Abstract

Population growth increases the demand for food and thus leads to expansion of cultivated land and intensification of agricultural production. There is a definite limit to both of these options for food security and their multiple negative effects on the environment undermine the aim for sustainability. Presently the impact of the Green Revolution on crop production is levelling off at high yields attained and even the potential of large scale irrigation programmes and transgenic crops seem to be limited in view of the expected increase in demand for food. Moreover, climate change threatens to affect agricultural production across the globe. Skyfarming represents a promising approach for food production that is largely environment independent and therefore immune to climate change. Optimal growing conditions, shielded from weather extremes and pests are aimed at raising plant production towards the physiological potential. Selecting rice as a pioneer crop for Skyfarming will not only provide a staple for a large part of the global population, but also significantly reduce the greenhouse gas emission caused by paddy cultivation. Multiplication of the benefits could be achieved by stacking production floors vertically. In Skyfarming the crop, with its requirements for optimal growth, development and production, determines the system’s design. Accordingly, the initial development must focus on the growing environment, lighting, temperature, humidity regulation and plant protection strategies as well as on the overall energy supply. For each of these areas potentially suitable technologies are presented and discussed.

Zusammenfassung

Der steigende Bedarf an Nahrungsmitteln infolge einer weiterhin exponentiell wachsenden Weltbevölkerung erfordert enorme Anstrengungen seitens der Agrarwirtschaft, die bislang mit Ausdehnung der Anbauflächen und mit Intensivierung der landwirtschaftlichen Produktion reagierte. Beiden Optionen zur Sicherung der Welternährung sind physische und biologische Grenzen gesetzt und die landwirtschaftlichen Aktivitäten führen ihrerseits zu mannigfaltigen Umweltwirkungen, die die ökologische Tragfähigkeit der Erde mindern können. Durch die Grüne Revolution konnte ein rasanter Anstieg der Nahrungsmittelproduktion erreicht werden, jedoch ist in einigen Regionen das Ertragspotential bestimmter Feldfrüchte nahezu erreicht und die Erwirtschaftung zusätzlicher Ertragssteigerungen wird zunehmend schwieriger. Auch der mögliche Beitrag von Bewässerungsprogrammen und seitens genetisch veränderter Varietäten scheint angesichts des zu erwartenden Anstiegs beim Nahrungsmittelbedarf begrenzt. Darüber hinaus sind negative Auswirkungen des Klimawandels auf die landwirtschaftliche Produktion zu erwarten. Skyfarming ist ein Ansatz zur weitgehend umwelt- und somit klimaunabhängigen Nahrungsmittelproduktion im Hochhaus. Unter optimalen Wachstumsbedingungen, geschützt vor Wetterextremen und Schadorganismen soll das physiologische Produktionspotential der Pflanzen weitestgehend ausgeschöpft werden. Mit Reis als Modellpflanze für Skyfarming wird einerseits ein wichtiges Grundnahrungsmittel bereitgestellt und andererseits die Möglichkeit eröffnet die durch den Naßreisanbau verursachte Emissionen klimarelevanter Gase signifikant zu reduzieren. Eine Vervielfachung des Ertrages ließe sich durch die vertikale Anordnung mehrerer Produktionsebenen erreichen. Bei Skyfarming steht die Kulturpflanze, mit ihren spezifischen Ansprüchen für optimale Entwicklung und Wachstum im Vordergrund eines systemischen Ansatzes. Dementsprechend muss der Fokus zu Beginn der Technologieentwicklung auf folgende Bereiche gerichtet sein: Wachstumsraum, Beleuchtung, Temperatur, Luftfeuchteregulierung, Pflanzenschutzstrategien, sowie – übergeordnet – Energieversorgung. Für jeden dieser Bereiche werden entsprechende Technologien vorgestellt und diskutiert.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The onset of agriculture around 10,000–12,000 years ago was one of the strongest cataclysms for development in human history. Limited availability of natural food resources, either due to environmental changes (e.g. Sage 1995) or overexploitation (Cohen 1977), forced hunter-gatherers to domesticate crops and in consequence to become sedentary. This radical change in life-style required a significantly higher degree of organization and laid the foundation for emerging civilization. Since then, the largest part of the diet of the global population is based on agricultural products. Nonetheless, agriculture fails where intense exploitation of a relatively small area of land is constrained by the natural environment (e.g. Arctic regions) or due to exhaustion of resources (e.g. loss of top soil). The latter is believed to have caused the collapse of entire civilisations in the past (Diamond 2005). However, judged by the growth of the global population and improvement in average standard of living, agriculture has been a very successful food supply strategy.

It took more than 150,000 years before modern man started cultivating crops (White et al. 2003), but later another developmental leap was needed to satisfy the food demand of the ever growing population. The Green Revolution combining advances in research, development, and technology transfer triggered a massive production increase, but also paved the way for the subsequent population explosion. Projections based on population development indicate the threat of substantial food shortage largely due to limited land, water and nutrient availability. This link between population growth and food production can only be broken by exercising stringent population control (Ehrlich et al. 1997), but even with the immediate global adoption of such policy it would take more than half a century before the world population finally stabilized (Weeks 2007). Yield reductions anticipated as a consequence of climate change (Reynolds 2010) further aggravate food insecurity. Agronomists are therefore obliged to intensify their search for new methods and technologies for sustainable food production, increasing resource efficiency, and protecting the remaining natural ecosystems and resources.

This paper aims (a) to provide an overview of the production limitations of conventional agriculture, (b) to present ‘Skyfarming’ as an alternative crop production system and (c) to give an overview of the most pressing research tasks towards a prototype.

2 Is a novel approach to crop production needed?

Crop production is the product of the area cultivated multiplied by yield. The potential of conventional crop production can be evaluated by varying these two parameters within their natural boundaries. Production potential and demographic trends will determine if the food demand in the coming decades can be satisfied.

2.1 Population growth and cereal demand

Prior to the discovery of agriculture, between 2 and 20 million people inhabited our planet (Cohen 1997). At the beginning of the nineteenth century the global population increased to more than one billion and numbered three billion in the year 1960. With a further doubling in the subsequent 40 years, global population nearly quadrupled within the twentieth century alone. According to the United Nations estimates, the world population of currently 6.9 billion will increase by an additional 1–3 billion until 2045, even if a significant reduction in fertility is assumed (UNPP 2009). In addition to food demand linearly increasing with population growth, higher food and especially meat consumption is often interlinked with societal development and increases in prosperity (Lakdawalla et al. 2005; Schroeder et al. 1996). The effects of urbanisation and technical advancements in food production and consumption are very complex (Stuart 2009), but it seems that food wastage per capita has been slightly reduced in recent decades (Thøgersen 1996). Nonetheless, and despite the fact that globally food production kept pace with population growth until today, about one billion people are currently under- or malnourished in developing countries. Food production often lagging behind population growth regionally has been the primary reason for this. In Africa, Asia and Latin America the problem is frequently aggravated by social and political instability as well as natural disasters (e.g. droughts, floods).

Cereal grains are the most important staple of all human food items. The FAO estimates that the annual world cereal production, which at the end of the 1990s amounted to 1.9 billion tonnes, must be increased by 50% to 2.8 billion tonnes by 2030 (Bruinsma 2003). This prognosis is based on the assumption that in 2030 about 8.3 billion people will live on Earth, which corresponds to the medium fertility variant of predictions by the United Nations (Fig. 1).

Population of the world, 2000–2050, by UN projection variants [data source: United Nation Population Division (UNPP 2009)]

Aside from the size of the population, people’s behaviour also determines the amount of cereals that are needed for food supply. Meat-based diets require more energy, land, and water resources than a predominantly vegetarian diet (Pimentel and Pimentel 2003). Currently, about 43% of the global maize and wheat production are used for feed. A reduced feed demand has therefore a considerable potential to increase food security, but forecasts indicate that global meat consumption will grow by one third within the next decade (Edgerton 2009). A more careful and preserving way of handling and using agricultural products could also significantly reduce the demand. It is estimated that post-harvest losses account for 10–40% of global yields (Oerke and Dehne 2004). This calls for improvements in harvest, process, transport and storage technologies. In addition, educational programmes could reduce wastage of prepared food. Estimates for the developed word indicate that 5–10% of the food is wasted at the household level (Nellemann et al. 2009).

2.2 Crop production

Conventional agriculture in general has two options for meeting the increasing demand for food: expanding the area and intensifying production. The limit is reached when all land suitable for agriculture is cropped and the potential yield for each crop is attained.

2.2.1 Expansion of the production area

Until the mid-twentieth century the growing demand for agricultural products was predominantly met through expansion of the areas under cultivation. Despite the exponential population growth the cropped area increased only 11% in the past four decades (FAO 2011). Thus, the land cultivated per person decreased by 40% from 4,300 to 2,600 m2. The only region that deviates from this trend is Sub-Saharan Africa where the increase of agricultural production is still largely based on the conversion of natural ecosystems into arable land (Fig. 2). However, there is still land remaining with potential for conversion in most regions. In South America and some parts of Africa south of the Sahara only about 20% of the land suitable for rain-fed agriculture is used for crop production so far. Significantly less land is available for conversion in South Asia, Africa north of the Sahara, and the Near East where about 90% of the potentially arable land is already under cultivation.

Contribution of area expansion and intensification to increase of the global cereal production in comparison to that of Africa [data source: Food and Agriculture Organization of the United Nations (FAO 2011)]

Land use change from natural ecosystems to agriculture leads to secondary effects that are likely to reduce the Earth’s human carrying capacity. More than half the land that could be taken additionally into agricultural use is covered by forest or designated for its nature conservation value. Conversion of this land results in loss of natural ecosystems and, primarily in the tropics, in an accelerated decline of biodiversity and ecosystem services (Ter Steege 2010). In view of the importance of biodiversity for sustainability (O’Riordan and Stoll-Kleemann 2002) it is highly questionably as to whether the responsibility can be taken for a further sacrifice of species, if we convert even more natural ecosystems for food production. In addition, expansion of agricultural land has a severe impact on the global greenhouse gas balance (Despommier 2010). Emissions caused by land-use change are especially high, if carbon-rich soils are converted (Germer and Sauerborn 2008) as attempted in the Indonesian Mega-Rice-Project. Furthermore, large shares of land reserves could only be productively cultivated at high expense, because they are often nutrient-poor and commonly located on steep slopes or otherwise less suitable marginal land.

2.2.2 Intensification of production

In the second half of the twentieth century the world’s arable area expanded far less than the population grew, while per capita food production increased. The agricultural area required to achieve a unit of produce in the early 1960s was lowered by 56% by the late 1990s (Bruinsma 2003). A major component of this Green Revolution was the breeding programme including the three most important cereals (rice, wheat and maize) towards an increased harvest index. The cultivation of these highly productive varieties required higher fertiliser and pesticide inputs, which in turn again raised agricultural productivity. From 1960 to 1990 the global use of mineral fertiliser grew sevenfold (Tilman 1998) causing frequent eutrophication of surface waters, pollution of groundwater, increased greenhouse gas emissions and other environmental implications. Moreover, phosphorus is a resource of limited availability and its supply from mined phosphate rock could ‘peak’ as soon as 2030 (Cordell et al. 2009; Gilbert 2009), but no strategies exist as to how to produce food with significantly less phosphorus.

At the beginning of this century the improved varieties were grown in Asia and Latin America on more than 80% of the wheat area and on more than 60% of the rice area (Evenson and Gollin 2003). While the Asian wheat production was doubled between 1970 and 1995, the Green Revolution had limited success in Sub-Saharan Africa. Reasons for this are found in unfavourable environmental conditions for the high-yielding varieties, limited possibilities for irrigation and poor availability of fertilizers. The latter are needed in particularly large quantities due to the fact that most soils in the region are inherently nutrient-poor (Grenz and Sauerborn 2007). Since the 1990s efforts have been made to breed higher yielding varieties that are well adapted to marginal sites and low input agriculture. Thus, both breeding and fertilisation programmes still have considerable potential to increase food production, especially where the Green Revolution has had little success so far. Beyond these programmes, irrigation and the use of genetically modified plants are the single most promising strategies to increase yields.

2.2.2.1 Irrigation

Irrigated agriculture comprises less than one-fifth of the cropped area, but produces about two-fifths of the world’s food. At the same time, irrigation accounts for about 70% of the global water withdrawals and for about 90% of the global consumptive water use (Döll 2010). In many places irrigation has caused falling groundwater tables, induced water scarcity and is a major cause of soil salinity. It is estimated that 20–50% of irrigated land worldwide is already salt-affected (Pitman and Läuchli 2004). Nonetheless, well adapted water management in rain-fed agriculture, including water harvesting and vapour shift techniques, are thought to be capable of increasing global crop production by almost 20% (Rost et al. 2009).

2.2.2.2 Genetically modified crops

Great expectations are tied to transgenic crops, but the quantitative effects of genetic engineering on crop production and yields has not been analyzed yet (Giger et al. 2009) and it is therefore difficult to estimate the future potential of genetic engineering for food security. Currently, about 92% of production areas of transgenic crops are located in the USA, Brazil, Argentina, India and Canada. The production is essentially limited to varieties of soybean, maize, cotton and rapeseed made resistant to certain herbicides and/or certain insects (Clive 2009). These plants and their transgenic properties are of limited importance to the food supply in developing countries. However, with the development of varieties that produce high yields on sites with unfavourable environmental conditions (e.g. salty or acidic soils, erratic precipitation) genetic engineering could contribute significantly to global food security. Accordingly, much effort is put into the engineering of C4-rice. The modification of the photosynthesis apparatus is expected to enable the plant to use solar radiation in hot climate much more efficiently, thus improving the yield potential in rice while not increasing the demand for water and nitrogen (Sheehy and Mitchell 2011).

2.3 Outlook

The global demand for cereals could theoretically be satisfied for the coming decades if rigorous birth control systems are implemented, meat production is reduced via changes in consumption patterns, and agricultural production is increased, either per unit area or by bringing new areas under cultivation. It is doubtful that stringent policies aiming at restricting population growth and changes in consumption behaviour can be implemented globally, and an increase in production based on conventional agriculture is likely to cause severe negative environmental impacts, thus impeding the sustainability of the food production and ultimately the world’s carrying capacity.

Expansion of the agricultural area will result in further loss and degradation of natural habitats, which not only contradicts moral principles, imposes pressure on ethnic minorities and compromises the drive for sustainability, but will also cause marked global economic disadvantages (Balmford et al. 2002). Intensification, on the other hand, enables growing food supplies and also reduces the need to expand production areas, whereby valuable ecosystems can be conserved. Nonetheless, intensification also bears the risk of imposing environmental damage and may aggravate the depletion of water, phosphorous and biodiversity resources. Moreover, there are biological and physical limits to intensification and as these are being approached, additional output is increasingly difficult to achieve. In countries which adopted intensification strategies more recently a sharp yield increase can be observed, whereas the impact of intensification levels off for countries in which these strategies were implemented earlier (Fig. 3).

Trends in cereal yields in three countries since 1960 [data source: Food and Agriculture Organization of the United Nations (FAO, 2011); Japan—linear regression (1961–1975 ⇒ y = −2.42e+02 + 1.26e + 01x; r 2 = 0.89, 1976–2009 ⇒ y = −3.37e+01 + 1.98e−02x; r 2 = 0.22), Germany—linear regression (1961–1998 ⇒ y = −1.91e+02 + 9.85e−02x; r 2 = 0.95, 1999–2009 ⇒ y = −6.65e+01 + 3.65e−02x; r 2 = 0.06), Uruguay—linear regression (1961–1976 ⇒ y = −5.94e+01 + 3.07e−02x; r 2 = 0.62, 1977–2009 ⇒ y = −1.95e+02 + 9.93e−02x; r 2 = 0.93)]

Significant changes in the global climate are presumed to lower agriculture productivity and aggravate food insecurity (Parry et al. 2004). Factors that could influence crop production are: changes in atmospheric CO2, higher temperature, reduction of available water, extreme meteorological events, loss of soil fertility, erosion, pests, diseases and sea-level rise. There is still considerable uncertainty regarding the quality and quantity of climate change impact on agriculture, but in view of the continuously increasing food demand a potential production decline unquestionably increases the need to research alternative food supply strategies.

3 Skyfarming: hightech alternative for plant production

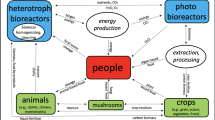

Skyfarming constitutes the innovative indoor crop production within purpose-built, multi-storey buildings to satisfy the growing staple food demand while arresting rampant conversion of natural ecosystems into crop land. The system aims to establish within a technically optimized building envelope, a highly productive and resource-efficient crop production under optimal growth conditions and without seasonal fluctuations.

The Skyfarming initiative pursues five major objectives:

-

(a)

Multiplication of crop yield through uninterrupted year-round production, independent of climate change by:

-

Optimal growth conditions (water, temperature, radiation, nutrients)

-

Avoiding yield losses by competition (weeds, pests, diseases).

-

-

(b)

Alleviation of environmental burden by:

-

Zero infiltration of mineral nutrients N and P into natural water bodies

-

Efficient water cycling by recovery of leaf transpired vapour

-

Reduced pesticide usage

-

Reduced pressure towards for agricultural land conversion; instead a return of sensitive and ecological valuable areas to nature, hence increased CO2-sequestration by the transition to perennial plants and increased soil carbon levels plus stabilization of ecosystem functions/services.

-

-

(c)

Short transport distances by relocation of the production to high demand areas, therefore lower transportation costs and environmental pollution (CO2-emission).

-

(d)

Recycling: energy, water and nutrient recovery and utilization of by-products.

-

(e)

Continuous production: buffer price shocks in international crop commodity market.

By combining these objectives the approach contributes to world food security, while assuring that the international sustainability criteria of environmental compatibility and social acceptability will be upheld. The challenge is to engineer an operational, resource-efficient production unit and to develop a specifically tailored building envelope, both of which can be economically mass-produced.

3.1 State of knowledge

Crop production in multi-story buildings is an idea conceived half a century ago in the dawn of the Green Revolution. Othmar Ruthner’s ‘Apparatus for the Artificial Cultivation of Plants’ is the first detailed technical description on how ‘to utilize a three-dimensional space for the cultivation’ of plants ‘independently of seasons and climatic conditions’ (Ruthner 1966). Riethus and Bau (1970) conducted a vegetable production trial for 4 years in a 13 m high greenhouse. They concluded that in temperate regions vegetable production in multi-story greenhouses is not possible due to the climatic conditions with the winter being too dark and the summer being too hot. The challenges seemed too great for the technological state-of-the-art and the idea sank into oblivion. More recently “vertical farming” has also been discussed in the USA (Fischetti 2008) although this has brought futuristic architectural designs to the foreground rather than the actual crop production technology. All these approaches aim at crops of higher market value, partly in combination with fish farming and/or animal husbandry. Also the first attempt to use patented stackable containers for indoor crop production focused on high priced herbs and salads (Hessel et al. 2003).

3.2 Skyfarming: unique features

In Skyfarming we plan to grow rice (Oryza sativa L.), thus considering for the first time a staple food for cultivation in multi-storey buildings. Rice is the primary source of food for more than three billion people. Its production takes up a large share of the global cropping area, has an unfavourable water balance and contributes significantly to the worldwide emission of greenhouse gases.

Today rice is grown on 159 million hectares, which represents over 22% of the global cereal production area. At the same time 24–30% of the water used by humans is for irrigation of rice (Bouman et al. 2007). Total annual water use for rice cultivation was 941 km3 from 1998 to 2001 (Siebert and Döll 2010). Tuong and Bouman (2003) projected that due to increased competition for water and expansion of the cultivated area, 15–20 million hectares of rice will suffer economical and physical water shortages from the year 2025. Despite the diminishing land and water resources, rice yields have to continuously increase in the next decades to feed the growing world population (Rijsberman 2006).

In addition to the natural resource requirements rice cultivation also threatens the environment via massive production of methane (CH4). Recent estimates suggest an annual global CH4 emission of approximately 600 Tg with 375 Tg from anthropogenic sources. Wetland rice cultivation emits 33–49 Tg CH4 per year which accounts for about 11% of all man made CH4 (Sass 2000). Thus, innovative rice cultivation systems have a high potential for mitigating greenhouse gas emissions and climate change.

Skyfarming follows an efficiency strategy, i.e. minimisation of resource use per unit of rice produced. This efficiency increase will be achieved through technical innovations, which optimise the growing conditions, augment the degree of biomass utilisation, and allow a high degree of energy, water, and nutrient recycling. To reduce material and energy demand it is planned to move the plants to areas where optimal conditions for the respective growth stage are most efficiently established and kept with a minimum of energy input. Nutrient-rich mist will replace heavy and difficult to handle rooting substrate or hydroponics, and will supply the required water and nutrient supply to the roots. This aeroponic system will significantly reduce the amount of water to be transported within the building and lower its statistical requirements.

Skyfarming will require only a minimal fraction of the land, water, and nutrients required in conventional agriculture. Moreover, it will be largely immune to the effects of climate change.

3.3 Production potential

In the absence of a prototype, current rice yield potentials and the dimensions of an imaginary Skyfarm can serve to extrapolate the magnitude of production potential. Presently, Egypt achieves the highest national average yield with more than 8 Mg ha−1. This represents two-thirds of the yield potential of current varieties grown under farm conditions. The theoretical yield potential of these varieties is in the magnitude of 16 Mg ha−1. The Skyfarm should protect the plants against any deviation from the optimal environmental conditions and from pests, thus enabling yields close to the theoretical potential. At a vegetation period of 100–120 days three harvests per year can be expected. A Skyfarm with a ground area of 1 ha, 20 floors and 90% usable area could therefore produce almost 900 Mg rice grain per year. Thus, Skyfarming could offer per ground area unit a productivity increase of 200-fold in comparison with the actual average global yield. In contrast to the described batch production a more continuous system is envisaged where the plants move through the building. This would allow a further minimisation of the area demand for the early growth stages and thus an additional increase in production per ground area.

3.4 Skyfarming: technical challenges

Replacing a significant proportion of the world’s flooded rice production with Skyfarms offers the potential of reducing pressure on land with important economic and environmental benefits. In principle, the combination of existing multi-storey building and greenhouse technology could, from a minimal ground area, provide enough staple food for an urban population (Despommier 2010). In practice, this ideal opportunity may be compromised by various factors causing suboptimal growing conditions including lack of water and nutrients, insufficient insolation, temperature and humidity deviation, pest prevalence and unstable energy supply.

However, several promising approaches are available to control these factors, even though they still require substantial research, modification and adaptation to ensure ideal growing conditions.

3.4.1 Rice production system and growing environment

Skyfarming aims to produce rice under fully controlled indoor conditions with environmental and production parameters fully optimized for rice in a multi-storey production facility. In order to minimize the static load, rice will be grown without substrate in a nutrient mist system, a so-called aeroponic system. The specific experimental research requirements for such a production system involve: (1) development of an aeroponic system providing optimal conditions to the rice roots regarding to water and nutrient supply and root zone temperature. (2) Definition of optimal growing conditions that allow maximizing of rice yield while minimizing inputs, including variable spacing of plants according to their development stage specific insolation requirements. (3) Definition of optimal conditions for development of the rice crop providing for a crop duration that allows for sufficient source development (vegetative growth) and optimized sink demands (reproductive growth).

Optimal root growth depends on specific parameters in the root zone such as, temperature, water availability, nutrient availability, and pH. Root-zone temperature determines the water uptake capacity of roots (Lösch 2001) as well as root growth. In aeroponic systems the temperature in the root zone directly depends on the nutrient mist temperature. The root zone pH in combination with temperature influences root systems development, tillering capacity and leaf area with a strong influence of the genotype (Schmierer 2010). Further research in aeroponic growth systems is needed to optimize the root structure, volume and length as well as root-zone temperature and pH for optimal nutrient and water efficiency of the rice.

Under open air conditions rice is regarded as a resource-demanding crop in terms of light intensity, water and nutrient requirements, water and nutrient management and temperature (Asch et al. 2005; Dobermann and Fairhurst 2000; Yoshida 1981). However, this characterization is based on a combination of factors occurring simultaneously under field conditions and does not necessarily reflect the biological requirements of the rice crop, as certain combinations of climatic and management factors never occur in field-based rice production. In general, experiments under controlled conditions try to mimic field conditions. Thus, they are also limited in their significance with regards to a fully optimised indoor production not limited by any resource and capable of providing any combination of humidity, light intensity, water availability, temperature, day length and atmospheric CO2 concentration not only to the aerial but also to the below ground parts of a rice plant. Therefore, knowledge of the ranges of combined environmental conditions under which an optimal rice yield can be achieved is extremely limited. Some published information can be used as guidelines when trying to define the optimal growing conditions for rice in a fully controlled indoor production facility. Nutrients need to be balanced in relation to the requirements of the rice plant; however, systematic losses due to soil and irrigation properties do not need to be considered (Janssen 1998). The ultimate water requirement of a rice plant, has yet to be determined, as all estimation of the water use of rice are based either on field observations (e.g. de Vries et al. 2010; Stürz et al. 2010) or using crop models describing the water loss pathways in production systems such as percolation, evaporation and transpiration. No estimations are available for rice water requirements that include environmental control over and subsequent re-cycling of water normally lost to soil and atmosphere or through the removal of biomass. Equally, a wealth of knowledge exists on the temperature requirements of rice under field conditions (e.g. Dingkuhn et al. 1995; Shrestha et al. 2011), but also here the results integrate the effects of soil, water and air temperature in combination with solar insolation, wind speed and air humidity. Little is known how rice will respond to specific combinations of atmospheric and root-zone temperatures in terms of development and growth (Gunawardena et al. 2003; Setter and Greenway 1988).

Crop models to date simulate field-based crop responses. Research for Skyfarming will adapt such a crop model to fully controlled indoor cropping in order to evaluate the effect of variable crop spacing in relation to development stage, the light intensity needed, the required day length, the root-zone and aerial temperature as well as to determine the phenological responses to such conditions. This will allow fine-tuning of the environmental conditions needed to crop rice, will provide a clearer picture of the light and temperature and thus energy requirements, and will better allow assessment of the production potential of such a Skyfarming facility.

3.4.2 High efficiency lighting

One of the key challenges in Skyfarming is the design of daylighting and artificial lighting systems as light is the all-important energy source used by plants for photosynthesis (intensity and exposure of light), photoperiodics (timing of light supply) and plant architecture (spatial light distribution).

In order to achieve the postulated yield of three harvests a year, illuminance levels on rice communities are to be supplied near the light saturation point, which lies at around 70–90 klx (Yoshida 1972)—assuming a rice canopy with a lot of mutual shading and typical daylight spectra. This level has to be supplied matching the plants circadian rhythm resulting in an estimated annual luminous exposure in the magnitude of 250 Mlxh. This corresponds generally well with the maximum worldwide annual luminance exposures as in equatorial desert climates in the range of a little above 200 Mlxh a−1 (de Boer and Mergenthaler 2011), correlating with the above mentioned worldwide highest yields in Egypt. However, in Skyfarming optimisation of energy input for the entire canopy is intended by providing the appropriate spacing between the plants, thus the individual leaves might be more productive and lower light intensities could be needed.

For standard single story greenhouses, daylight is the primary and often only source of light. In Skyfarming, the relative portion of daylight will decrease as the stacking density within the building cubature increases. Close to the outer skin of the Skyfarm daylight can be the primary light source, but daylight concentrating, guiding and distribution techniques must be introduced to use natural light spatially and seasonally most efficiently. The Skyfarm concept has to be transferable to different locations and climates with strongly differing natural light supplies. For an adaptable, flexible concept this will most probably result in modular construction schemes, using different architectural cubature concepts and different façade modules incorporating light guiding concepts (for instance reference to well established solutions for laterally lit office spaces).

The efficiency of the artificial lighting system in Skyfarming is determined by the ratio of emitted radiation in the relevant spectral domain (approximately 400–700 nm) per Watt electrical power and an optimized fit to the rice growing process dominated by photosynthesis (i.e. fit to the photosynthesis spectral sensitivity curve). So far the primary light sources in greenhouse technology have been fluorescent lamps with efficiencies in the range of 20–25% and high pressure sodium lamps with efficiencies in the range of 25–30%. As LED lighting technology is advancing rapidly, a boost in efficiency and strong advances in spectra design can currently be reported. Efficiencies between 37% (Osram 2010) and 46% (Valster 2010) are given for red light LEDs with a peak intensity at a wavelength of 660 nm, i.e. close to the maximum spectral sensitivity of the photosynthesis process. Combinations with blue or white LEDs allow the design of efficiently matched spectra for all needs of industrial plant production (e.g. including plant architecture). As comparison, daylight contains around 43% of the overall radiation energy in the considered spectral range. Therefore, designed LED spectra, lacking the infrared spectral components of daylight, currently promise to deliver radiation up to two times more efficient than daylight (i.e. lowering radiation load on plants). Economically, LEDs are on the brink of becoming a mass product in the field of general lighting with a strong declining cost function (around 80% cost reduction over the past 4 years). With a lamp life-time of up to 100,000 h they are already now an economical alternative to selected fluorescent lamp-based lighting systems. Since the semi conductor junction temperature in LEDs is very critical to the luminous flux output and LED lifetime, the thermal management of these engineered lighting systems will be of crucial importance in the densely stacked floors of Skyfarming.

Large parts of the planted area will solely rely on artificial lighting for which a necessary electricity demand in the magnitude of 1,000 kWh m−2 a−1 is expected. This has a significant impact on production costs, being at the current technological state still far from competitive. In addition it imposes high requirements on electricity supply, suggesting constructions near sites with surplus energy. Lighting energy demand minus the energy used directly for biomass generation gives the internal load which has to be tackled properly by the building facilities (ventilation and cooling). The technical means of breaking down the overall Skyfarm energy demand and therefore production costs include the above-mentioned optimization of the daylight contribution, further improvement of light sources, and the design of advanced integral energy management systems within the buildings incorporating, for instance, heat redistribution and recovery systems.

3.4.3 Temperature regulation and recovery of transpiration water

Depending upon the geographical location of a Skyfarm, it is taken into consideration that the heating and/or cooling loads in a building are provided using regenerative energy supported by reasonable and adequate distribution and transfer systems. The application of geothermal equipment, heat pumps, solar energy plants for heating and cooling as well as the possibility of utilizing ground water and surface water are considered in the process. Thermal loads are transmitted through water supported systems. Earth canals or rather air collectors are applied as a way of using regenerative energy in conditioning the necessary hygienic capacity of outside air flow. The indoor temperature conditions within the individual zones in the Skyfarm are monitored by process measuring and control systems and regulated through appropriate automatic interventions.

Transpiration is the evaporation of water from plants. It occurs chiefly at the leaves while their stomata are open and serves to supply photosynthesis, to bring minerals from the roots for biosynthesis within the leaf and to cool the leaf. Rice transpires 1 l of water for the production of 2–5 g of dry matter (Haefele et al. 2009). At an average transpiration efficiency and a harvesting index of about 0.5 (Yang and Zhang 2010; Ju et al. 2009), rice in a Skyfarm transpires about 1,000 l per m2 during one crop cycle for the production of 16 Mg grain ha−1. Accumulation of transpiration water inside a closed growing environment can result in reduced photosynthetic activity of rice plants and lead to condensation on the plants as well as other surfaces. Condensate on plants facilitates the infection by viruses and fungi and thus increases the risk of disease outbreaks. In addition, uncontrolled humidity encourages also the establishment of algae and other unwanted organisms. Therefore, dehumidification is vital for Skyfarming. As photosynthesis of rice remains efficient at high humidity levels in contrast to most other crops the needed degree of dehumidification and associated energy demand is lower. Three dehumidifying strategies are available:

-

1.

Natural ventilation (wind driven ventilation and stack ventilation) and forced ventilation (fan assisted ventilation) are the most common dehumidification methods in commercial greenhouses. Ventilation replaces warm and humid air inside the greenhouse with colder and dryer outside air. If cooling is not needed, ventilation requires energy to reheat the replaced air. Moreover, ventilation is unable to remove moisture from the inside when the outside air has a higher absolute humidity, but in temperate regions it is still the most economic dehumidification method for conventional greenhouses (Campen et al. 2003).

-

2.

The hygroscopic method uses a desiccant, such as aqueous chloride solutions of calcium or lithium for water removal from the air (Ertas et al. 1992). This method can achieve high efficiency especially if combined with air temperature conditioning (Jain and Bansal 2007). In terms of primary energy this concept shows considerable advantages compared to cold vapour refrigeration compressor systems. Instead of exegetic high-quality electricity more low-temperature heat for the conditioning of outside air can be applied. This method therefore leads to a reduction in operational costs (Casas and Schmitz 2005).

-

3.

Among the three dehumidification strategies, the condensation method is considered most feasible for indoor crop cultivation (Lee 2010). Glass panes in conventional greenhouses serve as natural dehumidifiers, but with improving insulation other cold surfaces for condensation are needed. Mechanisms to maintain cold surfaces that rely on standard climate conditioning systems are too expensive to operate (Campen et al. 2003). Especially in hot climates the integration of alternative cold sources could be advantageous and include geothermal, lakes, wells, underground aquifers and water tanks (Lee 2010).

The aim is to combine radiant cooling systems with the hygienic minimum limit of air flow capacity in order to minimise energy costs. The energy-consuming conditioning of outside air is therefore reduced to a minimum.

3.4.4 Phytosanitation

Insects and diseases are a major challenge to indoor plant production. When cultured in a closed system, plants are subject to different types of stress, mainly abiotic (temperature, light, humidity) and/or biotic stress (fungi, bacteria, viruses, insects). The former could be controlled in a Skyfarming system by continuously controlling the environment as well as the water and nutrient supply inside the containment. Technologies are available for filter-sterilizing liquids before they are introduced into the cultivation system. However, plant pathogens and pests have to be controlled at different stages and across the entire process. Three stages of control will have to be implemented: (1) seed production for starting the process has to be performed under conditions limiting infection with pathogens and pests. (2) Before entering the Skyfarming system, seeds have to be decontaminated. (3) Monitoring for contaminations has to be performed at all stages of the production process.

A plant production system such as Skyfarming has to be hermetically shielded from the outside environment to prevent any introduction of deleterious organisms. Before seeds will be allowed to enter the Skyfarming system they have to be decontaminated to eliminate fungi and/or bacteria. Such an approach is typically being used for initiating sterile tissue cultures. Methods for sterilizing plant materials to be cultured aseptically have been used successfully for some time (Wetter and Constabel 1982). Afterwards these seeds have to be subjected to a rigorous control verifying their sterility. Only seeds which are confirmed to be contamination free will be entered into the system. However, in spite of such rigorous controls during the initiation of cultures, there will always be the possibility that contamination by micro-organisms will emerge during cultivation. Therefore, it will be essential to implement provisions for monitoring plant health during culture. The culture system has to be constructed in such a way enabling isolation and removal of contaminated material without jeopardizing other plants. This could be achieved by subdividing the culture system in self-contained sections. Furthermore, the building itself has to be designed in such a way that it may be decontaminated as well. Finally, all supplies (water, substrate, nutrients, etc.) must be freed of contaminations before entering the culture area.

3.4.5 Sustainable energy supply options

The energy requirement of Skyfarming comprises: (1) light and heat demands of the crop and (2) energy demands of technical installations such as conveyors for translocation of plants, fans for air exchange, heat pumps for climate control, pumps for application of nutrient dilutions, and agitators for plant manipulation. Whereas the energy demand of the crop should be covered as far as possible by sunlight, the technical energy demand has to be covered to a large extend by electricity. To minimize energy import to the system, all operations have to be performed at high energy efficiency, including photosynthesis of the plants.

To make maximum use of solar radiation in Skyfarming, non-PAR wavelengths that are not absorbed by chlorophyll should be filtered by selective solar cells and used for photovoltaic energy generation. Although various semi-transparent solar cells have been produced in recent years, solar cells specifically transparent for photosynthetically active wavelengths have not been developed so far (Overton 2010). Using the reddish-purple betalain pigments with a maximum absorptivity of 535 nm as base for dye-sensitized solar cells might be a promising way to develop those selective solar cells (Zhang et al. 2008). As in Skyfarming the plant canopy area is multiplied by the number of floors, PAR as received by natural irradiation will not be sufficient. To minimize the requirement of additional artificial lighting, solar radiation should be harvested by mirror-systems from surrounding urban buildings, which also would increase the output of the selective photovoltaic generators as well as increasing PAR in the Skyfarm.

Only a minor part of the energy received by the plant canopy is converted to hydrocarbons and stored as chemical energy in the biomass. A good part of energy is needed for physiological processes, including transpiration of water. In Skyfarming, besides the recovery of evaporated water the heat of evaporation also has to be recovered. Recirculation of air and condensation of water, as mentioned above would also recover latent heat. By using heat-pumps for condensation, part of the airflow could be heated to temperatures suitable for drying of rice, which is an obligatory post-harvest operation as rice is harvested at a moisture content too high for storage.

For sustainable resources management only the product of interest, viz. the head rice yield (unbroken kernels) should be withdrawn from the system. All by-products such as broken kernels, husks, straw and roots should be used for energy generation, if no higher than the calorific value can be added. Here aeroponic cultivation in Skyfarms opens new avenues to harvest rice roots without any soil contamination. This allows isolating secondary metabolic products from root exudates such as momilactones, which have been proven to have antitumor efficacy (Toyomasu et al. 2008; Lee et al. 2008).

Remaining biomass can be converted to energy by combustion, gasification or anaerobic fermentation. As the crop residues still have high moisture content at harvest, biogas production by anaerobic fermentation of the moist feedstock would be the most preferable option. However, conventional fermenters are not suitable for digesting rice straw because of the high fibre content. Specially designed up-flow fermenters with a two-stage fermentation process have to be further developed and applied. Here the solid biomass dissociates liquor and moves in an up-flow induced by biogas bubbles (Mumme et al. 2010). At the top of the vertical fermenter the solids are removed from the liquor and biogas is removed from the liquor in a separate high rate methane reactor. In general, biogas based on energy-rich feedstock is a blend of 55–70% of CH4 and the rest mainly CO2. Rice straw, however, due to high content of lignin and silicate is a less energy-rich feedstock and has been reported to produce biogas at 47% CH4 (Dinuccio et al. 2010). By using roots and broken rice kernels as additional feedstock a higher biogas yield and also a higher CH4-content is expected.

After removing water and H2S, biogas can be directly used in gas engines of combined heat and power plants, where electricity is generated at an efficiency of 25–50%. Waste heat from engine cooling can be used for heating or drying purposes. The exhaust gas is rich in CO2 and can be used to increase the CO2-level in the cropping areas of the Skyfarm. CO2 enrichment to a concentration of 664 ppm has increased yields of 17 investigated rice varieties (Ziska et al. 1996).

The biogas digestate is rich in major plant nutrients such as nitrogen (N), phosphorus (P) and potassium (K), where concentrations (in dry matter) of 2.9% N, 1.3% P and 1.4% K have been found (Kratzeisen et al. 2010). By mechanical separation of solids those nutrients can be accumulated in the liquid phase to be finally recovered by membrane technology. This allows blending the separated components to aeroponic nutrient dilutions that are optimally adjusted to the varying needs of rice plants at different vegetation stages. Especially the recycling of nitrogen has a considerable energy saving effect, as the production of mineral nitrogen fertilizer requires about 50 MJ per kg N (Hülsbergen et al. 2001).

4 Conclusion

The world’s growing population demands ever increasing supplies of plant derived products. Conventional agricultural production is limited by land availability and production intensity. Pushing land expansion and/or intensification to the limit bears the risk of severe and often non-reversible impacts, including production resource exhaustion, ecosystem degradation and biodiversity loss.

Skyfarming is a novel vertical farming approach that is largely independent of climate change and has the potential to lower greenhouse gas emissions from agriculture. The plant, with its physiological requirements for high and continuous productivity, is the core determinant for the whole system design of this approach. Therefore, the selection of the most suitable varieties and investigation of their performance under Skyfarming conditions must run alongside the development of the artificial growing environment. Some technical components for the construction of the environment are already available; however, they need to be adjusted substantially, combined and tested under the objective target of this approach. This technical refinement requires a highly interdisciplinary cooperation due to the very close inter-linkage of all areas of competency.

In addition to the presented areas of crucial technology, more sciences need to be considered in the research and development towards Skyfarming. Not only questions that will arise in regard to the building itself (e.g. statics, insulation), but also the management of the production system (e.g. logistics, informatics) and its socio-economic embedding (e.g. architecture, urban planning) need to be considered. Nonetheless, these considerations can only be based on a precisely defined technology.

It is to be expected that even partial knowledge gained on the way towards Skyfarming will contribute significantly to food security and sustainability. Aeroponic systems, new insolation methods and pest-free plant cultivation could not only revolutionise the greenhouse industry, but are also apt to open whole new potentials for, e.g. rooftop farming. The innovative indoor climate management technologies and the natural light conduction deep inside buildings are both also promising for flat and office buildings to save energy and to reduce greenhouse emissions.

The development of Skyfarming with all its biotic, ecological, technical, societal and economic research needs and challenges requires substantial and long-term funding. Public investment in revolutionary food production is unavoidable if sustainability is taken seriously (Sachs 2008). The singular discussion of the expenditure for the development, building and operation of Skyfarms without consideration of the opportunity costs is not helpful. Based on Chinas average rice yield of 6.6 Mg ha−1 (FAO 2011), and unaccounted environmental costs of 2,061 € ha−1 a−1 (Table 1), the environmental protection value of Skyfarming would be almost 15,000 € year−1 and floor ha at an annual production of 48 Mg rice. Although we are aware that there are many conceptual and empirical problems inherent in such estimations, we think these calculations are essential in order to demonstrate that significant hidden environmental costs of conventional rice production, including natural ecosystem loss, greenhouse gas emissions, and nutrient and water depletion, could be avoided with Skyfarming.

References

Ahmad S, Li C, Dai G, Zhan M, Wang J, Pan S, Cao C (2009) Greenhouse gas emission from direct seeding paddy field under different rice tillage systems in central China. Soil Tillage Res 106(1):54–61

Asch F, Dingkuhn M, Sow A, Audebert A (2005) Drought-induced changes in rooting patterns and assimilate partitioning between root and shoot in upland rice. Field Crops Res 93(2–3):223–236

Balmford A, Bruner A, Cooper P, Costanza R, Farber S, Green RE et al (2002) Economic reasons for conserving wild nature. Science 297(5583):950–953

Bouman B, Humphreys E, Tuong T, Barker R (2007) Rice and water. Adv Agron 92:187–237

Bruinsma J (2003) World agriculture: towards 2015/2030: an FAO study. Earthscan Publications Ltd., London

Campen JB, Bot GPA, de Zwart HF (2003) Dehumidification of greenhouses at northern latitudes. Biosyst Eng 86(4):487–493

Casas W, Schmitz G (2005) Experiences with a gas driven, desiccant assisted air conditioning system with geothermal energy for an office building. Energy Build 37(5):493–501

Chapagain A, Hoekstra A (2011) The blue, green and grey water footprint of rice from production and consumption perspectives. Ecol Econ 70(4):749–758

Clive J (2009) Global status of commercialized biotech/GM crops: 2009. ISAAA, Ithaca

Cohen MN (1977) Food crisis in prehistory: overpopulation and the origins of agriculture. Yale University Press, New Haven

Cohen J (1997) Population, economics, environment and culture: an introduction to human carrying capacity. J Appl Ecol 34(6):1325–1333

Cordell D, Drangert J, White S (2009) The story of phosphorus: global food security and food for thought. Glob Environ Change 19(2):292–305

Costanza R, d’Arge R, de Groot R, Farber S, Grasso M, Hannon B et al (1997) The value of the world’s ecosystem services and natural capital. Nature 387(6630):253–260

de Boer J, Mergenthaler K (2011) Ein weltweit anwendbares einfaches Kennwertsystem zur Bewertung der Tageslichtversorgung von Innenräumen mit unterschiedlichen Fassaden. Bericht des Fraunhofer-Instituts für Bauphysik, Bericht WB 154/2011, Stuttgart

de Vries ME, Rodenburg J, Bado BV, Sow A, Leffelaar PA, Giller KE (2010) Rice production with less irrigation water is possible in a Sahelian environment. Field Crops Res 116(1–2):154–164

Despommier D (2010) The vertical farm: controlled environment agriculture carried out in tall buildings would create greater food safety and security for large urban populations. Journal für Verbraucherschutz und Lebensmittelsicherheit. http://www.springerlink.com/content/n727450821q512mt/. Accessed 4 Feb 2011

Diamond J (2005) Collapse. Penguin Group, New York

Dingkuhn M, Sow A, Samb A, Diack S, Asch F (1995) Climatic determinants of irrigated rice performance in the Sahel—I. Photothermal and micro-climatic responses of flowering. Agric Syst 48(4):385–410

Dinuccio E, Balsari P, Gioelli F, Menardo S (2010) Evaluation of the biogas productivity potential of some Italian agro-industrial biomasses. Bioresour Technol 101(10):3780–3783

Dobermann A, Fairhurst T (2000) Rice: nutrient disorders and nutrient management. Int. Rice Res. Inst. Manila, Philippines

Döll P (2010) Global irrigation map—Goethe-Universität. http://www.geo.uni-frankfurt.de/ipg/ag/dl/forschung/Global_Irrigation_Map/index.html. Accessed 10 Jan 2011

Edgerton MD (2009) Increasing crop productivity to meet global needs for feed, food, and fuel. Plant Physiol 149(1):7–13

Ehrlich PPR, Ehrlich AH, Daily GC (1997) The stork and the plow: the equity answer to the human dilemma. Yale University Press, New Haven

Ertas A, Anderson E, Kiris I (1992) Properties of a new liquid desiccant solution—lithium chloride and calcium chloride mixture. Sol Energy 49(3):205–212

Evenson RE, Gollin D (2003) Assessing the impact of the green revolution, 1960 to 2000. Science 300(5620):758–762

FAO (2011) FAO statistical database. http://faostat.fao.org/. Accessed 1 Feb 2011

Fischetti M (2008) Growing VERTICAL. Scientific American Earth 3.0. 18(4):74–77

Germer J, Sauerborn J (2008) Estimation of the impact of oil palm plantation establishment on greenhouse gas balance. Environ Dev Sustain 10:697–716

Giger E, Prem R, Leen M (2009) Increase of agricultural production based on genetically modified food to meet population growth demands. Sch Dr Stud J 1(1):98–124

Gilbert N (2009) The disappearing nutrient. Nature 461(7265):716–718

Grenz JH, Sauerborn J (2007) The potential of organic agriculture to contribute to sustainable crop production and food security in Sub-Saharan Africa. J Agric Rural Dev Trop Subtrop 89:50–84

Gunawardena TA, Fukai S, Blamey FPC (2003) Low temperature induced spikelet sterility in rice. II. Effects of panicle and root temperatures. Aust J Agric Res 54(10):947–956

Haefele S, Siopongco J, Boling A, Bouman B, Tuong T (2009) Transpiration efficiency of rice (Oryza sativa L.). Field Crops Res 111(1–2):1–10

Hessel L, Bialik K, David B, Ella G (2003) Self contained fully automated robotic crop production facility. United States Patent, USA

Hülsbergen KJ, Feil B, Biermann S, Rathke GW, Kalk WD, Diepenbrock W (2001) A method of energy balancing in crop production and its application in a long-term fertilizer trial. Agric Ecosyst Environ 86(3):303–321

Jain S, Bansal P (2007) Performance analysis of liquid desiccant dehumidification systems. Int J Refrig 30(5):861–872

Janssen BH (1998) Efficient use of nutrients: an art of balancing. Field Crops Res 56(1–2):197–201

Ju J, Yamamoto Y, Wang Y, Shan Y, Dong G, Miyazaki A, Yoshida T (2009) Genotypic differences in dry matter accumulation, nitrogen use efficiency and harvest index in recombinant inbred lines of rice under hydroponic culture. Plant Prod Sci 12(2):208–216

Kratzeisen M, Starcevic N, Martinov M, Maurer C, Müller J (2010) Applicability of biogas digestate as solid fuel. Fuel 89(9):2544–2548

Lakdawalla D, Philipson T, Bhattacharya J (2005) Welfare-enhancing technological change and the growth of obesity. Am Econ Rev 95(2):253–257

Lee WF (2010) Cooling capacity assessment of semi-closed greenhouses. MSc thesis. http://etd.ohiolink.edu/view.cgi/ris.cgi?acc_num=osu1274996517. Accessed 17 Feb 2011

Lee SC, Chung I, Jin YJ, Song YS, Seo SY, Park BS et al (2008) Momilactone B, an allelochemical of rice hulls, induces apoptosis on human lymphoma cells (Jurkat) in a micromolar concentration. Nutr Cancer 60(4):542–551

Liao Y, Gao Z, Bao Z, Huang Q, Feng G, Xu D et al (2008) China’s water pricing reforms for irrigation: effectiveness and impact. IWMI, Colombo

Lösch R (2001) Wasserhaushalt der Pflanzen: 61 Tabellen. Quelle & Meyer, Wiebelsheim

Maraseni TN, Mushtaq S, Maroulis J (2009) Greenhouse gas emissions from rice farming inputs: a cross-country assessment. J Agric Sci 147(02):117–126

Mumme J, Linke B, Tölle R (2010) Novel upflow anaerobic solid-state (UASS) reactor. Bioresour Technol 101(2):592–599

Nellemann C, MacDevette M, Manders T, Eickhout B, Svihus B, Prins A, Kaltenborn B (eds) (2009) The environmental food crisis—the environment’s role in averting future food crisis. United Nations Environment Programme, GRID-Arendal, Birkeland Trykkeri AS, Norway

O’Riordan T, Stoll-Kleemann S (2002) Biodiversity, sustainability and human communities: protecting beyond the protected. Cambridge University Press, London

Oerke E, Dehne H (2004) Safeguarding production—losses in major crops and the role of crop protection. Crop Protect 23(4):275–285

Osram (2010) Flower Power—Lichtstarke LED bringen Pflanzen zum Wachsen, OSRAM LED für hohe Effizienz bei 660 nm. Press release, Osram GmbH, Regensburg

Overton G (2010) Harnessing sunlight moves beyond conventional photovoltaics. Laser Focus World 46(6):59–63

Parry ML, Rosenzweig C, Iglesias A, Livermore M, Fischer G (2004) Effects of climate change on global food production under SRES emissions and socio-economic scenarios. Glob Environ Change 14(1):53–67

Pimentel D, Pimentel M (2003) Sustainability of meat-based and plant-based diets and the environment. Am J Clin Nutr 78(3):660S–663S

Pitman M, Läuchli A (2004) Global impact of salinity and agricultural ecosystems. In: Läuchli A, Lüttge U (eds) Salinity: environment–plants–molecules. Kluwer, Dordrecht. Accessed 10 Jan 2011

PointCarbon (2011) Home—Point Carbon—providing critical insights into energy and environmental markets. http://www.pointcarbon.com/. Accessed 15 Feb 2011

Reynolds MP (ed) (2010) Climate change and crop production. CABI, Oxfordshire

Riethus H, Bau H (1970) Das Turmgewächshaus nach Ruthner [Wien] und seine Bedeutung für den Gemüsebau. Techn. Univ., Universitätsbibliothek, Abt. Publikationen

Rijsberman FR (2006) Water scarcity: fact or fiction? Agric Water Manag 80(1–3):5–22

Rost S, Gerten D, Hoff H, Lucht W, Falkenmark M, Rockstrom J (2009) Global potential to increase crop production through water management in rainfed agriculture. Environ Res Lett 4(4):044002

Ruthner O (1966) Apparatus for the artificial cultivation of plants, bacteria, and similar organism. United States Patent Office, USA

Sachs JD (2008) Common wealth: economics for a crowded planet. Penguin Press, New York

Sage RF (1995) Was low atmospheric CO2 during the Pleistocene a limiting factor for the origin of agriculture? Glob Change Biol 1(2):93–106

Sass RL (2000) CH4 emissions from rice agriculture. In: IPCC (ed) Good practice guidance and uncertainty management in national greenhouse gas inventories. IPCC, Geneva

Schmierer M (2010) Optimierung von aeroponischen Anbausystemen von Reis. Diplomarbeit thesis, Universität Hohenheim, Stuttgart, Germany. http://www.asch-online.eu/downloads/Theses/Diplomarbeit-Schmierer-webversion.pdf. Accessed 11 Feb 2011

Schroeder TC, Barkley AP, Schroeder KC (1996) Income growth and international meat consumption. J Int Food Agribus Mark 7(3):15

Setter TL, Greenway H (1988) Growth reductions of rice at low root temperature: decreases in nutrient uptake and development of chlorosis. J Exp Bot 39(6):811–829

Sheehy JE, Mitchell P (2011) Rice and global food security: the race between scientific discovery and catastrophe. In: Pasternak C (ed) ACCESS NOT EXCESS—the search for better nutrition. Smith-Gordon, Cambridgeshire, pp 81–90

Shrestha S, Asch F, Dingkuhn M, Becker M (2011) Cropping calendar options for rice-wheat production systems at high-altitudes. Field Crops Res 121(1):158–167

Siebert S, Döll P (2010) Quantifying blue and green virtual water contents in global crop production as well as potential production losses without irrigation. J Hydrol 384(3–4):198–217

Stuart T (2009) Waste: the true cost of what the global food industry throws away. Penguin, London

Stürz S, Asch F, Sow A, Muller B, Manneh B (2010) Intra-annual genotypic patterns of growth and water use of irrigated rice in the Sahel. In: Thielkes E (ed) World food system—a contribution from Europe. Cuvillier Verlag, Göttingen

Ter Steege H (2010) Will tropical biodiversity survive our approach to global change? Biotropica 42(5):561–562

Thøgersen J (1996) Wasteful food consumption: trends in food and packaging waste. Scand J Manag 12(3):291–304

Tilman D (1998) The greening of the green revolution. Nature 396(6708):211–212

Toyomasu T, Kagahara T, Okada K, Koga J, Hasegawa M, Mitsuhashi W et al (2008) Diterpene phytoalexins are biosynthesized in and exuded from the roots of rice seedlings. Biosci Biotechnol Biochem 72(2):562–567

Tuong T, Bouman B (2003) Rice production in water scarce environments. In: Kijne JW, Barker R, Molden DJ (eds) Water productivity in agriculture: limits and opportunities for improvement. CABI, Wallingford, pp 53–67

UNPP (2009) World population prospects: the 2008 revision population database. United Nation Population Division. http://esa.un.org/UNPP/. Accessed 9 Dec 2010

Valster A (2010) Increase growth yield in horticulture by improvements in LED lighting. In: Haverlag M, Kroesen G, Taguchi T (eds) Proceedings of the 12th international symposium on the science and technology of light sources and the 3th international conference on white LEDs and solid state lighting, Eindhoven, The Netherlands, pp 83–84

Weeks JR (2007) Population: an introduction to concepts and issues. Wadsworth Publishing, Florence

Wetter LR, Constabel F (1982) Plant tissue culture methods. National Research Council of Canada, Prairie Regional Lab., Saskatoon

White TD, Asfaw B, DeGusta D, Gilbert H, Richards GD, Suwa G, Clark Howell F (2003) Pleistocene Homo sapiens from Middle Awash, Ethiopia. Nature 423(6941):742–747

Yang J, Zhang J (2010) Crop management techniques to enhance harvest index in rice. J Exp Bot 61(12):3177–3189

Yoshida S (1972) Physiological aspects of grain yield. Annu Rev Plant Physiol 23(1):437–464

Yoshida S (1981) Fundamentals of rice crop science. Int. Rice Res. Inst. Manila, Philippines

Zhang D, Lanier SM, Downing JA, Avent JL, Lum J, McHale JL (2008) Betalain pigments for dye-sensitized solar cells. J Photochem Photobiol A Chem 195(1):72–80

Ziska LH, Manalo PA, Ordonez RA (1996) Intraspecific variation in the response of rice (Oryza sativa L.) to increased CO2 and temperature: growth and yield response of 17 cultivars. J Exp Bot 47(9):1353–1359

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Germer, J., Sauerborn, J., Asch, F. et al. Skyfarming an ecological innovation to enhance global food security. J. Verbr. Lebensm. 6, 237–251 (2011). https://doi.org/10.1007/s00003-011-0691-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-011-0691-6