Abstract

This study addresses the degassing of expanded polystyrene (EPS) using waste cooking oil (WCO) to produce a recycled EPS with potential use as construction material. Morphological, chemical and mechanical tests were performed. Scanning electron microscopy was used to assess the recycled EPS surface and its relationship with the precursors. The micrographs presented a similar surface appearance to EPS; however, some heterogeneity was observed due to variations in the composition of the material. Spectra from the chemical characterization showed similar compositions originating from EPS and WCO, suggesting a mixed process between precursors without a chemical reaction between them. An absorption band at 2930 cm−1 was found in both EPS and recycled EPS, indicating the presence of a C–H aliphatic group. An absorption band at 752 cm−1 was found in the recycled EPS with WCO, indicating the presence of a substituted aromatic ring, which suggests a mixture of precursors at high temperature (165 °C) without further chemical reactions to produce a new material. The results obtained from mechanical tests were tensile strength: 16.13 ± 1.07 MPa, elongation modulus: 1798.388 MPa, flexural modulus: 1797.1899 MPa and compression strength: 18.10 ± 2.89 MPa.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Expanded polystyrene (EPS) is a well-known polymer widely used as packaging material for many types of goods. With almost 98 % gas by volume for construction applications, EPS is an inert closed-cell thermoplastic that is lightweight and exhibits stiffness and toughness properties, low thermal conductivity and high impact resistance to a wide range of chemical compounds over a range of pH values [1]. Due to these exceptional properties, EPS is in high demand for several industries worldwide; however, once the material is used, it is disposed of in landfills, where it can remain intact for several generations.

Managing this waste involves certain difficulties due to its low mass/volume ratio to transport costs; and landfill disposal is unfeasible due to its low degradability. Other methods for handling polymeric residues are: (a) energy recuperation by incineration, which comes with multiple concerns, primarily the release of green-house gases; (b) mechanical conversion of polymer into new products, although classification and energy input make it even more expensive than new polymer precursors [2], making this process environmentally unsustainable; and (c) chemical recycling based on depolymerization and chemical decomposition to produce low molecular weight products [3]. Recycling has greater relevance in the modern world, and the current strategies are aimed at ameliorating plastics pollution, thus reducing one of the most significant pollutants. In this way, EPS is usually recycled together with other plastics or other types of materials, such as wood [4, 5], organic wastes [6], cement [7, 8], and concrete [9, 10]. It is estimated that just 1 % of manufactured plastics is recovered by recycling around the world, whereas most of the remaining production is placed in municipal burial sites [7]. The exponential consumption of plastics and their waste has worsened the energy problem, making suitable waste handling and recycling urgent fields of investigation and application.

Oil is highly polluting due to its low density in comparison to water, resulting in a superficial layer of oil that reduces oxygen diffusion into any water source; moreover, the pollution produced by oil in water is 1:1,000,000 by volume. Oils and fats have been used by humans for thousands of years, initially as something to rub onto themselves and then as an ingredient in food preparation [11]. Palm oil is a vegetable oil obtained from the mesocarp of the fruit of the oil palm (Elaeis guineensis) and is a fat in the form of a liquid or a semisolid, according to the surrounding temperature, containing approximately 50 % saturated fatty acids, 40 % monounsaturated fatty acids and 10 % polyunsaturated fatty acids [11].

Currently, oil is used for the generation and preparation of food. Approximately 183.8 million tons are used for this purpose (Table 1). The largest consumer and generator of waste oil is China, which currently it makes up, according to the FAO, the largest areas of growth with figures of domestic consumption approximately 34,000 tons. The European Union has a consumption of 4 % less than China and is followed by South America, Brazil and Argentina, with approximately 7.5 million tons. As shown in Fig. 1 and in Table 2, the production is high and so is the consumption. Consumption has increased over time [12]. When using cooking oil for other purposes, 65 % is consumed in food production (oil consumption per person was estimated to be between 1.5 and 6 L [11, 12] and the remaining 35 % becomes waste at the end of its useful life, being disposed through pipes and siphons. Generally, the used cooking oil is not considered as a hazardous waste, but it does cause environmental problems [13].

Production and use of oils and fats according to the FAO: a general data and b classification by countries in 2011–2012 [12]

After using the oils, they are usually disposed of improperly. Because of a lack of regulations and environmental awareness, the waste is directed through drainage canals to water tributaries, causing pollution and problems that are difficult to treat, such as the formation of surface layers that impede the transfer of oxygen from air to water, causing large-scale complications for aquatic ecosystems, sewage networks and treatment plants [13]. Most of the waste from vegetable oil comes from food industries (fried food) restaurants, fast food chains and homes. Some figures indicate that 1 L of this residual oil can contaminate 1000 L of drinking water, and for this reason, applications that include the use of this waste are being developed to use the oil for new purposes and to minimize the pollution [13].

This paper presents a method to process recycled EPS and waste cooking oil (WCO) to obtain a material with useful properties for construction applications and presents its physical, chemical and mechanical characterization.

Experimental Study

Raw Materials

The commercial waste of EPS was cut into pieces of approximately 5 cm × 5 cm × 5 cm. Cooking oil was collected and stored and then filtered with a 410 μm filter to remove food waste particles. The diameter of the strainer was determined by means of an Eclipse Ni-U Nikon microscope.

Experimental Procedure

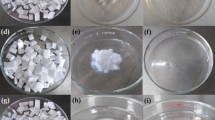

In a fume hood, pieces of EPS were dissolved one-by-one in abundant WCO until total degassing of each fragment occurred at 165 °C under atmospheric pressure. The mass formed under these conditions was agglomerated at the bottom. WCO was used in abundance to ensure that all of the EPS in contact with the oil dissolved and to avoid material fragmentation due to lack of solvent. While hot, the resulting mass can be processed into fibers (Fig. 2a), sheets (Fig. 2b) or blocks (Fig. 2c) and is then cooled until it reaches atmospheric temperature. Some samples of this material (recycled EPS) were subjected to chemical, morphological and mechanical tests.

Fourier-Transform Infrared Spectroscopy: FTIR

Fourier-transform infrared spectra were measured on an IR Prestige-21/Shimadzu spectrometer (Shimadzu, Japan) using the KBr disk technique. The measurements were conducted in the range of 400–4000 cm−1 at room temperature.

Scanning Electron Microscopy: SEM

SEM analyses were performed with a scanning electron microscope from JEOL (JSM 6490 LV, M/s Hitachi, Tokyo, Japan). Samples were mounted on bronze stubs using double-sided tape and were coated with a layer of gold (40–50 nm) for surface visualization.

Mechanical Tests

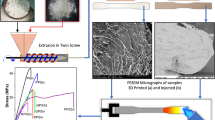

The mass obtained from degassing was subjected to degassing in a vacuum oven at 558.8 Torr and 220 °C for 4 h to remove excess oil and air still present in the recycled EPS and to decrease the number of imperfections in the new material. Subsequently, sheets of 120.0 ± 0.02 mm × 120 ± 0.02 mm with a thickness of 2 ± 0.02 mm and an average mass of 28.3 g were prepared by hydraulic pressing at an average temperature of 170 °C and a pressure between 0.5 and 7 psi. Probes for mechanicals tests were cut from these sheets. Mechanical testing was performed using a Shimadzu Model AGX Universal Testing Machine (Shimadzu, Japan). The stress–strain behavior was assessed for samples cut to 10 ± 0.02 mm × 115 ± 0.02 mm × 1.5 ± 0.02 mm, according to the specifications for a type IV probe in the ASTM D638 standard at a 30 mm/min elongation rate.

Flexural moduli in the three-point bending mode were determined according to the ASTM D790 standard using samples cut to 50.8 mm ± 0.02 mm × 12.7 ± 0.02 mm × 1.48 ± 0.02 mm in size at a 0.01 mm/mm/min flexural rate with a distance between supports of 25.4 mm.

Compressive strength tests were performed for samples cut to 25 mm ± 0.02 × 25 mm ± 0.02 and stacked to a height of 25 mm, as specified in the ASTM D696 standard at a 1.3 mm/min compression rate. The reported data are an average of tests on 5 trays.

Determination of the Fraction of Cooking Oil in Recycled EPS

Soxhlet extraction was used to determine the fraction of kitchen oil in a sample of 1.147 ± 0.001 g of recycled EPS. The average particle size was 4.5 mm, as determined with mesh N° 40. The time of residence of the sample in the Soxhlet extraction system was 90 min for the boiling solvent (hexane 99 % v/v).

Differential Scanning Calorimetry: DSC

The thermal properties of the WCO sample were determined using a TA Instruments Thermal Analysis differential scanning calorimeter (DSC). Scanning was performed at a heating rate of 10 °C/min and under a nitrogen flow of 50 mL/min. A sample was placed in a standard aluminum sample pan to determine its melting temperature.

Results and Discussion

The experimental results were statistically verified by analysis of variance.

Energetic Balance

A hotplate (Corning Hot Plate/Magnetic Stirrer) was used to achieve the proper temperature. The energetic consumption was performed using a 268.1 g sample of recycled EPS of 20 cm × 10 cm × 10 cm and an average density of 934 kg/m3 (Fig. 2c). The hotplate was used for approximately 90 min at 120 V and 7.71 A. The energetic consumption was 5180 MJ/kg of recycled EPS, which is higher than the energy embodied in brick production (2.7 MJ/kg) and less than the energy of other plastics used as building materials (Table 3). In this context, recycling EPS with WCO may reduce the energy used in producing new EPS by more than five times.

FTIR

Figure 3 and Table 4 show the FTIR spectra of the recycled EPS sample compared with the spectra of the precursors. The spectrum of the recycled EPS shares some absorption bands with the precursors: at 3000 and 2900 cm−1, which are in the range of the C–H stretching vibrations of –CH2– and –CH3 groups, and there are also two bands corresponding to C–H aromatic and C–H aliphatic that remain in the recycled EPS after its processing from EPS. The asymmetric (νasCH2) and symmetric (νsCH2) stretching vibrations of the –CH2– groups result in absorption bands at wave numbers of 2930 and 2855 cm−1, respectively, whereas that of the –CH3 groups is at 2855 cm−1. The number of –CH2– groups is proportional to the intensity of the asymmetric stretching vibration bands at 2930 cm−1. At 1466 cm−1, the band assigned to the –CH2 aromatic group appears and has a lower intensity in the recycled EPS than in EPS. The C=O group from cooking oil and the recycled EPS have the same absorption band at 697 cm−1, which is due to the WCO and belongs to (CH2)n>3.

From the FTIR spectra, it can be concluded that the precursors (WCO and EPS) are mixed at high temperatures and undergo a subtle reaction between; however, some properties from each precursor can be maintained in the final product.

SEM

Figure 4 shows the SEM micrographs of the surface morphology of the EPS samples prior to and after degassing using WCO. Figure 4a shows a typical structure of EPS (50×) with the net and the entrapped air, which are the main components in this polymer, whereas in Fig. 4b, a dense EPS particle is shown at higher magnification (3000×). At the end of the degassing process, the recycled EPS with WCO is obtained and is shown in Fig. 4c, where the polymeric net is collapsed by degassing at high temperatures (2000×).

Mechanical Assessments

The results of the mechanical tests of the tensile, flexural and compression for recycled EPS with oil are presented in Table 5 and Fig. 5. The properties were compared with those reported in the literature for trade polystyrene (Mw = 225.000 g/mol) following the same ASTM standards used previously (Table 6). The recycled EPS with WCO had lower mechanical resistance, lower elongation and lower compression modulus; however, the ductility was near the reported value. It is likely that the mechanical properties are reduced by the recycling process because of degradation in the polymeric chains due to oxidation [14]; however, there may be other factors that affect the material, making it resistant in the presence of air. After the second degassing process with WCO, the trapped air in the polymer mass was released, and these empty spaces could behave as defect concentrators, facilitating crack propagation under stress and therefore low resistance to mechanical tests.

The compression strength was measured by stacking sheets of approximately 1.5 mm to obtain a height of 25 mm, which is not comparable with the properties obtained from a flat sheet of the same height. Although the strength of the material is less than the reported strength for trade polystyrene, the ductility is maintained despite the change in the other properties. This behavior may be due to the presence of oil between polymer the chains, which reduces the viscosity of the polymer, making the chains mobile, which would represent an advantage for processing because an injection process can reach higher speeds, shorter times and lower temperature, all of which are useful for the production of thin-walled products, such as toys, dishes and packaging [15].

Based on the properties obtained for expanded recycled EPS using WCO, the material can be applied in the production of tiles for covering floors and walls. Recycled EPS has a compressive strength of 1810 N/cm2 according to the values given by Standards ICONTEC NTC 1085 and 919 (1100–1350 N/cm2), which is comparable to concrete and ceramic tiles. Therefore, the material is suitable for this application after a washing process to remove WCO.

Extraction by Soxhlet Technique

Samples with/without superficial washing (n = 3) were used in the extraction of oil by Soxhlet technique (Fig. 6).

The fraction of oil for the sample without any treatment was 12.130 ± 0.290 % w/w, whereas for the material washed with water and detergent, the fraction was 10.668 ± 0.142 % w/w. These results indicate that there is approximately 1.30 % of superficial WCO in the final material. This fraction demonstrates that the foreseen applications are viable because there is not a significant superficial fat content. Nevertheless, there may be leaching problems that could be solved by a rest following the production and molding to free the excess WCO. The washing of the material would then be performed.

Thermal Properties

A typical DSC thermogram of the WCO sample is shown in Fig. 7. After purging with nitrogen UAP at 50 mL/min for 30 min, the differential scanning calorimetry was performed in three cycles: first, the sample was heated from 0 to 250 °C using a ramp of 10 °C/min; second, the sample was cooled to 0 °C; and third, the sample was heated again at the same conditions of cycle 1.

In cycle 1, the glass transition temperature (Tg) for the sample is at 55 °C, which is less than the Tg of EPS (100 °C) due to a plastification process caused by WCO. After 113 °C, a broader shoulder is observed due to a chemical reaction between free WCO in the matrix and plasticized EPS. This fact is confirmed because the Tg is higher in cycle 3, where the second heating is performed. Cycle 3 increased the Tg of the recycled EPS to 62 °C because the available plasticizer in the matrix was consumed during the chemical reaction in the first cycle. Moreover, the broad shoulder disappeared in the second heating due to the chemical reaction that occurred during the first cycle.

Conclusions

The current investigation’s aim was to examine the possibility of combining two waste products, namely, EPS and WCO, in a recycling process to produce a solid polymeric product. This product underwent morphological examination (SEM) and was characterized chemically (FTIR) and physically (a mechanical testing regime). These results were compared with those of waste stream precursors.

Both precursor wastes (EPS and WCO) are significant pollutants when released into the environment. The wastes adversely affect both soil and water quality and their ability to support healthy, natural, ecosystems. Therefore, any process that removes these two waste products from the waste stream is highly beneficial to society. The ability to produce a potentially useful product from the EPS and WCO waste is a value added process.

The present investigation was motivated by a desire to produce a volume reduction (a 1:50 reduction of the original volume, depending of the initial density) of waste EPS without polymer degradation using a simple, low-cost process [16].

The SEM micrographs suggest similar surface morphology between the EPS sample and the EPS/WCO recycled product, with the observed heterogeneity due to the variation in the composition of the feed material.

Under the conditions employed in the laboratory and the variables adjusted to those mentioned in the methodology, the energy consumption for the production of one gram of recycled EPS is 18.6 MJ/kg. Therefore, this is an economically viable process to manage at the industrial level.

The FTIR spectra suggest that the recycled polymer product is a simple mixture of EPS and WOC without the presence of new chemical compounds produced by chemical interactions.

The results from mechanical testing, namely, the tensile strength, elongation modulus and flexural modulus (Table 2), were considerably lower than those for commercial polystyrene (Table 3). Furthermore, the recycled materials exhibit low density, brightness and ability to acquire fragrances and color (Fig. 2d), suggesting potential use as a construction material.

The total percentage of fat in the recycled EPS is approximately 12.1 % w/w. The total percentage of fat after the Soxhlet process is 1.3 % w/w. Therefore, the material is suitable for use as a construction material after leaching and washing to eliminate the majority of the fat content.

Finally, the DSC results show that the recycled material had different thermal properties than the initial raw materials, with a decreased glass transition temperature in comparison to EPS due to the presence of WCO.

References

Bhutta, M., Ohama, Y., Tsuruta, K.: Strength properties of polymer mortar panels using methyl methacrylate solution of waste expanded polystyrene as binder. Constr. Build. Mater. 25, 779–784 (2011)

Brandrup, J.: Recycling and Recovery of Plastics. Hanser Publishers, Munich (1996)

Manrich, S., Santos, A.: Plastic Recycling. Nova Science Publishers, New York (2009)

Agoua, E., Allognon-Houessou, E., Adjovic, E., Togbedji, B.: Thermal conductivity of composites made of wastes of wood and expanded polystyrene. Constr. Build. Mater. 41, 557–562 (2013)

Poletto, M., Dettenborn, J., Zeni, M., Zattera, A.: Characterization of composites based on expanded polystyrene wastes and wwod flour. Waste Manag. 31, 779–784 (2011)

Choi, N., Mori, I., Ohama, Y.: Development of rice husks-plastics composites for building materials. Waste Manag. 26, 189–194 (2006)

Asaad, J., Tawfik, S.: Polymeric composites based on polystyrene and cement dust wastes. Mater. Des. 32, 5113–5119 (2011)

Laukautis, A., Zurauskas, R., Keriene, J.: The effect of foam polystyrene granules on cement composite properties. Cem. Concr. Composite 27, 41–47 (2005)

Demirboga, R., Kan, A.: Thermal conductivity and shrinkage properties of modified waste polystyrene aggregates concretes. Constr. Build. Mater. 35, 730–734 (2012)

Tang, W., Cui, H., Wu, M.: Creep and creep recovery properties of polystyrene aggregate concrete. Constr. Build. Mater. 51, 338–343 (2014)

Adams, A.: Producción y consumo de aceites vegetales. Instituto Interamericano de Ciencias Agrícolas OEA, Bogotá (1965)

FAO (Food and Agriculture Organization the United Nations). : Perspectivas Alimentarias. IOP Publishing PhysicsWeb http://www.fao.org/fileadmin/templates/est/COMM_MARKETS_ MONITORING/Oilcrops/Documents/Food_outlook_oilseeds/FO_SPA_NOV11.pdf (2011). Accessed July 2015

World, O.: Latest OIL WORLD HEADLINES. IOP Publishing PhysicsWeb. http://www.oilworld.biz/app.php (2010). Accessed July 2015

Noguchi, T.: A new recycling system for expanded polystyrene using a natural solvent. Part 1. A new recycling technique. Pack. Technol. Sci. 11, 19–27 (1998)

Harper, C.: Modern Plastics Handbook. Mc Graw-Hill, New York (1999)

Garcia, M., Duque, G., Gracia, I., Lucas, A., Rodríguez, J.: Recycling extruded polystyrene by dissulution with suitable solvents. Mater. Cycles Waste Manag. 11, 2–5 (2009)

Scheuer, R.: Life cycle energy and environmental performance of a new university building: modeling challenges and design implications. Energy Build. 35, 1049–1064 (2003)

Mikolsczi, N., Bartha, L.: Investigation of hydrocarbon fractions form waste plastic recycling by FTIR, GC, EDXRFS and SEC techniques. Biochem. Biophys. Methods 70, 1247–1253 (2008)

Shogren, L.: Starch-poly (vinyl alcohol) foamed articles prepared by a baking process. Appl. Polym. Sci. 68, 2129–2140 (1998)

Acknowledgments

The authors wish to thank Dr. Jairo Perilla Perilla for the DSC analysis. The authors would also like to acknowledge the financial support received from the Universidad Jorge Tadeo Lozano (Project No. 411-08-11).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarmiento, A.M., Guzmán, H.L., Morales, G. et al. Expanded Polystyrene (EPS) and Waste Cooking Oil (WCO): From Urban Wastes to Potential Material of Construction. Waste Biomass Valor 7, 1245–1254 (2016). https://doi.org/10.1007/s12649-016-9511-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9511-7