Abstract

Tannin-furfuryl alcohol resins reacting under alcaline conditions to minimize self condensation of furfuryl alcohol and force its reaction with tannins have proved to be another alternative for formaldehyde free, environment friendly adhesives from renewable materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Materials and methods

Gel times at 100 °C of mixtures of furfuryl alcohol with either mimosa (Acacia mearnsii) tannin extract or pine (Pinus radiata) tannin extract were determined at different relative percentages of the two materials and at different pHs. The hardening of resins based on 100 parts mimosa tannin extract with 50 or 75 parts of furfuryl alcohol was followed by thermomechanical analysis (TMA) according to procedures already reported (Pizzi et al. 1998). Duplicate one layer laboratory particleboards of 350 × 300 × 14 mm3 dimension were prepared using a mixture of core particles of beech (Fagus sylvatica) and Norway spruce (Picea abies) wood particles at 28 kg/cm2 maximum pressure and 190–195 °C press temperature. The wood particles prior to resin addition had a moisture content of 2 %. The resin solids load on dry wood was maintained at 10 % of total solid resin mix of tannin + furfuryl alcohol. The panels were conditioned to 12 % EMC after pressing prior to testing. The total pressing time was maintained at 7.5 min. All particleboards were tested for dry internal bond (IB) strength according to EN 312 (1995). Thus, each IB and panel density result in Table 1 is the average of ten specimens.

2 Results and discussion

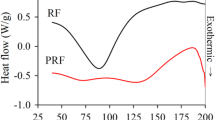

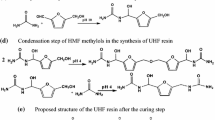

The results obtained first by determination of gel time and second by TMA indicate that the reaction of co-condensation of tannin extracts with furfuryl alcohol in absence of formaldehyde does occur and is yielding a bonded joint. The furfuryl alcohol self condensation reaction, predominant under acid conditions (Pizzi et al. 2008; Tondi et al. 2008), is minimized or even does not occur under alkaline pH. Thus, under alkaline conditions, gelling and hardening occurs predominantly by reaction and cross-linking between tannin and furfuryl alcohol. In the case of the slower reacting tannin of the two tannins, namely mimosa tannin extract, the maximum MOE value reached during initial TMA scan indicates that best results were obtained at a load of 50 % furfuryl alcohol on tannin extract and at pH 10. Either increasing the percentage furfuryl alcohol or the pH resulted in a decrease in maximum MOE value and thus in bonding performance. Decreasing the pH to lower than 10 resulted in considerably longer gel times down to pH 9, and in no gelling at all in the pH 3–8 range. This can be observed for mimosa tannin and furfuryl alcohol in Fig. 1.

a Gel time of mimosa tannin reacted with furfuryl alcohol in the pH range 1–11. In the pH range 3–8 the resin system does not gel. b Gel time of pine tannin reacted with furfuryl alcohol in the pH range 1–9. In the pH range 3–6 the resin system does not gel

a Gelierzeit von Mimosentannin in Reaktion mit Furfurylalkohol im pH-Bereich 1–11. Im pH-Bereich 3–8: das Klebstoffsystem geliert nicht, b Gelzeit von Kieferntannin in Reaktion mit Furfurylalkohol im pH-Bereich 1–9. Im pH-Bereich 3–6: das Klebstoffsystem geliert nicht

Pine tannin yielded both faster gel times and better TMA-derived MOE results. The gel time and the results were checked by preparing laboratory particleboard for the best cases scanned. The particleboard dry internal bond (IB) results are shown in Table 1. The results indicate that in the case of mimosa tannin the IB strength is marginal as regards satisfying the relevant European norm. Pine tannin, however, especially at the higher furfuryl alcohol proportion does yield IB strength results satisfying the relevant EN 312 norm, and this without any addition of formaldehyde. For pine tannin there also is a pH range where gelling of the tannin and furfuryl alcohol does not occur, although this pH range is narrower than for mimosa tannin due to the higher reactivity of pine tannin.

References

3European Norm EN 312 (1995) Wood particleboard—specifications

Pizzi A, Garcia R, Deglise X (1998) Thermomechanical analysis of entanglement networks—correlation of some calculated and experimental parameters. J Appl Polym Sci 67(9):1673–1678

Pizzi A, Tondi G, Pasch H, Celzard A (2008) MALDI-TOF structure determination of complex thermoset networks—polyflavonoid tannin-furanic rigid foams. J Appl Polym Sci 110(3):1451–1456

Tondi G, Pizzi A, Pasch H, Celzard A, Rode K (2008) MALDI-TOF investigation of furanic polymer foams before and after carbonization: aromatic rearrangement and surviving furanic structure. Eur Polymer J 44:2938–2943

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdullah, U.H.B., Pizzi, A. Tannin-furfuryl alcohol wood panel adhesives without formaldehyde. Eur. J. Wood Prod. 71, 131–132 (2013). https://doi.org/10.1007/s00107-012-0629-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-012-0629-4