Abstract

Wood polymer composites were investigated using aqueous solutions of polyglycerol methacrylate (PGMA), obtained from polyglycerol an agricultural by-product of the diester industry and glycidyl methacrylate, in order to improve the properties of the material. Treated blocks possess increased dimensional stability compared to untreated ones. The relationships between experimental conditions (PGMA concentration, curing temperature, addition of low molecular weight vinyl monomer) and performance of treated wood were investigated. Biological tests carried out using Coriolus versicolor, a white rot fungus, on beech blocks and Poria placenta, a brown rot fungus, on pine blocks demonstrated protection by chemical modification. Such an approach, using renewable starting materials and water-borne treatments, constitutes an attractive alternative to conventional preservation procedures using broadly active biocides.

Zusammenfassung

Es wurde eine Untersuchung von Verbundmaterial aus Holz und Polyglycerinmethacrylat (PGMA) durchgeführt. Die Polymerkomponente wurde aus Polyglycerin, einem Nebenprodukt der landwirtschaftlichen Diester-Industrie, und Glycidylmethacrylat hergestellt. Die Behandlung erfolgt in wäßrigem Medium. Im Vergleich zu unbehandeltem Holz besitzen die behandelten Blöcke eine erhöhte Formstabilität. Der Zusammenhang zwischen experimentellen Bedingungen (PGMA-Konzentration, Temperatur während der Behandlung, Beimengung von Vinylmonomeren mit niedriger Molmasse) und den Eigenschaften des behandelten Holzes wurden untersucht. Die biologischen Tests, die mit Kulturen von Coriolus versicolor, einem weißen Fäulnispilz, an Buchen-Blöcken, und parallel mit Poria placenta, einem braunen Fäulnispilz, an Kiefern-Blöcken durchgeführt wurden, zeigen, daß das behandelte Holze ausgezeichnet gegen Pilzbefall geschützt ist. Diese Art der Holzbehandlung mit Produkten aus der Biomasse in wäßrigem Medium stellt eine attraktive Alternative zu konventionellen Methoden dar, die auf dem Einsatz von Breitband-Bioziden beruhen.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Research on wood modification has been investigated since the 1930s (Meyer 1984, Rowell 1984). However, wood chemical composition alterations, experimental conditions and costs of the treatment did not allow a large development of such methods. Manufacturers prefer to use much cheaper wood species, often tropical species, with good natural properties. In addition, they have also used cheap preservative treated timber. Conventional wood preservation systems involve generally impregnation of broadly active biocides into the wood (Barnes and Murphy 1995). However, these techniques generate important environmental hazards, which may limit their scope of applications in the future (Suttie 1997). Furthermore, the increasing environmental pressures appeared since these last years in many European countries led to an important change in the field of wood preservation particularly with regard to the biocides toxicity and emissions of volatile organic compounds leading to the development of new friendly preservation methods. Alternative preservation techniques involve the formation of wood polymer composite which restrict the access of water into the wood preventing fungal biodegradation and also increasing its dimensional stability (Fujimara et al. 1990, Doss et al. 1991, Nakano 1993, Schneider 1994, Yasuda and Minato 1995). Such techniques present the advantage over traditional methods of not introducing toxic chemicals into the wood and consequently avoiding leaching of toxic substances in the environment.

A number of wood-polymer composite have been investigated to improved the dimensional stability of wood. They involved either the bulking of wood cell walls with various chemicals like polyethyleneglycols (PEGs) (Stamm 1959, 1965), phenol/formaldehyde resins or the filling of wood lumen by impregnation and polymerisation of vinyl monomers limiting vapor or liquid water diffusion (Meyer 1984).

The aim of this study is to investigate the use of new systems based on polyglycerol methacrylate (PGMA) to improve wood properties. The advantages of PGMA compared to the existing methods lie in the fact that a part of the starting materials are renewable matters and that the treatment can be carried out in aqueous phase limiting the rejection of volatile organic compounds. Like polyethyleneglycols, polyglycerols (PGs) are polyethers (Fig. 1), able to bulk the cell walls, keeping wood in a partially swollen state improving its dimensional stability (Hoffmann 1988a, b, 1990). Moreover, PGs possess numerous hydroxyl groups which permit to envisage derivatization with methacrylic acid units allowing the formation of a tridimensional network after impregnation and polymerisation decreasing their leachability.

2 Experimental

Glycidyl methacrylate (GMA), methyl ethyl ketone peroxide (MEKP) were purchased from Fluka Sigma-Aldrich Chimie SARL (St Quentin Fallavier, France). Polyglycerol was obtained from Novance (Compiègne, France) as a mixture of compounds with an average molecular weight of 242 (n~3). 1H NMR spectra were recorded in water on a Bruker AM 400 spectrometer. Chemical shifts are expressed in parts per million. IR spectra were obtained as thin films between NaCl plates on a Mattson Genesis Series FTIR.

2.1 Synthesis of polyglycerol methacrylate (PGMA)

Polyglycerol (30 g) was mixed on a mechanical stirrer in a 100 ml flask with 4-dimethylamino pyridine (DMAP) (300 mg). The mixture was then heated at 70°C to decrease its viscosity and glycidyl methacrylate (35.2 g) added dropwise over 2 min. The reaction was kept at the same temperature during 15 min, cooled to room temperature and the product used without further purification. 1H NMR (D2O): (δ): 1.88 (s, allylic CH3), 3.35–4.20 (m, CH and CH2), 5.63 (s, vinylic CH), 6.06 (s, vinylic CH). IR (NaCl disk): 3,400 cm-1 νOH, 1,718 cm-1 νCO, 1,635 cm-1 νC=C.

2.2 Chemical modification of blocks

Weighed (m 0) oven-dried beech (Fagus sylvatica) and pine (Pinus sylvestris) blocks (15×20×50 mm, radial x tangential x longitudinal) were used throughout this study. Solutions of PGMA (10, 20, 30 and 50% in mass) were prepared in distilled water and methyl ethyl ketone peroxide (2% in mass) added just before use. Blocks were placed in a beaker inside a desicator and a vacuum of 5 mbar was drawn for 15 min using a pump. Blocks were then covered with the solution of PGMA and the pressure returned to atmospheric. After two hours of soaking, blocks were drained for 5 min and cured under different experimental conditions (see results and discussion).

2.3 Anti-Swelling-Efficiency measurements

Anti-Swelling-Efficiency (ASE) was determined by measuring the increase in volume of treated and untreated pine blocks. Blocks were placed in a climatic chamber WTB BINDER type KBF 115 at temperature of 25°C and a humidity of 95% RH for 2 months. After stabilization of their weight, blocks were measured. The volumetric swelling coefficients were calculated according to the formula:

where V 2 = volume of water saturated wood and V 0 or 1 = volume of dry untreated or treated wood.

The percentage of swelling was calculated from the wet and oven-dried volumes of treated and untreated blocks according to:

where S c = volumetric swelling coefficient of unmodified samples and S m = volumetric swelling coefficient of modified samples.

2.4 Chemicals leachability

Leachability of the impregnated chemicals was determined by placing 4 samples in 800 ml of distilled water under agitation during different times (1 h, 2 h, 4 h, 8 h, 16 h and 48 h) with change of water between each time. The leached blocks were then dried at 80°C for 2 days (m 2) and the quantity of leached chemical (LC) expressed as a percentage of initially impregnated chemicals.

2.5 Decay test

Treated (4 replicates) and untreated (2 replicates) pine or beech blocks were placed on a traditional sterile culture medium prepared from malt (15 g) and gelose (15 g) in distilled water (1 l) and inoculated with Poria placenta or Coriolus versicolor before incubation at 25°C during 16 weeks. Treated blocks (4 replicates) were placed in the same conditions without fungal inoculation in order to estimate weight loss due to diffusion of the product in the medium. After incubation, the blocks were wrapped from the mycelium, dried at 80°C during 2 days and weighed (m 3). Weight loss was expressed as a percentage of the initial oven-dried weight of the sample

where m 0 or m 1 is the initial weight of the untreated or treated samples and m 3 the corrected weight of the sample, exposed to fungi.

3 Results and discussion

Direct esterification reactions of polyglycerol with methacrylic acid were unsuccessful and prompted us to investigate an indirect esterification method reported in the literature using glycidyl methacrylate (GMA) (Van Dijk Wolthuis et al. 1995, 1997). Reaction of GMA with polyglycerol allows the formation of the desired product.1H NMR analysis of the crude reaction mixture at different times indicates that the reaction occurs by transesterification of glycidyl methacrylate by polyglycerol leading to formation of glycidol which underwent subsequent nucleophilic attack by free hydroxyl groups of polyglycerol (Fig. 2).

Polyglycerol methacrylate was then investigated for wood treatment using standard vacuum/pressure impregnation. Impregnation solutions were prepared in water at different PGMA concentrations (10, 20, 30 and 50% in mass) with methyl ethyl ketone peroxide (2% in mass) used as free radical initiator. After impregnation blocks were cured at 80°C during 3 days and weighed (m 1). Half of the blocks was subjected to anti-swelling efficiency measurements, while the other half was leached with distilled water. The results are given in Table 1.

As expected, wood dimensional stabilization is important and proportional to the concentration of PGMA used. Treatment was more efficient in the case of pine blocks due to their higher impregnability compared to beech blocks. Polymerisation of PGMA in wood was investigated after leaching. Indeed, PGMA polymerisation carried out without solvent leads to the formation of an water insoluble polymer, so that unleached chemicals should essentially correspond to polymerised product. Polymerisation increases with the quantity of PGMA used indicating that initial PGMA concentration in impregnation solution is an important point for such type of treatments and particularly for their leaching durability.

Influence of temperature on the polymerisation of PGMA is reported in Fig. 3. Blocks were impregnated with PGMA solution (20% in water) in the presence of MEKP (2%) and heated at different temperatures during 3 days. Unpolymerised PGMA was leached with water, and the blocks weighed after drying (m2). Weight gains and polymerisation increase slightly with the temperature showing a limited effect of this parameter. Similarly, influence of the time on polymerisation at room temperature is reported in Fig. 4. Weight gains measured after leaching are similar after drying during 3 days at 25°C indicating that polymerisation occurred rapidly after impregnation. In order to improve retention of PGMA in the wood, we have also investigated the addition of methyl methacrylate (MMA) to previous solutions (Table 2).

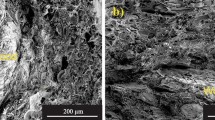

Addition of a low molecular weight monomer like MMA to PGMA allows to decrease the leachability of the impregnated chemicals. Growth of Poria placenta or Coriolus versicolor on pine or beech blocks treated with PGMA with or without addition of MMA is reported in Table 3. In all cases, treated blocks are more resistant than untreated one. Weight losses are comprised between 2.2 and 5.2% for the white rot fungus and 0.7 and 4.4% for the brown rot fungus. These results supported visual observations showing practically no mycelium development on treated samples compared to untreated one. Weight losses observed for beech controls allows to validate the treatment efficacy against Coriolus versicolor, while those observed in the case of pine controls are too low to completely validate and make conclusions from these results. However, these preliminary trials permit to predict a potential higher durability for such chemically treated blocks.

4 Conclusions

Like in our previous study, concerning the use of polyglycerol/maleic anhydride treatment (Roussel et al. 2001), the results show that wood properties can be considerably enhanced by treatment with polyglycerol derivatives. Polyglycerol methacrylate is easily synthesized starting from glycidyl methacrylate and polyglycerol, an industrial by-product, without the use of any solvent. Soluble in water, it allows water-borne treatment. Polymerisation of PGMA is achieved after standard vaccum/pressure impregnation by drying at room temperature with MEKP as free radicals initiator. PGMA concentration of the impregnation solution is important for the polymerisation and the retention of product in the wood, which could be increased by addition of low molecular weight monomer like methyl methacrylate. Modified blocks possess increased dimensional stability and are more resistant to wood rotting fungi. Such wood polymer composites could be promising preservation alternative with environmentally and socially acceptable characteristics to highly toxic biocides used currently in class 4. Further studies are however necessary to better determine the performances and the feasibility of this type of approaches.

References

Barnes HM, Murphy RJ (1995) Wood preservation. The classics and the new age. Forest Prod J 45(9):16–23

Doss NL, Elawady MM, Elawady NI, Mansour SH (1991) Impregnation of white pine wood with unsaturated polyesters to produce wood-plastic combinations. J Appl Polym Sci 42(9):2589–2594

Fujimara T, Inoue M, Vemura I (1990) Durability of wood with acrylic-high-pomymer. Dimensional stability with crosslinked acrylic copolymer in wood. Mokuzai Gakkaishi 36(10):851–859

Hoffmann P (1988a) On the stabilization of water logged oakwood in polyethyleneglycol (PEG) II. Designing a two step treatment for multiquality timbers. Studies Conservat 31:103–113

Hoffmann P (1988b) On the stabilization of water logged oakwood in polyethyleneglycol (PEG) III. Testing the oligomers. Holzforschung 42(5): 289–294

Hoffmann P (1990) On the stabilization of water logged oakwood in polyethyleneglycol (PEG) IV. Species from China and Corea. Holzforschung 44(2): 87–93

Meyer JA (1984) Wood-polymer materials in chemistry of solid wood. Adv Chem Series 257–289

Nakano T (1994) Reaction of glyoxal and glyoxal/glycol with wood. Wood Sci Technol 28:23–33

Rowell RM (1984) Penetration and reactivity of cell wall components in chemistry of solid wood. Adv Chem Series 175–210

Schneider MH (1994) Wood polymer composites. Wood Fiber Sci 26(1):142–151

Stamm AJ (1959) Effect of polyethyleneglycol on the dimensional stability of wood. Forest Prod J 9:375–381

Stamm A J (1965) Factors affecting bulking and dimensional stability of wood. Forest Prod J 14:403–408

Suttie E (1997) Novel wood preservatives. Chem Ind 18:720–724

Van Dijk-Wolthuis WNE, Franssen, Talsma OH, van Steenbergen MJ, Kettenes-van den Bosch JJ, Hennink WE (1995) Synthesis, characterization, and Polymerization of glycidyl methacrylate derivatized Dextran. Macromol 28(18):6317–6322

Van Dijk-Wolthuis WNE, Kettenes-van den Bosch JJ, van der Kerk-van Hoof A, Hennink WE (1997) Reaction of Dextran with glycidyl methacrylate: an unexpected transesterification. Macromol 30(11):3411–3413

Yasuda R, Minato K (1995) Chemical modification of wood by non formaldehyde cross-linking reagents. Wood Sci Technol 29:243–251

Acknowledgements

This work was supported by Ademe (Agence de l’Environnement et de la Maîtrise de l’Energie), Agrice (Agriculture pour la Chimie et l’Energie) and Onidol (Organisation Nationale Interprofessionnelle des Oléagineux).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soulounganga, P., Loubinoux, B., Wozniak, E. et al. Improvement of wood properties by impregnation with polyglycerol methacrylate. Holz Roh Werkst 62, 281–285 (2004). https://doi.org/10.1007/s00107-004-0485-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-004-0485-y