Abstract

The objective of this study was to monitor overall quality and to extend the shelf life of fresh-cut apple wedges. Fresh-cut apple wedges were treated with anti-browning agents and edible coatings alone as well as in combination and packed in polypropylene trays. Packed apple wedges were stored at 5 ± 2 °C and monitored for physical (colour, physiological loss in weight and firmness), bio-chemical (ascorbic acid, total antioxidant, phenol, polyphenol oxidase and peroxidase enzymes) and microbial quality. In general carboxymethyl cellulose and aloe vera coatings along with anti-browning agents helped in preserving quality of apple slices during storage. Microbial load was significantly low for wedges coated with carboxymethyl cellulose and aloe vera. Polyphenol oxidase and peroxidase enzyme activity was also low in the coated samples. Firmness of the uncoated apple wedges declined more rapidly than the coated ones during storage. The results showed that carboxymethyl cellulose and aloe vera coating in combination with anti-browning agents improved the quality of stored apple wedges.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, there has been an increasing market demand for the fresh-cut fruits and vegetables due to their fresh-like character, convenience and better nutritional value (Yousuf et al. 2018). The development of fresh-cut or minimally processed fruits involves unit operations such as grading, washing, sorting, peeling, slicing, chopping and packaging that result in quality deterioration manifested by cut-surface browning, moisture loss, softening, microbial contamination, increased respiration and ethylene evolution (Graça et al. 2015). The color of fresh-cut produce, including apple wedges is an important quality attribute. Browning tends to make the apple wedges aesthetically unattractive. These color changes are due to oxidative reactions of phenolic compounds by polyphenol oxidase (PPO) and the reaction products, o-quinones to various polymerized products. Anti-browning agents that function as reducing agents and enzyme inhibitors are effective to curb the browning reactions in the fresh-cut commodity. The respiratory activity of fresh-cut fruits increases 1.2–7.0 folds higher than the intact produce, due to tissue injury, depending on the cutting grade, temperature and product type (Ahvenainen 1996). Application of edible coatings on these commodities provides a semi-permeable barrier against O2, CO2, moisture and solute movement; thereby reducing respiration, moisture loss and oxidation reaction rates (Yousuf et al. 2018). These edible coatings can also act as a carrier of food additives such as anti-browning agents to prevent colour changes in the fresh-cut produce.

Although reports are there for individual application of anti-browning agent and edible coatings for maintaining quality of fresh-cut produce, combination of edible coatings and/or anti-browning dip may prove useful in further extending the shelf life of fresh-cut produce. Earlier, Guerreiro et al. (2017), Saba and Sogvar (2016), Liu et al. (2016) and Qi et al. (2011) have reported the synergistic effect of edible coatings and anti-browning agents to effectively prolong the shelf-life of fresh-cut apples. Since, India is a growing market for fresh-cut and minimally processed product, this study is important for the retention of quality characteristics of fresh-cut apple wedges cv. Royal Delicious, an important commercial cultivar. Therefore, the objective of this study was to evaluate the effect of different anti-browning agents and edible coatings on the nutritional quality attributes on ‘Royal Delicious’ fresh-cut apple through shelf-life.

Materials and methods

Plant material and sample preparation

The fruits of apple cultivar ‘Royal Delicious’, were procured from Seobagh, Kullu, Himachal Pradesh, India. After harvesting and sorting, the fruits were packed in cartons, transported to New Delhi within 24 h, and stored at 2 °C and 80–90% relative humidity at the Division of Food Science and Postharvest Technology, ICAR-Indian Agricultural Research Institute, New Delhi till further study. Fresh-cut apple wedges were obtained by coring and slicing the whole apple using a hand-operated apple slicer followed by treatment with anti-browning agents and edible coatings alone as well as in combination. Chemicals used for the study were procured from Sigma, Merck and SRL Technologies, India.

Formulation of the edible coatings

Preparation of aloe vera gel (AVG) edible coating

Aloe vera leaves (Aloe barbadensis Miller) were procured from a nursery near the campus. The AVG coating was prepared according to the method of Supapvanich et al. (2016). After washing with tap water, the leaf peel was removed. The inner transparent tissues was blended and then filtered through a muslin cloth. The pure aloe vera homogenates were diluted with distilled water to get the desired concentration of 15% (v/v). Based on preliminary sensory acceptability studies, the threshold for sensory acceptance was established at 15% due to a bitter taste perceived at higher concentrations.

Preparation of carboxy methylcellulose (CMC) coating

CMC coating was prepared by solubilizing CMC powder (1 g per 100 ml) in distilled water at 75 °C under magnetic stirring for 30 min (Maftoonazad and Ramaswamy 2005). A preliminary experiment was conducted to determine which concentration of CMC (0.25, 0.5, 0.75, 1.0, 1.5, 2.0%) would be most effective in extending the quality of apple wedges. Based on adherence of the edible coating and overall visual quality, it was found that 1% formulation of CMC was the most effective among the formulations tested.

Apple processing, packaging and storage condition

The fresh-cut apple wedges were immersed in the solutions of anti-browning agent/edible coating/distilled water for 5 min. The dips comprised of following treatments to study the physical, microbiological safety and quality parameters of fresh-cut apple wedges:

Treatment | Components |

|---|---|

T0 | Distilled water (control) |

T1 | 1% ascorbic acid + 1% CaCl2 |

T2 | 0.01% 4-hexylresorcinol + 0.5% ascorbic acid + 0.2% CaCl2 |

T3 | 0.1% cysteine |

T4 | 15% AVG |

T5 | 15% AVG + 0.01% 4-hexylresorcinol + 0.5% ascorbic acid + 0.2% CaCl2 |

T6 | 15% AVG + 1% ascorbic acid + 1% CaCl2 |

T7 | 15% AVG + 0.1% cysteine |

T8 | 1% CMC |

T9 | 1% CMC + 0.01% 4-hexylresorcinol + 0.5% ascorbic acid + 0.2% CaCl2 |

T10 | 1% CMC + 1% ascorbic acid + 1% CaCl2 |

T11 | 1% CMC + 0.1% cysteine |

The excess of solution was drained off and the apple wedges were air-dried. Wedges were packaged in polypropylene containers, shrink wrapped and stored at 5 ± 2 °C. The cut apple wedges were analyzed every day for a period of 7 days for different quality attributes.

Weight loss and fruit firmness

Weight of each polypropylene tray was measured each day using an electronic balance (Make: Precisa 310 M, Adair Dutt and Co. Pvt Ltd., Calcutta). Weight loss (WL) was expressed in percentage as follows:

where WL, weight loss (%); IW, initial weight (g) and FW, final weight (g) on sampling.

Firmness of apple slices was determined using a Texture Analyser (model TA + Di, Stable micro systems, UK) by measuring the maximum penetration force required for a 2 mm diameter stainless probe to penetrate into the apple wedge. Apple wedges were placed perpendicular to the probe to allow penetration. Three pieces from each container were used per treatment.

Browning and whiteness index

Flesh colour of wedges was measured with a portable colorTec PCM, using the CIE Lab scale (L*, a* and b*). The browning index (BI) used as an indicator of intensity of brown color and was calculated by the following formula:

where \( x = \left( {a^{*} + 1.75 L^{*}} \right) / \left( {5.646 L^{*} + a^{*} - 3.012 b^{*}} \right) \)

Numerical values of L*, a* and b* were also used to calculate whiteness index as follows:

Ascorbic acid, total phenols and antioxidant activity

Ascorbic acid content of the cut apple wedges was determined by titration with 2,6-dichlorophenolindophenol and expressed in mg of ascorbic acid per 100 g fresh weight (Ranganna 1999). Total antioxidant activity in the apple slices was determined by the CUPRAC method (Apak et al. 2004) and expressed as μmole Trolox g−1 fresh weight. The total phenolic content was measured by the Folin-Ciocalteu method. The results were expressed as the mg gallic acid equivalents (GAE) per 100 g of fresh weight (Singleton et al. 1999).

Polyphenol oxidase and peroxidase activity

The activity of polyphenol oxidase and peroxidase enzymes was spectroscopically measured (Gonzalez et al. 2000) and the enzyme activity was expressed as change in absorbance min–1 g–1 and one unit of enzyme activity equals to 0.001 absorbance unit min−1 g−1.

Microbiological examination

Microbial population in terms of total aerobic plate count (TAPC) of the minimally processed apple wedges was determined initially and after 7 days of storage. From each polypropylene shrink wrapped container, ten gram sample was blended with 90 mL of sterile normal saline for 1 min in a sterile stomacher bag. Appropriate dilutions were prepared and spread plated on plate count agar medium followed by incubation at 30 °C for 48 h. Microbial counts were reported as log10 colony forming units per gram of sample (Cappuccino and Sherman 2008).

Sensory analysis

Sensory analysis of treated and control fresh-cut apple wedges was evaluated by semi-trained panel of experts. Sensory parameters were assessed on a quantitative descriptive ranking method with 5 point scale (1 = worst and 5 = best). The assessed attributes included sweetness, flavour, sourness and firmness. Browning was also rated on a 5 point scale, where 1 = absence and 5 = marked presence. Evaluations were performed immediately after sample withdrawal from cold storage. The expert’s average response was calculated for each attribute. A score below 3 for any of the evaluated attributes indicated loss of acceptance from a sensory point of view (Alvarez et al. 2013).

Statistical analysis

Two-way analysis of variance was performed on the data sets using SAS 9.3 software and significant effects (p < 0.05) were noted. Significant difference amongst the means was determined by Tukey’s HSD.

Results and discussion

Weight loss and fruit firmness

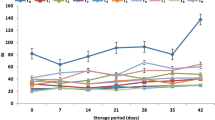

Water loss is an important factor that affects the quality of fresh-cut fruits. It is an indicator of freshness and generally increases during storage of the minimally processed produce (Antunes et al. 2010). The decrease of firmness is usually associated to moisture loss which leads to decreased turgor and crispness of the fresh-cut produce (Beaulieu and Gorny 2002). Apple wedges, either treated or untreated lost weight during the entire storage period of 7 days. CMC and AVG coated apple wedges along with anti-browning agents showed lowest water loss amongst all the treatments which could be attributed to the barrier properties of coatings towards loss of water. After 7 days of storage, untreated samples lost 3.67% of their weight while treated apple wedges had a significantly lower loss in weight in different combinations of anti-browning solutions (Fig. 1). The three best coating formulations CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%), AVG (15%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) and CMC (1%) + AA (1%) + CaCl2 (1%) prevented the weight loss significantly resulting in only 0.532, 0.668 and 0.676% loss, respectively. The HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) treatment among anti-browning combination is most effective in reducing weight loss while among coatings alone and their combinations with anti-browning agents the CMC and CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) were found best, respectively. This finding was in agreement with a report of Guerreiro et al. (2017) and Liu et al. (2016) who reported that the incorporation of anti-browning agents into edible coatings had the least loss of coated fresh-cut apples weight.

Firmness is a very important quality attribute that determines the acceptability of fresh-cut products. Softening or loss of firmness, an undesirable phenomena is affected by the pectin degrading enzymes that get released during cutting and also by decreased turgor due to moisture loss (Qi et al. 2011). In our study, firmness gradually declined during storage in all samples except those that were treated by calcium chloride (Table 1). The infiltration of calcium into the apple tissues might have resulted in better firmness of the apple wedges owing to the reaction with pectic acid present in the cell wall to form calcium pectate that imparts strength to the cell wall (Olivas et al. 2007). On the other hand, the firmness of the untreated apple wedges and those not treated with CaCl2 significantly decreased over the 7 days of storage. This might be explained owing to the pectic acid hydrolysis (Ponting et al. 1972). CMC and AVG coatings effectively retarded softening of the apple wedges. CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%), AVG (15%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) and CMC (1%) + AA (1%) + CaCl2 (1%) treated apples had the highest firmness, since CaCl2, a known firming agent helped apple wedges maintain firmness as described above. Previous studies also report the increase in firmness of apple wedges by calcium chloride treatment by strengthening the middle lamella and cell wall (Qi et al. 2011). Fruits coated with CMC and AVG in combination with HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) retained ~ 95 and ~ 93% of firmness, respectively, after 7 days of storage. Among anti-browning treatment, HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) combination was most effective in retention of firmness while CMC coating alone or in combination with HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) were found better to retain the firmness. Our results confirmed with Guerreiro et al. (2017) who reported the positive effect of coatings mixed with anti-browning agent in maintenance of fresh-cut apple firmness. Treating apple slices with CMC in combination with CaCl2 and ascorbic coating has been reported that significantly retained firmness of fresh-cut apples (Saba and Sogvar 2016).

Browning Index (BI) and Whiteness Index (WI)

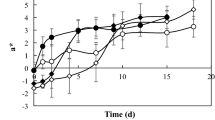

Browning and the loss of natural color are common characteristics of fresh-cut fruit due to the tissue damage provoked by slicing, which can induce enzymatic and non-enzymatic browning reactions thus, promoting loss of natural color (Chiumarelli and Hubinger 2012). The browning index (BI) measures the purity of the brown color and is regarded as an essential parameter in the processes, where both enzymatic and non-enzymatic browning takes place. We observed that untreated wedges showed highest BI as shown in Fig. 2a. Although, all the treatments significantly reduced the BI but the least value was observed in the wedges coated with CMC and AVG in combination with anti-browning agents. The most effective combination was CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%), followed by AVG (15%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) and CMC (1%) + AA (1%) + CaCl2 (1%). The effect of CMC and AVG in combination with anti-browning agents on BI was greater than that for anti-browning, CMC and AVG alone. Apple wedges treated with CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) showed ~ 89% lower BI on day 7 than control. Our results are in line with previous researcher (Qi et al. 2011) who reported the synergistic effect of edible coatings and anti-browning agents to maintain lower BI, better cut surface color and quality of apple wedges. Saba and Sogvar (2016) reported that the browning index was strongly suppressed in sample coated with CMC coating alone or carboxymethyl cellulose in combination with ascorbic acid. Recently, Guerreiro et al. (2017) observed that the edible coatings in combination with anti-browning agents (ascorbic acid, citric acid and sodium chlorite) effectively reduced browning in fresh-cut apples.

Figure 2b shows the effect of anti-browning solution and edible coatings and their combinations on WI of fresh-cut apple wedges during storage at 5 ± 2 °C. Apple wedges dipped in edible coating solutions maintained higher WI values than uncoated samples during the 7 days of storage, indicating the positive effect of the CMC and AVG coatings towards control of enzymatic browning. Rocculi et al. (2004) measured the changes in whitening index of fresh-cut apples dipped in solution of 0.5% of ascorbic acid, 0.5% of citric acid and 0.5% of calcium chloride. The fresh-cut apples were packed in polypropylene boxes and conditioned in Air, 90% N2 + 5% CO2 + 5% O2, 90% N2O + 5% CO2 + 5% O2, 65% N2O + 25% Ar, + 5% CO2 + 5% O2. Apple slices packed with 65% N2O + 25% Ar, + 5% CO2 + 5% O2 had increased WI and brightened after 8 days of storage WI whereas apples slices were packed in air and 90% N2 + 5% CO2 + 5% had lower WI. Chen et al. (2016) observed that the UV-C and citric acid + UV treated samples have the lowest BI and a* value and highest whiteness index and L* value throughout the storage period of 15 days compared with citric acid (CA) alone and control samples. It has been reported that the decrease of L* and whiteness index associated with the loss of water.

Ascorbic acid content, total phenols and antioxidant activity

Ascorbic acid is one of the important nutrients in apples and plays a significant role in several biological activities in human body. We observed that both CMC and AVG coating retarded the ascorbic acid loss when compared with control and wedges treated with anti-browning alone (Table 1). CMC coating in conjunction with anti-browning agents performed best. Ascorbic acid in fruits is lost due to the activities of phenol oxidase and ascorbic acid oxidase enzymes. Saba and Sogvar (2016) reported that the reduction in ascorbic acid in coated slices was slower than uncoated ones which might be due to the low oxygen permeability of carboxymetyhl cellulose (CMC) coating that resulted in decreased activity of the oxidizing enzymes hence preventing the loss of ascorbic acid. Similarly, Liu et al. (2016) have also reported retention of higher ascorbic acid in fresh-cut apples coated with chitosan containing ascorbic acid or calcium chloride. Among the anti-browning agents, HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) resulted in highest retention of ascorbic acid (~ 54%) in comparison to the control at end of storage. Among the coatings alone and coatings combination with anti-browning agents, CMC (~ 63%) and CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) (~ 136%) showed the lowest decrease in ascorbic acid.

A sharp reduction in total phenols and antioxidant activity was observed in untreated wedges during cold storage. However, the wedges treated with edible coating with or without anti-browning agents showed significantly retarded decline in these two attributes (Table 2). Saba and Sogvar (2016) also found that CMC in combination with anti-browning agents was more effective to maintain total phenol in apple slices during storage as compared to the uncoated ones. Treatment with edible coatings, CMC and AVG, were significantly more effective in preventing total phenols and antioxidant activity reduction during cold storage of wedges. These results are in agreement with previous reports where anti-browning treatments reduced the loss of phenols content in fresh-cut fruits (Gonzalez-Aguilar et al. 2005). The maximum retention of phenol content in fresh-cut fruits could maintain quality and prevent other undesirable reactions during extended cold storage (Gonzalez-Aguilar et al. 2005). It has been suggested that ascorbic acid exerts a protective effect on phenolic compounds by self-oxidation (Mayer and Harel 1979) and also by acting as an oxygen scavenger and avoiding polyphenol oxidase-catalyzed reactions. Therefore, it seems that the ascorbic acid treatment inhibited browning by increasing antioxidant capacity in apple slices. At the end of storage period the maximum retention (~ 77%) of total antioxidant activity and total phenol content was observed in HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) among anti-browning treatment alone, whereas for coating application alone and the combinations with anti-browning agents CMC (~ 58%) and CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) (~ 112%) were found to be better. According to Robles-Sanchez et al. (2013) antioxidant activity in fresh-cut mangoes treated with the edible coating in combination of anti-browning agents was significantly higher than in coating alone and control fruits.

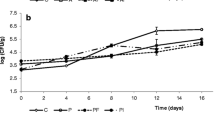

Polyphenol oxidase (PPO) and peroxidase (POD) activity

Since, oxidising enzymes such as PPO and POD get activated during minimal processing operations, they result in oxidation of phenolic substrates resulting in undesirable effects such as browning. The rise in respiration caused by the cutting operation is responsible for induction of these oxidizing enzymes. PPO and POD activities in all samples increased continuously along storage times. Coatings allowed maximum restriction of polyphenol oxidase and peroxidase activities which could be attributed to the barrier property towards respiratory gases. Further, application of CMC and AVG with anti-browning agents on apple wedges showed significant reduction in the activities of these oxidizing enzymes. Maximum inhibition of PPO and POD activity was observed in CMC + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) (Fig. 3a, b). At the end of storage period the PPO and POD activities in control sample were 48 and 77 U min−1 g−1, respectively while in CMC (1%) + HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) treated apple wedges the activity of PPO and POD were 36 and 61 units g−1 min−1, respectively. In agreement to these results it has been reported that CMC coatings in combination with CaCl2 and ascorbic acid decreased PPO and POD activities in fresh-cut apples (Saba and Sogvar 2016). The effect of ascorbic acid on peroxidase is in agreement with those of Jang and Moon (2011) who reported that the presence of ascorbic acid effectively reduced the peroxidase activity in the fresh cut apples may be the result of a lower oxidative stress on the surface of produce, because of the antioxidant nature of ascorbic acid. Similar reduction in PPO and POD activities by application of coatings and anti-browning agents has been previously reported by Qi et al. (2011) and Gonzalez-Aguilar et al. (2005).

Microbiological analysis

Microbial safety is one of the important factors to be considered for the preservation and to maintain the commercial marketability of fresh-cut produce (Graça et al. 2015; Sanchís et al. 2016). Since fruits such as apple are a good source of water and nutrients, they are excellent substrates for microbial growth. On day 0, the microbial count in all samples was below 3 log10 CFU g−1 (Table 3) that increased significantly on last day of storage. On day 7, untreated samples presented the highest microbial count (6.40 log10 CFU g−1) while all other samples presented counts < 4 log10 CFU g−1. Treated apple wedges presented a lower increase in microbial load that might be due to the addition of acidulants such as citric acid/ascorbic acid and calcium chloride (components of the dip) as antioxidant/firming agents. They are reported to confer antimicrobial activity to coatings and help control microbial growth in fresh-cut apples (Sanchís et al. 2016). Calcium ion, whose mode of action is mainly associated with maintaining cell wall structure and firmness has also been reported to retard microbial growth in fresh-cut produce (Cefola et al. 2014). Regarding organic acid salts, optimal antimicrobial activity is at low pH values when the undissociated form is present. In our research work with CMC and AVG coatings, the addition of organic acids lowered the pH of the formulations which fall within the optimum range for the antimicrobial activity of these organic acid salts. Sanchís et al. (2016) reported that edible coating showed a synergic effect with the antioxidant solution and the microbial count significantly reduced in treated samples during storage. As shown in Table 3, reducing the changes of oxygen and carbon dioxide by controlled atmosphere as provided by the coatings may not only inhibit respiratory processes but also suppress microbial count. In the present study, it was found that AVG and CMC with anti-browning agents showed more pronounced antimicrobial properties. Benitez et al. (2013) reported that the kiwifruit slices coated with aloe vera gel were effective in inhibition of microbial count.

Sensory quality

Figure 4 shows the changes in six sensory attributes of fresh-cut apple wedges as affected by anti-browning agents, edible coatings and time under cold condition. After 7 days of storage, the panel showed that the edible coatings had a good sensory appreciation while control was not suitable for consumption. The scores for all attributes for control sample fell below the threshold of acceptability. It is important to highlight here that the addition of anti-browning agents in edible coatings entail an increase in the sensory scores. The judges scored all the coated and anti-browning agents treated samples within the limit of marketability on basis of colour up to 7 days of storage at 5 ± 2 °C, whereas the control samples were below this limit within a day of storage. By day 7, the apple wedges coated with the CMC and AVG coatings containing anti-browning agents, were better than those which were treated either with anti-browning agents and coatings alone. Moreira et al. (2015) reported that combined application of coating and pulsed light treatment of fresh-cut apples maintained the sensory attribute scores above the rejection limits after prolonged storage. CMC coating maintained fruit flavour of the wedges till last day of storage. Benitez et al. (2013) observed that the polysaccharides based coating enhanced the fruity flavour of the fresh-cut kiwifruit slices from the sixth day which was liked by the sensory panel. The lowest rated samples were those treated solely with cysteine, CMC and AVG due to loss of fruit flavor. Similarly, Moreira et al. (2015) found that the combination of coatings and pulsed light treatments led to the lowest scores for aroma. However, Benitez et al. (2013) reported that the kiwifruit slices treated with aloe vera coating were preferred by sensory panel compared to the other coatings.

Conclusion

The present research indicated that the application of CMC and AVG coating formulated with anti-browning agents significantly influenced the quality and shelf-life of ‘Royal Delicious’ apple wedges by controlling weight loss, enzymatic browning and inhibiting the growth of microorganisms during storage at 5 ± 2 °C. Overall, the combination of the edible coating with the anti-browning agents proved to be better to maintain the aesthetic, nutritional and microbial quality of apple slices till 7 day storage period. Combination of CMC (1%) with HR (0.01%) + AA (0.5%) + CaCl2 (0.2%) was found to be the best treatment for maintaining quality and reducing surface browning of fresh cut wedges up to 7 days of storage at 5 ± 2 °C.

References

Ahvenainen R (1996) New approaches in improving the shelf-life of minimally processed fruits and vegetables. Trends Food Sci Technol 7:179–186

Alvarez V, Ponce A, Moreira MR (2013) Antimicrobial efficiency of chitosan coating enriched with bioactive compounds to improve the safety of fresh cut broccoli. Food Sci Technol 50:78–87

Antunes MDC, Dandlen S, Cavaco AM, Miguel G (2010) Effects of postharvest application of 1-MCP and post cutting dip treatment on the quality and nutritional properties of fresh-cut kiwifruit. J Agric Food Chem 58(10):6173–6181

Apak R, Guclu K, Ozyurek M, Karademir SE (2004) Novel total antioxidants capacity index for dietary polyphenol and vitamins C and E using their cupric ion reducing capability in the presence of neocuprine: CUPRAC method. J Agric Food Chem 52:7970–7981

Beaulieu JC, Gorny JR (2002) Fresh-cut fruits. http://www.ba.ars.usda.gov/hb66/146freshcutfruits.pdf. Accessed 1 Dec 2007

Benitez S, Achaerandio I, Sepulcre F, Pujola M (2013) Aloe vera based edible coatings improve the quality of minimally processed ‘Hayward’ kiwifruit. Postharvest Biol Technol 81:29–36

Cappuccino JG, Sherman N (2008) Microbiology: a laboratory manual, vol 9. Benjamin Cummings, Boston

Cefola M, Pace B, Lucrezia S (2014) Postharvest performance of fresh-cut ‘Big Top’ nectarine as affected by dipping in chemical preservatives and packaging in modified atmosphere. Int J Food Sci Technol 49:1184–1195

Chen C, Hu W, He Y, Jiang A, Zhang R (2016) Effect of citric acid combined with UV-C on the quality of fresh-cut apples. Postharvest Biol Technol 111:126–131

Chiumarelli M, Hubinger MD (2012) Stability, solubility, mechanical and barrier properties of cassava starch–Carnauba wax edible coatings to preserve fresh-cut apples. Food hydrocoll 28:59–67

Gonzalez EM, de Ancos B, Cano MP (2000) Partial characterization of peroxidase and polyphenol oxidase activities in blackberry fruits. J Agric Food Chem 48(11):5459–5464

Gonzalez-Aguilar GA, Ruiz-Cruz S, Soto-Valdez H, Vazquez- Ortiz F, Pacheco-Aguilar R, Wang CY (2005) Biochemical changes of fresh-cut pineapple slices treated with anti-browning agents. Int J Food Sci Technol 40:377–383

Graça A, Santo D, Esteves E, Nunes C, Abadias M, Quintas C (2015) Evaluation of microbial quality and yeast diversity in fresh-cut apple. Food Microbiol 51:179–185

Guerreiro AC, Gago CML, Faleiro ML, Miguel MGC, Antunes MDC (2017) The effect of edible coatings on the nutritional quality of ‘Bravo de Esmolfe’ fresh cut apple through shelf-life. Food Sci Technol 75:210–219

Jang JH, Moon KD (2011) Inhibition of polyphenol oxidase and peroxidase activities on fresh-cut apple by simultaneous treatment of ultrasound and ascorbic acid. Food Chem 124(2):444–449

Liu X, Ren J, Zhu Y, Han W, Xuan H, Ge L (2016) The preservation effect of ascorbic acid and calcium chloride modified chitosan coating on fresh-cut apples at room temperature. Colloids Surf A Physicochem Eng Asp 502:102–106

Maftoonazad N, Ramaswamy HS (2005) Postharvest shelf-life extension of avocados using methyl cellulose-basedcoating. Food Sci Technol 38:617–624

Mayer AM, Harel E (1979) Polyphenol oxidases in plants. Phytochemistry 18(2):193–215

Moreira MR, Tomadoni B, Martín-Belloso O, Soliva-Fortuny R (2015) Preservation of fresh-cut apple quality attributes by pulsed light in combination with gellan gum-based prebiotic edible coatings. Food Sci Technol 64:1130–1137

Olivas GI, Mattinson DS, Barbosa-Canovas GV (2007) Alginate coatings for preservation of minimally processed “Gala” apples. Postharvest Biol Technol 45(1):89–96

Ponting JD, Jackson R, Watters G (1972) Refrigerated apple slices: effects of pH, sulfites and calcium on texture. J Food Sci 36:349–350

Qi H, Hu W, Jiang A, Tian M, Li Y (2011) Extending shelf-life of fresh-cut ‘Fuji’ apples with chitosan-coatings. Innov Food Sci Emerg Technol 12:62–66

Ranganna S (1999) Handbook of analysis and quality control for fruits and vegetable products, 3rd edn. Tata McGraw-Hill Publishing Company Ltd, New York

Robles-Sanchez RM, Rojas-Graü MA, Odriozola-Serrano I, Gonzalez-Aguilar G, Martin-Belloso O (2013) Influence of alginate-based edible coating as carrier of antibrowning agents on bioactive compounds and antioxidant activity in fresh-cut Kent mangoes. Food Sci Technol 50(1):240–246

Rocculi P, Romani S, Rosa MD (2004) Evaluation of physico-chemical parameters of minimally processed apples packed in non-conventional modified atmosphere. Food Res Int 37:329–335

Saba MK, Sogvar OB (2016) Combination of carboxymethyl cellulose-based coatings with calcium and ascorbic acid impacts in browning and quality of fresh-cut apples. Food Sci Technol 66:165–171

Sanchís E, Gonzálezb S, Ghidellia C, Shethb CC, Mateosb M, Paloua L, Pérez-Gagoa MB (2016) Browning inhibition and microbial control in fresh-cut persimmon (Diospyros kaki Thunb. cv. Rojo Brillante) by apple pectin-based edible coatings. Postharvest Biol Technol 112:186–193

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Foline Ciocalteau reagent. Methods Enzymol 299:152–178

Supapvanich S, Mitrsang P, Srinorkham P, Boonyaritthongchai P, Wongs-Aree CJ (2016) Effects of fresh Aloe vera gel coating on browning alleviation of fresh cut wax apple (Syzygium samarangenese) fruit cv. Taaptimjaan. Food Sci Technol 53:2844–2850

Yousuf B, Qadria OS, Srivastavaa AK (2018) Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: a review. Food Sci Technol 89(2018):198–209

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumar, P., Sethi, S., Sharma, R.R. et al. Improving the shelf life of fresh-cut ‘Royal Delicious’ apple with edible coatings and anti-browning agents. J Food Sci Technol 55, 3767–3778 (2018). https://doi.org/10.1007/s13197-018-3308-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3308-6