Abstract

The study analyses the relationship between local and global modulus of elasticity and develops and evaluates different models to predict local from global modulus measurements. The mechanical tests were performed on four species commonly used in Italy for structural purposes: fir, Douglas-fir, Corsican pine and chestnut. Two or three cross-sections and two provenances were sampled for each species. A theoretical analysis showed that the local–global modulus relationship was of polynomial form with only one coefficient. The effect of the species on the relationship was significant as well as the cross-section but only for softwoods. The effect of the cross-section was explained by the presence and the size of defects in the mid span. The different models were applied and then compared by means of the optimum grading: only slight differences among models emerged. Although optimum grading was strongly dependent on the sampling and on the grade combination, for softwoods the model for species and section showed very similar results to the grading with the true local modulus; inclusion of the knot values in the model led to only slight improvements. For chestnut all models were found to be comparable.

Zusammenfassung

Diese Studie untersucht den Zusammenhang zwischen lokalem und globalem E-Modul von Schnittholz und entwickelt und vergleicht verschiedene Modelle, um den lokalen E-Modul aus globalen Messungen zu bestimmen. Die Versuche wurden an vier in Italien häufig als Bauholz verwendeten Holzarten durchgeführt: Tanne, Douglasie, Korsische Schwarzkiefer und Edelkastanie. Je Holzart wurden zwei oder drei Querschnitte aus jeweils zwei Wuchsgebieten beschafft. Eine theoretische Untersuchung zeigte, dass der Zusammenhang zwischen lokalem und globalem E-Modul einer Polynom-Funktion mit nur einem Koeffizienten entspricht. Signifikanten Einfluss auf den Zusammenhang hatte die Holzart und bei Nadelhölzern auch der Querschnitt, was durch das Vorhandensein und die Größe der Äste im mittleren Prüfbereich begründet wurde. Die verschiedenen Modelle wurden angewandt und bezüglich ihrer Auswirkung auf die optimale Sortierung verglichen: Es zeigten sich nur geringe Unterschiede. Obwohl die optimale Sortierung sehr stark von der Probenahme und der Sortierklassen-Kombination abhing, führte das Modell auf Basis von Holzart und Querschnitt bei den Nadelhölzern zu sehr ähnlichen Ergebnissen wie eine Sortierung nach dem gemessenen lokalen E-Modul; die Berücksichtigung der Astwerte führte nur zu geringen Verbesserungen. Für die Edelkastanie waren alle Modelle vergleichbar.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The standard EN 338 (2009) defines timber strength classes applied when designing structures. The modulus of elasticity is one of the three wood properties (together with bending strength and wood density) used to allocate single timber elements to the strength classes. An accurate modulus of elasticity measurement is therefore essential to use timber properly: an overestimation could lead to unsafe structures, while an underestimation to yield losses.

The standard EN 408 (2012) provides two methods for the determination of the static modulus of elasticity in bending, defined as local (E local ) and global (E global ) modulus, and both methods have advantages and disadvantages. In the E local determination method the mid-span deflection is measured. It represents the pure bending deflection (no shear effect), but it is also subject to higher risks of measurement errors due to the reference points for deflection measurement, initial specimen twist and, mainly, due to the little deflection size (Boström et al. 1996; Solli 1996; Boström 1997; Källsner and Ormarsson 1999; Solli 2000). Besides, the E local is measured in the third span and considers only a small part of the test specimen volume (Bogensperger et al. 2006). The E global determination method provides the measurement of the total deflection, which is representative of the whole span, less subject to measurement errors (although it may include higher deflection measures due to the local indentation at the loading points), but it combines bending and shear deformation (Solli 2000).

Previous studies investigated the relationship between local and global modulus. Boström (1999) found an effect of the shear deformation, the specimen depth and the wood quality (critical defect) on the relationship between local and global modulus in Norway spruce and Scots pine from Sweden. For high values of the modulus of elasticity, E local was higher than E global , the opposite for low values; the ratio E local /E global was mainly affected by shear deformations for large dimension specimens, while for small dimension timber there was a greater influence of the critical defect on E local than E global . Holmqvist and Boström (2000) and Solli (2000) reported similar results for Norway spruce. The linear models were: E local = 1.13 × E global − 800 (R² = 0.82, N = 800, Holmqvist and Boström 2000) and E local = 1.18 × E global − 856 (R² = 0.89, N = 200, Solli 2000). Denzler et al. (2008) showed that in spruce the ratio E local /E global was above the unity for high values of modulus of elasticity and below the unity for low values in spruce. The regression model for spruce was: E local = 1.224 × E global − 1,584 (R² = 0.90; N = 3491). On the contrary Ravenshorst and van de Kuilen (2009) showed a very constant relationship between E local and E global both for spruce, some tropical hardwoods and chestnut, while no effect of depth was reported. The regression model for the 1,354 specimens was: E local = 1.16 × E global − 257 (R² = 0.88; spruce N = 601, chestnut N = 300, cumarù N = 192, massaranduba N = 54, purpleheart N = 45, tauari vermelho N = 51 and azobé N = 111). Finally, Ridley-Ellis et al. (2009) measured both bending modulus of elasticity and shear modulus in specimen of Sitka spruce and concluded that the main reason of the difference between E local and E global was the high variability of E local within the specimen, not shear deformation.

The determination of the characteristic values of structural timber (EN 384 2010) provides the measurement of E global for the modulus of elasticity and the following conversion equation to pure bending modulus (E EN384) is applied: E EN384 = 1.3 × E global − 2,690. Such equation was tested for Central European species and it seemed to underestimate E local , independently by size, species (spruce, pine, Douglas-fir and larch were analysed), nor wood quality. However, the difference was considered marginal and the authors suggested to keep the EN 384 equation unchanged (Denzler et al. 2008). Bogensperger et al. (2006), on the contrary, discussed the mechanical inconsistency of the EN384 linear equation and proposed the substitution by a hyperbolic function. Nevertheless, most of the cited studies were concerned with Central or Northern European species and provenances. The aim of this study was thus (a) to analyse the effects of species, size and wood quality over the relationship between E local and E global for structural timber of Italian provenances; (b) to develop models that include such factors, aimed to predict E local from E global measurements; (c) to evaluate the models and, thus, to verify the fitting of EN384 conversion equation to South Europe timber.

2 Materials and methods

2.1 Sampling

Tests were performed on a total of 1,939 specimens of four species: fir (Abies alba Mill.—ABAL) and Douglas-fir (Pseudotsuga menziesii Franco—PSMN) sampled in central Italy; Corsican pine (Pinus nigra Arnold subsp. laricio (Poir.) Maire—PNNL) and chestnut (Castanea sativa Mill.—CTST) sampled in southern Italy. For each species 2 or 3 cross-sections and 2 provenances were sampled. The number of specimens grouped by species and size is reported in Table 1 (Nocetti et al. 2010).

2.2 Methods

After kiln-drying to a nominal moisture content of 12 %, the knot characteristics of each specimen were recorded by means of GoldenEye (MiCROTEC Srl). The machine uses X-ray technology to detect the presence of each knot in the timber element and measures knot dimension and position and returns a “knot parameter” (KN) calculated by an algorithm that combines the projected knot area over a window length of 150 mm and the knot position. The greater the defect the higher is KN (Giudiceandrea 2005; Bacher 2008). Here, the highest KN detected in the mid-test span (selected as described in the following) was assigned to the specimen.

Four point edgewise bending tests were then carried out in accordance with EN 408 (2012). The critical section of each specimen was defined by visual grading and placed in the mid-test span. The local deformations were measured in the neutral axis on both sides of the beam and the mean of the two measures was used to calculate E local (Eq. 1). In the same test setup, the total deformations were measured in the central point on the tension (for the large cross-sections—80 × 150 mm only) or compression (for medium and small cross-sections) edge of the beam and used to calculate E global (Eq. 2). The load was applied until failure and the bending strength parallel to grain (f m ) was computed (Eq. 3).

With P: the applied load increment, P max: the load at failure, l: the length between the two supports, b: the thickness, h: the width, a: the distance between the load point and the nearest support, l 1 : the central gauge length, w local and w global : the deformation increments.

Following testing, density and moisture content were determined cutting a small specimen from each test piece in accordance with EN 408 (oven-dry method). The moisture content adjustment for modulus of elasticity and the size adjustment for bending strength were made according to EN 384 (2010).

2.3 Data analysis

After the development of the theoretical aspects of the static modulus determination, non-linear (second degree polynomial equation) as well as linear models were calculated assuming E local as dependent variable and E global as predictor variable.

Then, the General Linear Model (GLM) was used to conduct analysis of variance for experiments with factors and covariates: the effect of the species and of the cross-section in the relationship between local and global modulus of elasticity was investigated. In this case, the dependant variable was the E local , the fixed effect was the species in a first step and the cross-section later, and the covariate was the E global . This type of model encompasses both analysis of variance and regression.

A partitioning cluster analysis was then performed to study the effect of the presence of defects (knots) on the static modulus determination. The algorithm of Hartigan and Wong (1979) was used (k-means clustering); the knot parameter (KN) was used as explanatory variable and two clusters were specified.

Finally, multivariate linear models were calculated keeping the E local as dependent variable and E global as well as KN as predictors.

The statistical analysis was made using R software version 2.13 (R Development Core Team 2011).

2.3.1 Optimum grading

The optimum grading procedure was applied to analyse the effect of the modulus of elasticity measurement and its calculation over the timber grading. The optimum grades were computed by following the instructions of the standard EN 14081-2 (EN 2010). An important point to highlight was that no unique algorithm existed for optimum grading, while the grading results were obviously strongly dependent on the algorithm used. The algorithm used is detailed in the following:

-

1.

The adjusted bending strength values were sorted in descending order and the maximum number of pieces that satisfied the required strength values for the highest strength class tested (EN 338 2009) was identified.

-

2.

Step (1) was repeated for the modulus of elasticity values and for the density values. Thus 3 groups of pieces were identified, one for each grade determining property.

-

3.

The group with the highest number of pieces was selected and sorted again for the two other properties (i.e., if the largest group was the one initially ranked for strength, then it was selected and ranked firstly for modulus and secondly for density and strength; the maximum number of pieces that satisfied the requirement for modulus were then identified, and the procedure was repeated, ranking firstly for density and secondly for modulus and strength; finally the maximum number of pieces that satisfied the requirement for density were selected).

-

4.

The characteristic values of the population so identified were computed and compared to the highest class thresholds. When not all the requirements were met, steps (1), (2) and (3) were repeated for the selected population.

-

5.

When all the requirements were met, the population was checked to be higher than 20 pieces and, subsequently, the pieces were assigned to the tested grade. The process went back to step (1) considering the next grade and without considering the population previously graded.

3 Results

3.1 Descriptive statistics and measurement uncertainty

Table 2 presents the mean and the standard deviation values for static mechanical parameters, wood density and moisture content. It was verified that the moisture content of each species was close to the nominal value of 12 % without a high dispersion of values. It was also verified that a significant difference existed between E local and E global (means comparison on paired samples, t = 28.4; p < 0.001; N = 1,939), and between E local and E EN384 (t = 3.2; p = 0.001; N = 1,939): the mean ratio E local /E global was found to be between 1.07 and 1.11 (mean relative difference of 8.6 %).

Furthermore, Fig. 1 shows that the E local was higher than the E global for high modulus samples (global modulus higher than 8300 MPa), and lower for low modulus values.

Relationship between local and global modulus of elasticity (the straight line represents the linear regression, the dotted line is the E local = E global line)

Zusammenhang zwischen lokalem und globalem E-Modul (die durchgezogene Linie stellt die Regressionsgerade dar, die gestrichelte Linie entspricht E local = E global )

To evaluate the experimental measurement error on the local and global modulus of elasticity, 30 static tests were performed on the same beam (Douglas-fir, PSMN). The load was applied at a constant rate at a low level of loading (40 % of the estimated rupture force). For each repetition, the beam was removed and placed again between the supports and loading points as if it was a new one; the dimensions were also measured each time.

The repeatability results are presented in Table 3. The expanded uncertainty was computed using a coverage factor equal to 2 (95 % confidence interval). The measurement uncertainty was found to be higher for the E local (4.7 %, ±620 MPa) than for the E global (4.0 %, ±490 MPa).

3.2 Relation between Elocal and Eglobal conversion equation

The theoretical aspect of the determination of static modulus was first developed. In a second step, the experimental adjustments between local and global modulus were presented.

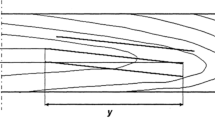

Considering the test geometry defined in Fig. 2, the displacement Uy, along the Y axis and between the points [0, C], can be expressed as follows (Brancheriau et al. 2002):

Geometric description of a four point bending test. P load increment, l 1 central gauge length, l test span, a distance between the load points, h specimen width, b specimen thickness

Geometrische Darstellung der 4-Punkt-Biegeprüfung. P: Belastung; l1: Messbereich für E local ; l: Spannweite; a: Abstand zwischen den Lasteinleitungsstellen; h: Prüfkörperhöhe; b: Prüfkörperbreite

With P: the applied load increment, l: the length between the two supports, S: the cross-section area, a: the distance between the load point, I GZ : the second moment of area, E x : the modulus of elasticity, G XY : the shear modulus, ν XY and ν XZ : the Poisson’s ratios.

According to the determinations of the local and global modulus (EN 408 2012), the deformation increments w local and w global were deduced from Eq. 4 and (l = 3a):

With b: the thickness, h: the height of the beam and l 1 : the central gauge length.

Equation 5 was equivalent to the local modulus equation of the standard. The modulus E x was thus equal to the local modulus value E local . The expression of the global modulus E global was written in Eqs. 8 and 9 using the following Eq. (7):

The Poisson’s term in Eq. 9 was negligible because inferior to 0.002 in the case of a standard static test. The theoretical relation between the local and global modulus (Eq. 10) was finally written as follows using a Taylor series development (for h/a = 3/18):

This last equation shows that the relationship between local and global modulus was not linear and was furthermore a function of the shear modulus. Assuming that the shear modulus was a constant (assumption of the EN 384 conversion equation) and independent of the longitudinal modulus of elasticity, this relation indicates that the link of modulus should be adjusted in a polynomial form without intercept. The results of the non-linear regression between E local and E global (Eq. 10) are given in Table 4. The Taylor series development was also statistically tested at a higher rank, but the associated regression coefficient was not significant. To be coherent with the conversion equation of EN 384 standard, the linear adjustments coefficients are also presented in this table (regression plots in Fig. 3). Table 4 shows that the non-linear models are equivalent to the linear ones. This table also shows that the species directly affected the adjustment coefficients.

3.3 Factors affecting the relation between Elocal and Eglobal

The effect of the species on the relationship between local and global modulus of elasticity was investigated and the results of the GLM procedure are reported in Table 5. The linear model was thus written as:

For example with PNNL, the model became: E local = 1.29 × E global − 2520.

The results in Table 5 show that the factor “species” has a significant effect on the linear relationship E local − E global . The degree of significance varied according to the species and a high difference was found between fir (ABAL) and Douglas-fir (PSMN), while no significant difference was detected between fir and pine (PNNL). Chestnut (CTST) was also different from the other softwoods.

For each species, the effect of the section on the E local − E global relationship was tested and the results are presented in Table 6. As excepted for chestnut, the effect of the section on the relationship was significant. For the softwoods, the difference between sections was very high between the small one (50 × 70 mm) and the two others (70 × 110 and 80 × 150 mm), which, on the contrary, did not differ from each other significantly.

To highlight this phenomenon, Fig. 4 was drawn for the softwoods with different markers according to the section (50 × 70 mm, 70 × 110 mm and 80 × 150 mm). This Figure shows that for low values of modulus of elasticity (less than 13,000 MPa) a difference existed between the section 50 × 70 mm and the two others: to equal values of E global correspond lower values of E local .

To verify the possible role of the critical defect (knots) on the relationship E local /E global and the deformation measurement with the small sections, a cluster analysis was performed using the knot parameter (KN) as explanatory variable in order to separate the specimens of small section (50 × 70 mm) into two groups. The partitioning shown in Fig. 5 was obtained as a result of the analysis (ratio of within group to between group distance = 0.28). The specimens in cluster 1 are separated by low values of knot parameter, that means small knots, and are characterized by high values of E local in respect to E global . In cluster 2 the specimens with bigger knots are allocated and E local decreases when compared to E global (Fig. 6).

Relationship between E local and E global according to the two clusters (black cluster 1, gray cluster 2), as a result of the partitioning analysis using knot parameter as explanatory variable for the small section softwoods (50 × 70 mm)

Zusammenhang zwischen globalem und lokalem E-Modul bei den zwei Clustern, bei denen die kleinen Querschnitte (50 × 70 mm) in Proben mit kleinen bzw. großen Ästen getrennt wurden

Because of the observed significant effect of KN and section on the E local vs E global relationship, these variables were included in the bending strength in a multivariate linear model calculation. The results obtained (Table 7) show a slight improvement of the prediction in respect to the linear models reported in Table 4.

3.4 Comparison of the models: influence on grading

In a first step the conversion equation reported in EN 384 was compared with the linear models developed for each species (Table 4) and it was noticed that all the computed moduli from the equation of the standard are included in the 95 % confidence interval of the species equations.

Secondly, all the models were compared by means of the optimum grade calculation. The optimal grading procedure was used with different local modulus of elasticity: the measured value E local obtained by static test was first included in the procedure, then replaced by the conversion equation of the EN 384 standard, the linear equations per species given in Table 4, the equations per species and section (Table 6) and the multi-linear equations per species (Table 7). Several strength class combinations were tested: i.e., C40-C30-C18/C35-C24-C16/C35-C18/C30-C18/C24 for softwoods and D40-D30-D18/D35-D18/D30-D18/D24 for chestnut.

The samples tested in this study were mainly limited by bending strength: attempts of grading performed only by modulus of elasticity proved totally ineffective.

In general, no differences could be detected for combinations with only 1 or 2 classes, small variations appeared when 3 classes were used together. In Fig. 7 the results of the optimal grading are presented for the class combination C35-C24-C16 (a logarithmic scale was used to highlight the differences in the lower grades). In that case no differences emerged concerning the higher grades for all the species, while only slight differences are shown concerning the other grades between the grading with E local and the ones with the other models. Results were also found to be very similar between EN 384 equation and linear equations per species. These remarks were true for all the species.

Optimal grading computed with different local modulus of elasticity.  E

local

,

E

local

,  EN 384 conversion equation,

EN 384 conversion equation,  equation per species,

equation per species,  equation per species and section,

equation per species and section,  multi-linear regression equation. a

Abies alba, b

Pinus nigra, c

Pseudotsuga menziesii, d

Castanea sativa, N number of pieces

multi-linear regression equation. a

Abies alba, b

Pinus nigra, c

Pseudotsuga menziesii, d

Castanea sativa, N number of pieces

Optimale Sortierung nach verschiedenen lokalen Elastizitätsmoduln.  lokaler E-Modul,

lokaler E-Modul,  Gleichung aus EN 384,

Gleichung aus EN 384,  Gleichung je Holzart,

Gleichung je Holzart,  Gleichung je Holzart und Querschnitt,

Gleichung je Holzart und Querschnitt,  Multiple lineare Gleichung. a

Abies alba, b

Pinus nigra, c

Pseudotsuga menziesii, d

Castanea sativa, N Anzahl der Prüfkörper

Multiple lineare Gleichung. a

Abies alba, b

Pinus nigra, c

Pseudotsuga menziesii, d

Castanea sativa, N Anzahl der Prüfkörper

Focusing on each species, the models were all equivalent for Castanea sativa. The multi-linear equations were in better agreement with the E local grading than the EN 384 equation and the models per species for Pinus nigra and Pseudotsuga menziesii. However, concerning Abies alba, the multi-linear equations did not improve the grading in reference compared to the one of E local . For all the species, the model per species and section was also in very good agreement with the grading with E local . The effect of the section was thus the predominant effect on the optimal grading.

4 Discussion

E local was found to be higher than E global at mean level, in a range coherent with that reported in previous studies (Boström 1999; Holmqvist and Boström 2000; Ravenshorst and van de Kuilen 2009). The measurement uncertainty was higher for E local (±620 MPa) than for E global (±490 MPa). This fact was mainly explained by the difference in the deflection range (Denzler et al. 2008). However, no authors indicated the value of these errors and, surprisingly, the error difference between the two determination methods was found to be less than 1 % (4.7 % for E local and 4.0 % for E global ). From this last observation, it would be better to directly measure the local modulus, unless such a measurement is more time consuming. The measurement uncertainty of E local and E global has an effect on the R² values of the linear models (Table 4). If a perfect linear relationship between the two modulus is assumed, an analysis of variance taking into account the uncertainties leads to maximum values of: R² = 0.992 (PSMN), R² = 0.990 (PNNL), R² = 0.986 (ABAL) and R² = 0.964 (CTST) (three decimals are given to highlight the difference between these four values). The true experimental values were R² = 0.900 (PSMN), R² = 0.890 (PNNL), R² = 0.809 (ABAL) and R² = 0.811 (CTST). The rank order between the linear models is thus a consequence of the measurement uncertainty coupled with the species effect and the size effect.

Considering a clear and homogeneous beam, the main difference between local and global modulus is the shear deformation. From this last remark, the comparison local–global modulus is the same problem than comparing local modulus in 4 point bending and ‘global’ modulus in 3 point bending with a low level of stress (Brancheriau et al. 2002). A theoretical development (Eq. 9 and 10) demonstrated that the relationship between local and global modulus was not linear but of second order. Other authors proposed different theoretical expressions (ASTM 2009; Boström 1999; Källsner and Ormarsson 1999). These formulas used a form factor (‘K’ equal to 5/6 for a rectangular cross section) and the deflection equation was written:

This last equation assumed at least a parabolic distribution of the bending moment M z . This assumption was false in the case of a four point bending test. However, an analogy with a uniform loading allowed overcoming this problem. The polynomial form (Eq. 10 and Table 4) explained the fact that the constants of the linear adjustments were always significant (the polynomial form was approximated by a straight line). The non-linear and linear models were found to be equivalent for the timber tested in the present work (Table 4), but the advantage of the non-linear model was that only one coefficient was needed. The value of this coefficient was circa 8 × 10−6 which corresponded to 1/(414*G yx ) with G yx equal to 300 MPa (coherent value for structural timber).

Afterwards, the effects of the species and section were demonstrated to be significant over the relationship between local and global modulus; only for chestnut no differences were detected between cross-sections (Table 5 and 6). Moreover, E local was found to be higher than E global for high stiffness values and lower for lower stiffness values (Fig. 1). Similar results were reported by Boström (1999); Holmqvist and Boström (2000); Solli (2000) and explained by the fact that the ratio E local /E global was mainly affected by shear deformations for large dimension specimens, while for small dimension timber there was a greater influence of the critical defect (Ridley-Ellis et al. 2009). Models taking into account the effect of the height were thus used and Boström (1999) showed the effect of the beam depth on the relation between E local and E global . In this study, the cross-section that distinguishes itself is the small one.

Previous works associated the influence of the cross section on the relationship between local and global modulus with the presence of stiffness reducing defects, mainly knots (Boström 1999; Holmqvist and Boström 2000; Ridley-Ellis et al. 2009). Here we clearly demonstrated the effect of the knots on the modulus measurement (Fig. 5). The influence of knots is higher on small cross sections because of both their higher dimension relative to the depth of the specimen (h) and the shorter test span (calculated as a function of h). Besides, the stiffness reducing effect is higher on local than on global modulus because of the position of knots relative to the reference points for deflection measurement (closer for local modulus determination).

Finally the comparison of the conversion models was investigated by means of the optimum grading, such as to analyse the possible influence of the different conversion functions on timber grading. First of all it has to be said that the study was difficult because the optimum grading was strongly dependent on the timber resource (strength limited timber) and on the grade combination. Several grade combinations were tested and one combination was shown, which was able to highlight the differences between the models (Fig. 7).

Similar results were found between EN 384 equation and linear equations per species. The means were significantly different (t test on paired samples): mean difference = −281 MPa for fir, −121 MPa for pine, 76 MPa for Douglas-fir and −536 MPa for chestnut (Table 2). However, all the computed moduli from the equation of the standard were included in the 95 % confidence interval of the species equations and the optimum grading procedure used individual values for grouping the beams by grade. This remark explained the observed similarity.

For softwood, the effect of the section was found to be the predominant effect on the optimum grading and the equation per species and section gave similar grading results to the E local .

A multiple linear model including the amount of defect in the section and the depth was thus tested. This choice was motivated because it constituted the simplest type of multivariate model. However, the efficiency was not better than a model per species for fir and it was only slightly better than the model per species and per section for pine and Douglas-fir.

The relationship between the local modulus and these parameters was probably not linear and a specific study should be done to determine the best non-linear model.

For chestnut, no predominant effect could be identified and all the models were comparable. This could be explained either by the similarity of the cross-sections tested (80 × 80 mm and 50 × 100 mm), or by a less influence of the defects (knots) on the modulus of elasticity determination in hardwoods. Therefore, further studies are needed before a conclusion on that can be drawn.

In the end, the conversion equation in the current European standard (EN 384 2010) can be improved but, in practice, the conversion equation used can have an important effect mainly for stiffness limited material: the optimum grading is dependent on the resource and on the grade combination. The EN 338 (2009) standard defines thresholds for the characteristic values of density, modulus of elasticity and bending strength. These thresholds are ordered from the class the less resistant to the strongest class. In the two-dimensional space generated by the modulus of elasticity and the bending strength, the thresholds are a curve that bounds the resources strength-limited and stiffness-limited. Populations with the modulus-strength point lying below this curve are limited in strength. The parameter determining the grading is thus the bending strength because for a nearby bending strength of the threshold value, the average modulus is always greater than the standard threshold value. In this particular case, the bias induced by a conversion equation will have little influence on the final grading. On the contrary, when the modulus- strength point lies above the curve, the populations are stiffness-limited. As grading algorithms seek to approach more closely the boundaries of class, a bias in the conversion equation will have a significant effect on the final result for the stiffness-limited populations.

The bias of the conversion equation is the uncertainty (confidence interval) induced by the statistical fit between the local and the global modulus. If this uncertainty is low, it will be possible to divide the resource in several groups (classes) with a low probability of recovery; that means quasi-equality between grading from the local modulus and grading from the conversion equation. The number of classes will decrease when uncertainty increases to keep this quasi-equality between local modulus and conversion equation. The maximum difference between optimum grading with the EN 384 equation and with a direct determination of the local modulus would be reached in the case of a combination of many grades (3 or more, not very common in practice) applied on a stiffness limited resource (when the modulus of elasticity is the main grading parameter). However, no difference would be found in the case of one grade applied to a strength limited resource (in this case, the main parameter is the modulus of rupture).

Moreover, the EN 384 equation as well as the use of linear models may lead to higher estimation errors for low stiffness material (Bogensperger et al. 2006) and, therefore, to bigger consequences for timber grading. Thus, the conversion equation should be in better agreement with the theory: Eq. 10 with or without the development in Taylor series or an equivalent proposed for example by Bogensperger et al. (2006). Further analysis could be very interesting in this direction.

5 Conclusion

Determination of local and global modulus was performed on 1,939 structural beams of four species with different cross-sections. The mean value of the local modulus was higher than the global modulus in a ratio of 8.6 %. However, the difference was not constant: the local modulus was superior to the global modulus for the high modulus samples, and inferior for low modulus values.

The measurement uncertainty was ± 620 MPa for the local modulus and ± 490 MPa for the global modulus. Nevertheless, the error difference between the two determination methods was found to be less than 1 %, so as to reconsider the possibility to directly measure the local modulus.

A theoretical analysis showed that the relationship between local and global modulus was not linear. This analysis also indicated that the link of modulus should be adjusted in a polynomial form with only one coefficient.

The factor “species” was found to be significant for the linear relationship between local and global modulus and the degree of significance varied according to the species; while the effect of the section was highly significant for the softwoods, but not for chestnut. The section effect was explained by the presence and the size of defects in the mid span (knots).

In order to analyse the effect of the different conversion equations, the local modulus (true values, EN 384 equation, equations per species, equations per species and per section, and multi-linear equations per species) were compared by means of the optimum grade calculation. No big differences in the grading results emerged due to the use of the various models for the timber tested in this work (strength limited), but dissimilarities could be expected when low stiffness material is analysed.

References

ASTM D198 (2009) Standard test methods of static tests of lumber in structural sizes. ASTM International, West Conshohocken, USA

Bacher M (2008) Comparison of different machine strength grading principles. In: COST E53 Conference 29th–30th October, Delft, The Netherlands, pp 183–193

Bogensperger Th, Schickhofer G, Unterwieser H (2006) The mechanical inconsistence in the evaluation of the modulus of elasticity according to EN384. CIB W18 Meeting 39, Florence, Italy. Paper 39-21-2

Boström L (1997) Measurement of modulus of elasticity in bending. CIB W18 Meeting 30, Vancouver, Canada. Paper 30-10-2

Boström L (1999) Determination of the modulus of elasticity in bending of structural timber—comparison of two methods. Holz Roh- Werkst 57(2):145–149

Boström L, Ormarsson S, Dahlblom O (1996) On determination of modulus of elasticity. CIB W18 Meeting 29, Bordeaux, France. Paper 29-10-3

Brancheriau L, Baillères H, Guitard D (2002) Comparison between modulus of elasticity values calculated using 3 and 4 point bending tests on wooden samples. Wood Sci Technol 36(5):367–383

Denzler JK, Stapel P, Glos P (2008) Relationship between global and local MOE. CIB W18 Meeting 41, St. Andrews, Canada. Paper 41-10-3

EN 13556 (2003) Round and sawn timber—nomenclature of timbers used in Europe. CEN European Committee for Standardization, Brussels

EN 14081-2 (2010) Timber structures—strength graded structural timber with rectangular cross section. Part 2: Machine grading; additional requirements for initial type testing. CEN European Committee for Standardization, Brussels

EN 338 (2009) Structural timber—strength classes. CEN European Committee for Standardization, Brussels

EN 384 (2010) Structural timber—determination of characteristic values of mechanical properties and density. CEN European Committee for Standardization, Brussels

EN 408 (2012) Timber structures—Structural timber and glued laminated timber—determination of some physical and mechanical properties. CEN European Committee for Standardization, Brussels

Giudiceandrea F (2005) Stress grading lumber by a combination of vibration stress waves and X-ray scanning. In: 11th International Conference on scanning technology and process optimization in the wood industry (ScanTech 2005), pp 99–108

Hartigan JA, Wong MA (1979) A K-means clustering algorithm. Appl Stat 28:100–108

Holmqvist C, Boström L (2000) Determination of the modulus of elasticity in bending of structural timber—comparison of two methods. In: Proceedings of the 6th World Conference on Timber Engineering, 31st July–3rd August, Whistler, Canada

Källsner B, Ormarsson S (1999) Measurement of modulus of elasticity in bending of structural timber. RILEM symposium on timber engineering, Stockholm, pp 639–648

Nocetti M, Bacher M, Brunetti M, Crivellaro A, van de Kuilen JW (2010) Machine grading of Italian structural timber: preliminary results on different wood species. In: Proceedings of the 11th World Conference on Timber Engineering, 20th–24th June, Riva del Garda, Italy

R Development Core Team (2011) R: a language and environment for statistical computing. Available: http://www.r-project.org

Ravenshorst GJ, van de Kuilen JW (2009) Relationship between local, global and dynamic modulus of elasticity for soft- and hardwoods. CIB W18 Meeting 42, Dübendorf, Switzerland. Paper 42-10-1

Ridley-Ellis D, Moore J, Khokhar A (2009) Random acts of elasticity: MoE, G and EN408. In: Wood EDG Conference, 23rd April 2009, Bled, Slovenia

Solli KH (1996) Determination of modulus of elasticity in bending according to EN-408. CIB W18 Meeting 29, Bordeaux, France. Paper 29-10-2

Solli KH (2000) Modulus of elasticity—local or global values. In: Proceedings of the 6th World Conference on Timber Engineering, 31st July–3rd August, Whistler, Canada

Acknowledgments

The authors thank the Autonomous Province of Trento (Italy) for funding the mechanical tests; Luciano Scaletti and Paolo Pestelli for the laboratory work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nocetti, M., Brancheriau, L., Bacher, M. et al. Relationship between local and global modulus of elasticity in bending and its consequence on structural timber grading. Eur. J. Wood Prod. 71, 297–308 (2013). https://doi.org/10.1007/s00107-013-0682-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0682-7