Abstract

The objective of this study was to investigate Listeria monocytogenes adhesion in new and used polyethylene cutting board surfaces and evaluate its removal using different sanitizers (peracetic acid, chlorhexidine, sodium hypochlorite and organic acids). Results showed that the number of adhered cells increased with time on both surfaces evaluated. Statistically significant differences (p < 0.05) between new and used polyethylene surfaces were observed on the adhesion of microorganism. Treatments with the peracetic acid and sodium hypochlorite sanitizers were very effective to inactivate attached L. monocytogenes on the polyethylene cutting board, avoiding the possible formation of biofilms at all contact times studied. Other sanitizers did not succeed in inhibiting completely the pathogen in the maximum concentration (2.0 %) after 24 h of bacterial growth for both surfaces (chlorohexidine), 3 h of bacterial growth on new and 6 h on used surfaces (organic acid). The results indicate that peracetic acid and a sodium hypochlorite treatment present a better method to remove microbial contamination on the surfaces of cutting boards.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Technologic and scientific advancements have been used by the food industry in the past to improve product safety. Despite this, foodborne diseases continue to present an unacceptable public health risk due to ingestion of food contaminated with pathogenic microorganisms. Bacterial biofilms are generally described as bacterial communities deposited on and attaching to surfaces forming microcolonies surrounded by a matrix of exopolymers (Ölmez and Temur 2010; Srey et al. 2013). They become a problem in food industries as they render their inhabitants tolerant to antimicrobial agents and cleaning, besides causing deterioration, loss of quality or transmission of pathogens.

The protective nature of biofilms impedes the efficacy of sanitizing treatments, thus the use of efficient and adequate physical or chemical sanitizers is necessary to prevent biofilm formation and/or reduce microbial contamination.

L. monocytogenes is widely distributed in nature and is often found in meat products. It is mainly transmitted to humans through food. This pathogen is capable of causing gastroenteritis and severe systemic infection or abortion. It tolerates high salt concentrations (up to 30 %), grows at pH values below 5.0 and is able to multiply at temperatures below 0 °C and in environments with reduced water activity (Gandhi and Chikindas 2007). These bacteria are well equipped to survive and grow in floors, drains and equipment in food processing environments, especially in cold and wet refrigerated rooms (Carpentier and Cerf 2011).

Different groups of chemical disinfectants are used by the food industry to eliminate bacteria associated with the contact surfaces and the hands of manipulators. The efficacy of sanitizers is generally higher against planktonic cells (cells in suspension) than against cells present in biofilms. Bacterial cells that attach to inert surfaces and are periodically exposed to a sanitizing agent can develop decreased sensitivity or tolerance to this agent (Beltrame et al. 2013; Riazi and Matthews 2011). Disinfection using the commercial recommended doses sometimes does not eliminate bacteria in the expected levels, which may result in critical hazards to the health of consumers. Therefore, more studies analyzing the bactericidal properties of disinfectants at different concentrations and against different microbial densities are required to establish guidelines for their application.

The aim of this study was to investigate the adherence of L. monocytogenes ATCC 7644 on cutting board surfaces and to compare the effect of peracetic acid, chlorhexidine, sodium hypochlorite and organic acid treatments on these bacteria. For each sanitizer tested, different concentrations were evaluated over 72 h, determining the total count on new and used polyethylene cutting boards, before and after the application of the sanitizer.

2 Materials and methods

2.1 Preparation of the polyethylene coupons

In this study coupons of white high-density polyethylene (type HDPE plastic, 1.0 cm by 1.0 cm, new or used for around 2 months) were prepared as described (Parizzi 1999). The coupons were first autoclaved (121 °C for 30 min) to inactivate spores and microbial flora. Subsequently, they were cleaned by brushing employing liquid detergent and water and rinsed with distilled water. Next, they were immersed in 70 % ethanol for 1 h for fat removal and again rinsed with distilled water. Washed coupons were dried and then exposed to ultraviolet light of a wavelength of 254 nm for 1 h to sanitize.

2.2 Bacterial strain and suspension culture

The strain of L. monocytogenes (ATCC 7644) was obtained from the Biotechnology laboratory library strains (URI Erechim, Brazil). Stock cultures were stored at −80 °C in 0.7 mL of tryptic soy broth (TSB; Difco, Becton–Dickinson, Sparks, MD, USA) and 0.3 mL of 50 % glycerol. The strain was cultured in Luria–Bertani broth—LB (tryptone 10.0 g/L, yeast extract 5.0 g/L, NaCl 5.0 g/L) and incubated at 30 °C for 24 h.

2.3 Sanitizers

Four types of sanitizers commonly used in the food industry were used in this study: peracetic acid (15 % w/v, Johnson Diversey, São Paulo-SP, Brazil), chlorohexidine (20 % w/v, AD Foods Indústria de Produtos Alimentícios Ltda, Laguna-SC, Brazil), sodium hypochlorite (10 % w/v, CSM Produtos Químicos Ltda, Chapecó-SC, Brazil) and organic acids (formulated with lactic acid 30 %, citric acid 3 %, ascorbic acid 3 %, and salts of fatty acids 7 % in water, AD Foods Indústria de Produtos Alimentícios Ltda, Laguna-SC, Brazil). The sanitizer solutions were prepared in sterilized distilled water immediately prior to testing, according to the suppliers’ instructions.

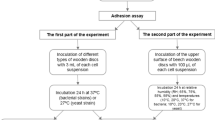

2.4 Effect of the incubation time on L. monocytogenes adhering to the surface

Sterile polyethylene coupons (new and used) were transferred to conical tubes, containing 100 mL of LB supplemented with a suspension of bacterial cells, in order to obtain a count of 103 CFU/mL (CFU, colony forming units). Inoculated coupons were incubated at 35–37 °C and examined at 0.1, 1, 3, 6, 12, 24, 48, and 72 h to assess the adhesion levels of pathogens. At each time point, a coupon was removed from the tube and immersed separately in 10 mL of 0.1 % peptone water for 1 min to remove planktonic cells. Subsequently, it was immersed in a tube containing 5 mL of the same diluent solution and vortexed for 1 min to remove sessile cells (Parizzi 1999). Then, the coupons were dried in a laminar flow biosafety cabinet for 2 h with the fan running before counting surviving pathogens.

2.5 Efficacy of chemical sanitizer treatment

All chemicals were prepared immediately before each experiment and were used within 30 min. Coupons inoculated in a suspension of bacterial cells with a concentration of 103 CFU/mL were prepared as detailed in Sect. 2.4 and bacteria were counted as described in Sect. 2.6. Then, coupons were transferred to one tube with the respective sanitizer solution of the concentration desired (0.2, 0.5, 0.8 and 2.0 %) of peracetic acid, chlorhexidine, sodium hypochlorite and organic acids and incubated for 10 min at 25 °C and held at 25 °C, to evaluate their efficiency against bacteria attached.

2.6 Bacterial count

Bacteria were counted as previously described (Kim et al. 2008) with adaptations. The bacterial adhesion counts were carried out using swabs on cutting boards which were transferred to tubes with diluent solution (0.1 % peptone and 3.0 % tween 80 in water). Tween 80 was added to remove residual disinfectants and to neutralize components. After vortexing, aliquots (1 mL) of sample were diluted ten-fold in 9 mL of sterile buffered peptone water (Merck) and 0.1 mL of sample and diluents was plated onto LB agar (Merck) in duplicate. All plates were incubated at 35–37 °C for 24 h, and then colonies were counted.

2.7 Scanning electron microscopy (SEM) of new and used surfaces

The new and used surfaces (1.0 cm by 1.0 cm) with and without bacterial attachment were post-fixed for an additional 2 h with 1 % osmium tetroxide in 0.05 M sodium cacodylate buffer. After fixation, coupons were dehydrated with an ethanol series (30–100 %) and dried twice with hexamethyldisilazane for 15 min. The dried samples were mounted on specimen stubs and sputter coated with gold in a sputtering unit (Sputter Coater POLARON, SC7620, VG Microtech, UK) with a thickness of around 92 Å. Digital images were collected with SEM/EDS (Leo 440i/6070, Cambridge, England).

2.8 Statistical analysis

All experiments were run in triplicate and repeated three separate times. Data were analyzed using standard analysis of variance (ANOVA), with p < 0.05 set as the level of statistical significance and using Statistica 8.0 software (StatSoft Inc®, USA) for analysis.

3 Results and discussion

3.1 Adherence on new and used coupons of polyethylene at different time points

The data in Fig. 1 show the growth of L. monocytogenes on new and used cutting boards during 72 h at 25 °C. The experimental conditions used resulted in a maximum count of 6.92 and 6.11 log10 CFU/cm2 on used and new surfaces, respectively. As demonstrated in Fig. 1, used coupons showed a significant difference (p < 0.05) in the intensity of adhesion compared with new surfaces, which indicates that used coupons are more prone to bacterial colonization. According to Teixeira et al. (2008), this increase in adhesion may be due to the protection against shear forces offered to the cells by microscopic niches. Furthermore, it is important to emphasize that the used surfaces may be rougher, which facilitates adhesion of microorganisms and impairs hygiene and cleaning procedures. Several studies showed that increasingly rough surfaces will cause a corresponding increase in microbial retention contributing to the adhesion of L. monocytogenes (Palmer et al. 2007; Rodriguez et al. 2008; Sinde and Carballo 2000; Teixeira et al. 2008).

Populations (log10 CFU/cm2) of L. monocytogenes on new and used surfaces of polyethylene coupons depending on time. All experiments were run in triplicate and repeated three separate times. Mean values and standard deviations (error bars) for each time point tested are indicated. Time points for which differences in population growth were statistically significant are marked by a * (p < 0.05)

3.2 Survival of L. monocytogenes on polyethylene coupons after chemical sanitizer treatment

Figure 2 shows the L. monocytogenes survival on new and used polyethylene coupons after treatment with different chemical sanitizers. The count of L. monocytogenes before sanitizer treatment was around 6 log10 CFU/cm2.

Survival numbers (log10 CFU/cm2) of L. monocytogenes adhering to new and used surfaces of polyethylene coupons after treatment with peracetic acid (a), chlorhexidine (b), organic acid (c) and sodium hypochlorite (d). Sanitizer concentrations are indicated in the top left of each panel. All experiments were run in triplicate and repeated three separate times. Mean values and standard deviations (error bars) are indicated

The supplier recommends a concentration of 0.5 % as appropriate for the hygienization of surfaces in contact with food. In the present study, it was observed that this recommendation was confirmed after 3 h of bacterial growth. The best efficiencies were observed with peracetic acid, chlorhexidine and sodium hypochlorite, which completely kill populations of adhered L. monocytogenes on new surfaces, while organic acids only reduced the colonization by 1 log10 levelof the initial counting (Fig. 2).

Under our experimental conditions, peracetic acid was the best sanitizer to inhibit growth of L. monocytogenes. It reduced bacterial growth at least around 3 log10 levels on new and used coupons, which corroborates with results from Bloomfield and Scott (1997). The authors considered the sanitizer to be able to reduce the population by 3 log10 levels.

According to Srey et al. (2013), peracetic acid has certain advantages over other sanitizers, since it does not react with proteins to produce toxic or carcinogenic compounds, has low environmental impact and prevents the biofilms formation. Rossoni and Gaylarde (2000) showed that peracetic acid in a concentration of 250 mg/L proved to be effective against E. coli and Pseudomonas fluorescens reducing the number of adhering cells by 90 %. On the other hand, at the same experimental conditions, the colonization by S. aureus was reduced by 50 %. However, an increase to 90 % was observed when using a sanitizer concentration of 1.000 mg/L.

Similar efficacy levels have been reported by Martín-Espada et al. (2014), who observed that peracetic acid is effective against P. aeruginosa biofilms formed on polystyrene surfaces, inhibiting almost 100 % of the microbial population, during 15 min, using a sanitizer concentration of 1.61 %.

In a study performed by Briñez et al. (2006), the authors evaluated the bactericidal efficacy of peracetic acid in combination with hydrogen peroxide against pathogenic and non pathogenic strains of Staphylococcus spp., Listeria spp. and E. coli, and verified that the combination was effective (reductions of >5 log10 CFU/mL) at concentrations from 0.1 % and 10 min of exposure in all cases. Aarnisalo et al. (2007) evaluated the disinfecting efficacy of sodium hypochlorite against 10 strains of L. monocytogenes and showed that this disinfectant was not efficient in the suspension.

The organic acid sanitizer showed a low efficiency in inactivating adhering pathogens, even at a high concentration (2 %), after 6 h of bacterial growth on both surfaces (Fig. 2). Similar results were shown by Van Netten et al. (1994), who studied the bactericidal effect of lactic acid decontamination on meat-borne pathogens (Salmonella spp. and L. monocytogenes) for 30–90 s. The treatment with 2 % lactic acid was suitable for elimination of Salmonella on meat but not for L. monocytogenes.

In this way, the use of peracetic acid at appropriate concentrations should prove efficacious for control of L. monocytogenes and limit development of decreased susceptibility or tolerance.

3.3 SEM observations

Scanning electronic microscopy (SEM) was used to observe new and used coupons. Surfaces were sanitized only with peracetic acid taking into account its performance in the reduction of L. monocytogenes. From the SEM images it can be determined that on both coupons without L. monocytogenes exposure cells were absent on the surfaces (Fig. 3a, b). After 72 h of contact, few bacterial cells were adhering to the surface and were distributed regularly (Fig. 4a, b).

Similar results were observed by Kalmokoff et al. (2001), who studied biofilm formation by different strains of L. monocytogenes on stainless steel surfaces. After 72 h of contact with the surface at 21 °C, the authors observed that the strains adhered uniformly to the surface, forming few cellular groupings.

Used surfaces showed irregularities that can negatively influence the cleanability and increase susceptibility to bacterial attachment (Fig. 4b), since bacterial adhesion results from the interplay of forces including van der Waals, electrostatic, and hydrophobic interactions (Boks et al. 2008). Beresford et al. (2001) and Teixeira et al. (2008) studied the adherence of L. monocytogenes to several surfaces such as polypropylene and metals, and observed that the extent of adhesion was higher on polypropylene, which presents more irregularities. This adhesion occurs due the higher roughness and differences in the topography. In the present work, this increase in irregularity of new (Figs. 3a, 4a) to used surfaces (Figs. 3b, 4b) also was observed, which can hinder the sanitization treatments to remove and/or completely inactivate the microorganisms and indicate the possibility for microbial growth or serve as a contamination source (Brilhante São José and Dantas Vanetti 2012). This suggests that pathogens can persist in protected sites on the surface and that thus removal is more difficult.

4 Conclusion

L. monocytogenes was able to adhere to used and new polypropylene surfaces, achieving counts of 6.92 and 6.11 log10 CFU/cm2, respectively, differing statistically. Peracetic acid treatment was identified to be the most effective method of L. monocytogenes removal on cutting boards at all microbial densities evaluated. Microorganisms were not completely removed from polyethylene surfaces after treatment with 2.0 % organic acid and chlorhexidine. This information is of special importance to improve the efficacy of inactivation of L. monocytogenes and thus, to advance product safety.

References

Aarnisalo K, Lundén J, Korkeala H, Wirtanen G (2007) Susceptibility of Listeria monocytogenes strains to disinfectants and chlorinated alkaline cleaners at cold temperatures. LWT Food Sci Technol 40:1041–1048. doi:10.1016/j.lwt.2006.07.009

Beltrame CA et al (2013) Comparative lethality kinetic curves and predictive models of F-value for Listeria monocytogenes using different sanitizers. Food Sci Nutr 1:27–31. doi:10.1002/fsn3.5

Beresford MR, Andrew PW, Shama G (2001) Listeria monocytogenes adheres to many materials found in food-processing environments. J Appl Microbiol 90:1000–1005

Bloomfield SF, Scott E (1997) Cross-contamination and infection in the domestic environment and the role of chemical disinfectants. J Appl Microbiol 83:1–9. doi:10.1046/j.1365-2672.1997.00199.x

Boks NP, Norde W, van der Mei HC, Busscher HJ (2008) Forces involved in bacterial adhesion to hydrophilic and hydrophobic surfaces. Microbiology 154:3122–3133. doi:10.1099/mic.0.2008/018622-0

Brilhante São José JF, Dantas Vanetti MC (2012) Effect of ultrasound and commercial sanitizers in removing natural contaminants and Salmonella enterica Typhimurium on cherry tomatoes. Food Control 24:95–99. doi:10.1016/j.foodcont.2011.09.008

Briñez WJ, Roig-Sagués AX, Hernández Herrero MM, López-Pedemonte T, Guamis B (2006) Bactericidal efficacy of peracetic acid in combination with hydrogen peroxide against pathogenic and non pathogenic strains of Staphylococcus spp., Listeria spp. and Escherichia coli. Food Control 17:516–521. doi:10.1016/j.foodcont.2005.02.014

Carpentier B, Cerf O (2011) Review-Persistence of Listeria monocytogenes in food industry equipment and premises. Int J Food Microbiol 145:1–8. doi:10.1016/j.ijfoodmicro.2011.01.005

Gandhi M, Chikindas ML (2007) Listeria: a foodborne pathogen that knows how to survive. Int J Food Microbiol 113:1–15. doi:10.1016/j.ijfoodmicro.2006.07.008

Kalmokoff ML, Austin JW, Wan XD, Sanders G, Banerjee S, Farber JM (2001) Adsorption, attachment and biofilm formation among isolates of Listeria monocytogenes using model conditions. J Appl Microbiol 91:725–734

Kim H, Bang J, Beuchat LR, Ryu JH (2008) Fate of Enterobacter sakazakii attached to or in biofilms on stainless steel upon exposure to various temperatures or relative humidities. J Food Prot 71:940–945

Martín-Espada MC, D’Ors A, Bartolomé MC, Pereira M, Sánchez-Fortún S (2014) Peracetic acid disinfectant efficacy against Pseudomonas aeruginosa biofilms on polystyrene surfaces and comparison between methods to measure it. LWT Food Sci Technol 56:58–61. doi:10.1016/j.lwt.2013.11.013

Ölmez H, Temur SD (2010) Effects of different sanitizing treatments on biofilms and attachment of Escherichia coli and Listeria monocytogenes on green leaf lettuce. LWT Food Sci Technol 43:964–970. doi:10.1016/j.lwt.2010.02.005

Palmer J, Flint S, Brooks J (2007) Bacterial cell attachment, the beginning of a biofilm. J Ind Microbiol Biotechnol 34:577–588. doi:10.1007/s10295-007-0234-4

Parizzi SQF (1999) Adesão bacteriana em diferentes superfícies avaliada pela microscopia de epifluorescência e contagem em placas. Dissertation, Federal University of Viçosa

Riazi S, Matthews KR (2011) Failure of foodborne pathogens to develop resistance to sanitizers following repeated exposure to common sanitizers. Int Biodeterior Biodegrad 65:374–378. doi:10.1016/j.ibiod.2010.12.001

Rodriguez A, Autio WR, McLandsborough LA (2008) Effect of surface roughness and stainless steel finish on Listeria monocytogenes attachment and biofilm formation. J Food Prot 71:170–175

Rossoni EMM, Gaylarde CC (2000) Comparison of sodium hypochlorite and peracetic acid as sanitising agents for stainless steel food processing surfaces using epifluorescence microscopy. Int J Food Microbiol 61:81–85. doi:10.1016/S0168-1605(00)00369-X

Sinde E, Carballo J (2000) Attachment of Salmonella spp. and Listeria monocytogenes to stainless steel, rubber and polytetrafluorethylene: the influence of free energy and the effect of commercial sanitizers. Food Microbiol 17:439–447. doi:10.1006/fmic.2000.0339

Srey S, Jahid IK, Ha SD (2013) Biofilm formation in food industries: a food safety concern. Food Control 31:572–585. doi:10.1016/j.foodcont.2012.12.001

Teixeira P, Lima J, Azeredo J, Oliveira RM (2008) Adhesion of Listeria monocytogenes to materials commonly found in domestic kitchens. Int J Food Sci Technol 43:1239–1244

Van Netten P, Huis in’t Veld JH, Mossel DA (1994) The immediate bactericidal effect of lactic acid on meat-borne pathogens. J Appl Bacteriol 77:490–496

Acknowledgments

The authors thank CNPq, CAPES, FAPERGS, Science and Technology Secretary RS and URI-Erechim for the financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beltrame, C.A., Martelo, E.B., Mesquita, R.A. et al. Adhesion of Listeria monocytogenes to cutting board surfaces and removal by different sanitizers. J. Verbr. Lebensm. 10, 41–47 (2015). https://doi.org/10.1007/s00003-014-0923-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-014-0923-7