Abstract

The study aims to monitor pesticide and antibacterial drug residues in food of animal origin namely eggs, chicken, chevon and cow milk using two modified multi-residue analytical methods for simultaneous detection and quantification of thirteen pesticides with gas chromatography-electron capture detector (GC-ECD) and four antibacterial drugs with high performance liquid chromatography–diode array detector (HPLC-DAD). A total of 462 egg, 503 chicken, 575 chevon and 570 milk samples were collected from the local markets, dairy farms and households in twelve districts of West Bengal and four districts of Odisha, India. Samples were procured in summer and winter season. The validation of the method included the determination of limit of detection, limit of quantification, linearity, accuracy and precision and an inter- and intra-day assay of the method. Good linearity was obtained (r2 > 0.99), the recovery % ranged from 85.07 to 93.53% for antibacterial drugs and from 82.0 to 99.47% for pesticides, inter-assay and intra-assay variability were below 10 and 15% and repeatability was < 20% in both cases. The proposed modified methods thus proved reliable and were applied for monitoring pesticide and antibacterial drug residues in animal samples. The results revealed that 5.17% of the chicken samples were positive for delta-hexachlorocyclohexane, 11.33% for gamma-hexachlorocyclohexane and 11.93% for alachlor whereas 2.09% of the chevon samples were positive for alachlor and 1.57% for chlorpyrifos. However, all these values were within the maximum residue levels as set by European Commission and Codex Alimentarious Commission, suggesting no serious threat to public health.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the advent of pesticides and veterinary drugs, there has been a tremendous improvement in the agricultural yield and animal production, but at certain costs. The pesticide and veterinary drug residues have been a topic of interest in recent years owing to their potential to cause public health hazards. The major public health risks linked to exposure to veterinary drugs are hypersensitivity reactions, carcinogenicity, mutagenicity, teratogenicity, and damage to gut microbiota (Beyene 2016). Various short-term hazards (e.g., skin and eye irritation, headaches, dizziness, and nausea) and chronic impacts (e.g., cancer, asthma, and diabetes) are associated with pesticide use. In addition, their risks are difficult to elucidate due to the involvement of various factors, like time period and level of exposure, type of pesticide (regarding toxicity and persistence) and the environmental characteristics of the affected areas (Kim et al. 2016).

India is sixth largest manufacturer of pesticides in the world and third in Asia; producing a total 217,000 metric tons of pesticides in 2019. Therefore, there is an urgent need to monitor these residues and to implement control measures from a food safety point of view. To ensure that pesticide residues are not found in food or feed at levels presenting an unacceptable risk for human consumption, MRLs have therefore been set by the European Union (EU) and Codex Alimentarius Commission (CAC). Also, the joint FAO/WHO Expert Committee on Food Additives (JECFA) has been participating in evaluating the safety of residues of veterinary drugs in food (EU 2010; CAC 2015).

In India, the food safety is based on the guiding principle of risk analysis of the CAC. The government of India regulates the pesticide residues detected in various food items through Food Safety and Standards Act (FSSA), 2006 and MRLs on pesticides and agrochemicals are incorporated in the Food Safety and Standards Regulations, 2010. FSSA authorizes the Food Safety and Standards Authority of India (FSSAI) to “specify the limits for use of food additives, crop contaminants, pesticide residues, residues of veterinary drugs, heavy metals, processing aids, mycotoxins, antibiotics and pharmacological active substances and irradiation of food”.

Analytical methodology for pesticide/antibacterial residues usually involves different methods for extraction and clean-up, sample purification and preparation steps to isolate the targeted pesticide/antibacterial drug for analysis, followed by a final analysis typically with chromatographic measurements. A number of gas chromatography (GC) based pesticide analyses by coupling with electron capture detector (ECD) for animal food matrices have been reported (Lazaro et al. 1996; Doong and Lee 1999; Schenck and Donoghue 2000; Yague et al. 2001; Goulart et al. 2009; Khay et al. 2009; Tao et al. 2009). Furthermore, a multi-residue technique for pesticide analysis has been developed for fruits and vegetables (Rejczak and Tuzimski 2015), sunflower seeds (Tuzimski and Rejczak 2014), edible oils (Tuzimski and Rejczak 2016), rapeseed oil (Rejczak and Tuzimski 2017a, b), wine (Tuzimski et al. 2019), soya milk (Rejczak and Tuzimski 2016), apple (Tuzimski 2005), bovine milk (Rejczak and Tuzimski 2017a, b) and nitroimidazole derivatives in bovine milk (Tuzimski and Rejczak 2017) and some anticancer drugs in human blood samples (Tuzimski and Petruczynik 2020) using HPLC–DAD. But multi-residue techniques using QuEChERS method for analysis of antibacterial drugs in animal substrates is scarcely available. Adaptions in the experimental procedure of the original QuEChERS method (Anastassiades et al. 2003) enabled the determination of different analytes in various food samples (Wilkowska and Biziuk 2011). The surveillance/monitoring of pesticides and antibacterial drug residues in foods of animal origin can reveal the current status of contamination, thereby enabling preventive or control measures to be initiated before the contamination becomes so widespread that threatens human health or results in economic losses (Biswas et al. 2010). The report in respect to xenobiotic residues in animal substrates is scarcely available in India. Considering the above, the present research work was undertaken to monitor some pesticides and antibacterial residue in animal products using modified multi-residue methods utilising a QuEChERS approach.

2 Materials and methods

2.1 Sample collection

A total of 462 eggs, 503 chicken, 575 chevon and 570 milk samples were procured from dairy farms, households and local markets from twelve districts of West Bengal and districts of Odisha in India (Table 1). Sampling was performed during summer (May/June) and winter (November/December) season. Samples were collected in glass bottles for milk samples, and polythene packets for the rest of the samples, stored on ice and immediately transported to the laboratory for storage at – 18 °C. Analysis was performed within 24 h after collection of the samples.

2.2 Chemicals and reagents

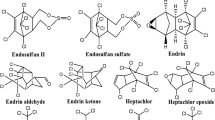

Thirteen analytical grade pesticide standards i.e. alpha-hexachlorocyclohexane (α-HCH), γ-HCH, δ-HCH, α-endosulfan, β-endosulfan, alachlor, chlorpyrifos, cypermethrin, 2,4′-dichlorodiphenyldichloroethane (o,p′-DDD), 4,4′-dichlorodiphenyldichloroethane (p,p′-DDD), 2,4′-dichlorodiphenyldichloroethylene (o,p′-DDE), 4,4′-dichlorodiphenyldichloroethylene (p,p′-DDE) and 4,4′-Dichlorodiphenyltrichloroethane (p,p′-DDT) and four antibacterial drug standards, i.e. ceftriaxone, oxytetracycline, enrofloxacin and amoxicillin with more than 98% purity were purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germany) and supplied by Eurasian Associates (Kolkata, India). All organic solvents used were GC and HPLC grade from E. Merck (India) and SampliQ C-18 was purchased from Agilent.

2.3 HPLC parameters and condition

The HPLC System consisted of SHIMADZU LC-20 AT Liquid Chromatograph coupled with Diode Array Detector (SPD-M10A VP). The column used was Thermo Hypersil ODS C18 (250 × 4.6 mm, 5 µ). The flow rate was adjusted to 1 mL min−1 with 254 nm (ceftriaxone, oxytetracycline and enrofloxacin) and 228 nm (amoxicillin) wavelength. The standard and sample were injected into HPLC (20 µL each). The mobile phase used for ceftriaxone, oxytetracycline and enrofloxacin was acetonitrile (30%) in pump ‘A’ and phosphate buffer (10 mM potassium dihydrogen phosphate + triethylamine), pH 2.5 (70%) in pump ‘B’. The mobile phase used for amoxicillin was acetonitrile:water (9:1) (50%) in pump ‘A’ and orthophosphoric acid 0.01 M (50%) in pump ‘B’.

2.4 GC parameters and conditions

The GC System VARIAN (CP-3800) Gas Chromatography included a DB-5MS column of 30 m length and 0.25 mm diameter and coupled with Electron Capture Detector. The film thickness (Agilent J&W) was 0.25 µm. The flow rate was set at 1 mL min−1 (carrier gas: nitrogen). The make-up gas included 35 mL min−1 nitrogen. 2 µL of the standard and sample was injected into GC. The split ratio was set at 10:1 with injector temperature of 275 °C and detector at 320 °C. The column oven was as follows: initially 150 °C, hold: 1 min, rate: 5 °C min−1; 190 °C, hold: 0 min, rate: 2 °C min−1; 225 °C, hold: 0 min, rate: 40 °C min−1; 290 °C, hold: 7 min. The total GC analysis time needed was 35 min.

2.5 Sample preparation for pesticide analysis using GC–ECD

Sample preparation for analysis of pesticides was done according to the method described by Lehotay et al. (2005) and Singh et al. (2013) but with some modification. Chicken and chevon samples (100 g each) were cut into small pieces and homogenised, while 100 g milk samples were homogenised, and three pieces of egg were homogenised to obtain a 100 g egg sample. The homogenised sample (10 g) was taken in a 50 mL centrifuge tube, then 10 mL of millipore water, 1.5 g of sodium chloride and 5 g of sodium sulphate was added, followed by homogenisation for 3 min using a micro-homogeniser. Ethyl acetate (10 mL) was added and again homogenised for 3 min. Continuous agitation was done in a reciprocal shaker set at 200–250 rpm for 1 h followed by centrifugation at 10,000 rpm for 10 min in a cooling centrifuge. The supernatant (10 mL) was collected, followed by repetition of steps from addition of 10 mL ethyl acetate until collection of the supernatant. Thus, a total of 20 mL was collected, out of which 10 mL was condensed at 40 °C in a rotary vacuum evaporator. From the remaining 10 mL of the extract, 1.5 mL was taken in a 2 mL eppendorf tube followed by addition of 50 mg C-18, 50 mg primary secondary amine (PSA) and 200 mg magnesium sulphate. The extract was vortexed for 1 min and centrifuged at 10,000 rpm for 5 min. The supernatant was collected after syringe filtration containing 0.2 µm filter paper. 2 µL of the extract was injected in the GC–ECD and analysis was done for pesticides.

2.6 Sample preparation for antibacterial drug analysis using HPLC–DAD

Sample preparation for analysis of antibacterial drugs was done by reported methods (Lehotay et al. 2005; Smyrniotakis and Archontaki 2007; Tauber et al. 2015) with some modification. A 100 g of chicken and chevon sample was cut into small pieces and homogenised, while 100 g of milk sample was only homogenised and three pieces of egg were homogenised to obtain 100 g of egg sample. The homogenised sample (10 g) was taken into a 50 mL centrifuge tube. Acetonitrile and methanol mixture (8:2) was prepared. A 10 mL of mixed solvent [containing 8 mL of the above mixture (acetonitrile and methanol) and 2 mL acidified water (8:2)], 1 g sodium chloride and 3 g anhydrous sodium sulphate were added to the centrifuge tube followed by homogenisation for 3 min using a micro-homogeniser. Continuous agitation was done in a reciprocal shaker set at 200–250 rpm for 1 h followed by centrifugation at 10,000 rpm for 10 min in a cooling centrifuge (− 5 °C). The supernatant (10 mL) was collected and 10 mL of the mixed solvent was added in the sediment and homogenised for 3 min using a micro-homogeniser, followed by mixing at 200–250 rpm for 1 h, and 10 mL was collected. Thus, 20 mL was collected in total, out of which 10 mL was condensed at 40 °C in a rotary vacuum evaporator and 1.5 mL of the remaining 10 mL of extract was taken in a 2 mL Eppendorf tube followed by addition of 50 mg C-18, 50 mg PSA and 250 mg magnesium sulphate. The extract was vortexed for 1 min and centrifuged at 10,000 rpm for 5 min. The supernatant was collected after syringe filtration (0.2 µm filter paper). A 20 µL of the extract was injected in HPLC and analysis was done for antibacterial drugs.

2.7 Method validation

To confirm that the proposed analytical methods are suitable for their intended use, a validation process was performed by estimating linearity, inter and intra-day assay variation, accuracy and precision, LOD and LOQ. Sensitivity was evaluated in terms of LOD and LOQ which were calculated by using the method of Singh et al. (2013) and were in accordance with VICH GL 49/FDA (2011) guidelines. Linearity was determined by constructing calibration curves with standard solutions in ethyl acetate for pesticides and in water for antibacterial drugs. Accuracy data were obtained from recovery studies. Repeatability was evaluated through within-run precision of the method.

2.8 Identification and confirmation criteria

A series of blank water samples and ethyl acetate samples spiked with antibacterial drug and pesticide standards, respectively, at different concentration levels and sample solutions spiked at the same levels were prepared to establish the standard and matrix-matched calibration curves, respectively. For each level, three replicate extractions and determinations were performed and the calibration curve of each pesticide and antibacterial drug was constructed by plotting the peak areas versus the corresponding concentration of the analytes. The procedure was repeated three times in a day and on consecutive three days to assess the coefficient of variation percentage (CV%) of modified methods. The identification of the target compounds involved comparison of the retention time (RT) and peak area in standard and test samples.

3 Results and discussion

The LOD, LOQ, accuracy and repeatability with 4–5 different spiking levels are depicted in Table 2. Good linearity and correlation coefficients were obtained, containing all pesticides in the range of 0.01–0.2 ppm and antibacterial drugs in the range of 0.2–10 ppm, with a coefficient of correlation (r2) higher than 0.99 in both cases. Recovery rates or accuracy ranged between 85.07 and 93.53% for antibacterial drugs and between 82.0 and 99.47% for pesticides. Inter-assay and intra-assay coefficients of variation were below 10 and 15%. The repeatability ranged between 4.07 and 15.99% for antibacterial drugs whereas it ranged between 3.68 and 19.48% for pesticides. In the pesticide analysis field, recovery rates in the range of 70–120% are considered to be acceptable and can be used in routine analysis, as recommended by the Codex Alimentarius and EU Commission guidelines (LeDoux 2011). The recovery results obtained in the present study were similar or even higher than the developed and validated methods in foods of animal matrices (Lazaro et al. 1996; Khay et al. 2009; Schenck and Donoghue 2000; Goulart et al. 2009; Yague et al. 2001; Doong and Lee 1999). In a study conducted using HPLC–DAD (Cinquina et al. 2003), the mean recovery % of enrofloxacin was around 84% which corroborated with the present study. Thus, the proposed methods are efficient and reliable and were suitably applied to real samples for monitoring purposes. Chromatograms of pesticide standards, pesticide fortified samples and pesticide extracted from field samples are depicted in Fig. 1. Standard curves for the pesticide and antibacterial residues are provided in the Supplementary Material (Fig. S1).

Table 3 shows the positive samples (contaminated) of animal food matrices by different pesticides collected from different districts of West Bengal and Odisha, India. The study revealed that 5.17% of the chicken samples were positive for δ-HCH, 11.33% for γ-HCH and 11.93% for alachlor whereas 2.09% of the chevon samples were positive for alachlor and 1.57% for chlorpyrifos. There was no detectable level of antibacterial drug residue in the studied samples. All these values were within the MRL values set by EU and CAC for the animal substrates and thereby safe for human consumption.

Organochlorine pesticides (OCPs) have been detected in different food matrices due to their wide usage in the past, very slow degradation in the environment or in organisms and bioaccumulation. The carry-over of pesticide residues from feed/fodder to animal products is also possible (LeDoux 2011). This may be the reason that in spite of the ban, OCPs such as γ-HCH, δ-HCH and alachlor have been detected in few of the chicken and chevon samples in the present study. Some compounds like lindane, α-HCH, chlorpyrifos show detectable amounts of residues in different matrices e.g. egg, milk, body fat, chicken and meat whereas o,p′-DDD, α- and β-endosulfan were absent (Kan and Meijer 2007; Ahmad et al. 2010) which was comparable with the present study.

The use of pesticides in the states of West Bengal and Odisha around 1995–1996 was 5338 metric tonnes (MT) and 1006 MT respectively, whereas it declined to 2624 MT and 770 MT, respectively in the year 2016–2017. These data clearly indicate that there is definite trend of decline in the pesticide use in the states of West Bengal and Odisha owing to the restriction or ban of pesticides, the imposition of integrated pest management, use of bio-pesticides and other measures. The consumption of more easily biodegradable bio-pesticides, in the states of Odisha and West Bengal in the year 2010–2011 was 365 and 665 MT, whereas it was 271 and 838 MT, respectively in the year 2016–2017 (Directorate of Plant Protection, Quarantine and Storage 2020). Thus, the contamination levels of pesticides in agricultural run-off, sewage wastes may be much lower and thereby the concentration might be even lesser in the food chain. This explains the below detection level (BDL) values of the majority of the samples obtained in the present study.

4 Conclusions

The modified procedure for analysis of pesticides and antimicrobials in animal substrates using GC–ECD and HPLC–DAD proved to be reliable and acceptable and therefore was applied for monitoring of pesticide and antibacterial drug residues in animal products. The modified multi-residue method may be applied as a less expensive alternative to methods utilizing LC–MS/LC–MS/MS. Four pesticides such as δ- and γ-HCH, alachlor and chlorpyrifos were detected in some samples. They were below the maximum permissible limit suggesting a negligible public health hazard consuming contaminated edible animal products in the states of West Bengal and Odisha.

Availability of data and material

Data will be made available to other researchers upon reasonable request.

References

Ahmad R, Salem NM, Estaitieh H (2010) Occurrence of organochlorine pesticide residues in eggs, chicken and meat in Jordan. Chemosphere 78:667–671

Anastassiades M, Lehotay SJ, Štajnbaher D, Schenck FJ (2003) Fast and easy multi-residue method employing acetonitirile extraction/partitioning and dispersive solid phase extraction for the determination of pesticide residues in produce. J AOAC Int 86:412–431

Beyene T (2016) Veterinary drug residues in food-animal products: its risk factors and potential effects on public health. J Vet Sci Technol 7:1000285. https://doi.org/10.4172/2157-7579.1000285

Biswas AK, Kondaiah N, Anjaneyulu ASR, Mandal PK (2010) Food safety concerns of pesticides, veterinary drug residues and mycotoxins in meat and meat products. Asian J Anim Sci 4:46–55

Cinquina AL, Roberti P, Giannetti L, Longo F, Draisci R, Fagiolo A, Brizioli NR (2003) Determination of enrofloxacin and its metabolite ciprofloxacin in goat milk by high-performance liquid chromatography with diode-array detection optimization and validation. J Chromatogr A 987:221–226

Codex Alimentarius (2015) CAC/MRL–2, Maximum residue limits (MRLs) and risk management recommendations (RMRs) for residues of veterinary drugs in Foods

Directorate of Plant Protection, Quarantine and Storage (2020) http://ppqs.gov.in/divisions/pesticides-monitoring-documentation. Accessed 14 Mar 2020

Doong RA, Lee CY (1999) Determination of organochlorine pesticide residues in foods using solid-phase extraction clean-up cartridges. Analyst 124(9):1287–1289

European Union (2010) Commission regulation (EU) no. 37/2010, on pharmacologically active substances and their classification regarding maximum residue limits in foodstuffs of animal origin

FDA (2011) CVM Guidance for Industry (GFI) #208, VICH GL 49, Studies to evaluate the metabolism and residue kinetics of veterinary drugs in food-producing animals: validation of analytical methods used in residue depletion studies. http://www.fda.gov/downloads/AnimalVeterinary/GuidanceComplianceEnforcement/GuidanceforIndustry/UCM207939.pdf. Accessed 20 Sept 2018.

Goulart SM, de Queiroz ME, Neves AA, de Queiroz JH (2009) Low-temperature clean-up method for the determination of pyrethroids in milk using gas chromatography with electron capture detection. Talanta 75(5):1320–1323

Kan CA, Meijer GAL (2007) The risk of contamination of food with toxic substances present in animal feed. Anim Feed Sci Technol 133:84–108

Khay S, Abd El-Aty AM, Choi JH, Shin EH, Shin HC, Kim JS, Chang BJ, Lee CH, Shin SC, Jeong JY, Shim JH (2009) Simultaneous determination of pyrethroids from pesticide residues in porcine muscle and pasteurized milk using GC. J Sep Sci 32(2):244–251

Kim KH, Kabir E, Jahan SA (2016) Exposure to pesticides and the associated human health effects. Sci Total Environ 575:525–535. https://doi.org/10.1016/j.scitotenv.2016.09.009

Lazaro R, Herrera A, Arino A, Conchello MP, Bayarri S (1996) Organochlorine pesticide residues in total diet samples from Aragon (northeastern Spain). J Agric Food Chem 44:2742–2747

LeDoux M (2011) Analytical methods applied to the determination of pesticide residues in foods of animal origin. A review of the past 2 decades. J Chromatogr A 1218(8):1021–1036. https://doi.org/10.1016/j.chroma.2010.12.097

Lehotay SJ, Mastovska K, Yun SJ (2005) Evaluation of two fast and easy methods for pesticide residue analysis in fatty food matrixes. J AOAC Int 88:630–638

Rejczak T, Tuzimski T (2015) A review of recent developments and trends in the QuEChERS sample preparation approach. Open Chem 13:980–1010

Rejczak T, Tuzimski T (2016) Simple, cost-effective and sensitive liquid chromatography diode array detector method for simultaneous determination of eight sulfonylurea herbicides in soya milk samples. J Chromatogr A 1473:56–65

Rejczak T, Tuzimski T (2017a) Method development for sulfonylurea herbicides analysis in rapeseed oil samples by HPLC–DAD: comparison of zirconium-based sorbents and EMR-lipid for clean-up of QuEChERS extract. Food Anal Methods 10:3666–3679

Rejczak T, Tuzimski T (2017b) QuEChERS-based extraction with dispersive solid phase extraction clean-up using PSA and ZrO2-based sorbents for determination of pesticides in bovine milk samples by HPLC-DAD. Food Chem 217:225–233

Schenck FJ, Donoghue DJ (2000) Determination of organochlorine and organophosphorus pesticide residues in eggs using a solid phase extraction cleanup. J Agric Food Chem 48:6412–6415. https://doi.org/10.1021/jf000142c

Singh AK, Sar TK, Mandal TK (2013) Monitoring of pesticide residue in bovine milk from Nadia District, West Bengal. Bull Environ Contam Toxicol 91:13–17

Smyrniotakis CG, Archontaki HA (2007) C18 columns for the simultaneous determination of oxytetracycline and its related substances by reversed-phase high performance liquid chromatography and UV detection. J Pharm Biomed Anal 43:506–514

Tao S, Liu WX, Li XQ, Zhou DX, Li X, Yang YF, Yue DP, Coveney RM (2009) Organochlorine pesticide residuals in chickens and eggs at a poultry farm in Beijing, China. Environ Pollut 157:497–502

Tauber V, Pătruț E, Chiurciu V (2015) Development and validation of an HPLC method for the determination of oxytetracycline and enrofloxacin in veterinary formulations. Medicam Vet Vet Drug 9(2):65–69

Tuzimski T (2005) Use of thin-layer chromatography in combination with diode-array scanning densitometry for identification of fenitrothion in apples. JPC J Planar Chromat 18(106):419–422

Tuzimski T, Petruczynik A (2020) Review of chromatographic methods coupled with modern detection techniques applied in the therapeutic drugs monitoring (TDM). Molecules 25(17):4026

Tuzimski T, Rejczak T (2014) Determination of pesticides in sunflower seeds by high-performance liquid chromatography coupled with a diode array detector. J AOAC Int 97(4):1012–1020

Tuzimski T, Rejczak T (2016) Application of HPLC–DAD after SPE/QuEChERS with ZrO2-based sorbent in d-SPE clean-up step for pesticide analysis in edible oils. Food Chem 190:71–79

Tuzimski T, Rejczak T (2017) A QuEChERS-based sample preparation method for the analysis of 5-nitroimidazoles in bovine milk by HPLC–DAD. J AOAC Int 100(6):1671–1680

Tuzimski T, Rejczak T, Pieniążek D, Buszewicz G, Teresiński G (2019) Comparison of SPE/d-SPE and QuEChERS-based extraction procedures in terms of fungicide residue analysis in wine samples by HPLC–DAD and LC-QqQ-MS. J AOAC Int 99(6):1436–1443

Wilkowska A, Biziuk M (2011) Determination of pesticide residues in food matrices using the QuEChERS methodology. Food Chem 125:803–812

Yague C, Bayarri S, Lazaro R, Conchello P, Arino A, Herrera A (2001) Multiresidue determination of organochlorine pesticides and polychlorinated biphenyls in milk by gas chromatography with electron-capture detection after extraction by matrix solidphase dispersion. JAOAC Int 84:1561–1568

Acknowledgements

The authors are grateful to Indian Council of Agricultural Research, New Delhi, India for providing financial assistance to carry out the project entitled “Outreach programme on Monitoring of Drug Residues and Environmental Pollutants”.

Funding

The study was part of the project entitled “Outreach programme on Monitoring of Drug Residues and Environmental Pollutants”, under West Bengal University of Animal and Fishery Sciences, sponsored by Indian Council of Agricultural Research, New Delhi, India.

Author information

Authors and Affiliations

Contributions

Investigation, writing-original draft preparation, SK; investigation, writing, review and editing, RB; conceptualisation, supervision, TKS; conceptualisation, funding acquisition, supervision, TKM.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akhtar, S., Buragohain, R., Sar, T.K. et al. Monitoring of pesticide and antibacterial drug residues in animal products from two states in India by modified multi-residue analytical methods using GC–ECD and HPLC–DAD. J Consum Prot Food Saf 16, 171–181 (2021). https://doi.org/10.1007/s00003-021-01315-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-021-01315-3