive and time-consuming task. Through the use of machine learning, substantial progresses in organic chemical synthesis have been made over the past decades (Coley 2017; Ahneman 2018; Klucznik 2018). For some some dinoflgellates biotoxin molecules, de novo synthesis could be considered as feasible (saxitoxin, tetrodotoxin, akadaic acid) but for other biotoxins such as palytoxin, yessotoxin, brevetoxin, gamberiol, de novo synthesis is considered exceedingly complex and economically unfeasible.

3.1 AI and de novo dinoflagellate biotoxin chemical synthesis

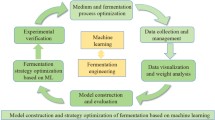

Using finger prints derived from a neural algorithm, Wei et al. (2016) have identified chemical reaction types involved in compounds chemical synthesis with more than 80% accuracy. Since the development of this algorithm, new deep-learning neural networks, which involved around 12 Million of known single-step reactions, and allowed the prediction of reactions which can be used in any single step of multi-step synthesis, have been developed (Coley 2017). Recently Klucznik et al. (2018), developed an highly effctive Chematica Computer program capable of designing novel efficient synthesis of medicinally relevant drugs, making Chematica algorithm able to propose optimized synthetic pathways for the design of any molecules of interest. For example, a standard de novo synthesis of saxitoxin, a toxin used in the treatment of chronic pain, has been achieved in ten steps with a final yield < 5% (Fleming 2006) in 2006. As represented in Fig. 2, using deep-learning neural networks, medicinal organic chemists can use valuable retrosynthetic schemes allowing total drug synthesis in better yields, reducing the number of steps, and predicting compound stereochemistry, structure identification (NMR, UV, IR), and some physical-chemistry properties.

3.2 AI and saxitoxin hemisynthesis

Knowing the metabolic pathways involved in the production of natural compounds, chemical structure of which is quite complex, it is sometimes possible to isolate a particular intermediate metabolite, which is part of the metabolic pathway of the targeted natural drug. Starting from this metabolite, specific chemical reactions are carried out to get the desired final drug in less steps and better yields (Lone and Bhat 2015). In this perspective, AI technologies have been used at different levels

-

saxitoxin biosynthesis pathway determination (Tsuchiya 2016; Hunter 1993).

-

hemi-biosynthesis of saxitoxin analogues starting from a specific intermediate named “shunt product (C′)” derived from biosynthetic precursors involved in saxitoxin pathway (Cho 2019).

-

detection and relative toxicity of saxitoxin analogues nonsulfated, monosulfated and disulfated (Lukowski 2019).

4 AI and saxitoxin genomic studies

Artificial intelligence has made faster, cheaper and more accurate DNA sequencing, and has allowed to gain perspective on the particular genetic blueprint that orchestrates the whole activities of a given organism. In this feature, it has been reported (Kellmann 2008) that saxitoxin biosynthetic pathway is encoded by more than 35 kb and comparative sequence analysis assigns 30 catalytic functions to six proteins. Using in silico functional inferences based on saxitoxin open reading frames combined with liquid chromatography–tandem mass spectrometry analysis, the description of the saxitoxin biosynthetic pathway has been revised, and a saxitoxin biosynthetic gene cluster (stx) has been identified and shown to be involved in saxitoxin production. Knowing the right saxitoxin metabolic pathway, it could be possible to construct an algorithm which satisfies not only each constraint but also allows several alternative pathways that by-pass key enzymes. Recently, new methods in artificial intelligence which offer the possibility to integrate chemistry and biology into complex reaction schemes to provide access to complex molecules not achievable with either alone, have been reported (Lin 2019). These authors concluded that in the next future, building a xenobiotic molecule of a scale of a natural product will require integrated computer-aided design packages that combine retrosynthesis, metabolic flux analysis, protein engineering and genetic circuit design automation. Such AI technologies have been already applied for systems biology with a high research impact (Cevora 2019).

5 Conclusion

Dinoflagellates is one of the rich biotechnological sources of biotoxins, with interesting biological activities not only in pharmacological and medical fields, but also as promising tools for chemical biology. Despite such recognized value, scarcity of such biotoxins remains a major issue, that new marine natural products start-ups have to face economically and in terms of viability. The problem becomes even more complex since these high-value biotoxins are mainly found in dinoflagellates species which are extremely fragile microalgae and which culture required high-tech bioreactors. To circumvent those problems, available AI technologies based on learning neural networks could be applied at each phase of biotoxin production: chemical synthesis and hemisynthesis, biotoxin structural identification, bioreactor engineering systems, biological pathways identification through marker-passing algorithm. AI clearly appears as a promising tool to help new start-uppers to jump in the restricted biotoxin market, in proposing not only biotoxins at reasonable prices but also allowing the discovery of new drugs, considering that dinoflagellates marine organisms are the sources of several thousand drugs of interest, which remain to be discovered (Kobayashi 2016). Of course to generalize AI technique to other dinoflagellate species to produce other high-value toxins, we will need to generate enough data to train a deep neural network.

Nevertheless, our perspectives are to use the knowledge we acquired with the use of artificial intelligence networks for the optimization of the production of new high-added-value toxins from new species of dinoflagellates, known to be difficult to grow.

References

Ahneman DT, Estrada JG, Lin S, Dreher SD, Doyle AG (2018) Predicting reaction performance in C-N cross coupling using machine learning. Science 360:186–190. https://doi.org/10.1126/science.aar5169

Assunçao J, Guedes AA, Malcata FX (2017) Biotechnological and pharmacological applications of biotoxins and other bioactive molecules from dinoflagellates. Mar Drugs 15(12):393. https://doi.org/10.3390/md15120393

Brandessence Market Research via Comtex. Microalgae market 2019 industry research, share, trend, global industry size, price, analysis, regional outlook to 2025 research report. Aug 2019. https://brandessenceresearch.biz/Researchpostld=65810&

Cadoret JP, Murdor M, Lerouge P, Cabigliera M, Henriquiez V, Carlier A (2008) Les microalgues: usines cellulaires productrices de molécules commerciales recombinantes. Med Sci 24(4):735–782. https://www.ifremer.fr/docelec/

Cevora G (2019) The relationship between biological and artificial intelligence. eprint arXiv:1905.00547; Bibcode:2019arXiv190500547C

Cho Y, Tsuchiya S, Omura T, Koike K, Oikawa H, Kanoki K, Oshima Y, Yotsu-Yamshita M (2019) Metabolomic study of saxitoxin analogues and biosynthetic intermediates in dinoflagellates using 15N-labelled sodium nitrate as a nitrogen source. Sci Rep 9:3460. https://doi.org/10.1038/s41598-019-39708-y

Coley CW, Barzilay R, Jaakkola TS, Green WH, Jensen KJ (2017) Prediction of organic chemistry reactions outcomes using machine learning. ACS Cent 3:434–443. https://doi.org/10.1021/acscentsci.7b00064

Fleming JJ, Du Bois J (2006) A synthesis of (+)-saxitoxin. J Am Chem Soc 1281(2):3926–3927. https://doi.org/10.1021/ja0608545

Hamilton SH, Jakema AJ, Norton JP (2008) Artificial intelligence techniques: an introduction to their use for modelling environmental systems. Math Comp Simul 78(s 2–3):378–400. https://doi.org/10.1016/j.matcom.2008.01.028

Hoffmann RW (2012) Streamlining organic synthesis for the 21st century. Russ J Org Chem 48(5):625–637. https://doi.org/10.1134/5107042801

Hunter L, Mavrovouniotis M (1993) Artificial intelligence and biomolecular biology. American Association for Artificial Intelligence, Menlo Park (ISBN:0-262-58115-9)

Kellman R, Mihali TK, Jeon YJ, Pickford R, Pomati F, Neilan BA (2008) Biosynthetic intermediate analysis and functional homology reveal a saxitoxin gene cluster in cyanno bacteria. Appl Environ Microbiol 74(13):4044–4053. https://doi.org/10.1128/AEM.00353-08(Epub 2008)

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Fact 17:36. https://doi.org/10.1186/s12934-018-0879-x (PMCID: PMC5836383)

Klucznik T, Mikulak-Kluczni SL, Grzybowski BA (2018) Efficient syntheses of diverse, medicinally relevant targets planned by computer and executed in the laboratory. Chemistry 4:522–532. https://doi.org/10.1016/.chempr.2018.02.002

Kobayashi J (2016) Search for new bioactive marine natural products and application to drug development. Chem Pharm Bull 64(8):1079–1083. https://doi.org/10.1248/cpb/c16-00281

Lin G-M, Warden-Rothman R, Voigt CA (2019) Retrosynthetic design of metabolic pathways to chemicals not found in nature. Curr Opin Syst Biol 14:82–107. https://doi.org/10.1016/j.coisb.2019.04.004

Lone SH, Bhat KA (2015) Hemisynthesis of a naturally occurring clinically significant antitumor arglabin from ludartin. Tet Lett 56(14):1908–1910. https://doi.org/10.1016/j.tetlet.2015.02.100

Lukowski AL, Denomme N, Hinze ME, Hall S, Isom LL, Narayan ARH (2019) Biocatalytic detoxification of paralytic shellfish toxins. ACS Chem Biol 145:941–948. https://doi.org/10.1021/acschembio.9b00123(Epub 2019)

Newhouse T, Baran P, Hoffmann RW (2009) The economies of synthesis. Chem Soc Rev 38:3010–3021. https://doi.org/10.1039/B821200G

Segler MH, Preuss M, Waller MP (2018) Planning chemical syntheses with deep neural networks and symbolic AI. Nature 555(7698):604–610. https://doi.org/10.1038/nature25978

Singh V, Haque S, Niwas R, Srivastava A, Pasupuleti M, Tripathi CK (2016) Strategies for fermentation medium optimization: an in-depth review. Front Microbiol 7:2087. https://doi.org/10.3389/fmcib.2016.02087 (PMID: 2811566)

Sun Z, Lin T, Zhou ZG, Jiang Y (2016) Microalgae as a source of lutein: chemistry, biosynthesis and carotenogenesis. Adv Biochem eng/biotechnol 153:37–58. https://doi.org/10.1007/10_2015_331

Ten-Lohuis MR, Miller DJ (1998) Genetic transformation of dinoflagellates (Amphidinium and Symbiodinium): expression of GUS in microalgae using heterologous promoter constructs. Plant J 13:427–435. https://doi.org/10.1046/j.1365-313X.1998.00040.x

Tsuchiya S, Cho Y, Konoki K, Nagasawa K, Oshima Y, Yotsu-Yamashita M (2016) Biosynthetic route towards saxitoxin and shunt pathway. Sci Rep 6:20340. https://doi.org/10.1038/srep20340

Wei JN, Duvenaud D, Aspuru-Guzik A (2016) Neural networks for the prediction of organic chemistry reactions. ACS Cent Sci 2:725–732. https://doi.org/10.1021/acscentsci.6b00219

Acknowledgements

Thanks to Planktovie S.A for helpful discussions. Aix Marseille University (France) and A. Le Bivic and L. Kodjabachian, IBDM–CNRS Marseille directors, are greatly acknowledged for facilities offered.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kraus, Jl. Artificial intelligence applied to the production of high-added-value dinoflagellates toxins. AI & Soc 35, 851–855 (2020). https://doi.org/10.1007/s00146-020-00959-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00146-020-00959-3