Abstract

In theory, state of the art inductively coupled plasma mass spectrometry (ICP–MS) instrumentation has the prerequisite sensitivity to carry out multi-elemental trace analyses at sub-ng L−1 to sub-pg L−1 levels in solution. In practice, constraints mainly imposed by various sources of contamination in the laboratory and the instrument itself, and the need to dilute sample solutions prior to analysis ultimately limit detection capabilities. Here we review these sources of contamination and, wherever possible, propose remedial strategies that we have found efficacious for ameliorating their impact on the results of multi-elemental trace analyses by ICP–MS. We conclude by providing a list of key points to consider when developing methods and preparing the laboratory to routinely meet the demands of multi-elemental analyses at trace analytical levels by ICP–MS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Interest in obtaining reliable information at ultra-trace concentrations, i.e., low or sub-ng L−1 for liquids and low or sub-ng g−1 for solids, has existed for decades [1] and is constantly growing. In the environmental monitoring sector, multi-elemental analyses at ultra-trace levels are routinely required in applications such as the characterization of pristine freshwater systems [2], or the detection of anthropogenic pollution in snow and ice cores from polar regions [3,4]. Due to climatic and geographic conditions, e.g., with circulation patterns shielding the Antarctic from distant pollution sources, element loads in these remote regions represent the lowest in the world and yet analyses at sub-ng L−1 levels can be used to provide paleoclimatic information [5,6].

A second analytical area requiring the determination of a wide range of elements at extremely low concentrations comprises the purity testing of reagents and materials used or manufactured by the semiconductor industry. Extreme analytical challenges are associated with quantification of impurities at ng L−1 and sub-ng L−1 levels in high-purity water, acids, or organic solvents, especially for such elements as Na, Mg, Al, K, and Ca [7–9]. For electronic-grade silica, ceramics or pure metals, detection of these elements at low ng g−1 levels is desirable [10,11].

Clinical samples serve as a final example to illustrate the diversity of applications in which multi-elemental analyses at ultra-trace levels play a key role. To evaluate potential negative health effects from low-level environmental exposure to potentially toxic elements, and from elements released from implants [12], dental alloys, and elements used as catalysts in the pharmaceutical industry [13], accurate determination of many elements at sub-μg L−l or even sub-ng L−1 levels in body fluids is necessary. This represents a considerable analytical challenge due to the complex matrices of clinical samples [14,15].

Due to their versatility and multi-element capabilities, inductively coupled plasma (ICP)-based instruments for optical emission spectrometry (OES) and mass spectrometry (MS) have become widely accepted in analytical laboratories. Though ICP–OES can reach sub-μg L−1 limits of detection for some elements, it is hardly the first choice for truly ultra-trace analyses. Therefore, in the majority of recent studies, low concentrations of analytes have been reported from ICP–MS measurements, either with quadrupole mass filter (ICP–QMS) or double focusing, sector field (ICP–SFMS) instruments, the latter also being known as high-resolution ICP–MS [16]. In the following, use of ICP–MS in general and ICP–SFMS in particular, for the conclusion of the analysis will be assumed.

In order to generate analytical data of high quality at ultra-trace levels all potential sources of contamination must be identified and, as far as humanly possible, eliminated. In this paper, we will not consider potential sample contamination during sampling, eventual preservation, storage, and transport—these topics are sufficient for several separate reviews. For the sake of simplicity, it will be assumed that each sample delivered to the analytical laboratory accurately represents the object under study. This review will thus focus on adulteration that may occur in the steps of preparation and instrumental analysis.

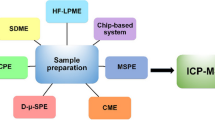

Sample preparation

Before analysis, all samples need some sort of preparation—ranging from simple transfer of an acidified water sample to an autosampler tube and addition of internal standards to very complicated procedures involving multi-step sample digestion and dilutions. If the most common method of quantification by external calibration is used, a set of calibrants including a zero-standard (synthetic blank) must also be prepared.

Reagent blanks

It seems imperative to start any discussion on sample preparation with reagent blanks. In practically all applications relying upon solution nebulization of aqueous matrices, water is the most frequently used reagent. Prior to ICP–MS analysis digests of solid samples are usually diluted >100-fold with water, and thus the purity of the latter is of the utmost importance. Though ultra-pure water with guaranteed impurity contents at or below the ng L−1 level is commercially available, because of the challenges involved in avoiding contamination during transport and storage, and cost issues incurred when considering the volumes consumed in the average analytical laboratory, most laboratories rely upon in-house water-purification systems. The current industry standard for purification of tap water in analytical laboratories involves a combination of reverse osmosis and ion-exchange processes. With deference to the name of the largest supplier of purification equipment, the resultant de-ionized water is often referred to as Milli-Q water.

To evaluate impurity levels in Milli-Q water (laboratory de-ionized water, purified first by reverse osmosis and then by use of four ion-exchanger cartridges connected in series), three stills (feed and receiving containers connected at 90 ° by elbows, all in Teflon, parts from Savillex, Minnetonka, Minnesota, USA) were filled with approximately 1 L water directly at the tapping point situated in a clean laboratory area with HEPA filtered incoming air. At the same time, an aliquot was collected in a Teflon bottle (reference sample). The stills were tightly closed, mounted on a heating device and water in the stills was evaporated at 80 °C until only approximately 50 mL was left in the feed containers, thus providing a pre-concentration factor of approximately 20. This remaining water was acidified by addition of in-house distilled HNO3 (2% by volume or 0.28 mol L−1) and analysed by ICP–SFMS using an instrument reserved for clean reagents only. Blank subtraction was accomplished using acidified reference water. The following elements were present in pre-concentrated water: Si (mean concentration from three aliquots was 1.2 μg L−1); B (200 ng L−1); Zn (25 ng L−1); P (17 ng L−1); Al (11 ng L−1); Fe (8 ng L−1); Ni (4 ng L−1); and Cu (2 ng L−1). The corresponding relative standard deviations for these mean values were below 20%. For Na, K, Ca, and Mg (mean concentrations in the low ng L−1 range), standard deviations were above 30%, probably reflecting variable contamination from stills and sample handling. Concentrations below 1 ng L−1 were found for the rest of the approximately 60 analytes studied.

This experiment demonstrates that, except for Si, B, and Zn, all other elements are present in fresh Milli-Q water at sub-ng L−1 concentrations (actually below 50 pg L−1 for most of the analytes tested), i.e., at levels sufficiently low for almost any application. Occasionally, concentrations of some elements (mainly Si and B, but also Al, Ba, and U) may increase in de-ionized water either as result of sudden changes in the pressure of the feeding water or when approaching the loading capacity of the ion-exchangers.

Sub-boiling distillation in Teflon stills provides a simple and cost efficient means of purifying Milli-Q water further and ensuring good water quality irrespective of the lifespan of the ion-exchanger cartridges, although slight increases in the concentrations of some “common” analytes (e.g., Na) can be expected, because of extra handling of the water. This water is herein referred to as distilled de-ionized water (DDIW). Typical concentrations of a few selected elements measured in laboratory water after various purification steps (reverse osmosis–ELIX water, Milli-Q, and DDIW), and commercially available ultra-pure water (Fisher) are summarized in Table 1. As these values are not blank corrected, they all include the instrument blank component (see below), but because samples were analysed in the same analytical session, this contribution is expected to be the same regardless of water source. For most elements, differences in water purity between different sources can be detected only at low or sub-ng L−1 concentrations. As a rule, both Milli-Q and DDIW are of similar purity to commercial ultra-pure water. It should be noted that the Milli-Q purification unit used for these experiments is almost a decade old and even better water quality can be expected with modern systems incorporating additional filtering or “polishing” stages.

As with water, frequently used acids (HNO3 and HCl) can be easily purified in-house from low-grade (i.e., PA) feed using sub-boiling distillation in quartz or Teflon stills. When distillation is done continuously under optimized conditions, the purity of the resulting acid is comparable with that of commercially available supra pure grades and for most elements the contribution from the acid in a 10% by volume solution of HNO3 (1.4 mol L−1) in Milli-Q water is negligible. When only limited volumes of acids are necessary (typically HF or HClO4), purchasing commercial ultra-pure acids can prove to be a more cost-effective alternative than setting up in-house purification. However, one should be prepared for possible variations in purity between different batches. For example, we have observed that the level of S in some batches of ultra-pure HF may be orders of magnitude higher than in PA-grade supplies. At the ng L−1 level, higher levels of elements in some batches are not uncommon in acids and other laboratory chemicals, e.g., Sn or Ti in H2O2.

All the previous discussion on laboratory reagent purity was related to freshly produced, or, in the case of commercial products, newly opened chemicals. During the preparation of solutions, levels of impurities in water and acids can increase significantly because of leaching from storage containers, contact contamination from pipette tips or dispensers, or accumulated contamination from the laboratory environment while containers are open. Data presented in Table 2 demonstrate changes in concentrations of 24 elements in Milli-Q water during handling in the laboratory. Five sub-samples of water were tapped into thoroughly acid-cleaned 2-L HDPE bottles. One bottle was set aside to be used as reference sample and the other four were used for routine preparation at different locations in the laboratory. At the end of the working shift, all water samples were acidified to 2% by volume HNO3 (0.28 mol L−1) and analysed by ICP–SFMS. Increased concentrations were found for many elements (Table 2) with some waters accumulating up to 100-fold higher levels of some analytes compared with the original contents. This is in spite of the fact that all handling of water containers was performed in a clean laboratory by personnel wearing clean room clothing, hair nets, and gloves, following routines to limit handling contamination, including rinsing of all pipette tips in the sequence supra pure HNO3 then Milli-Q water prior to use.

It is interesting to note that concentrations of such “common” elements as Fe and Zn increased <15 times even in the most contaminated bottles. At the same time, significantly higher maximum increases in the 30 to 50-fold range were found for the relatively environmentally-uncommon elements, Bi and Sb. The latter elements most probably originated from the use of make-up, where they are used at high concentrations either as additives for inhibiting bacterial growth in lipid-rich formulations or as a bulk component in which stibnite constitutes the black pigment in mascara. Although the wearing of decorative cosmetics is prohibited in the laboratory, minute amounts of make-up present as residues on skin, under nails, etc., may still contaminate a clean environment.

It should also be mentioned at this juncture that settling dust is obviously of concern at all stages in which the sample is exposed to the laboratory atmosphere, as would be the case during the course of these experiments. Measurements performed in this laboratory showed that the dust sedimentation rate on the surface of an instrument was reduced from 3000 to 20 pg cm−2 h−1 by introduction of a HEPA filtered air supply. Therefore the increases in concentrations evident in the results summarized in Table 2 are too great to be explained solely by contamination by settling dust, at least for the elements Al, Ca, Fe, K, Mg, Na, and Zn.

Another source increasing the concentrations of uncommon elements in laboratory air is the dilution of stock 1000 mg L−1 standards by pipetting, a process that can result in the formation of tiny aerosols contaminating the atmosphere and surrounding surfaces of the preparation area. As a result, the accumulation of ultra-trace analytes (e.g., Ir, Re, Tl) can be detected in reagents and standards handled in the vicinity of the standard preparation area. The reservation of an area dedicated to the dilution of trace element standards with concentrations above 10 mg L−1 is therefore recommended in order to limit the risks of such contamination.

Laboratory ware

Sample containers also are potential sources of contamination. This contribution can be minimized by using sample bottles with large volume-to-surface ratios (1 or 2-L volume) made of virgin Teflon and thoroughly acid washed prior to use. One of the important advantages of Teflon is its ability to withstand the high temperatures and concentrated acids necessary for efficient cleaning. Although this approach is widely used for the analysis of ultra-pure waters and other reagents used in semiconductor applications, it can not be recommended for all samples because of limited throughput (i.e., cleaning) and cost considerations. Because most routine applications rely on the use of autosamplers, sample tubes with volumes in the range 1–15 mL are most frequently used. Although such autosampler tubes are available in Teflon, disposable tubes made of polystyrene and polypropylene are much more widespread. In the selection of a specific tube variety suitable for a given application it is therefore important to consider the amounts of target analytes that can be leached into the sample matrix during preparation, storage, and analysis. The amounts will depend on the materials comprising the tube/stopper/cap, the washing procedure (if any), the strength of the acid (or acid mixture) in the sample, the duration of contact, and the temperature during leaching.

Table 3 summarizes leaching tests for 15-mL polypropylene tubes. This includes 12 h leaching of unwashed tubes (5% and 1% by volume HNO3), tubes washed in a metal-free laboratory dishwasher using a mixture of hot HNO3/HCl (PA-grade) followed by 20% by volume HNO3, and washed tubes that have been filled with 5% supra pure HNO3 for storage and rinsed with Milli-Q water before use. The efficiency of this washing procedure is evident from the significant decreases in the leachable concentrations of many analytes, although keeping washed tubes filled with weak acid and use of an additional rinse helps reduce contamination from tubes even further. From our experience in testing a variety of commercially available disposable polystyrene and polypropylene autosampler tubes, the following general observations have been made:

-

All tubes are sufficiently clean as supplied to be used for geological and regulation-focused environmental applications.

-

None of the tube types is clean enough to be used as supplied for applications requiring measurements of “common” elements at sub-μg L−1 concentrations.

-

Even pre-washed tubes can release significant quantities of some elements (Al, Si, Zn, Sn, Ti, Cd) in contact with relatively concentrated acids (e.g., >5% by volume HNO3). This effect is accelerated by higher temperatures.

Handling contamination

After considering some of the factors potentially limiting detection capabilities, it is useful to evaluate the lowest concentration in the simple matrix at which reliable (accurate and reproducible) measurements can be performed. The following experiments were conducted for this purpose: by serial dilution of 10 mg L−1 multi-element standards (Perkin–Elmer), a duplicate set of spiked solutions (concentration range 0–100 ng L−1) were prepared in 1% and 5% by volume HNO3 matrices. Acid-washed polypropylene tubes, DDIW, and distilled acid were used for preparation of these solutions following general procedures used for the analysis of pure industrial and natural waters in the laboratory. The concentrations of approximately 70 elements in spiked solutions were determined by use of an ICP–SFMS instrument reserved for analysis of pure reagents (negligible long-term memory effects) using internal standardization (indium added at 2 μg L−1 to all solutions) and external calibration (at 1 μg L−1). Duplicate samples were analysed in two separate sequences, one for each acid strength, with spiked solutions arranged in a random order.

The limit of quantification (LOQ) is defined as the concentration corresponding to 10 × SD for blanks measured under repeatability conditions [17]. While frequently perceived as a useful measure of performance in analytical studies, the LOQ calculated in this fashion can prove to be overly optimistic. Consequently, more modern guidelines [18] generally include some requirement for validation of the LOQ determined as above. Here the lower limit of reporting (LLOQ) for each analyte was set at the lowest spike concentration that could be measured with the following criteria fulfilled:

-

average found concentration (two separate preparations/analyses) within 20% of the theoretical value;

-

relative standard deviation for two replicates below 20%;

-

all spike solutions at higher concentrations also satisfying the first two requirements (Table 4).

Although probably not the most familiar means of assessing the detection capability in the analytical community this approach serves to validate the results in the fashion specified in Ref. [18]. It also provides important information on the efficacy of ICP–SFMS for determinations at low concentrations using “routine” measurement conditions (“hot” plasma, samples prepared in disposable autosampler tubes, solution delivered to nebulizer by peristaltic pump, analyses performed in truly multi-element mode with an effective measurement time of <1 s per isotope, etc.).

It was possible to achieve LLOQs at or below the 1 ng L−1 level for more than half of the elements tested. It is interesting to note that despite low blanks, it was impossible to obtain reliable results for Bi, Th, Hf, and Zr using solutions prepared in 1% HNO3, because recoveries of spiked concentrations were too low. The effect is demonstrated in Table 5, where measured concentrations for selected elements in blanks and samples spiked at 1, 5, 20, and 50 ng L−1 are presented. It seems that low recoveries for some elements present in solutions with low acid strength are caused by losses of analytes on the tubing. Those trapped quantities can be eluted by either increasing the HNO3 concentration in the rinse solution to 5% by volume (Bi) or by using traces of HF (Th, Hf, and Zr). This phenomenon is much less pronounced for spike solutions prepared in 5% by volume HNO3. These findings have two important implications. First, the accurate determination of these elements in such matrices as surface waters, melted snow, and pure industrial solutions would require sample acidification at or higher than 5% by volume HNO3. Second, elements deposited on tubing surfaces can result in false signals for subsequent solutions, particularly in cases where variable acid matrices are analysed, e.g., when some of the samples have been digested using mixtures containing HF.

Analysis of clean water samples as described above can be regarded as one of the favourite (and simplest) ICP–MS applications, because of negligible matrix effects, predictable spectral interferences, and limited handling contamination. For matrices requiring extensive preparation, the latter component often becomes the major obstacle defying the attainment of LLOQs equivalent to those that can be achieved for water samples. Let us consider the analysis of whole blood after digestion with HNO3 [13]. Briefly, 1 mL blood is digested with 1 mL HNO3 in a closed Teflon vessel using a laboratory microwave oven. The digest is diluted to 10 mL with Milli-Q water and analysed by ICP–SFMS. All plastic ware used in the analysis is disposable except for the digestion vessels themselves, which are cleaned between runs in a sequence with ethanol and 50% by volume HNO3, followed by rinsing thoroughly with Milli-Q water.

Table 6 summarizes figures of merit for this procedure assessed from analysis of approximately 2,200 whole blood samples taken for routine health evaluation from Scandinavian donors. Method LOQs for this particular study were evaluated as average blank concentrations (one preparation blank per 20 patient samples was prepared using 1 mL Milli-Q water instead of blood) plus 10 × SD of these preparation blanks (n > 100). While this definition of the LOQ is also unconventional (c.f. Keith et al. [17]), it accounts for day-to-day variations in every link in the analytical chain and thus faithfully reflects the capabilities of a method in routine use. Method reproducibility was assessed by using replicate preparation and analysis of randomly selected samples (relative standard deviation, n = 50). Mean/median concentrations were calculated using the entire data set without exclusion of outliers. For Cd, Hg, Tl, and U, LOQs for the whole blood method are only a few times poorer than for clean water analysis (c.f. Table 4, taking into consideration the 10-fold dilution of the blood samples) reflecting more extensive sample handling and minor variations in long-term instrument performance (data were acquired from >20 separate measurement sessions). Because neither a shielded torch nor an X-skimmer cone are employed in the introduction system of the ICP–SFMS instrument dedicated to body fluid analyses, lower sensitivities (by factors of 10–15, see the following section) may add to higher LOQs also. The median blood U concentration (15 ng L−1) is within the range of blank levels leaching from common tubes used for blood collection (5–20 ng L−1, [19]), suggesting that meaningful analysis of this element in blood collected using these tubes is impossible. Depending on the type of collection tubes this contribution can be significant for V, Cr, Co, Ni, Li, and Tl.

For elements such as Al, Zn and Cu, LOQs for blood are poorer than those for water by almost three orders of magnitude. Handling contamination is much more severe for these “common” elements, and memory effects from blood samples may also contribute to blank levels for the last two analytes. Owing to the higher LOQs, it was impossible to achieve good reproducibility for Al, Co, Cr, Ni, and Sn in blood samples from the occupationally unexposed population using the routine method (Table 6). On the other hand, high LOQs can be tolerated for Cu, Mn, Pb, and Zn as typical concentrations in whole blood are at least ten times higher.

Instrumental analysis

To cope with the demands for reliable ultra-trace analyses, a number of technical developments aimed at improving instrumental sensitivity have been implemented. For example, the typical sensitivity offered by a first generation ICP–SFMS instrument equipped with standard introduction system for mid-mass isotopes of abundance close to 100% (Rh, In, or Cs) is in the range 80–120 Mcounts s−1 per mg L−1 with a sample consumption of 0.5–1.0 mL min−1. Improving the skimmer cone design (high performance skimmer) augmented this value to 200 Mcounts s−1 per mg L−1; reducing the plasma potential using a shielded torch gave sensitivities in the range 1–2 Gcounts s−1 per mg L−1, and combined with the X-cone skimmer design up to 5 Gcounts s−1 per mg L−1 can be achieved. By using the latest high-efficiency nebulizer systems (Aridus, Cetac Technologies, Omaha, USA, or the APEX, Elemental Scientific, Omaha, USA), one can reach 20–30 Gcounts s−1 per mg L−1 with a sample uptake of only 0.05 mL min−1. Even higher sensitivities can be obtained for selected analytes by generation of gaseous species (cold vapour, hydrides or oxides) from measurement solutions, although these gains come at the expense of sample volume and multi-elemental capabilities.

Improvements in ion-path designs and in the quality of electronic components have resulted in the instrumental background, defined as the signal monitored at a mass free from natural isotopes (e.g., 220 amu), decreasing from 50-100 counts s−1 to 1–2 counts s−1 (or 0.2 counts s−1 for sector instruments). Theoretically, the detection capability of modern instrumentation should easily reach the sub-ng L−1 or even sub-pg L−1 region. In reality, however, several additional instrumental factors complicate the possibility of reaching such low levels in real samples.

First, in order to use the widespread solution nebulization introduction system, solid matrices have to be converted into solutions by means of dissolution, digestion or sintering/fusion, effectively resulting in dilution factors that directly affect LOQs. Even for liquid (aqueous) samples with concentrated matrices (brackish and seawaters, body fluids, alcoholic and non-alcoholic beverages, etc.) dilution is required in order to control matrix effects. The degree of dilution depends upon the instrumentation used and the configuration of the introduction system; those providing the highest sensitivities have usually been most prone to matrix effects. In some applications, matrix separation/analyte pre-concentration can be successfully used to eliminate the need for sample dilution. Apart from involving additional sample handling, this approach limits multi-element capabilities as it is often applicable to only a limited number of analytes [20–22].

Second, detection capabilities can be affected by spectral interferences originating from plasma gases, solvent, and sample matrix. The importance of proper corrections for accurate measurements at low concentrations can hardly be overemphasized, and there are a number of useful reports on this topic [23–25]. Among the approaches developed to deal with spectral interferences are the selection of less affected isotopes, the chemical separation of interfering elements, plasma parameter optimization, the use of mixed or alternative gas plasmas, reaction/collision cells, and high resolution. Unfortunately, none of these approaches is capable of eliminating all potential spectral interferences, and instrumental performance (versatility, measurement time, and sensitivity) can often be affected. For example, significant reductions of sensitivity using collision cells (for low-mass analytes) or sector instruments in high-resolution mode (for all analytes) may affect instrumental detection capabilities.

Third, measured analyte signals may contain contributions from instrumental background and contamination during sample preparation. According to experience gained from applications of ICP–SFMS to a great variety of sample types, instrumental sensitivity is seldom the decisive factor, because in most cases the detection capabilities are blank-limited. Aiming at “world record” sensitivity in excess of 1010 counts s−1 per mg L−1 is unnecessary, given that even instrumental (not to mention preparation) blanks can be in the 100–1000 counts s−1 range for many “common” analytes of broad interest. Given that the instrumental configuration and measurement conditions providing the highest sensitivity are usually sub-optimum with regard to tolerance to matrix effects, and are likely to result in increased costs for the sample-introduction system and reduced useful lifetime of some instrumental parts (e.g., the secondary electron multiplier or the slits), efforts focused on improving blanks are often preferable and ultimately more cost-effective than gains in sensitivity.

In the general case, the signal measured is the sum of the analyte signal (useful component carrying information about the concentration of elements in the original sample studied) and unwanted contributions. The latter includes the contributions from sample preparation discussed above, but also a combination of the continuous instrumental background, the instrumental blank, and spectral interferences. A discussion of the latter, post preparation sources of unwanted contributions and strategies to limit their impacts will be subject of the remainder of this treatise.

Continuous instrumental background

To a first approximation, the continuous instrumental background is independent of mass and is caused by photons from the ICP reaching the detector, and, e.g., pick-up and thermal or Johnson noise in the detector and electronic components in the amplifying circuits [26]. In modern ICP-MS instruments with detectors operating in pulse-counting mode the background is usually in the low to sub-counts s−1 range and rarely of importance for practical LOQs. Possible exceptions are the determination of Ra, Pu, and other actinides at sub-pg L−1 concentrations in purified chromatographic fractions (when potential sources of spectral interferences and matrix effects are removed) using long acquisition times.

Spectral interferences

Although strictly outside the scope of this report, a few comments concerning spectral interferences need to be made here. Current knowledge on the nature, extent, and severity of spectral interferences differs greatly depending on the origin of the interference, analyte mass, and sample matrix. Interferences that originate from the plasma gas (e.g., 40Ar+ on 40Ca+, 40Ar16O+ on 56Fe+, 40Ar2 + on 80Se+), impurities in the plasma gas, or commonly used solvents are relatively well known, with the possible exception of rare examples, for example 36Ar4+ , H 162 O2+ and 18O2+ on 9Be+ [27]. Interferences from major matrix elements in saline solutions (e.g., 23Na35Cl+ on 58Ni+, 23Na37Cl+ on 60Ni+, 32S +2 on 64Zn+) are also of little surprise and have been extensively discussed in connection with analysis of seawater or body fluids [28,29]. However, potential interferences from “unusual” matrix elements, minor, or even trace elements in samples are less obvious. For example, 238U16O2+ on 127I+ has to be considered in the analysis of uranium-rich samples. For the determination of 75As+, interference from 40Ar35Cl+ has reached almost canonical status, and 150Nd2+ and 150Sm2+ are well-known in geological matrices whereas 59Co16O+ or 58Ni16OH+ often are neglected though the latter will be the major obstacles for accurate measurement of As in digests of Ni-based alloys and button batteries.

Another phenomenon associated with spectral interferences is abundance sensitivity manifested as an increase in the background level in the vicinity of intense signals, caused by scattered ions [30]. This effect is known to limit detection of traces Pu in samples high in uranium [31], 90Sr in the presence of excess 88Sr [32], but also Y and Zr in seawater, a matrix with a high Sr content. Although the phenomenon is usually expected to primarily disturb isotopes in the immediate vicinity of source signals, its effects can actually be traced 10–20 masses away, as can be seen in spectra monitored for 50 μg L−1 and 500 μg −1 U standards (Fig. 1). The implication for real world samples is that the response detected at masses close to an intense signal for a matrix element or matrix-related interference may be artificially increased by this effect and that this additive interference cannot be simply corrected for by blank subtraction.

Instrumental blank

By instrumental blank we mean contributions to the analyte signal not caused by the element in the measurement solution. There are many potential sources of these contributions; the most widely recognized is that of ions released from the cones, Ni being the most commonly used material followed by Al, Pt, and Cu. Instrumental blanks from cones vary substantially between or even within measurement sessions, being highest for new (or newly cleaned) cones, and sharply decreasing for surfaces becoming covered by deposited layers of sample matrix. An important feature of practically all types of instrumental blanks, irrespective of source, is that they seldom follow sensitivity changes for analytes present in the measurement solutions, i.e., instrumental drift, during prolonged runs. Consequently, the use of internal standardization can actually complicate correction for instrumental blanks, e.g., arising from the cones, by blank subtraction. An efficient way of reducing the contribution from the cones is to coat the surface before commencing analysis by aspirating a solution of high concentration (0.1–0.2%) for 15–20 min during instrument warm-up. For instruments dedicated to analyses of saline waters or body fluids 10-fold diluted seawater can be used as such a solution. For analysis of fresh waters and digests of geological/environmental matrices, a solution of Si can be recommended for coating the cones [33]. It should be stressed that Si deposited on the cones will prevent use of the instrument for analysis of low Si concentrations (below 50 μg L−1) and may produce a number of Si-based spectral interferences, especially on masses in the range 42–90. The latter disadvantage is of no significance for ICP–SFMS as any contributions from these interferences can be eliminated by use of high-resolution modes.

The torch can also contribute to the blanks, most notably for Si. This is probably the major reason that, irrespective of the purity of the measurement solution, the Si blank can rarely be lower than 200 ng L−1, even when using Teflon spray chamber and nebulizer, and sapphire injector. Using a standard, inexpensive version of the introduction system made of borosilicate glass the presence of even minute concentrations of HF in measurement solutions will increase the Si and B blanks to above 10 μg L−1.

Other interface parts also add to increased instrumental blanks. For example, second-generation ICP–SFMS instruments from Thermo Scientific (Element2) have a silver-plated interface. Although not in direct contact with the plasma, this plating results in a background equivalent concentration (BEC) for Ag of approximately 1 ng L−1, compared with levels <0.05 ng L−1 Ag that can be reached with the older Element. Elevated blanks can also be observed for Sn, Pt, and Au, the last two being major constituents used in the construction of the plasma shield. Usually the BEC for Pt is below 0.1 ng L−1, but it is still significantly higher than that for Ir (<0.001 ng L−1), an element not used in the current interface design. BECs for elements originating from instrument parts around the interface tend to increase with temperature inside the torch box, e.g., at higher RF power settings or lower than optimum sample gas flow rates. The corresponding signals persist even under “dry plasma” conditions, i.e., operating the plasma without aspiration of analyte solution, thus providing a diagnostic check.

Even inner parts of the mass spectrometer may be sources of instrumental blanks. Analysis of solutions with HF concentrations above 0.1% caused a significant increase in the apparent Ta blank, probably because of a contribution from chemical erosion of the slit material. BECs of up to 500 ng L−1 will effectively prevent determination of this low-abundance element in most environmental/geological materials digested using HF. The same effect, though less pronounced, can be seen during the analysis of solutions containing above 10% by volume HNO3. Occasionally, high S blanks, in the 10–50 μg L−1 range, may appear using ICP–MS. The appearance can often be traced to changes of vacuum pump oil and may persist for several weeks.

Gaseous impurities in Ar gas (Kr and Xe) are not among the typical analytes measured by ICP–MS, but they can affect the determination of other elements via isobaric interferences (i.e., on Sr or Te isotopes). It is generally assumed that the Hg instrumental background is caused by impurity in the plasma gas, but because there may be notable differences in BECs, typically ranging from 0.5 to 15 ng L−1, seen on instruments of the same type and fed from the same liquid Ar tank, it is likely that a significant portion of the Hg is actually released from components of gas lines rather than originating from the tank itself.

If a peristaltic pump is used to deliver solution to the nebulizer, elements released from tubing material (Tygon or Santoprene) can be an important source of instrumental blanks. The contamination release rate depends on the tubing type (material, length, and internal diameter), age, history, and sample matrix. Highest blanks are found with new tubing made of Santoprene in acid mixtures containing HF, with potentially affected elements including Zn, Sn, (Santoprene), Si, Na, Ca, Al, Fe, Ti, Mg, S, and B. During the first few hours after tubing replacement, release of Ba, Cu, Mn, Ni, Pb, and Sr at concentrations in the 10–100 ng L−1 range may also occur. Good practice would include “pre-conditioning” of new tubing by pumping through 10% by volume HNO3 solution overnight using a stand-alone peristaltic pump, so that the initial contaminant release peak will not affect the analyses. Avoiding changes in pumping rate during the first few hours of tubing use is an additional benefit of this procedure. Remaining contamination will contribute <1 ng L−1 for most elements, a level that usually can be adequately corrected for by blank subtraction.

However, for analysis of Na, Ca, Al, Fe, Zn, and Sn at concentrations <50 ng L−1, contact between the sample solution and the peristaltic pump tubing should be avoided, especially if the sample matrix contains HF. Recent developments in sample-introduction systems enable delivery of solutions via a sampling loop that is filled by a vacuum pump and then discharged in a flow of carrier solution propelled by a peristaltic pump (SC-FAST, Elemental Scientific, Omaha, NE, USA). With this arrangement there is no contact between the analyte solution and the peristaltic pump tubing. Operating the nebulizer in self-aspiration mode is another alternative.

Memory effects

Instrumental blank contributions considered so far are specific for the configuration of the introduction system and are not directly dependent on the use history of any particular machine. However, the instrumental blank signals monitored may partly be attributed to short or long-term memory effects from preceding samples/standards. Short-term memory effects vary substantially, depending on:

-

analyte;

-

chemical form of analyte;

-

sample matrix;

-

configuration of introduction system; and

-

rinse solution matrix.

With standard sample uptake using a peristaltic pump operated at constant rate, most analytes, e.g., the transition elements, exhibit similar memory effects with responses decreasing to 0.1% of the maximum value within 2–3 min after terminating aspiration. For these elements, the length of tubing, spray chamber volume, and the sample/rinse solution matrix have little effect on wash-out characteristics.

Several elements, for example Mo, As, Sb, Sn, Te, and Li, need up to 15–20 min to achieve a 1000-fold decrease in intensity after switching from sample to rinse solution. However, for some elements, wash-out to similar levels would require significantly longer times. For the elements Bi, Zr, W, Ta, and Th, complete wash-out even from the 1 μg L−1 level may take a few hours. Wash-out is improved drastically by increasing the HNO3 concentration to at least 5% by volume, or by using traces of HF in the rinse solution. Shorter wash-out times can be accomplished by using shorter tubing or avoiding the use of peristaltic pumps, confirming that the severe memory effects for these elements occur because of interactions between the sample solution and the tubing walls.

Similar effects with long wash-out times can be observed for a few platinum group elements (PGEs, specifically Ir, Pd, Ru) and Au in sample solutions with relatively weak (<5% by volume) HNO3 matrices. To combat this effect, either a mixture of HNO3 with HCl or addition of minute quantities of complex-forming reagents (e.g., EDTA) to all measurement and rinse solutions can be used.

For Os, I, Br, Hg, and B severe memory effects are caused by the formation of gaseous species. After terminating aspiration of the measurement solution these species will be continuously released from vaporizing droplets deposited on spray chamber walls, and be transported to the ICP in the Ar flow. For large-volume, double-pass, Scott-type spray chambers this effect is far more pronounced than for small cyclonic chambers, because of the greater internal surface area and much longer droplet residence time in the former [34]. By using introduction systems without spray chambers, e.g., direct injection nebulizers inserted into the ICP torch [35], pronounced memory effects for these analytes can be completely eliminated. Inhibiting volatile species formation by using basic media for both sample introduction and rinsing is efficient for reducing wash-out times for halogens, B, and Os [36,37]. With more modern sample-introduction systems, for example that mentioned above (the SC-FAST [34]), the wash-out characteristics are at least an order of magnitude better, because of the significantly higher ratio of rinse solution volume to sampling loop surface area per unit time, avoidance of sample contact with peristaltic pump tubing, and the double-port rinsing station for the sample probe. Thus there are measures available to minimize the amount of instrument time squandered on non-productive rinsing processes.

In multi-element analysis it is difficult to optimize the introduction system configuration and the measurement conditions with regard to memory effects for all analytes, making some compromise inevitable. Whenever possible, samples with grossly different concentrations should not be analysed within the same measurement sequence. For trace and ultra-trace elements, calibration standards may be an important source of memory effects. For elements such as Rh, Ru, Pd, Ir, Os, and Re, matching typical concentration levels in natural samples would require standards in the low and sub-ng L−1 range. Owing to stability issues and increased preparation uncertainty arising from multiple dilutions of 0.1% single-element stock, it is not recommended to use calibration standards with concentrations below 50–100 ng L−1. It is advisable that calibration for ultra-trace elements with prolonged memory effects is performed at the end of the measurement session, and the stability of such calibration over the entire run is checked by analysis of matrix-matched control material distributed among the samples at regular intervals [33]. Between sessions, the introduction system can be efficiently cleaned off-line.

Even very severe memory effects originating from the introduction system can be eliminated by thorough cleaning (or replacement) of contaminated parts. Unfortunately, as some fraction of the material reaching the vacuum region of the mass spectrometer can be deposited on inner surfaces [38] this can then become a potential source of long-lasting memory effects. The severity of this phenomenon increases with the duration of the exposure and decreases with increasing mass of the deposited matrix element. For example, loading an ICP–MS device with a 20 mg L−1 solution of Pb or Bi for 30 min will result in enhancement of the instrumental blank by approximately 20 ng L−1 after replacement of the entire introduction system. A similar level of Li exposure gives rise to blanks in the μg L−1 range. Depending on the severity of instrument contamination, such elevated blanks may persist for several days or even weeks. Consequently, it will be impossible to reach low ng L−1 Na and Mg blanks after the instrument has been used for seawater analysis, even after replacement of the entire introduction system, from probe to cones. The possibility of accurate analysis of Fe in brackish and sea waters will be jeopardized by any preceding analysis of blood samples, which contain approximately 500 mg L−1 Fe, on the same instrument. Running acid digests of soils and sediments will prevent low-level Al and Mn measurements in serum or plasma samples. Analyses of geological samples prepared by LiBO2 fusion [39] are incompatible with applications requiring low μg L−1 Li or B determinations. Similarly, using boric acid to complex excess fluoride ions in digests containing HF will also interfere with the ability to measure the latter analyte. Analysis of special steels and alloys may leave the instrument with elevated blank levels for Fe, Ni, Cr, Mo, Co, and W. Considering the extremely diverse application areas for ICP–MS, the list can be continued almost indefinitely. Hence, depending on the application history of a given instrument, such long-lasting memory effects can be an important or even decisive contribution to instrumental blanks.

The use of dedicated introduction systems for different sample types is certainly useful but a complete resetting of instrument blank levels would require cleaning or replacement of internal parts, extraction lens, photon stop, quadrupole, etc., also. As this would be accompanied by loss of vacuum, combining the analyses of grossly different matrices on a single instrument without affecting detection capabilities is a very challenging, if not impossible, task.

Concluding remarks

A plethora of factors have to be carefully considered to perform accurate and reproducible analyses at the ultra trace levels matching the performance offered by modern analytical instrumentation. Providing a detailed “recipe” that would be directly applicable to every analytical task is, of course, impossible. As for clean-sampling techniques [40], controlling unwanted contributions should be viewed as a flexible “philosophy” requiring chemical and analytical understanding by the practitioner and a healthy dose of common sense. However, some general hints and starting points for method development for ultra trace analysis by ICP–MS can be suggested.

-

Acquire as much relevant information as possible about the matrix and expected concentration levels of both analytes and potentially interfering elements in the samples studied. The targeted purity levels should be “fit for purpose” to be cost-efficient.

-

While developing sample preparation/analysis procedures, limit the number of steps and general manipulations of the sample/sample digest, especially those open to the laboratory environment. The less laboratory ware (homogenizing equipment, vessels, vials, tubes, filters/filter holders, electrodes, pipette tips, magnet stirrers, etc.) that comes in contact with samples the better the chances of limiting contamination.

-

Make sure that available reagents are of sufficient purity, instead of limiting volumes used. High reagent/sample ratios usually improve analyte recovery and it is often advantageous to use relatively high acid concentrations at the measurement stage. Be aware though that the purity of water and acid aliquots used for sample preparation may deteriorate rapidly while in use.

-

Pay proper attention to maintaining a clean laboratory environment. Instead of creating confined “clean room” zones, focus on isolating potentially severe contamination sources such as crushing, grinding, sieving, cutting and ashing operations, and handling highly concentrated standard solutions. It is advisable to ban the wearing of cosmetics and introducing changes of clothes/shoes before entering laboratory areas. With a carefully laid out and managed laboratory, sub-ng L−1 LOQs can be achieved routinely without needing to implement a Class-10 or even a Class-100 environment.

-

Develop adequate cleaning routines for disposable laboratory ware. For some “common” elements, however, extensive washing procedures may not be effective because of contamination introduced during handling.

-

Make a thorough evaluation of potential spectral interferences, taking into account even seemingly unlikely species (including multiply charged, truly polyatomic ions) beyond the standard interference table offerings available from instrument producers. The lower the concentration of analyte, the higher the probability that minor, “unusual” interferences will adversely affect the accuracy. Select a suitable strategy to correct for, or preferably eliminate, these interferences, depending on their severity and the instrumentation available. Whenever possible, measure several isotopes per element to verify the efficiency of corrections.

-

Be prepared for unexpected sources of contamination in the laboratory. Test all detergents, hand wash formulations, lotions, etc., for potential impurities. Remember that “metal free” is not equivalent to “sufficiently pure for all applications”, e.g., a “metal free” dispenser may actually introduce measurable quantities of PGEs to dispensed solutions.

-

Periodically evaluate typical instrumental blanks for each instrument. As far as is practically feasible, try to implement a dedicated introduction system, or ideally, a dedicated instrument approach. Account for memory effects in introduction systems, and optimize the calibration strategy with regard to the concentrations of analytes in standards and their placement in the measurement sequence, etc.

-

A realistic assessment of the detection capabilities of the analytical method requires that a set of method blanks are analysed randomly in a sequence with authentic samples. For the preparation of such preparation blanks, make sure that all manipulations with real samples are replicated as closely as possible. Remember that, for analytes potentially affected by spectral interferences from matrix elements, LOQs derived from preparation blanks might, nevertheless, be completely irrelevant.

-

In order to verify measurement accuracy at ultra low concentrations, the development of new reference materials certified for as many trace elements as possible is necessary [41]. Until such materials become available the publication of surplus data obtained for non-certified elements in commercially available reference materials will aid performance evaluation [33,42]. Where available, inter laboratory exercises, round robins, and performance-evaluation tests remain the most valuable options [13,43].

References

Zief M, Speights R (1972) Ultrapurity: methods and techniques. Dekker, New York

Field P, Sherell RM (2003) Direct determination of ultra-trace levels of metals in fresh water using desolvating micronebulization and HR-ICP–MS: application to Lake Superior waters. J Anal At Spectrom 18:254–259

Krachler M, Zheng J, Fisher D, Shotyk W (2005) Analytical procedures for improved trace element detection limits in polar ice from Arctic Canada using ICP–MS. Anal Chim Acta 530:291–298

Dick D, Wegner A, Gabrielli P, Ruth U, Barbante C, Kriews M (2007) Rare earth elements determined in Antarctic ice by inductively coupled plasma—time of flight, quadrupole and sector field-mass spectrometry: an inter-comparison study. Anal Chim Acta 621:140–147

Gabrielli P, Barbante C, Boutron C, Cozzi G, Gaspari V, Planchon F, Ferrari C, Turetta C, Hong S, Cescon P (2005) Variations in atmospheric trace elements in Dome C (East Antarctica) ice over the last two climatic cycles. Atmos Environ 39:6420–6429

Marteel A, Gaspari V, Boutron CF, Barbante C, Gabrielli P, Cescon P, Cozzi G, Ferrari CP, Dommergue A, Rosman K, Hond SM, Hur SD (2009) Climate-related variations in crustal trace elements in Dome C (East Antarctica) ice during the past 672 kyr. Clim Change 92:191–211

Shabani MB, Shiina Y, Kirscht FG, Shimanuki Y (2003) Recent advanced applications of AAS and ICP–MS in the semiconductor industry. Mater Sci Eng B102:238–246

Balram V (2005) Recent developments in analytical techniques for characterization of ultra pure materials–an overview. Bull Mater Sci 28:345–348

Takahashi J (2006) Determination of impurities in semiconductor grade hydrochloric acid using the Agilent 7500cs ICP–MS. http://www.agilent.com/chem. Accessed 10 June 2009

De Mattos JCP, De Moraes Flores EM, Krivan V (2008) Trace element analysis of silicon nitride powders by direct solid sampling graphite furnace atomic absorption spectrometry. J Anal At Spectrom 23:931–937

Matschat R, Heninrich HJ, Czerwensky M, Kuxenko S, Kipphardt H (2005) Multielement trace determination in high purity advanced ceramics and high purity metals. Bull Mater Sci 28:361–366

Sarmiento-Gonzales A, Marchante-Gayon JM, Tejerina-Lobo JM, Paz-Jimenez J, Sanz-Medel A (2008) High-resolution ICP–MS determination of Ti, V, Cr, Co, Ni, and Mo in human blood and urine of patients implanted with a hip or knee prosthesis. Anal Bioanal Chem 391:2583–2589

Rodushkin I, Ödman F, Olofsson R, Axelsson MD (2000) Determination of 60 elements in whole blood by sector field inductively coupled plasma mass spectrometry. J Anal At Spectrom 15:937–944

Heitland P, Köster HD (2006) Biomonitoring of 30 trace elements in urine of children and adults by ICP–MS. Clin Chim Acta 365:310–318

Heitland P, Köster HD (2007) Biomonitoring of 37 trace elements in blood samples from inhabitants of northern Germany by ICP–MS. J Trace Elem Med Biol 20:253–262

Becker JS (2007) Inorganic mass spectrometry: principles and applications. Willey, New York

Keith LH, Libby RA, Crummett W, Taylor JK, Deegan J Jr, Wentler G (1983) Principles of environmental analysis. Anal Chem 55:2210–2218

CDER (Center for Drug Evaluation and Research) (2001) Guidance for industry: bio-analytical method validation, U.S. Food and Drug Administration p 6. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM070107.pdf. Accessed June 27 2009

Rodushkin I, Ödman F (2001) Assessment of the contamination from devices used for sampling and storage of whole blood and serum for element analysis. J Trace Elem Med Biol 15:40–45

Benkhedda K, Lariviere D, Scott S, Evans D (2005) Hyphenation of flow injection on-line preconcentration and ICP–MS for the rapid determination of 226Ra in natural waters. J Anal At Spectrom 20:523–528

Grinberg P, Willie S, Sturgeon R (2005) Determination of U, Th and Pu in natural waters, biological materials and clinical samples by ETV-CP-MS. J Anal At Spectrom 20:717–723

Nygren U, Rodushkin I, Nilsson C, Baxter DC (2003) Separation of plutonium from soil and sediment prior to determination by inductively coupled plasma mss spectrometry. J Anal At Spectrom 18:1426–1434

Thomas R (2002) A beginner’s guide to ICP–MS: part XII-A review of interferences. Spectrosc 17:24–31

Riondato J, Vanhaecke F, Moens L, Dams R (2000) Fast and reliable determination of (ultra-)trace and/or spectrally interfered elements in water by sector field ICP–MS. J Anal At Spectrom 15:341–345

Vanhaecke F (2002) ICP–MS Alternative means for the elimination of interferences. Anal Bioanal Chem 372:20–21

Begley IS, Sharp BL (1997) Characterisation and correction of instrumental bias in inductively coupled plasma quadrupole mass spectrometry for accurate measurement of lead isotope ratios. J Anal At Spectrom 12:395–402

Pappas RS, Stanfill SB, Watson CH, Ashley DL (2008) Analysis of toxic metals in commercial moist snuff and Alaska Iqmik. J Anal Toxic 32:281–291

Rodushkin I, Ruth T (1997) Determination of trace metals in estuarine and sea-water reference materials by high resolution inductively coupled plasma mass spectrometry. J Anal At Spectrom 12:1181–1185

Riondato J, Vanhaecke F, Moens L, Dams R (1997) Determination of trace and ultratrace elements in human serum with a double focusing magnetic sector inductively coupled plasma mass spectrometer. J Anal At Spectrom 12:933–937

Thirlwall M (2001) Inappropriate tail corrections can cause large inaccuracy in isotope ratio determination by MC-ICP–MS. J Anal At Spectrom 16:1121–1125

Rodushkin I, Lindahl P, Holm E, Roos P (1999) Determination of plutonium concentrations and isotope ratios in environmental samples with a double-focusing sector field ICP–MS. Nucl Instrum Methods Phys Res 423A:472–479

Helal AI, Zahran NF, Amr MA, Abd El-Lateef AM, Bashter II, Mohsen HT, Abbas Y (2004) Ultratrace and isotope ratios analyses of some radionuclides by ICP–MS. Radiochim Acta 92:369–374

Engström E, Stenberg A, Senioukh S, Edelbro R, Baxter DC, Rodushkin I (2004) Multi-element characterization of soft biological tissues by inductively coupled plasma-sector field mass spectrometry. Anal Chim Acta 521:123–135

Mahar MM, Tyson JF, Neubauer K, Grosser X (2008) High throughput sample introduction system for the analysis of drinking water and wastewaters by ICP–MS. J Anal At Spectrom 23:1204–1213

Minnich MG, Miller DC, Parsons PJ (2008) Determination of As, Cd, Pb, and Hg in urine using inductively coupled plasma mass spectrometry with the direct injection high efficiency nebulizer. Spectrochim Acta 63B:389–395

Cho T, Akabane I, Murakami Y (1990) Basic study on the application of tetramethylammonium hydroxide (TMAH) alkaline digestion for the determination of some volatile elements by ICP–MS. In: Jarvis KE, Gray AL, Williams JG (eds) Plasma source mass spectrometry: the proceedings of the third surrey conference on plasma source mass spectrometry. Royal Society of Chemistry, London, pp 94–119

Malinovsky D, Rodushkin I, Baxter DC, Öhlander B (2002) Simplified method for the Re-Os dating of molybdenite using acid digestion and isotope dilution ICP–MS. Anal Chim Acta 463:111–124

Andrén H, Rodushkin I, Stenberg A, Malinovsky D, Baxter DC (2004) Sources of mass bias and isotope ratio variation in multi-collector ICP–MS: optimization of instrumental parameters based on experimental observations. J Anal Atom Spectrom 19:1217–1224

Burman JO, Pontér C, Boström K (1978) Metaborate digestion procedure for inductively coupled plasma-optical emission spectrometry. Anal Chem 50:679–680

Ultra-clean sampling for waters, soil/sediments, and tissues. http://frontiergeosciences.com. Accessed 28 July 2009

Krachler M, Heisel C, Kretzer JP (2009) Validation of ultratrace analysis of Co, Cr, Mo and Ni in whole blood, serum and urine using ICP-SMS. J Anal Atom Spectrom 24:605–610

Rodushkin I, Engström E, Sörlin S, Baxter DC (2008) Levels of inorganic constituents in raw nuts and seeds on the Swedish market. Sci Total Environ 392:290–304

Rodushkin I, Engström E, Stenberg A, Baxter DC (2004) Determination of low-abundance elements at ultra-trace levels in urine and serum by inductively coupled plasma-sector field mass spectrometry. Anal Bioanal Chem 380:247–257

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodushkin, I., Engström, E. & Baxter, D.C. Sources of contamination and remedial strategies in the multi-elemental trace analysis laboratory. Anal Bioanal Chem 396, 365–377 (2010). https://doi.org/10.1007/s00216-009-3087-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3087-z