Abstract

A simple analysis method to detect clomazone residues in soybean and soil was developed using solid phase extraction coupled with high performance liquid chromatography with diode-array detection. The pesticide residues present in soybean and soil matrices were extracted with methanol–water and extracts purified with Florisil cartridges. The analytes from soybean and soil matrix were eluted with petroleum ether-acetic ether (10 mL, 95:5, v/v) and petroleum ether-acetic ether (2 mL, 95:5, v/v), respectively. The overall recovery of fortified soybean and soil at the levels of 0.01, 0.1 and 0.5 mg/kg ranged from 89.75% to 106.6%, and the coefficients of variation (CV) ranged from 1.68% to 4.93% (n = 3). The limit of quantification (LOQ) is 0.01 mg/kg. This method has been applied to the analysis of clomazone in real samples of soybean and soil. The dissipation of residue over the time in soil coincided with C = 1.189e−0.0926t and the half-lives (T1/2) was 7.48 days. The final residue in soybean was lower than 0.01 mg/kg at harvest time. Direct confirmation of the analyte in real samples was achieved by gas chromatography-mass spectrometry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Clomazone (Fig. 1), 2-(2-chlorobenzyl) methyl-4, 4-dimethyl-3-isoxazolidinone, is a herbicide produced in the early 1980s, which selectively blocks both chlorophyll and carotenoid synthesis in weeds (Ferhatoglu and Barrett 2006). Because of the broad-spectrum activity and low production costs, clomazone is frequently used against species of annual broadleaf weeds and grass in the cultivation of soybeans (Vyas et al. 2000). There is a possibility that clomazone residues may remain in soybean and will therefore be consumed by humans. Japan and South Korea set the tolerance for the residues of clomazone at 0.05 mg/kg in soybean.

Several methods have been developed for determination of clomazone in rice (Quayle et al. 2006), tobaccos (Mayer-Helm et al. 2008), and environmental water (Zanella et al. 2002). Soybean, however, receives no concern to our present knowledge, which is perhaps due to the difficulty in sample preparation. Soybean, is rich in proteins and lipids, requires a powerful cleanup procedure to remove coextractives. In our study, a Florisil solid phase extraction (SPE) procedure is investigated and optimized, the analyte is eluted from SPE cartridges with petroleum ether-ethyl acetate (95/5, v/v), and quantified by a selective detector which is high performance liquid chromatography with diode-array detection (DAD) to further reduce interference. The developed method is proved to be effective in ensuring analysis at 0.01 mg/kg and other concentrations with sufficient accuracy and precision. The method is also found to be applicable to soil analysis, and successfully employed for determination of clomazone levels in soybean and soil samples collected from the trial field.

Materials and methods

Clomazone standard (purity, 99.5%) was supplied by Institute of Agro-environmental Protection, Ministry of Agriculture of China (China), their commercial formulation (23% EC) were obtained from Shandong Cynda Chemical Corporation Limited (China). HPLC grade methanol was procured from Thermo Fisher Scientific Inc (USA). Other solvents and chemicals used were of analytical grade from Dikma Limited (China). SPE cartridges (Florisil, 500 mg, 3 mL) were purchased from Agela Technologies Inc (China).

High Performance Liquid Chromatograph (SHIMADZU) equipped with an analytical column (250 mm × 4.5 mm I.D., 5 μm ODS) attached to a DAD detector. The chromatographic conditions used for the analysis of clomazone residues were as follows: the mobile phase was methanol–water (75:25, v/v).The total flow was 1.0 mL/min. The injection volume was 20 μL; Detection was performed at 230 nm. Under these conditions, the retention time of clomazone was about 6.5 min. All measurements were carried out at room temperature.

GC–MS analysis was performed with a Shimadzu GCMS-QP2010 E (EI) system. A HP-5 capillary column (30 m × 0.25 mm × 0.25 μm film thickness) was used through out the entire experiment. Helium (>99.999%) was used as carrier gas at a flow of 30 cm/s. Chromatographic separations were performed at the initial temperature held at 120°C for 1 min, then the temperature was ramped at 15–240°C/min, then programmed at 3–270°C/min, and finally programmed at 5–290°C/min which was held for 2 min. Injector and interface temperatures were set at 280 and 250°C, respectively. Aliquots of 1 μl of the samples were injected under the splitless mode. Eluent from the GC column was fed into a 70-eV electron-impact ionization source maintained at 200°C. Spectra were acquired in full-scan mode (m/z 40-500).

Standard solution (1,000 mg/L) of clomazone were prepared in methanol. The solutions required for preparing a standard curve (0.05, 0.1, 0.5, 1, 2, 5 μg/mL) were prepared from the stock solution by serial dilutions. All solutions were protected against light with brown container and were stored in a refrigerator at 4°C.

Soil sample: 20 g homogenized soil was weighted out exactly into a 250 mL polypropylene container, and 60 mL methanol–water (2/1, v/v) was added. The mixture was vigorously shaken for 60 min, and then filtered through a 12 cm Buchner funnel. The filtrate was transferred to a separatory funnel (250 mL) with 30 mL 2% Na2SO4 aqueous solutions and then 60 mL of dichloromethane as the rinse. After the mixture was shaken for 2 min, the dichloromethane layer was collected, and the aqueous layer was extracted two more times, using 20 mL of dichloromethane each time. The combined dichloromethane extract was dried over anhydrous sodium sulfate (2-cm bed), followed by the removal of the solvent in a vacuum rotary evaporator at 40°C. The residue of the extracts was dissolved with 3 mL petroleum ether. Extract purification was performed on Florisil cartridges. Florisil cartridges were preconditioned with ethyl acetate and petroleum ether. The cartridges were loaded with 2 mL petroleum ether extract above. This eluate (2 mL) was discarded. The cartridges were washed with petroleum ether (2 mL), and discarded. The cartridges were re-washed with 2 mL petroleum ether-ethyl acetate (98/2, v/v), and discarded. The analyte was eluted with 2 mL petroleum ether-ethyl acetate (95/5, v/v), and concentrated in a rotary evaporator (40°C) and completely dried under a nitrogen purge. The residue was re-dissolved with 2 mL methanol for HPLC analysis.

Soybean sample: 20 g sample of corn homogenized was extracted with 50 mL methanol–water (3/2, v/v), by shaking thoroughly in a conical flask for 60 min on a mechanical horizontal shaker, and then filtered through a 12 cm Buchner funnel. The filtrate was transferred to a 250 mL separatory funnel, and 10 g NaCl was added, then 60 mL of dichloromethane as the rinse, After the mixture was shaken for 2 min, the dichloromethane layer was collected, and the aqueous layer was extracted two more times, using 20 mL of dichloromethane each time. The combined dichloromethane extract was dried over anhydrous sodium sulfate (2-cm bed), followed by the removal of the solvent in a vacuum rotary evaporator at 40°C. The residue of the extracts was dissolved with 5 mL petroleum ether-ethyl and for purification by Florisil cartridges. Florisil cartridges were preconditioned n-hexane and ethyl acetate. The cartridges were loaded petroleum ether extract (2 mL). This eluate (2 mL) was discarded. The cartridges were washed with petroleum ether (2 mL), and discarded. The cartridges were re-washed with 2 mL petroleum ether-ethyl acetate (98/2, v/v), and discarded. The analyte was eluted with 10 mL petroleum ether-ethyl acetate (95/5, v/v), and concentrated in a rotary evaporator (40°C) and completely dried under a nitrogen purge. The residue was re-dissolved with 2 mL methanol for HPLC analysis.

Field trials were carried out in an experimental plot, located at Tongzhou district of Beijing, China. Each experimental block was 30 m2 and each treatment replicated three plots. The control plots were localized, tagged and separated by guard rows to avoid contamination by drift, etc. Soybean plants, receiving routine horticultural treatment, were sprayed with the commercial formulation of clomazone (23% EC) at the dosages of 6,600 mL active ingredient per hectare (double the recommended by manufacturer). Soybean samples were collected at harvest time. Immediately after picked, the samples were put into polyethylene bags and transported to the laboratory where they were chopped, thoroughly mixed, and divided into three sub-samples each. The sub-samples were kept deep-frozen (−30°C) until analysis.

At 0 (2 h after spraying), 1, 3, 7, 14, and 21 days after spraying, about 200 g soil samples were collected randomly from several points in each plot. Soil was sampled to a depth of 0–10 cm in each plot using a tube auger and kept at −30°C until analysis. Control samples were obtained from the soil under the control plots.

Results and discussion

Quantitation was accomplished by using the standard curves constructed by plotting the analyte concentration against peak areas under the proposed chromatographic conditions. A good linearity was achieved from 0.05 to 5 μg/mL with correlation coefficient R 2 = 0.9998. The standard curve equation was y = 16,206 x + 469.88. Linearity correlation was shown in Fig. 2.

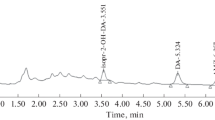

The fortified recovery experiment was set at three concentration levels (0.01, 0.1, 0.5 mg/kg), and with three repetitions at each level. The fortified recoveries of clomazone in soil and soybean samples were 89.75–106.6%, the coefficient of variation (CV) were 1.68–4.93% (Table 1). Figure 3 shows the chromatograms of the pesticide standard and spiked samples.

The limit of detection (LOD) was estimated to be 0.2 ng, based on a signal-to noise ratio (S/N) of 3, the limit of quantification (LOQ) for this method was defined as the lowest concentration of compounds in a sample that could be quantitatively determined with suitable precision and accuracy, LOQ of clomazone was found to be 0.01 mg/kg.

The residue dynamics of clomazone in soil was demonstrated in Fig. 4. The residues were 2.472, 1.032, 0.565, 0.455, 0.256, 0.237 mg/kg after 0 (2 h after spraying), 1, 3, 7, 14, and 21 days of application. Its dissipation rate was 58.2% 1 day after application, and then increased to 89.6% at the end of 2 weeks. The dynamics regression equation and the half-life of clomazone in soil were as follows: C = 1.189e−0.926t, R 2 = 0.743, T1/2 = 7.48 days. In previous reports, the soil half-life for clomazone, under a range of topsoils, varied from 6 to 59 days in Australia (Cumming et al. 2002). Rate of pesticide dissipation in soil exhibits a high degree of variability, the sources of which are usually unclear. Anaerobic, flooded field soil conditions may decrease the half-life quite significantly when compared with dissipation in aerobic soils (Quayle et al. 2006). The decrease in residue levels during the days after treatments in soil is presented in Table 2. Confirmation tests by GC–MS were used to determine whether or not peaks detected at the retention times of the analytes were in fact clomazone (Fig. 5).

No clomazone residues (<0.01 mg/kg) were detected in soybeans at harvest time withholding period of 3 months after treatments of the pesticide. The maximum residue limits (MRLs) of clomazone set by the Japan and Korea government for soybeans was 0.05 mg/kg, and no MRLs of the pesticide has been set by Chinese legislation or Food and Agriculture Organization/World Health Organization yet. According to MRLs set by Japan and South Korea, applying clomazone in soybeans is safety. This work would be helpful for the Chinese government to establish MRLs of clomazone in soybean and provide guidance on safe and proper use of the pesticide.

An effective, simple method for determination of clomazone in soybean and soil has been developed. The method shows satisfactory validation parameters in terms of linearity, lower limits, accuracy and precision. As a result of this study the procedure has been successfully applied in dissipation study of clomazone in real soybean and soil samples.

References

Cumming JP, Doyle RB, Brown PH (2002) Clomazone dissipation in four Tasmanian topsoils. Weed Sci 50:405–409

Ferhatoglu Y, Barrett M (2006) Studies of clomazone mode of action. Pestic Biochem Physiol 85:7–14

Mayer-Helm B, Hofbauer L, Muller J (2008) Method development for the determination of selected pesticides on tobacco by high-performance liquid chromatography-electro spray ionization-tandem mass spectrometry. Talanta 74:1184–1190

Quayle WC, Oliver DP, Zrna S (2006) Field dissipation and environmental hazard assessment of clomazone, molinate, and thiobencarb in Australian rice culture. J Agric Food Chem 54:7213–7220

Vyas MD, Singh S, Singh PP (2000) Weed management in soybean (Glycine max I merrill). Ann Plant Protection Sci 8:76–78

Zanella R, Primel EG, Machado SLO, Goncalves FF, Marchezan E (2002) Monitoring of the herbicide clomazone in environmental water samples by solid-phase extraction and high-performance liquid chromatography with ultraviolet detection. Chromatographia 55:573–577

Acknowledgment

This work was supported financially by the National Natural Science Foundation of China (no. 20777078).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Cao, D. & Deng, Z. Determination of clomazone residues in soybean and soil by high performance liquid chromatography with DAD detection. Bull Environ Contam Toxicol 86, 444–448 (2011). https://doi.org/10.1007/s00128-011-0224-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-011-0224-0