Abstract

This research reports on the studied effect of the intensity of ultrasound (24 kHz) on the quality characteristics of olive oil, sesame oil, sunflower seed oil, and tallow olein. These characteristics (free acidity, peroxide value, conjugated dienes concentration, viscosity, iodine value, turbidity, color values, and melting behavior) were determined in oil samples before and after ultrasonic treatment. Changes in the oxidation parameters showed that the high-intensity ultrasound treatment accelerated the deterioration of oils. In most cases, extra-virgin sesame oil was most resistant to deterioration from sonicating treatments. The decreases in β-carotene content and Hunter values revealed that ultrasound might have good potential for bleaching oils at an appropriate intensity and frequency. The differential scanning calorimeter thermograms, viscosity, and turbidity results indicated that ultrasound probably accelerates the polymerization of the oils. The present study has confirmed that some changes in the physicochemical parameters or structures of oil components had occurred. These changes depended on the sources and initial conditions of the oils as well as the intensity of the applied ultrasound.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Interest in using ultrasonic techniques in the food industry has been growing because of their potential benefits in simplifying handling and speeding up processing times. For most applications, acoustic waves at a low frequency (usually 16–50 kHz) are usually used. When low-frequency ultrasound passes through a medium, it generates extreme physical forces through acoustic streaming, cavitation, shear, micro-jet, and shock waves. These physical forces have been used for oil extraction [1, 2], degassing [3], generating emulsions [4], inactivating pathogenic bacteria on food contact surfaces [5], inhibiting enzymes [6], tenderizing meat [7], and modifying crystallization [8].

However, although many reports are available on the use of ultrasound in food processing, few have studied its side effects. For example, one of the first industrial applications of high-intensity acoustic energy was for the process of emulsification. Emulsions in foods and beverages or medicines have the ability to incorporate lipophilic functional components (such as flavors, antioxidants, preservatives, and nutraceuticals) into products [8]. Therefore, the effect of ultrasound on lipophilic ingredients needs to be evaluated.

In sonication equipments, the power or energy transmitted per unit medium area is known as the intensity and is proportional to the square of the amplitude (I ∝ A 2). This means that the amplitude of ultrasound waves influences the intensity of cavitation by determining the number of bubbles that implode per unit of time. Thus, during intense cavitation, extreme temperatures and pressures can be produced inside the collapsing bubbles and cause the molecules present within the bubbles to decompose severely. Under these extreme conditions, this can generate several highly reactive radicals in the sonicated water, e.g., H· and ·OH. Therefore, the amplitude must be carefully controlled and maintained during sonication.

Generally, the total amount of energy received per unit area in oil is higher than in an aqueous medium. The velocity of sound in edible oils and their density are low compared with water: in olive oil and water, the velocity of sound is 1431 and 1531 m s−1, respectively, and the density is 0.9118 and 1 kg m−3, respectively [9]. The amplitude intensity of ultrasound, I, is inversely related to the density of the medium and sound velocity in the medium (Eq. 1):

where P amax is the maximum pressure amplitude of the wave, ρ is the density of the medium, and V is the velocity of sound in the medium [7].

In most previous studies, the effects of ultrasound on oils have been evaluated when they have been a part of the plant tissue, food ingredient, or emulsion [10, 11]. In these complex components, there are other substances that could have a destructive or protective influence on oils during treatment by ultrasound. Therefore, in the present study, only pure oil samples were used to investigate the effects of ultrasound on lipids. The aim of the study was to treat oils with ultrasound at different amplitudes to investigate how ultrasound and its intensity influence the physicochemical characteristics of different edible oils.

Materials and Methods

Materials

Different brands of unrefined sunflower, extra-virgin olive, extra-virgin sesame oils, and tallow olein were obtained from a local supermarket (Tehran, Iran). All solvents were obtained from the Merck Chemical Company (Darmstadt, Germany).

Ultrasonic Treatment

Sonication was performed at a low frequency, 24 kHz, and at a power of 400 W using an ultrasonic processor (model UP400S, Hielscher Ultrasonics GmbH, Teltow, Germany) operating in the continuous sonication mode. This simple ultrasonic device consisted of an electrical generator, an IP40 grade transducer, and a cylindrical titanium sonotrode (horn) combined with a stand generator. For each experiment, approximately 100 mL of oil was treated for 5 min at a minimum, intermediate, and maximum power level corresponding to 25, 60, and 100 % of the maximum amplitude that could be delivered by the sonicator. All ultrasonic treatments were performed in triplicate. As the specific heat and density of the different samples varied, the power intensities for each oil sample at these operating amplitudes were calculated as described by Margulis and Margulis [12] (Table 1). Table 1 shows that the bulk temperature of the oils increased as the ultrasound intensity increased. Therefore, to minimize these thermal effects, a glass cooling cell containing the oil sample was submerged in an ice bath and the process temperature was controlled throughout the experiments (except for calorimetric power measurements). However, it would be difficult to keep the sample at a constant temperature, especially during ultrasound treatment at higher amplitudes. Therefore, the oil temperature was carefully checked at 100 % ultrasound amplitude intensity and, if necessary, the sonicator was turned off so that the ultimate temperature was maintained at about 65 °C.

Physical and Chemical Analysis

The physicochemical parameters of the oils were determined following the methods described by American Oil Chemists’ Society [13]. Fatty acid methyl esters were prepared according to AOCS method Ce 1-62 and analyzed using gas chromatography–mass spectrometry (Shimadzu model 14A equipped with a mass spectrometer EI (HP-6890)) according to the method described by Eroshin et al. [14]. The fatty acid composition was used to determine the iodine value or degree of unsaturation using the following formula [15]:

The saponification number was calculated from fatty acid composition according to AOCS method Cd 3-25. The oil quality indices, acid value, and peroxide value were determined according to AOCS methods Ca 5a-400 and Cd 8-53, respectively. The color of the oil samples was determined using a color flex spectrocolorimeter (Hunter Lab Colorimeter D-25, Reston, VA, USA) after being standardized using Hunter Lab color standards. The Hunter L (lightness), a (redness to greenness), and b (yellowness to blueness) values were measured [16]. The conjugated dienes contents were determined by ultraviolet spectrophotometry using an Agilent HP 8452A spectrophotometer (Santa Clara, CA, USA) using the coefficients from IUPAC method 2.206 [17]. The refractive indices of the samples were measured using a Carl Zeiss Abbé refractometer (model 32-G 110e, Jena, Germany) immediately after sonification.

A Metrohm Rancimat 679 (Herisau, Switzerland) was used to determine the oxidative stability of the oil samples. The samples were heated at 120 °C with air bubbled through the oil at a flow rate of 10–12 L h−1. The oxidation process was monitored continuously by conductometry according to AOCS method Cd 12-57.

The quantification of the total chlorophyll and carotenoid pigments, expressed as milligrams per kilograms, were measured directly by the adsorption at 670 and 450 nm, respectively, of samples diluted in n-hexane [16]. All the spectrophotometric measurements were performed using an ultraviolet–visible diode array spectrophotometer (HP 8452 A, Agilent).

An Anton Paar’s viscometer (model SVM 3000, Anton Paar GmbH, Graz, Austria) was used to measure the density, kinematic, and dynamic viscosity of oils at 25 °C according to the ASTM D7042-14 standards [18]. Samples (2.5 mL) were injected and the viscometer automatically calculated the kinematic viscosity and delivered the results equivalent to ASTM D445 [18]. All measurements were made in triplicate and the average values are reported. The crystallization behavior of the edible oils was determined using a Perkin-Elmer differential scanning calorimeter (DSC) (Norwalk, CT, USA). The equipment was calibrated with pure indium and a baseline obtained using an empty open aluminum pan [19]. Oil samples (0.5 mg) were weighed into the aluminum pans that were placed in the sample chamber then subjected to a temperature program of heating to 80 °C for 5 min then cooling to −50 °C at a rate of 2 °C/min. Each DSC scan used a new sample to ensure that all samples started with the same thermal history and were in the same ‘standard’ state.

Turbidity is the cloudiness or haziness of a fluid caused by light being scattered by particles. The loss of intensity of light transmitted through oils owing to this scattering effect was measured using a turbidimeter (model 2100 N, Hach, Loveland, CO, USA) with the results being reported in nephelometric turbidity units. These optical experiments used 20 mL oil samples with the temperature maintained at 25 °C.

Statistical Analysis

All ultrasonic treatments were conducted in triplicate with the results for each treatment being presented as mean ± SD. Means and standard deviations were calculated using SPSS (version 22.0, SPSS Inc., Chicago, IL, USA) statistical software. SPSS was also used to perform one-way analysis of variance with Duncan’s significant difference test being used at a 95 % confidence level (p < 0.05) to identify differences between sample treatment means.

Results and Discussion

Effect of Ultrasound Treatment on Fatty Acid Composition

Table 2 compares the fatty acid composition of oils treated or untreated with ultrasound at 24 kHz at different amplitudes. Comparing the fatty acid composition of the controls and treated oils showed that increasing the ultrasound amplitude significantly (p < 0.05) decreased the content of C18:3 and C18:2 fatty acids because this induced greater ultrasonic cavitation and thus degraded the oils. This phenomenon can cause lipid oxidation through two mechanisms: the first is caused by the high temperatures achieved during cavitation, and the second by the free radicals generated by sonolysis [20].

Effect of Ultrasonic Treatment on Physicochemical Characteristics of the Oils

The effects of ultrasound treatment on the physicochemical characteristic of oils (iodine value, free fatty acid percentages, peroxide value, conjugated diene content, and induction period) were evaluated (Table 3). Regarding free fatty acids, there were no significant differences between the controls and the treated oils. Free fatty acids are formed by the hydrolysis of triacylglycerides in the presence of moisture. Therefore, it can be concluded that sonication has no direct effect on hydrolytic reactions.

The peroxide (hydroperoxides) value is the most common index of lipid oxidation and represents the total hydroperoxides content in a sample, which correlated well with the conjugated diene value [21]. For all oils, the formation of the priming oxidation products (peroxide and conjugated diene) increased with increasing ultrasound intensity. These changes in oxidation parameters confirmed that ultrasound caused a rapid increase in the primary oxidation of edible oils. Cavitation is a significant cause of sonication, which occurs severely as the amplitude of the ultrasound increases. Collapsing bubbles during cavitation generate local hot spots with high temperatures and pressures (approximately 5000 °C and 500 MPa, respectively) [2]. These conditions can release free radicals and increase shear forces that accelerate oxidation.

Despite an iodine value of 50.96, tallow olein showed a great increase in peroxide values as the ultrasound intensity increased (Table 3). The two reasons for this behavior might be the lack of antioxidant content as a protection factor against the free radicals and the low density of tallow olein, which increases the intensity of the ultrasound (Eq. 1).

In all samples, except sunflower oil, the formation of peroxides and conjugated products increased as the absorbed ultrasound power increased. The total amount of energy received per unit area of sunflower oil per second was lower than for the other oils (Table 1) but similar changes in peroxide values were observed. This behavior in sunflower oil may have been because of its high iodine value (111.62) and low natural induction period (2.55 h).

From the results in Table 3, it could be concluded that these changes in the physicochemical characteristics depend on the sources and initial conditions of the oils as well as the intensity of the ultrasound applied.

Effect of Ultrasound on Oil Viscosity

The viscosity of food systems is a critical functional property and is difficult to predict and control during processing. All the edible oils showed Newtonian behavior, i.e., the components of the stress tensor were linear functions of the first spatial derivatives of the velocity components. The viscosity or internal friction of the fatty acids are affected by their chain length and number of double bonds [22]. The effects of ultrasound on viscosity were evaluated and are presented in Table 4. Tallow olein gave consistently high absolute viscosities while the sunflower oil gave consistently low viscosities at all levels of ultrasound intensity compared with the other edible oils. All the viscosity values of the oil samples increased as the ultrasound amplitude increased. All standard errors were low, meaning that the measured viscosity values were stable. The increases in viscosity, observed as a result of ultrasound treatment, might be explained by the polymerization of the oils. However, the oxidative cleaving of hydrocarbon chains combined with the strained interaction of non-homogeneous compounds in the oils can produce the overall effect of increasing the viscosity. The molecules of edible oils are similar in size and shape and flow fairly freely but oxidation creates new and different compounds, which introduce new forces of interaction between the molecules. This therefore impedes the relative motion of the fluid and increases viscosity. One example is where carboxylic acid compounds can become highly associated, making them behave like a larger molecule. Similar results of changing viscosities in vegetable oils have also been observed during frying by Diamante and Lan [23] and Santos et al. [24]. It should also be noted that increasing the ultrasound intensity did not significantly affect sesame oil viscosity (p > 0.05).

Effect of Ultrasound on Turbidity of Oils

The appearance of foods can affect the overall acceptability of the product by consumers. Applying high-intensity ultrasound waves caused turbidity in the oils (Table 3). The smallest changes in turbidity after ultrasonic treatment were observed in sesame oil with more severe changes observed in the tallow olein and olive oil samples. Generally, turbidity or haze is formed in oils because of waxes or the polymerization of fatty acids, which often occurs at high temperatures (160–250 °C). However, during sonication treatment, turbidity appears more rapidly at a lower temperature compared with the classical thermo-oxidation process. Chemat et al. have reported cloudiness in sunflower oil after treatment with ultrasound [25].

Effect of Ultrasound on Oil Color

Some studies have applied low-frequency ultrasound to reduce the bleaching time of oil, which can avoid the harmful effects of using acid-activated earths [9]. The color intensity of the oils before and after sonication treatment was measured (Table 5). In all samples except tallow olein, redness and yellowness values decreased significantly (p < 0.05) as ultrasound intensity increased. This corresponded to changes in the β-carotene and chlorophyll contents of the oils (Table 3). The β-carotene and chlorophyll contents decreased by about 50 % when ultrasound was applied at 100 % amplitude. This might be linked to the number of double bonds in pigments in the oil that are affected by ultrasound. There is some evidence that applying ultrasound may lead to the degradation and isomerization of carotenoids [26]. Adekunte et al. [27] evaluated the potential of ultrasound as a non-thermal technique for inactivating microorganisms in tomato juice. They found that color modifications occurring after ultrasound treatment were related to a decrease in carotenoid pigment because of isomerization. Color changes caused by the degradation of carotenoid pigments and non-enzymatic browning have also been found in sonicated pineapple, grape, and cranberry juices under pulsed and continuous thermo-sonication treatments when compared with the conventional procedure [28].

The results for tallow olein were different at an ultrasound intensity of 100 % where the Hunter L, a, and b values increased significantly (p < 0.05) as the ultrasound amplitude increased. Maillard reactions were probably responsible for the increase in the intensity of yellowness and redness in the oil. Darker colors have also been observed in the ultrasound-assisted preparation of chocolate mousse compared with conventional preparation because of the formation of browning pigments [29].

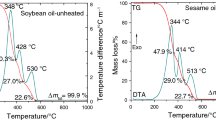

Ultrasonic Treatment and Melting Behavior of Oils

The characteristic thermal properties of the treated oils (enthalpy, T onset, and T offset) are shown in Table 6. High-intensity ultrasound expanded the melting range of the treated oils. Significant differences in crystallization enthalpy were found between the different oil samples. Untreated oils and samples treated with 100 % amplitude intensity had the lowest and the highest crystallization enthalpies, respectively, while intermediate values were found for the other oil samples. Differences in major (e.g., triacylglyceride and fatty acids) and minor (e.g., diacylglyceride, free acidity, and lipid oxidation products) chemical components (Table 3) might have affected the melting behavior of the samples. A more ordered crystal structure might be hypothesized for untreated samples with their more uniform chemical composition compared with the sonicated oils, which resulted in a wide melting temperature range. Besbes et al. [30] found that when the oils oxidized, the DSC traces were affected. In the present study, as the content of oxidation products such as polar compounds, hydroperoxides, and aldehydes increased, the melting range shifted to a lower temperature and the enthalpy decreased. In all oils, the high-intensity ultrasound expanded the melting range and increased the enthalpy. This may have been caused by the polymerization of fatty acids as also shown by the results of turbidity and viscosity where ultrasound accelerated polymerization.

Conclusions

The present study confirmed that ultrasound caused some modifications to the physicochemical parameters or structures of oil components. This study provides information on the thermal and physicochemical properties and lipid oxidation of different sonicated oils, which is useful for designing sonication processes for edible oils. The experimental data on the oxidation parameters showed that ultrasound treatment, especially high-intensity ultrasound, accelerated the deterioration of oils. This confirmed the hypothesis that ultrasonic oxidation of edible oils can probably be attributed to cavitation. In most cases, the vegetable oils exhibited more stability than tallow olein. Extra-virgin sesame oil showed better resistance to sonicating treatments than olive and sunflower oils. On the basis of the results of β-carotene content and Hunter color values, ultrasound may have good potential for bleaching oils as long as an appropriate intensity and frequency are chosen and that oxidation reactions are considered. However, the present study revealed that ultrasound probably accelerates the polymerization of oils, which increased their viscosity, turbidity, and melting enthalpy.

References

Pingret D, Fabiano-Tixier AS, Le Bourvellec C, Renard CMGC, Chemat F (2012) Lab and pilot-scale ultrasound-assisted water extraction of polyphenols from apple pomace. J Food Eng 111:73–81

Chemat F, Huma Z, Kamran Khan M (2011) Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem 18:813–835

Knorr D, Zenker M, Heinz V, Lee DU (2004) Applications and potential of ultrasonics in food processing. Trends Food Sci Technol 15:261–266

Jafari SM, He Y, Bhandari B (2007) Production of sub-micron emulsions by ultrasound and microfluidization techniques. J Food Eng 82:478–488

Awad TS, Moharram HA, Shaltout OE, Asker D, Yousse MM (2012) Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res Int 122:500–507

Riener J, Noci F, Cronin DA, Morgan DJ, Lyng G (2009) The effect of thermosonication of milk on selected physicochemical and microstructural properties of yoghurt gels during fermentation. Food Chem 114:905–911

Koohmaraie SM (1996) Biochemical factors regulating the toughening and tenderisation processes of meat. Meat Sci 43:S193–S201

Patrick M, Blindt R, Janssen J (2004) The effect of ultrasonic intensity on the crystal structure of palm oil. Ultrason Sonochem 11:251–255

McClements DJ (2005) Food emulsions: principles, practice, and techniques. CRC, Boca Raton, pp 87–90

Virot M, Tomao V, Le Bourvellec C, Renard CMCG, Chemat F (2010) Towards the industrial production of antioxidants from food processing by-products with ultrasound-assisted extraction. Ultrason Sonochem 17:1066–1074

Mason TJ, Chemat F, Vinatoru M (2011) The extraction of natural products using ultrasound or microwaves. Curr Org Chem 15:237–247

Margulis MA, Margulis IM (2003) Calorimetric method for measurement of acoustic power absorbed in a volume of a liquid. Ultrason Sonochem 10:343–345

AOCS (1996) Official methods and recommended practices of the AOCS, 4th edn. AOCS, Champaign

Eroshin VK, Satroutdinov AD, Dedyukhina EG, Christyakova TI (2000) Arachidonic acid production by Mortierella alpine with growth-coupled lipid synthesis. Process Biochem 35:1171–1175

Kyriakidis NB, Katsiloulis T (2000) Calculation of iodine value from measurements of fatty acid methyl esters of some oils: comparison with the relevant American Oil Chemists Society method. J Am Oil Chem Soc 77:1235–1238

Minguez MI, Rejano J, Gandul B, Higinio A, Garrido J (1991) Color-pigment correlation in virgin olive oil. J Am Oil Chem Soc 68:332–336

IUPAC (1992) Standard methods for the analysis of oils, fats and derivatives, 7th edn. Blackwell, Oxford

ASTM D7042-14 (2014) Standard test method for dynamic viscosity and density of liquids by stabinger viscometer (and the calculation of kinematic viscosity), ASTM International, West Conshohocken, PA

Tana CP, Che Mana YB, Selamatb J, Yusoffc MSA (2002) Analytical, nutritional and clinical methods section comparative studies of oxidative stability of edible oils by differential scanning calorimetry and oxidative stability index methods. Food Chem 76:385–389

Sivakumar M, Tang SY, Tan KW (2014) Cavitation technology—a greener processing technique for the generation of pharmaceutical nanoemulsions. Ultrason Sonochem 21:2069–2083

Pingret D, Durand G, Fabiano-Tixier AS, Rockenbauer A, Ginies C, Chemat F (2012) Degradation of edible oil during food processing by ultrasound: electron paramagnetic resonance, physicochemical, and sensory appreciation. J Agric Food Chem 60:7761–7768

Huang Q, Li L, Fu X (2007) Ultrasound effect on the structure and chemical reactivity of cornstarch granules. Starch 59:371–378

Diamante LM, Lan T (2014) Absolute viscosities of vegetable oils at different temperatures and shear rate range of 64.5 to 4835 s−1. J Food Process 25:261–267

Santos JCO, Santos IMG, Souza AG (2005) Effect of heating and cooling on rheological parameters of edible vegetable oils. J Food Eng 67:401–405

Chemat F, Grondin I, Costes P, Moutoussamy L, Shum Cheong Sing A, Smadja J (2004) High power ultrasound effects on lipid oxidation of refined sunflower oil. Ultrason Sonochem 11:281–285

Pingret D, Fabiano-Tixier AS, Chemat F (2013) Degradation during application of ultrasound in food processing: a review. Food Control 31:593–606

Adekunte AO, Tiwari BK, Cullen PJ, Scannell AGM, O’Donnell CP (2010) Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem 122:500–507

Bermúdez-Aguirre D, Barbosa-Cánovas GV (2012) Inactivation of Saccharomyces cerevisiae in pineapple, grape and cranberry juices under pulsed and continuous thermo-sonication treatments. J Food Eng 108:383–392

Vercet A, Burgos J, López-Buesa P (2001) Manothermosonication of foods and food-resembling systems: effect on nutrient content and nonenzymatic browning. J Agric Food Chem 49:483–489

Besbes S, Blecker C, Deroanne C, Lognay G, Drira NE, Attia H (2005) Heating effects on some quality characteristics of date seed oil. Food Chem 97:469–476

Acknowledgments

The authors are grateful to Dr. Maryam Mizani for her useful suggestions and discussions.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Hosseini, S., Gharachorloo, M., Tarzi, B.G. et al. Effects of Ultrasound Amplitude on the Physicochemical Properties of Some Edible Oils. J Am Oil Chem Soc 92, 1717–1724 (2015). https://doi.org/10.1007/s11746-015-2733-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2733-1