Abstract

Microcystins (MCs) are among the most prevalent and potent of the cyanobacterial toxins (cyanotoxins) and their potential occurrence in waters required for drinking has prompted investigations into remedial water treatments for their removal. We have investigated the suitability of local pumice, as a possible low-cost material for environmental application for the removal of cyanotoxins. Adsorption and desorption rates of pure MC-LR, one of the most common and toxic forms of MC and with crude extracts of the cyanobacterium. Microcystis aeruginosa containing MCs, were studied using bench-scale, pumice-packed glass columns, with good retention of the toxins being achieved. Research is in progress to optimize MC removal and to determine the applicability of pumice as a treatment material for cyanotoxin removal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Toxic cyanobacterial blooms commonly occur in lakes which are used as drinking water sources (Codd 2000). Their toxins can present health risks to humans via untreated- or inadequately treated drinking water (Codd et al. 2005). Several strategies for the removal of cyanotoxins from water have been investigated. Water treatment methods including chemical coagulation, flocculation and sand filtration may not only be insufficient but may also enhance the release of cyanotoxins contained within the producer-cells, thus requiring further treatment of the water for drinking purposes (Feitz et al. 1999). In the case of rapid filtration and slow sand filtration, these may not always be efficient in removing cyanobacterial cells and lysed cells on the filters may lead to release of cyanotoxins into the water. Chlorination has been shown in several studies to be only partially effective in removing cyanobacterial toxins. Chlorination is capable of oxidizing and detoxifying cyanotoxins but also has the disadvantage of generating toxic by-products such trihalomethanes (Rositano et al. 1995). Ozone treatment of MCs and nodularin has shown reductions in cyanotoxin concentrations to below detection limits (Rositano et al. 1998). The latter study also revealed that destruction of the toxins was pH-dependent being less effective under alkaline conditions which often occur during intense cyanobacterial blooms. However, satisfactory removal of MCs by ozone in a full-scale drinking water treatment was found to be achievable following pre-ozononation and rapid sand filtration (Onstad et al. 2007). Different sources of activated carbon have been investigated for their ability to adsorb MCs from aqueous solutions (Pendleton et al. 2001) but whilst offering potential, these sorbents are expensive and in limited supply in some locations requiring effective water treatment. Another method was investigated by Lawton et al. (1999): photo-irradiation is a promising method for removing MCs from water by ultraviolet radiation at wavelengths around 238 nm. However this process is also expensive to install and maintain. More affordable and low technology methods of drinking water treatment are needed in many parts of the world. For example, Morris et al. (2000) have reported that more than 81% of MC-LR can be removed from water by naturally-occurring clay particles. A number of other natural and artificial materials that possess a significant internal porosity may be used as sorbents for drinking water treatment. Pumice has been used as a filter medium in water treatment (Lura et al. 2004) and for adsorbing phosphate (Njau et al. 2003). Its porous structure provides a large number of attachment sites for microbial growth. This enables pumice to be used suitably as a medium for bio-filtration in water treatment systems. Pumice has also been reported to be used in dual media filtration systems (Pumex UK Ltd. 2000). The use of pumice for slow filtration to remove pathogens from irrigation waters at low cost has been demonstrated and is a well-established procedure in horticulture (Wohanka et al. 1999). Deep filters of pumice, fine sand, rock wool or mixtures of these materials are also used. Hexadecyltrimethyl-ammonium bromide-modified pumice has been used for the removal of pesticides in water (Akbal et al. 2000).

No work has apparently been performed on the potential use of pumice for the removal cyanotoxins from waters. The objective of this study was to determine the potential use of naturally-occurring pumice particulates to remove MC-LR both in dissolved form from water and when faced with cyanobacterial cell biomass, as can occur during bloom conditions in aquatic environments.

Materials and Methods

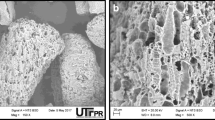

Pumice from the Pumice Research Centre, Suleyman Demirel University, was investigated as an adsorbent for the removal of microcystin from water. The chemical composition of the pumice is given in Table 1. Microcystin affinity onto the surface of pumice can be manipulated by pre-treatment with alkali, acids and heat. This removes impurities in the raw pumice. The pumice particulates were treated in succession with 3 M HCl, 0.5 M NaOH and 6 M HCl, then washed with distilled water and dried overnight at 180°C. Samples were kept in desiccators until used (Jones et al. 1986). Raw pumice contains various extractable materials which can affect adsorption and the large proportion of silica sites exposed results in a negatively charged surface. Washing with acidic and alkaline solution will provide a positively-charged surface.

Cultures of Microcystis PCC7813, which produces MCs, were grown under a continuous light régime (fluorescent white light, irradiance on growth flask surfaces, about 25 μEm−2 s−1 at 20–24°C, in BG11 medium with nitrate (Stanier et al. 1971) and sparged with filtered air at 800–1,500 mL min−1. Cells were harvested by centrifuging and lyophilized. MCs were extracted from batches of 40 mg freeze-dried cells suspended in milliQ water (18.2 Mohm cm), ultrasonicated for 5 min and cooled on ice. After three freeze-thaw cycles, the supernatant was collected by centrifuging at 10,000 × g for 10 min. The toxins were quantified by high-performance liquid chromatography with photodiode array detection (HPLC-PDA, Waters) using a Symmetry column (C18 Waters, 3.9 mm internal diameter 150 mm, 5 mm particle size), maintained at 40°C, with a mobile phase of acetonitrile + 0.1% TFA /MilliQ water +0.1% TFA, using a linear gradient from 25% to 75%. The flow rate was 1 mL min−1. The UV detector was set to 238 nm. The detection limit for MC-LR was 5 ng on column (25 μL injection volume). For a 25 μL injection this works out to be 200 ng per mL of sample. Microcystin-LR was purified from Microcystis PCC7813 as described earlier (Lawton et al. 1994). Microcystin concentration was quantified by HPLC-PDA according to calibration Eq. 1:

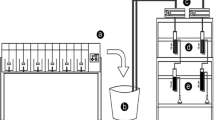

Batch and column experiments were carried out. The batch experiments were conducted in flasks to determine the effect of pH (2, 3, 4, 6, 7, 8 and 9) on toxin adsorption. For column experiments, glass columns (6.5 cm long, 0.6 mm internal diameter) were used, in which 1.0 g of modified pumice was loosely packed above a layer about 10 mg of glass fibre. The column was initially saturated with acidified deionised water. The amount of toxin (μg) removed from solution per gram of pumice at each toxin concentration was determined by difference and plotted against the concentration (μg mL−1) of toxin at equilibrium using the following modified equation (Zhou et al. 1998).

where Ceq is the amount of toxin adsorbed to pumice (μg mg−1), C 0 (μg mL−1) is the initial concentration and C t (μg mL−1) is the remaining concentration of toxin in solution at equilibrium. V (mL) is the volume of the solution; M, is the mass of pumice.

In order that an adsorption-based process is feasible for industrial application, the material used for adsorption should ideally be able to be regenerated for re-use. Columns which had been preloaded with MC beforehand were eluted with water. The eluate was monitored by HPLC-PDA to monitor for MC peaks and the same column was eluted with 2 mL methanol + 0.1 % TFA and the eluate checked again by HPLC-PDA.

All tests were conducted three times and the data from the replication of experimental treatments were analyzed by ANOVA (SPSS 10.0).

Results and Discussion

The findings from the batch experiments indicated that the MC-LR remained in the aqueous phase with increasing pH. Maximal adsorption of the toxin by the pumice occurred at pH 4. In agreement with wide findings that solution pH affects the adsorption of many organic compounds; Miller et al. (2000) have reported that MC adsorption onto soil was greater at low- rather than higher pH values. Similar results were obtained by Yuan et al. (2002) in investigating MC-LR removal by coagulation and by Pendleton et al. (2001), using activated carbon for MC adsorption.

A 100% adsorption of purified MC-LR onto pumice particulates was achieved in the column trials at all loadings tested (Fig. 1). In these tests, the concentration of MC-LR applied to the columns was 2.15 ± 0.19 μg mL−1. The volumes of toxin solution applied per run ranged from 1 mL to10 mL. In total, 21.5 ± 1.24 μg mL−1 of microcystin-LR was removed from 10 mL of toxin solution applied.

A 100% adsorption of MC-LR from the broken cell extracts of Microcystis PCC7813 was achieved at up to 6 mL of extract applied per column. The percentage removal of the toxin then decreased, probably due to other compounds in the broken cell extracts competing with MC-LR for binding sites (Fig. 2). Columns were overloaded when applied with 7 mL of crude cell extract containing MC-LR at 21.6 μg mL−1 and started to bleed. The total removed MC-LR concentration was determined as 17.96 ± 0.3 μg mL−1 at this volume.

The concentration of purified MC-LR applied to the columns (2.15 μg mL−1) greatly exceeded that of the provisional Guideline Value of the World Health Organization for MCs in drinking water (1 μg L−1 MC-LR; Falconer et al. 1999). Dissolved and cell-bound MC concentrations in raw waters containing cyanobacterial blooms are frequently above this, e.g. from about 5 to at least 70 μg L−1 in the case of scum formation (Hart et al. 1998; Welker et al. 2001; Young et al. 2006). Microcystin-LR is seldom the only MC structural variant present in a toxic cyanobacterial bloom (e.g. Young et al. 2006). Whilst MC-LR is among the most toxic of the MCs, in some waterbodies it is not the most commonly-occurring variant (Falconer et al. 1999). Whether the removal efficiency of pumice varies between MC variants needs to be investigated. The regeneration of loaded adsorbents can be an important factor in influencing the economic viability of water treatment process costs enabling the reuse of the adsorbent material. Some adsorbents are regenerated by washing out with an appropriate solution, the type and strength of which depends on the adsorbed materials. Diluted solutions of mineral acids like hydrochloric, sulphuric, acetic and nitric acid, or sodium hydroxide are used for eluting adsorbents for another cycle of application (Karahan et al. 2001). For this purpose we examined MilliQ water, 0.1 M HCl and 0.1 M NaOH but with no success in removing adsorbed MC-LR from pumice. However washing with methanol plus 0.1% v/v TFA as a leaching solution was very effective. The average desorption rate found for different volumes of extracts was 89.7 ± 2.5% (Table 2). The recovery of MC-LR by elution thus indicated that pumice can be regenerated for reuse. Removal of purified MC-LR from water was greater than MC-LR removal from crude aqueous extracts of MC-LR-containing Microcystis cells, probably due to competition for binding sites by other cell products. In this study pumice also acted as a filter device. Minor peaks of non-MC-LR variants were revealed in HPLC-PDA after passage through pumice columns, possibly due to the removal of interfering compounds in the cell extracts by the pumice.

In conclusion, this work has demonstrated the possible use of an abundant and readily available natural material for the removal of cyanotoxins by water treatment. Pumice may have particular applications where the availability of low-cost materials for environmental and health protection measures is economically critical. More research is needed to optimize adsorption capacity and to screen different types of pumice for cyanotoxin removal, both alone and in combination with other adsorbents.

References

Akbal FO, Akdemir N, Onar AN (2000) FT-IR spectroscopic detection of pesticides after sorption onto modified pumice. Talanta 53:131–135. doi:10.1016/S0039-9140(00)00380-5

Codd GA (2000) Cyanobacterial toxins, the perception of water quality and the prioritization of eutrophication control. Ecol Eng 16:51–60. doi:10.1016/S0925-8574(00)00089-6

Codd GA, Morrison LF, Metcalf JS (2005) Cyanobacterial toxins: risk management for health protection. Toxicol Appl Pharmacol 203:264–272. doi:10.1016/j.taap.2004.02.016

Falconer I, Bartram J, Chorus I, Kuiper-Goodman T, Utkilen H, Burch M, Codd GA (1999) Safe levels and practices. In: Chorus I, Bartam J (eds) Toxic cyanobacteria in water, a guide to their public health consequences, monitoring and management. E & FN Spon, London, pp 157–178

Feitz AJ, Waite TD, Jones GJ, Boyden BH, Orr PT (1999) Photocatalytic degradation of the blue-green algal toxin microcystin-LR in a natural organic-aqueous matrix. Environ Sci Technol 33:243–249. doi:10.1021/es970952d

Hall T, Hart J, Croll B, Gregory R (2000) Laboratory-scale investigations of algal toxin removal by water treatment. J Inst Water Environ Manag 14:143–149. doi:10.1111/j.1747-6593.2000.tb00241.x

Hart J, Fawell JK, Croll B (1998) The fate of both intra- and extracellular toxins during drinking water treatment. Water Supply 16:611–616

Jones A, Wood DN, Razniewska T, Gaucher M, Behie LA (1986) Continuous production of Penicillium chrysogeneum cells immobilized on celite biocatalyst support particles. Can J Chem Eng 64:547–552

Karahan AG, Gurbuz F, Tuncmen H (2001) Microalglerce Cu and Cd sorbsiyon and desorbsiyonu (in Turkish). J Fisheries Aquatic Sci 18:173–182

Lawton LA, Edwards C, Codd GA (1994) Extraction and high performance liquid chromatographic method for the determination of microcystins in raw and treated waters. Analyst 119:1525–1530. doi:10.1039/an9941901525

Lawton LA, Robertson PKJ, Cornish BJPA, Jaspars M (1999) Detoxification of microcystins (cyanobacterial hepatotoxins) using TiO2 photocatalytic oxidation. Environ Sci Technol 33:771–775. doi:10.1021/es9806682

Lura P, Bentz DP, Lange DA, Kovler K, Bentur A (2004) Pumice aggregates for internal water curing international RILEM symposium, Evanston, IL, March 22–24, pp 137–151

Miller MJ, Critchley MM, Hutson J, Fallowfield HJ (2000) The adsorption of cyanobacterial hepatotoxins from water onto soil during batch experiments. Water Res 35:1461–1468

Morris RJ, Williams DE, Luu HA, Holmes CFB, Andersen RJ, Calvert SE (2000) The adsorption of microcystin-LR by natural clay particles. Toxicon 38: 303–308. doi:10.1016/S0041-0101(99)00149-X

Njau KN, Minja RJ, Katima JH (2003). Pumice soil as potential wetland substrate for treatment of domestic wastewater. Water Sci Technol 48:85–92

Onstad GD, Strauch S, Meriluoto J, Codd GA, von Gunten U (2007) Selective oxidation of key functional groups in cyanotoxins during drinking water ozonation. Environ Sci Technol 41:4397–4404. doi:10.1021/es0625327

Pendleton P, Schumann R, Wong S (2001) Microcystin-LR adsorption by activated carbon. J Colloid Interface Sci 240:1–8. doi:10.1006/jcis.2001.7616

Pumex UK Ltd (2000) Brochure of pumice as used in water and wastewater treatments. Pumex UK Ltd, Newcastle-under-Lyme, Staffs. England.

Rositano J, Bond P, Nicholson B (1995) By-products of the destruction of cyanobacterial peptide hepatotoxins using chlorine. In: Proceedings of the 16th AWWA Federal Convention of the American Water Works Association Baltimore, MD. American Water Works Association, vol 1, pp 937–942

Rositano J, Nicholson B, Pieronne P (1998) Destruction of cyanobacterial toxins by ozone. Ozone Sci Eng 20:223–238

Stanier RY, Kunisawa R, Mandel M, Cohen-Bazire G (1971) Purification and properties of unicellular blue-green algae (order Chroococcales). Bacteriol Rev 35:171–205

Ueno Y, Nagata S, Tsutsumi T, Hasegawa A, Yoshida F, Suttajit M, Mebs D, Pütsch M, Vasconcelos V (1996) Survey of microcystins in environmental water by a highly sensitive immunoassay based on monoclonal antibody. Nat Toxins 4:271–276

Welker M, Steinberg C, Jones G (2001) Release and persistence of microcystins in natural waters. In: Chorus I (ed) Cyanotoxins occurrence, causes, consequences, Springer, New York, pp 83–101

Wohanka W, Lendtke H, Luebke M (1999) Optimization of slow filtration as a means for disinfecting nutrient solutions. Acta Hortic 2:539–543

Young FM, Metcalf JS, Meriluoto JAO, Spoof L, Morrison LF, Codd GA (2006) Production of antibodies against microcystin-RR for the assessment of purified microcystins and cyanobacterial environmental samples. Toxicon 48:295–306. doi:10.1016/j.toxicon.2006.05.015

Yuan BL, Qu JH, Fu ML (2002) Removal of cyanobacterial microcystin-LR by ferrate oxidation-coagulation. Toxicon 40:1129–1134. doi:10.1016/S0041-0101(02)00112-5

Zhou JL, Huang PL, Lin RG (1998) Sorption and desorption of Cu and Cd by macro-algae and microalgae. Environ Pollut 101:67–75. doi:10.1016/S0269-7491(98)00034-7

Acknowledgments

We thank Drs. James Metcalf, Louise Morrison and Fiona Young for support in the laboratory studies and for useful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gurbuz, F., Codd, G.A. Microcystin Removal by a Naturally-Occurring Substance: Pumice. Bull Environ Contam Toxicol 81, 323–327 (2008). https://doi.org/10.1007/s00128-008-9458-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-008-9458-x