Abstract

In an attempt to determine the residual levels of lead (Pb), cadmium (Cd), mercury (Hg) and tin (Sn) in canned meat products marketed in Egypt, a total number of 160 random samples (40 each) of canned chicken luncheon (CCL), canned beef luncheon (CBL), canned frankfurter (CF) and canned corned beef (CCB) were randomly collected from different supermarkets in Egypt to be analyzed using atomic absorption spectrophotometry. From the obtained results, it was found that the mean values of residual levels of Pb in examined CCL, CBL, CF and CCB samples were 0.330, 0.224, 0.206 and 0.334 mg/kg, respectively, while those of Cd were 0.057, 0.053, 0.039 and 0.042 mg/kg, those of Hg were 0.387, 0.450, 0.402 and 0.332 mg/kg, and finally those of Sn were 2.061, 2.308, 0.755 and 1.997 mg/kg. The obtained results were compared with the permissible limits of heavy metals recommended by international and national authorities. In addition, the public health significance as well as the sources of contamination of canned meat products by heavy metals were addressed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Meat and meat products constitute a large portion of human diet and represent an important source of animal protein and a wide range of other nutrients, but may also carry toxic substances. Canned food is widely distributed and a popular food source around the world, because they constitute inexpensive and affordable products (Storelli et al. 2010). In Egypt, there are several popular canned meat and meat products. However, the assessment of the safety of such products does not attract the attention of researchers, so there is only limited information about their status.

Lead (Pb), cadmium (Cd), mercury (Hg) and tin (Sn) are widely distributed heavy metals in our environment. It is known that these elements have no beneficial effects for human beings, and there is not any known homeostasis mechanism for them (Vieira et al. 2011). Whilst, they have several adverse effects on human health. Pb is a metabolic poison and a neurotoxin that binds to essential enzymes and several other cellular components and inactivates them (Cunningham and Saigo 1997). Moreover, it is known to induce reduced cognitive development and intellectual performance in children and increased blood pressure and cardiovascular diseases in adults (EC 2002). Cd is recognized as one of the most toxic elements to human beings and animals. It predominantly accumulates in kidney, bound to metalothioneines, with a biological half-life of more than 10 years. Excessive long-term Cd exposure may produce irreversible adverse renal effects as reported by WHO (1992). Cd toxicity affects tissues such as appetite and pain centers (in the brain), brain, heart and blood vessels, kidney and lungs. This toxicity may cause anemia, dry and scaly skin, emphysema, fatigue, hair loss, heart disease, depressed immune system response, hypertension, joint pain, kidney stones or damage, liver dysfunction or damage, loss of sense of smell, lung cancer, pain in the back and legs and yellow teeth in humans (Kocak et al. 2005). Acute Hg poisoning results in lung damage, while chronic exposure is characterized by neurological and psychological disorders such as tremors, changes in personality, restlessness, anxiety, sleep disturbance and depression, and irreversible kidney damage even after exposure cessation (Järup 2003).

Acute toxicity resulted from dissolution of Sn from the internal surfaces of tinned cans and associated with watery diarrhea, vomiting, sickness and a great abdominal pain was recorded by Barker and Runte (1972) and Sedgwick (1888).

Although some people are exposed to these heavy metals at their workplace, for most people the main source of exposure to these toxic substances is through ingestion of food and drinking of water. Although the resulting public health risks of any contaminant are a function of concentration, it is well-known that long duration of intake of these metals at relatively low levels can lead to adverse results (Castro-González and Méndez-Armenta 2008). Hence, the accumulation of heavy metals in our environment is of increasing concern nowadays due to food safety issues and potential public health hazards (McLaughlin et al. 1999). The discharge of hazardous pollutants into the environment obstinately raises heavy metal concentrations that enter the food chain. Contamination of meat and meat products with heavy metals can take place during the handling, transportation and processing of meats, from farm to fork. Contact between food and metal, including but not restricted to processing equipment and utensils, food store, food packages and food cans, is another important source of food contamination with heavy metals (Morgan 1999). In this concern, it was found that the addition of spices to canned food and soldering process of cans add considerable amount of heavy metals to canned food (Maggi et al. 1979; Müller et al. 1996; Mol 2011).

The monitoring of meat and meat products for chemical hazards is required to ensure that approved compounds are not being misused and do not contain a risk to consumers (Pullen 1990). Thus, several monitoring programs have been carried out in several nations with the purpose of avoiding the distribution of foodstuffs that contain chemical residues in high levels and could have a risk to human health if consumed (Lόpez-Alonso et al. 2000). On contrary, in Egypt there is not any official monitoring programs by the national authorities determines the level of heavy metals in foods (Hassan et al. 2015). Therefore, the present study was designed to determine the residual concentrations of some heavy metals (Pb, Cd, Hg and Sn) in canned chicken luncheon (CCL), canned beef luncheon (CBL), canned frankfurter (CF), and canned corned beef (CCB) marketed in Egypt.

2 Materials and methods

2.1 Collection of samples

A total number of 160 random samples of canned meat, 40 samples of CCL, CBL, CF, and CCB each were collected from different markets in Beni-Suef, Assiut and Cairo governorates, Egypt. The collected samples were transferred immediately and in their original cans to the laboratory for further preparation and identification.

2.2 Digestion of samples

Meat product samples were dried at 105 °C, and then subjected to dry ashing at 450 °C/5 h in a muffle furnace, using high purity magnesium oxide and magnesium nitrate as ashing aids to limit volatilization losses of some elements. For each metal two gram of dried samples were dissolved in distilled water in a digestion flask and digested with a mixture of 10 ml of nitric acid (HNO3) 65 % (supra-pure, Merk, Darmstadt, Germany) and 2 ml of perchloric acid (HClO4) 70 % (extra-pure-Merk, Darmstadt, Germany) (Zantopoulos et al. 1996). The content of the flasks was vigorously shaken and allowed to stand overnight at room temperature. Then, these flasks were heated for 3 h in water bath adjusted at 70 °C to ensure complete digestion of samples. During the heating period, the digestion flasks were vigorously shaken at 30 min intervals. Finally, the flasks were cooled to room temperature and each tube then was diluted with 20 ml de-ionized water, and filtered by using Watt man filter paper No. 42. The filtrate was collected in glass tubes and these tubes were capped with polyethylene films and kept at room temperature until analysis of residual concentrations of Pb, Cd, Hg and Sn (Tsoumbaris 1990).

2.3 Preparation of blank and standard solution

Blank and standard solutions using pure certified metal standards for Pb, Cd, Hg and Sn were prepared by the method described above (Sect. 2.2).

2.4 Instrument and measurement

Buck scientific 210VGP Atomic Absorption Spectrophotometer (AAS) was used to determine heavy metal levels in the selected samples. The digest, blank and standard solutions were aspirated by AAS and analyzed for heavy metal content. Analysis of Pb, Cd and Sn was conducted by air/acetylene flow (5.5/1.11/m) flame technique, while cold vapor technique was used for Hg determination (AOAC 1990). The analytical detection limits of Pb, Cd, Hg and Sn for the used instrumentation were 0.005, 0.02, 0.005 and 0.02 ppm, respectively.

2.5 Calculation

Pb, Cd, Hg and Sn concentrations were recorded directly from the digital scale of AAS and calculated according to the following equation:

where R is the reading of element concentration (ppm) from digital scale of AAS, D is the dilution of the prepared sample, and W is the weight of the sample.

The concentration or the absorption values of heavy metals in blank samples were also calculated and subtracted from each analyzed sample. The estimated values of Pb, Cd, Hg and Sn were expressed as mg/kg wet weight (ppm).

2.6 Statistical analysis

All the data were analyzed using SPSS/PCT (Foster 2001). Independent T test was performed to evaluate differences.

2.7 Comparing with permissible limits

The obtained results of residual concentrations of studied heavy metals in different canned meat products were compared with the acceptable limits recommended by national and international organizations, which are illustrated in Table 1.

3 Results and discussion

3.1 Residual levels of Pb in examined canned meat products

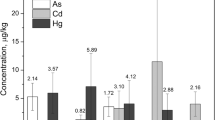

From the results recorded in Table 2, it is obvious that the residual level of Pb in examined CCL samples ranged from a non-detectable level (ND) to 1.140 mg/kg with a mean value of 0.330 mg/kg, while in CBL, it ranged from ND to 0.630 mg/kg with a mean value of 0.224 mg/kg (Table 2). The obtained results of Pb in CF (Table 4) ranged from ND to 0.630 mg/kg, with a mean value of 0.206 mg/kg. Concerning CCB (Table 5), residual levels of Pb ranged from ND to 0.830 mg/kg with a mean value of 0.334 mg/kg. There was no significant difference between the mean residual levels of Pb in all examined canned meat products (p < 0.05). The data outlined in Table 6 show that 27, 22, 29 and 33 out of 40 samples of each CCL, CBL, CF and CCB (representing 67.5, 55, 72.5 and 82.5 %, respectively), exceeded the maximum acceptable limit (0.1 mg/kg) of Pb in meat and meat products of bovine animals and poultry recommended by European Commission (EC 2006) and Egyptian Standards (ES 2010). With regard to the permissible limits of Pb (0.5 mg/kg) stated by Food and Agricultural Organization (FAO 1983) and Food and Drug Administration (FDA 2013), we found that 12, 9, 1 and 10 out of 40 samples of each CCL, CBL, CF and CCB (representing 30, 22.5, 2.5 and 25 %, respectively), were above such limits (Table 6).

Higher values of Pb reported in examined canned meat products can be explained in light of the concept of Ihedioha and Okoye (2012) who suggested that the presence of Pb in foods, including meat and meat products, is attributed to the release of Pb into the atmosphere by metal fumes or suspended particles from smelting or fuel combustion and disposal of wastes, which then contaminate animal feed and water and accumulates inside their tissues. Beside contaminated animal tissues, air in the manufacturing atmosphere, water used for processing, other raw materials, cooking utensils and food packages are potential sources of contamination of processed foods by Pb. In addition, the use of spices during processing (Landis and Ming-Ho 2004) and the release of substantial quantities of Pb from the soldering line into the food (Maggi et al. 1979) are referred to as additional sources.

3.2 Residual levels of Cd in examined canned meat products

The results illustrated in Table 2 reveal that the Cd residual levels in the examined CCL samples ranged from ND to 0.110 mg/kg with a mean value of 0.057 mg/kg, and Table 3 denotes that in CBL levels ranged from ND to 0.100 mg/kg with a mean value of 0.053 mg/kg. Concerning CF, levels (Table 4) ranged from ND to 0.090 with a mean value of 0.039 mg/kg. Moreover, Table 5 shows that in CCB levels ranged from ND to 0.110 with a mean value of 0.042 mg/kg. Compared with the maximum acceptable limit of Cd (0.05 ppm) in meat and meat products of bovine animals and poultry recommended by EC (2006) and ES (2010; Table 6), it was noticed that 23, 17, 12 and 12 out of 40 samples of each CCL, CBL, CF and CCB (representing 57.5, 42.5, 30 and 30 %, respectively), exceeded these limits. Nevertheless, in none of the examined samples the permissible limit of Cd (0.5 ppm) stated by JECFA (2006) was exceeded.

The residual concentrations of Cd reported in the current study that are higher than the permissible limits recommended by EC (2006) and ES (2010) might be explained in the light of previously published reports. Abdel-Sabour (2001) and Hassan et al. (2015) find that high levels of Cd in the Egyptian environment and accordingly in plants and animal tissues and products could be attributed to the increasing emission of Cd into atmosphere from mining and smelting industries and the contamination of river Nile with the industrial wastes especially by plastics industries. Besides, Cd escapes into the air from iron and steel production industries and the high usage of phosphate fertilizers. These findings support the concepts of Müller et al. (1996) and Bakircioglu et al. (2011) who declared that the addition of spices during production of canned meat might be the main reason for contamination with Cd, since spices could contain Cd concentrations up to 200 ng/g, so that contamination of food products by Cd is the result of the manufacturing procedure, the equipment used during the process as well as packaging materials and storage. In this regard, the Ministry of Health ESR (1995) indicated that approximately 1/3 of cadmium dietary intake is attributed to the ingestion of animal products, while plant products provide the remaining 2/3.

3.3 Residual levels of Hg in examined canned meat products

The obtained results (Table 2) indicated that the residual levels of Hg in examined CCL samples ranged from ND to 0.840 with a mean value of 0.387 mg/kg. Referring to the data of CBL samples (Table 3), it ranged from (ND) to 0.900 with a mean value of 0.450 mg/kg. Whereas in examined CF samples it ranged from ND to 0.980 with a mean value of 0.402 mg/kg (Table 4). As illustrated in Table 5, the residual in CCB samples ranged from ND to 1.220 with a mean value of 0.332 mg/kg. The recorded residual levels of Hg in examined canned meat products are relatively low, and can be explained in light of published papers by the Ministry of Health ESR (1995) and Dudka and Miller (1999). Stating that consumption of seafood is the main source of the Hg accumulation in human bodies, and dietary intake of Hg through other food remains relatively low. They explain that fish and shellfish have a high ability to bio-accumulate environmental Hg in their tissues, therefore keep it in high levels, and have a distinct capacity to convert inorganic Hg into organic, thus, rendering Hg more easily transferable throughout the aquatic food chain. Therefore, there are not any recommended standards for Hg in other foods than seafood. In this concern it was reported that the main sources of food contamination with Hg may be industrial wastes, pesticides and fungicides (Zarski et al. 1997), while, Rashad et al. (2013) noticed reduced levels of Hg in the Egyptian environment in their study on environmental monitoring of Hg in soil, air and plants.

3.4 Residual levels of Sn in examined canned meat products

From Table 2 it can be recognized that the residual level of Sn in examined CCL samples ranged from ND to 6.220 with a mean value of 2.061 mg/kg, and in examined CBL samples it ranged from ND to 6.350 with a mean value of 2.30 mg/kg (Table 3), whereas it ranged from ND to 5.280 with a mean value of 0.755 mg/kg in examined CF samples (Table 4). Regarding CCB samples, it can be concluded from the data shown in Table 5 that it ranged from ND to 5.460 with a mean value of 1.997 mg/kg. Concerning the permissible limits of Sn in canned foods (Table 6), it was observed that none of the examined samples of canned meat products exceeded either the permissible limit of Sn stated by JECFA (2006) or of EC (2006) (250 and 200 mg/kg wet weight of canned food, respectively).

In general, the residual concentrations of Sn in all examined canned food items were quite low, which could be a result of improved quality assurance measures during processing and storage conditions of canned foods (EC 2001).

4 Conclusion

It could be concluded from the current study that the elevated values of Pb and Cd could be attributed to the contaminated animal tissues used for processing, air in the manufacturing atmosphere, water used for processing, other raw materials, cooking utensils and food packages as well as the use of spices during processing. Additionally, high Cd values support the previous reports of high Cd levels in the Egyptian environment. The reduced residual concentration of Hg in examined canned food samples reflects the low level of Hg in the Egyptian environment and supports the previously recorded concept that dietary intake of Hg through food remains relatively low and strictly linked to seafood. Sn residual levels in examined canned foods were relatively low, which could be a result of increasing improvements in quality assurance measures and storage conditions of canned food.

References

Abdel-Sabour MF (2001) Cadmium status in Egypt. J Environ Sci 13:351–360

AOAC (Association of Official Analytical Chemists) (1990) Official methods of analysis, vol 1, 15th edn. Arlington, Virginia, p 247

Bakircioglu D, Kurtulus YB, Ucar G (2011) Determination of some trace metal levels in cheese samples packed in plastic and tin containers by ICP-OES after dry, wet and microwave digestion. Food Chem Toxicol 49:202–207

Barker WH, Runte V (1972) Tomato juice-associated gastroenteritis. Am J Epidemiol 96:219–226

Castro-González MI, Méndez-Armenta M (2008) Heavy metals: implications associated to fish consumption. Environ Toxicol Pharmacol 26:263–271

Cunningham WP, Saigo BW (1997) Environmental science, a global concern, 4th edn. WMC Brown Publisher, New York

Dudka S, Miller P (1999) Accumulation of potentially toxic elements in plants and their transfer to human food chain. J Environ Sci Health B 34:681–708

EC (European Commission) (2001) Commission regulation (EC) No. 466/2001 setting maximum limits for certain contaminants in foodstuffs. Off J Eur Commun 16/03/01:77/1–77/12

EC (European Commission) (2002) Commission regulation (EC) No. 221/2002 of 6 Feb 2002 amending regulation (EC) No. 466/2001 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Commun L 37/4

EC (European Commission) (2006) Commission regulation No. 1881/2006 of 19 Dec 2006 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Union L 364/5

ES (Egyptian Standards) (2010) Maximum levels for certain contaminants in foodstuffs. Egyptian Organization for Standardization. ES, No. 7136, Cairo

FAO (Food and Agricultural Organization) (1983) Hazardous substance in fish and fishery products. FAO Fishery circular No. 464, pp 5–100

FDA (Food and Drug Administration) (2013) Recommendation of the United States Public Health Service, College Park

Foster JJ (2001) Data analysis using SPSS for windows: a beginner’s guide, 2nd edn. London Sage, London

Hassan ARHA, Zeinhom MM, Abdel-Wahab MA, Tolba MH (2015) Heavy metal dietary intake and potential health risks for university hostel students. Biol Trace Elem Res. doi:10.1007/s12011-015-0451-z

Ihedioha JN, Okoye COB (2012) Cadmium and lead levels in muscle and edible offal of cow reared in Nigeria. Bull Environ Contam Toxicol 88:422–427

Järup L (2003) Hazards of heavy metal contamination. Br Med Bull 68:167–182

JECFA (Joint FAO/WHO Expert Committee on Food Additives) (2000) Evaluation of certain food additives and contaminants. Fifty-three report of joint FAO/WHO expert committee on food additives. In: WHO technical report series 896. World Health Organization, Geneva

JECFA (2006) Evaluation of certain food contaminants. Sixty-four report of joint FAO/WHO expert committee on food additives. In: WHO technical report series 930. World Health Organization, Geneva

Kocak S, Tokusoglu O, Aycan S (2005) Some heavy metals and trace essential detection in canned vegetable foodstuffs by differential pulse polarography. Electron J Environ Agric Food Chem 4:871–878

Landis WG, Ming-Ho Yu (2004) Introduction to environmental toxicology; impacts of chemicals upon ecological system. Lewis Publishers, CRC Press, LLC, New York, pp 221–223

López-Alonso M, Benedito JL, Miranda M, Castillo C, Hernández J, Shore RF (2000) Arsenic, cadmium, lead, copper and zinc in cattle from Galicia, NW Spain. Sci Total Environ 246:237–248

Maggi E, Bracchi GP, Campanini G, Dazzi G, Madarena G (1979) Mercury, chromium, lead and organochlorine pesticide residues in some food products of animal origin: a review. Meat Sci 3:309–319

McLaughlin MJ, Parker DR, Clarke JM (1999) Metals and micronutrients—food safety issues. Field Crops Res 60:143–163

Ministry of Health ESR (1995) 1990/1991 New Zealand Total Diet Study, contaminant elements, report FW95/7

Mol S (2011) Determination of trace metals in canned anchovies and canned rainbow trouts. Food Chem Toxicol 49:348–351

Morgan JN (1999) Effects of processing on heavy metal content of foods. Adv Exp Med Biol 459:195–211

Müller M, Anke M, Hartmann E, Illing-Günther H (1996) Oral cadmium exposure of adults in Germany. 1. Cadmium content of foodstuffs and beverages. Food Addit Contamin 13:359–378

Pullen MM (1990) Residues. In: Pearson AM, Dutson TR (ed) Meat and health (advances in meat research), vol 6. Elsevier, Amsterdam pp 135–145

Rashad M, Darwish KhM, Abdel Salam HE, Shalaby EA (2013) Environmental monitoring of mercury in urban soils, air and plants of a Mediterranean area, Alexandria, Egypt. Int J Energy Environ 4:311–320

Sedgwick LW (1888) Noxious salts of tin in fruits prepared in tin vessels. Lancet 131:1129

Storelli MM, Barone G, Cuttone G, Giungato D, Garofalo R (2010) Occurrence of toxic metals (Hg, Cd, and Pb) in fresh and canned tuna: public health implications. Food Chem Toxicol 48:3167–3170

Tsoumbaris P (1990) Heavy metals determination in foodstuff. Dissertation, University of Thessalonica, Greece

Vieira C, Morais S, Ramos S, Delerue-Matos C, Oliveira MBPP (2011) Mercury, cadmium, lead and arsenic levels in three pelagic fish species from the Atlantic Ocean: intra- and inter-specific variability and human health risks for consumption. Food Chem Toxicol 49:923–932

WHO (1992) Cadmium. In: Environmental health criteria, vol 134. World Health Organization, Geneva

Zantopoulos N, Antoniou V, Petsaga V, Zdrags A (1996) Copper concentration in sheep liver and kidney in Greece. Vet Human Toxicol 38:184–185

Zarski TP, Zarska H, Samek M, Siluk I (1997) Mercury contamination of the tissues of cattle from various regions of Poland (Warsaw Agricultural University Press). Vet Med 20:107–111

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalafalla, F.A., Ali, F.H.M., Hassan, AR.H.A. et al. Residues of lead, cadmium, mercury and tin in canned meat products from Egypt: an emphasis on permissible limits and sources of contamination. J. Verbr. Lebensm. 11, 137–143 (2016). https://doi.org/10.1007/s00003-016-1020-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-016-1020-x