Abstract

Porous carbon adsorbents were prepared from microalgae (Chlorococcum sp.) via directly hydrothermal carbonization coupled with KOH or NH3 activation for Cr(VI) adsorption. KOH-activated porous carbons exhibit high Cr(VI) adsorption capacities than those obtained via NH3 modification (370.37 > 95.70 mg/g). The superior Cr(VI) adsorption capacity is due to high surface areas (1784 m2/g) and pore volumes of porous carbon with mesoporous and macroporous structures. The Cr(VI) adsorption result was well fitted to the Langmuir model, showing that the removal of Cr(VI) was attributed to the monolayer adsorption of activity site on carbon surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Porous carbon materials from biomass have attracted attention due to their potential applications in energy storage, catalysis, water purification, gas adsorption, and separation [1,2,3]. Recently, methods for producing porous carbon materials from cheap natural resources using environmental friendly process are being extensively explored, for example, the use of plant biomass as a precursor and hydrothermal carbonization (HTC) process [4, 5]. Although HTC is a traditional route to produce activated carbons, it offers clear advantages; in that, it is a kilogram-scalable process allowing to produce various carbons and hybrid nanostructures under mild hydrothermal conditions [6,7,8].

Hydrochar, obtained from HTC, is receiving more attention in the field of wastewater treatment as adsorbent because of its intrinsic properties, such as low cost, porous structures, high surface area, large pore volumes, availability of abundant functional groups, and environmental kindness [9]. Kumar et al. reported that hydrochar produced from switchgrass could serve as an excellent adsorption to remove uranium from groundwater [10]. Researchers developed a simple process for direct synthesis of magnetic carbon composites through HTC, and magnetic hydrochar was used to remove heavy metals and organic pollutants, such as arsenic, cadmium, lead, phosphate, chromium, and fluoride [11,12,13]. Due to a large surface area and a highly ordered structure, porous carbon which was prepared by activation of hydrochar have been already investigated as promising adsorbents for various organic pollutants and metal ions. Zhu [14] used wheat straw as director precursor and prepared porous carbon impregnated by bismuth, which possesses a Cr(VI) adsorption capacity of 12.23 mg/g at 25 °C for 24 h. Cao [15] reported that melamine-derived, nitrogen-doped carbon nanoadsorbents could be used for Cr(VI) removal with adsorption capacity of 29.40 mg/g at pH 7. The porous carbon was derived from coconut shell, and it resulted in high removal efficiency at pH < 7. It was also found that removal efficiency increases with a decrease in chromium concentration, and the adsorption follows the Freundlich isotherm [16]. An investigation on the use of diatomite to remove chromium was also conducted [17]. Microemulsion-treated diatomite is quite efficient in removal process of metallic ions. The adsorption capacity of diatomite was found to be 1.68 mg of Cr(VI)/g at pH of 2.95. Cellulose is the most abundant among renewable and natural polymers, and it has three reactive hydroxyl groups. It was reported that an adsorption capacity of 73.46 mg of Cr(VI)/g spheroidal cellulose was achieved at pH of 6.0 [18]. It was reported that an adsorption capacity of 6.70 mg of Cr(VI)/g was achieved at pH of 7 using modified carbon foam as adsorbent in aqueous solution [19]. Monser carried out an adsorption study on modified activated carbon, which have tetrabutyl ammonium iodide and sodium diethyl dithiocarbamate immobilized at their surface, for the removal of Cr(VI) from wastewater. It was reported that maximum removal of Cr(VI) is 6.84 mg/g and the adsorption followed the Langmuir isotherm [20].

It is well known that microalgae, a kind of single-celled aquatic plant with very high photosynthesis efficiency and fast growth rate, is considered as an appropriate source for producing bio-fuel, bio-chemicals, food, or medical industry [21,22,23,24]. There have been a few studies on the direct use algae or microalgae for producing carbon materials [25, 26]. The use of microalgae with high nitrogen content as precursor to produce N-containing carbon materials for carbon capture and storage (CCS) has been scarce [27, 28]. Nitrogen-doped carbon materials are synthesized based on the HTC of microalgae and glucose, resulting in materials possessing nitrogen content in excess of 7 wt%. Increasing the HTC temperature leads to form more condensed nitrogen-containing functional group [25]. In fact, researches and applications about microalgae were mainly focused on the utilization of nitrogen element for preparing nitrogen-doped carbon, but the microalgae rich in carbohydrate tend to be ignored.

In this work, sugar-rich microalgae (Chlorococcum sp.), with carbohydrate content of 49.6%, was used as an feedstock for directly preparing porous carbons through HTC along with chemical activation using KOH and NH3 under varying conditions. The synthesized carbons were investigated in adsorption experiments for the removal of heavy metal Cr(VI) from aqueous solutions. The adsorption capacity was as high as 370.37 mg/g for Cr(VI) which is well beyond ordinary sorption capacities, providing the efficiency of the materials to bind and buffer ions, or more specifically to remove heavy metal pollutants. This study further focuses on the relationship between the porous structures and their high Cr(VI) adsorption capacity of carbon materials.

Experiment

Materials

The sugar-rich microalgae (Chlorococcum sp.) used in this work was self-cultured by our co-workers. The compositions of microalgae were shown in Table 1. All the other chemicals were purchased from Sinopharm Chemical Reagent Co., Ltd., and used as received without further purification.

Preparation of Porous Carbons

The hydrochar was prepared by HTC of microalgae (Chlorococcum sp.). Briefly, 2.25 g of microalgae, 0.70 g oxalic acid, and 30 mL distilled water were placed in a stainless steel autoclave (Parr rector, 100 mL), heated up to 200 °C, and maintained at this temperature for 3 h. After the reaction, the autoclave was cooled down to room temperature. The solid products named as hydrochar were collected by filtration, washed with distilled water, and finally dried at 110 °C for 12 h [28].

In this study, hydrochar underwent direct KOH activation and NH3 activation for preparing the porous carbons. Typically, 1.0 g hydrochar was mixed with 2.0 g KOH and 20 mL distilled water and stirred at 600 rpm for 4 h, followed by another 12 h of static soaking under ambient conditions. After drying overnight at 105 °C, the mixture was first heated to 400 °C with a retention time of 30 min at heating rate of 8 °C/min, and then to 650–750 °C with a retention time of 60 min at 10 °C/min under flowing N2 (120 mL/min). After cooling down naturally, the sample was repeatedly washed by distilled water until a pH value of 7 was reached. The porous carbons thus synthesized were denoted as AC-KOH-x, where x refers to the activation temperature (°C). As for the NH3 activation, the hydrochar was heated to 900 °C at 8 °C/min with N2 (120 mL/min) and were subjected to a second heat treatment under flowing NH3 (60 mL/min) at 900 °C for 30 min to form the NH3 activated carbons. The cooling steps were performed in N2 atmosphere (120 mL/min). Carbons by NH3 activation were named as AC-NH3-y, where y refers to the activation temperature (°C).

Cr(VI) Adsorption

The Cr(VI) solution (500 mg/L) was prepared with potassium dichromate (K2Cr2O7; guaranteed reagent) and then diluted to different concentration range from 10 to 150 mg/L. Adsorption experiments were conducted in Erlenmeyer flasks (100-mL capacity) by adding 50 mL K2Cr2O7,10 mg and 2 mL 1,5-diphenylcarbazide C13H14N40 (DPC) chromogenic agent, successively. The pH was adjusted to the value of 3 by the addition of 0.1 M HCl into the solution. The adsorption experiments were performed in Erlenmeyer flasks placed in a laboratory shaker at a speed of 200 rpm for 24 h at 25 °C. The solutions were then filtered through a standard filtration paper, and the concentration of chromium was determined using ultraviolet spectrophotometer (UV-2150) at its maximum wavelength of 540 nm. The DPC chromogenic agent was prepared by adding 0.05 g DPC solid and 1 mL H2SO4 into 100 mL acetone solution, and then sealed in the dark.

The removal capacity of Cr was calculated as follows:

where Q is the removal capacity of Cr at equilibrium (mg/g); C0 and Ct are the initial and equilibrium concentrations of Cr (mg/L), respectively; V is the volume of the solution (mL); and m is the weight of absorbents (mg).

Characterization

Elemental analysis (C, H, and N) was performed on a dry basis using a Thermo Scientific Flash 2000 analyzer. The morphology of the samples was examined by scanning electron microscopy (SEM) using S-4800 instrument. Nitrogen sorption isotherms and textural properties of samples were measured on Micromeritics TriStar II Plus equipment at liquid nitrogen temperature. Before measurement, the samples were degassed in a vacuum at 200 °C for at least 12 h. The specific surface area and pore size distribution were calculated by BET method and BJH model, while the total pore volume was calculated by the adsorption in pressure P/P0 = 0.985.

Results and Discussion

Physicochemical Properties and Structure Characterization

Elemental compositions of the raw material and the prepared carbons are shown in Table 1. The HTC of microalgae leads to increasing both carbon and nitrogen retention in the final hydrochar, which shows the value of carbon content ranging from 48.40 to 66.30% and the nitrogen content increasing to 2.94%. During the HTC, Maillard-type cascade reaction takes place between the amino groups in amino acids and the carbonyl moieties present in carbohydrates and their derivatives (e.g., HMF) [26], resulting in the enrichment of carbon and nitrogen. It is worth noting that the specific surface area of the hydrochar prepared from sugar microalgae is as small as 11.05 m2/g. Further KOH activation of hydrochar has caused a sharp decrease in nitrogen amounts while the carbon content increases gradually, indicating that a deeper graphitization was formed and nitrogen-containing functional group on the surface was not stable as the activation temperature increases. On the contrary, the final nitrogen content of activated carbon obtained with NH3 activation was significantly higher than that of hydrochar, since the content is 5.16% even at 900 °C.

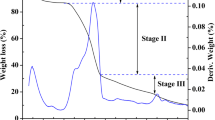

In order to further understand the physicochemical properties of these kinds of porous carbon, we examined the porosity of the activated materials through N2 sorption at − 196 °C. The N2 sorption isotherm curve is shown in Fig. 1. Obviously, AC-KOH-650 and AC-NH3 both exhibit type I isotherm, typical of microporous materials. At low relative pressure (P/P0 < 0.1), N2 adsorption has a rapid increase, revealing the presence of microspores. Subsequent horizontal or nearly horizontal plateau indicates that the microspores were filled up; thus, little further adsorption could occur. And adsorbate may be condensed under the saturation pressure. The sorption isotherm curve of porous carbon altered obviously with the increase of the KOH activation temperature. The isotherms with conspicuous hysteresis loops in AC-KOH-700 and AC-KOH-750 show a combination of type I and type IV isotherms, indicating the presence of mesopore structure. The N2 adsorption has a sharp increase at low relative pressure (P/P0 < 0.1), while capillary condensation makes mesoporous filling at a high relative pressure range (P/P0 = 0.5–1.0).

The detailed textural parameters of these porous carbons are given in Table 2. Compared with hydrochar, KOH and NH3 activation carbons (e.g., AC-KOH-750 sample) have a relative high specific surface area and total pore volume, whose SBET is as high as 1784 m2/g and the Vt value is 1.20 mL/g, while the hydrochar has low total surface area (11.05 m2/g) and negligible pore volume. The significant increase in specific surface area and pore volume is due to the pore formation and etching capabilities of KOH and NH3. It should be noted that, for all KOH activation carbons, the specific surface area and total pore volume increase with the rise of activation temperature. With the increase of the activation temperature, more energy is provided for the reaction between the carbon atoms and steam resulting in the formation of new pores and enlargement of the existing pores. It can be seen that mesopores and macropores have a greater effect on increasing the surface areas of the prepared activated carbons rather than in the micropores. This can be related to the fact that the reaction rates at such high temperatures are so fast that once the micropores are developed, further carbon burnoff occurs rapidly, leading to the enlargement of micropores to mesopores and macropores. Meanwhile, the fraction of mesoporous and macroporous volumes to total pore volumes (Vn) follow the same trend, with values increasing from 33.33 to 51.67%, as the temperature rises from 650 to 750 °C, whereas the average pore size increases from 3.39 to 4.26 nm. Compared with KOH activation, the pore formation and etching capabilities of NH3 activation are much weaker, but its surface area has also reached 487 m2/g with a very low ratio of mesoporous and macroporous volumes to total pore volumes, whose proportion is just 18.52%, indicating that most of the structure in NH3 activation carbons is microporous, which is consistent with the adsorption isotherm above.

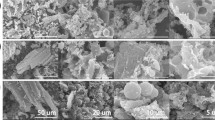

The SEM images of several porous carbon samples are shown in Fig. 2. The panoramic image of hydrochar (in Fig. 2a) exhibits irregular- and clear-shaped bulks with some disorder accumulations. While after chemical activation with KOH, the SEM image for the AC-KOH-750 °C sample clearly demonstrates the formation of irregular and macro-porous networks (in Fig. 2b). The notable morphological change has shown that the KOH activation is an effective method and redox reaction which can etch the graphite layer to form porous carbon usually occurs at high temperature. The specific reaction process can be described by the following reaction:

The generated sylvite can be removed by subsequent washing. After being activated with NH3, the hydrochar shows a great number of spherical particles with disorder accumulations. In this case, we can reasonably assume that the activation process of NH3 occurs on the surface of the carbon layer and the reaction of NH3 and oxygen-containing functional groups on the carbon surface makes the particles transform into clusters.

Analysis of Adsorption Capacity for Cr(VI)

It is generally believed that the adsorption of porous carbon on the adsorbate mainly depends on the following two ways: (1) the synergistic effect of functional groups on the carbon surface, especially oxygen-containing functional groups (such as −OH) and (2) physical adsorption which depends on the specific surface area, pore size distribution, and pore volume of the porous carbon. In order to analyze the possible adsorption mechanism of porous carbon on heavy metal ions, we studied the adsorption of porous carbon on heavy metal ions Cr(VI) from industrial wastewater.

The adsorption isotherms on several porous carbon of initial Cr(VI) concentration ranging from 40 to 120 mg/L under the same addition of adsorbent (10 mg porous carbon was added, scilicet 0.2 g/L) were shown in Fig. 3. It is obvious that the adsorption capacity of hydrochar prepared with different activation methods showing the following relationship: KOH activation carbon > NH3 activation carbon > untreated hydrochar. And the obvious difference in adsorption capacity of these carbon materials is closely associated with the discrepancy in their structure. Hydrochar exhibits irregular-shaped bulks with some disorder accumulations, small specific surface area, and pore volume. Although the value of nitrogen content is 2.94%, the comprehensive adsorption effect is limited because of the lack of physical adsorption. However, the specific surface area of KOH activation carbon is as high as 1100–1800 m2/g, coupled with almost all microporous and mesoporous structures and considerable nitrogen content (1.70%), greatly improving the irregular multi-phase activity site on carbon surface, with favorable adsorption properties. Compared with KOH activation carbon, the carbon activated by NH3 has smaller surface area (487 m2/g) and weaker adsorption performance due to limited pore formation capacity of NH3 and large amount of ash, in spite of high nitrogen content (up to 5.16%). It should be noted that, for all KOH activation carbons, the adsorption capacity of Cr(VI) increases with the rise of activation temperature, with values ranging from 178.57 to 333.33 to 370.37 mg/g, which is consistent with the change in specific surface area and total pore volume. The removal capacity of Cr(VI) on hydrochar derived from various biomass has been showed in previous studies: 8.45 mg/g for Arundo donax Linn particles (Sun et al. 2014) and 5.50 mg/g for oak wood (Mohan et al. 2011). By contrast, the removal capacity of hydrochar obtained in the present study is much better to those reported by other researchers. With the decrease of micropore volumes to total pore volumes from 650 to 750 °C, the adsorption capacity displayed increased trend. Therefore, it is reasonable to speculate that the physical adsorption of three kinds of porous carbon, that is, the surface structure, is the main factor of the adsorption of Cr (VI), while the surface functional groups have limited influence. In addition, the adsorption curve slope of KOH activation carbon and NH3 activation carbon is large at low initial concentration of the solution, which indicates that the adsorption efficiency of the samples is much higher at low concentration. As for the hydrochar, the adsorption curve of hydrochar is relatively stable.

To analyze the adsorption isotherms of Cr(VI) onto porous carbons, the Langmuir and Freundlich isotherm models were employed to describe the equilibrium adsorption [29, 30]. The linear form of the Langmuir model and the Freundlich model could be described as follows in turn:

where Qe (mg/g) and Ce (mg/L) are the equilibrium concentrations of Cr(VI) on the adsorbent and solutions, respectively. Qmax (mg/L) is the Langmuir constant representing the maximum monolayer adsorption capacity (amount of adsorbed metal ions per 1 g of sorbent as a monolayer). KL and KF are the Langmuir constants and Freundlich constants. If the adsorption is feasible, the 1/n value is between 0 and 1. Otherwise, 1/n > 1 indicates that the adsorption model is not applicable.

The model parameters and the correlation coefficient of the adsorption of Cr(VI) onto several kinds of porous carbon are shown in Table 3. According to the Langmuir isotherm model, the adsorption capacity of KOH activation carbon, NH3 activation carbon, and hydrochar on Cr(VI) ions was 370.37, 95.60, and 17.60 mg/g, respectively. It is obvious that the adsorption capacity of KOH activation carbon exhibited higher adsorption capacity on Cr(VI) ions compared with those activated with NH3 or untreated hydrochar. Naturally, the adsorption capacity of activated carbon increases with the rise of activation temperature, with values ranging from 178.57 mg/g (650 °C) to 370.37 mg/g (750 °C). The reason for such high surface areas and uptake capacities is the efficient chemical activation of hydrochars due to their surface characteristics. As for the Freundlich isotherm model, although the parameter 1/n (0 < 1/n < 1) indicates that the model can be applied to the adsorption of Cr(VI) on porous carbon, the change of KF is irregular and the correlation degree R2 cannot fully meet the requirements comparing with the Langmuir isotherm model.

In general, the adsorption of Cr(VI) is well fitted to the Langmuir model (Fig. 3), indicating that the removal of Cr(VI) can be attributed to the monolayer adsorption on carbon surface [29]. The adsorption capacity of the porous carbon with high specific surface area is much larger due to the evenly distribution of adsorption site on carbon surface, which is consistent with the analysis about the structure of porous carbon. That is, the physical adsorption of these kinds of porous carbon is the main factor which affects the adsorption of Cr(VI), while the effect of surface functional groups is limited. All in all, we can make a conclusion that the porous carbon owned the high surface area as the carrier of adsorption site and can potentially promote the adsorption of Cr(VI) in water treatment.

Conclusion

This study reports the synthesis of porous carbon sorbents through the HTC of microalgae (Chlorococcum sp.) along with KOH or NH3 activation. The results indicated that porous carbons using KOH activation exhibit a higher Cr(VI) adsorption capacity than the carbon treated by NH3 and Cr(VI) uptakes of 370.37 and 95.60 mg/g, respectively. The superior Cr(VI) adsorption capacity is due to the presence of high surface areas and mesoporous and macroporous structures. The adsorption of Cr(VI) is well fitted to the Langmuir model, indicating that the removal of Cr(VI) can be attributed to the monolayer adsorption of activity site on carbon surface.

References

Minami, E., & Saka, S. (2005). Biomass resources present in Japan—annual quantities grown, unused and wasted. Biomass and Bioenergy, 29(5), 310–320.

Gupta, R. B., & Demirbas, A. (2010). Gasoline, diesel and ethanol biofuels from grasses and plants. Cambridge: Cambridge University Press.

Azar, C., Lindgren, K., Larson, E., & Möllersten, K. (2006). Carbon capture and storage from fossil fuels and biomass—costs and potential role in stabilizing the atmosphere. Climatic Change, 74(1-3), 47–79.

Sevilla, M., Macia-Agullo, J. A., & Fuertes, A. B. (2011). Hydrothermal carbonization of biomass as a route for the sequestration of CO2: chemical and structural properties of the carbonized products. Biomass & Bioenergy, 35(7), 3152–3159.

Liu, W. J., Zeng, F. X., Jiang, H., & Zhang, X. S. (2011). Preparation of high adsorption capacity bio-chars from waste biomass. Bioresource Technology, 102(17), 8247–8252.

Libra, J. A., Ro, K. S., & Kammann, C. (2011). Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels, 2(1), 89–124.

Sevilla, M., & Fuertes, A. B. (2009). Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chemistry, 15(16), 4195–4203.

Sevilla, M., & Fuertes, A. B. (2009). The production of carbon materials by hydrothermal carbonization of cellulose. Carbon, 47(9), 2281–2289.

Titirici, M. M., Thomas, A., & Antonietti, M. (2007). Back in the black: hydrothermal carbonization of plant material as an efficient chemical process to treat the CO2 problem? New Journal of Chemistry, 31(6), 787–788.

Kumar, S., Loganathan, V. A., Gupta, R. B., & Barnett, M. O. (2011). An assessment of U(VI) removal from groundwater using biochar produced from hydrothermal carbonization. Journal of Environment Management, 92(10), 2504–2512.

Liu, Z. G., & Zhang, F. S. (2009). Removal of lead from water using biochars prepared from hydrothermal liquefaction of biomass. Journal of Hazardous Materials, 167(1–3), 933–939.

Liu, Z. G., & Zhang, F. S. (2011). Removal of copper (II) and phenol from aqueous solution using porous carbons derived from hydrothermal chars. Desalination, 267(1), 101–106.

Kumar, S., Kothari, U., Lee, Y. Y., & Gupta, R. B. (2011). Hydrothermal pretreatment of switchgrass and corn stover for production of ethanol and carbon microspheres. Biomass & Bioenergy, 35(2), 956–968.

Zhu, N., Yan, T., Qiao, J., & Cao, H. (2016). Adsorption of arsenic, phosphorus and chromium by bismuth impregnated biochar: adsorption mechanism and depleted adsorbent utilization. Chemosphere, 164, 32–40.

Cao, Y. H., Huang, J. N., Li, Y. H., Qiu, S., Liu, J. R., Khasanov, A., Khan, M. A., Young, D. P., Peng, F., Cao, D. P., Peng, X. F., Hong, K. L., & Guo, Z. H. (2016). One-pot melamine derived nitrogen doped magnetic carbon nanoadsorbents with enhanced chromium removal. Carbon, 109, 640–649.

Alaerts, G. J., Jitjaturunt, V., & Kelderman, P. (1989). Use of coconut shell-based activated carbon for chromium(VI) removal. Water Science Technology, 20, 1701–1704.

Dantas, T. N., Neto, A. A. D., & Moura, M. C. (2001). Removal of chromium from aqueous solutions by diatomite treated with microemulsion. Water Research, 35(9), 2219–2224.

Liu, M., Zhang, H., Zhang, X., Deng, Y., Liu, W., & Zhan, H. (2001). Removal and recovery of chromium(III) from aqueous solutions by a spheroidal cellulose adsorbent. Water Environment Research, 73(3), 322–328.

Lee, C. G., Lee, S., Park, J. A., Park, C., Lee, S. J., Kim, S. B., An, B., Yun, S. T., Lee, S. H., & Choi, J. W. (2017). Removal of copper, nickel and chromium mixtures from metal plating wastewater by adsorption with modified carbon foam. Chemosphere, 166, 203–211.

Monser, L., & Adhoum, N. (2002). Modified activated carbon for the removal of copper, zinc, chromium and cyanide from wastewater. Separation and Purification Technology, 26(2-3), 137–146.

Singh, J., & Cu, S. (2010). Commercialization potential of microalgae for biofuels production. Renewable & Sustainable Energy Reviews, 14(9), 2596–2610.

Demirbas, A., & Demirbas, M. F. (2011). Importance of algae oil as a source of biodiesel. Energy Conversion and Management, 52(1), 163–170.

Wang, J. J., Tan, Z. C., Zhu, C. C., Miao, G., Kong, L. Z., & Sun, Y. H. (2016). One-pot catalytic conversion of microalgae (Chlorococcum sp.) into 5-hydroxymethylfurfural over the commercial H-ZSM-5 zeolite. Green Chemistry, 18(2), 452–460.

Miao, G., Zhu, C. C., Wang, J. J., Tan, Z. C., Wang, L., Liu, J. L., Kong, L. Z., & Sun, Y. H. (2015). Efficient one-pot production of 1,2-propanediol and ethylene glycol from microalgae (Chlorococcum sp.) in water. Green Chemistry, 17(4), 2538–2544.

Falco, C., Sevilla, M., White, R. J., Rothe, R., & Titirici, M. M. (2012). Renewable nitrogen-doped hydrothermal carbons derived from microalgae. ChemSusChem, 5(9), 1834–1840.

Sevilla, M., Gu, W., Falco, C., Titirici, M. M., Fuertes, A. B., & Yushin, G. (2014). Hydrothermal synthesis of microalgae-derived microporous carbons for electrochemical capacitors. Journal of Power Sources, 267, 26–32.

Heilmann, S. M., Davis, H. T., Jader, L. R., Lefebvre, P. A., Sadowsky, M. J., Schendel, F. J., von Keitz, M. G., & Valentas, K. J. (2010). Hydrothermal carbonization of microalgae. Biomass & Bioenergy, 34(6), 875–882.

Luo, H., Zhu, C. C., Tan, Z. C., Bao, L. W., Wang, J. J., Miao, G., Kong, L. Z., & Sun, Y. H. (2016). Preparation of N-doped activated carbons with high CO2 capture performance from microalgae (Chlorococcum sp.). RSC Advances, 6(45), 38724–38730.

Baláž, M., Bujňáková, Z., Baláž, P., Zorkovska, A., Dankova, Z., & Briancin, J. (2015). Adsorption of cadmium(II) on waste biomaterial. Journal of Colloid Interface Science, 454, 121–133.

Shang, J. G., Pi, J. C., Zong, M. Z., Wang, Y. R., Li, W. H., & Liao, Q. H. (2016). Chromium removal using magnetic biochar derived from herb-residue. Journal of the Taiwan Institute of Chemical Engineers., 68, 289–294.

Acknowledgements

Authors acknowledge financial supports provided by the National Natural Science Foundation of China (21406255), the Shanghai Science and Technology Committee (16dz1207200), and the Youth Innovation Promotion Association CAS (2015231).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Sun, Y., Liu, C., Zan, Y. et al. Hydrothermal Carbonization of Microalgae (Chlorococcum sp.) for Porous Carbons With High Cr(VI) Adsorption Performance. Appl Biochem Biotechnol 186, 414–424 (2018). https://doi.org/10.1007/s12010-018-2752-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2752-0