Abstract

Physico-chemical characterization of six commercially important Indian bamboo species has been performed. The maximum starch content was found in B. vulgaris, highest hot water soluble constituents noticed in B. pallida, Bangalore, while lowest content of these soluble constituents was observed in B. tulda, Bihar. All the bamboo species have alkali solubility ranging from 26.1 to 28.3 %. B. pallida, Bangalore and D. strictus, Gurgaon have the lowest and highest lignin content and antifungal decay resistance, respectively. Maximum and minimum ligno-cellulose content was found to be in B. arundinacea, Allahabad, and B. tulda, Bihar bamboo species.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bamboo is an important forest resource in many countries of the world. Bamboo industry is closely related to people’s daily life style and has an important role in the economy of Asian countries. Bamboo is an important construction material which provides homes for a billion of people, not only in rural areas but also in urban environment. Bamboo being considered as inexpensive and renewable material has potential to be used as a substitute for wood or expensive timber in bamboo producing countries. India is very rich in bamboo diversity. There are 124 indigenous and exotic species, under 23 genera, found naturally (Naithani 1993). Among different bamboo species growing in India, B. bamboo and D. strictus are the two genera which constitute highest proportions of bamboo forest (Liese 1980). Main species are D. strictus (45 %), B. bambos (13 %), D. hamiltonii (7 %), B. tulda (5 %) and B. pallida (4 %).

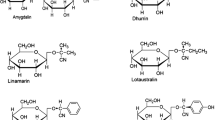

The main constituents of bamboo culms are cellulose, hemicelluloses and lignin, which amount to over 90 % of the total mass. The minor constituents of bamboo are resins, tannins, waxes and inorganic salts. Bamboo possesses a very high moisture content which is influenced by season of felling, age and species of culm. Untreated bamboo contains about 2–6 % of starch, making it more vulnerable to decay by various organisms, especially stain fungi (Kumar et al. 1994). Lignin is composed of three units: phydroxyphenyl, guaiacyl, and syringyl in varying ratios. Lignin contributes to the compression strength of woody stems. The high lignin concentration in the cell wall is beneficial to the fibreboard industries but disadvantageous for pulp and paper industry (Khalil et al. 2010).

Although bamboo has been used for many purposes, its wider acceptance however is hindered due to its susceptibility to biological degradation (fungi, termites, borers) (Way et al. 1998). Decay resistance property of bamboo depends on several factors such as species, climatic conditions, application mode etc. It is strongly associated with the physico-chemical properties of bamboo culm such as porosity, cellulose, starch and other sugars. For effective utilization of bamboo, knowledge of these parameters and durability is essential. Information on these aspects of bamboo is scanty in literature. The objective of the present study is therefore the characterization of commercially important Indian bamboo species.

2 Materials and methods

2.1 Raw material procurement and sample preparation

Seven bamboo species procured from different agro climatic regions were stored in the Micro Model Complex, IIT Delhi. 3-year old untreated samples of different bamboo species from different climatic zones were selected and analysed.

2.2 Sample preparation and chemical analysis

Bamboo sample ground to fine particle size (40–60 meshes) was air-dried and stored in air-tight containers for chemical analysis. Moisture content (ASTM D 4442-92), water solubility (ASTM D 1110-84), ash content (ASTM D 1102-84), ethanol toluene solubility (ASTM D 1107-96), 1 % NaOH solubility (ASTM D 1109), lignin (ASTM D 1106-96), ligno-cellulose content (method of elimination), starch content (Humphreys and Kelly 1961), soil block analysis (ASTM D 1413) have been investigated using three replicates.

3 Results and discussion

3.1 Physico-Chemical characterization of untreated samples of various bamboo species

Results given in Table 1 show significant variation among various species. Moisture content in different bamboo species is found to be in the range from 6 to 10 %. Age of bamboo, season of felling and species seem to primarily influence the moisture content of the culms. It has been reported that season of bamboo harvesting has a greater influence than any other factor. Low moisture content in culms was found in dry seasons as compared to culms cut in rainy seasons. Lignin content varied in the range of 20–27 %. Alves et al. (2008) reported lignin content of 24–27 % for pine and spruce wood. Ligno-cellulose content in bamboo culm ranges between 46 and 57 % in different species. Among species tested, D. strictus is found in top place in this context. It is probably the reason that traditionally D. strictus has been used for housing in rural areas. High lignin and ligno-cellulose content of D. strictus in bamboo culm impart structural rigidity which contributes greatly to the higher strength properties. This makes it a desirable construction and building material. Hot water soluble content of bamboo includes tannins, gums, sugars, and colouring matter and starch, whereas cold water solubles do not include starch. The maximum and minimum hot water soluble content was noticed in B. pallida, (Bangalore) and B. tulda, (Bihar) respectively. The ethanol-toluene extract of bamboo consists of the soluble materials not generally considered part of the wood polymeric structure. They are primarily the waxes, fats, resins, and some gums, as well as some water-soluble substances. The amounts are influenced by seasoning and drying. The ethanol toluene solubility was found in the range 3.2–5.2 %. Alkali solubility determines the presence of degraded cellulosic content caused by pests and environment. All the bamboo species showed high alkali solubility, i.e. 26.1–28.3 %, suggesting that bamboo should be treated as soon as the culms are to be hatched and require proper management and storage to avoid degradation of cellulosic material caused by the action from the pests. Interestingly, results confirmed that all the tested untreated bamboo species have a significant starch content indicating low decay resistance against all pests. The maximum starch content was found in B. vulgaris, i.e. 9.7 %. The low decay resistance of all these untreated bamboo species against fungi Polyporus versicolor has been determined.

3.2 Decay resistance of various untreated bamboo species

Decay resistance analysis of treated as well as untreated samples was done using soil block analysis method at 30 °C and 70 % relative humidity. The samples were exposed to P. versicolor fungi for 12 weeks. The mass loss of untreated bamboo samples for various species is tabulated (Table 2).

No direct correlation between starch content and decay resistance has been observed. All the above tested specimens showed low decay resistance against fungus. After incubation for 12 weeks, more than 50 % reduction in mass has been observed in all the bamboo species. B. pallida, (Bangalore) and D. strictus (Gurgaon) were found to have the least and highest natural resistance, respectively. The poor natural resistance of bamboo against pest in natural conditions makes treatment of harvested bamboo necessary.

4 Conclusion

The study indicates the small variation in physico-chemical properties and decay resistance among different bamboo species and within the climatic zones. B. tulda, Bihar was found to have lowest alkali solubility, water soluble, ethanol toluene soluble, and starch content. Lignin content is directly related to the strength properties. Lignin content of bamboo is found to be comparable to wood. B. pallida, Bangalore and D. strictus, Gurgaon have the lowest and highest lignin content, respectively. Removal of lignin from pulp is an onerous task for pulp and paper industry. Lowest ligno-cellulose content in B. arundinacea, Allahabad makes it most desirable for this industry. B. pallida, Bangalore is the most susceptible to fungal attack. Lowest weight loss (54.1 %) exhibited by D. strictus also ensures the highest antifungal resistance of above species. Lowest decay resistance and highest lignin content of D. strictus, makes it the most suitable species for application in housing sector.

References

Alves A, Rodrigues J, Wimmer R, Schwanninger M (2008) Analytical pyrolysis as a direct method to determine the lignin content in wood: part 2: evaluation of the common model and the influence of compression wood. J Anal Appl Pyrol 81:167–172

Humphreys FR, Kelly J (1961) Starch analysis. Chem Acta 24:66–70

Khalil HPSA, Yusra AFI, Bhat AH, Jawaid M (2010) Cell wall ultrastructure, anatomy, lignin distribution, and chemical composition of Malaysian cultivated kenaf fiber. Ind Crops Prod 31(1):113–121

Kumar S, Shukla KS, Tndra DT, Dobriyal PB (1994) Bamboo preservation techniques: a review. Published by International Network for Bamboo and Rattan (INBAR) and Indian Council of Forestry Research Education (ICFRE), 30

Liese W (1980) Bamboo Research in Asia. In: Proceedings of a workshop held in Singapore, 28–30 May 1980, pp 161–173

Naithani HB (1993) Contributions to the taxonomic studies of Indian bamboos. Ph.D. Thesis, vol. I. H.N.B. Garhwal University, Srinagar, Garhwal

Way HW, Varma RV, Tiansen X (1998) Insect pests of bamboos in Asia: an illustrated manual. International Network for Bamboo and Rattan, Beijing, pp 11–12

Acknowledgments

Financial assistance provided by Ministry of Rural Developed (MORD) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaur, P.J., Kardam, V., Pant, K.K. et al. Characterization of commercially important Asian bamboo species. Eur. J. Wood Prod. 74, 137–139 (2016). https://doi.org/10.1007/s00107-015-0977-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0977-y