Abstract

Microalgae are regarded as a promising and feasible source of diverse products for application in the nutraceutical, pharmaceutical, cosmeceutical, and chemical industries. Such products include biofuels, lipids, polyunsaturated fatty acids, pigments, enzymes, polysaccharides, and proteins. The recovery of products from algal biomass is a matter of constant development and progress. In the present chapter, the standard techniques for the extraction of biofuels and high-value metabolites from microalgae in the laboratory are reviewed. Traditional methods such as solvent extraction, as well as novel techniques, like supercritical fluid extraction, microwave-assisted extraction, and ultrasound-assisted extraction, are presented in this work, including the suitability of these methods for specific types of metabolites. Pretreatment techniques for the enhancement of product recovery are discussed. This chapter is intended as a reference of the existing methods for the researcher looking forward to study the production of metabolites by microalgae, in order to aid the selection of a suitable technique for specific metabolites.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Microalgae are photosynthetic microorganisms that represent an attractive alternative source of lipids for biodiesel production. Because of their unicellular structure, they have the potential for high oil production without challenging the use of agricultural resources. Microalgae are able to grow in saltwater, brine, nutrients from residual wastewaters, and waste CO2 (Griffiths et al. 2012; Wijffels et al. 2013; Hernández et al. 2014). Microalgae include prokaryotic cyanobacteria and eukaryotic photosynthetic organisms (Brasil et al. 2017) that utilize solar energy, nutrients, and carbon dioxide (CO2) to produce a wide variety of complex molecules. The primary metabolism of these microorganisms synthesizes proteins, carbohydrates, and lipids; and secondary metabolites, such as carotenoids, alkaloids, terpenoids, and polyketides, are species dependent (Cuellar-Bermudez et al. 2015; Mazard et al. 2016).

Some of these metabolites are of particular interest to the industry because of their high-value metabolites. Examples of these are antioxidants, pigments, pharmaceuticals, polyunsaturated fatty acids (PUFAs), and biomass for animal feed, fertilizers, or energy (Mata et al. 2010).

The study of microalgae has gained interest due to their capacity to produce valuable molecules under different environmental conditions, a feature that makes them an attractive candidate for the production of energy, like biodiesel and biogas (Nie et al. 2018).

Another area worth exploring is the use of microalgae as a platform for wastewater treatment. Phycoremediation is a feasible solution to mitigate the environmental impact of industries with high waste production. For example, there are reports of microalgae biomass production from sewage, swine wastewater, or even poultry waste. Spirulina platensis, Spirulina maxima, and Chlorella sp. have been used for this purpose (Wu and Wilson 1981).

A critical step for the recovery of valuable products from microalgae is the extraction method. To achieve the extraction of the desired products, microalgae cells have to go through cell disruption for the release of the molecules of interest and then to apply one of several methodologies, such as solvent extraction, mechanical methods, freeze-thawing, enzymatic lysis, microwave-assisted extraction, and ultrasound extraction, among others. For cell rupture at large-scale settings, mechanical methods are preferred, since they allow complete disintegration of the cells, with high product yield (Moraes et al. 2010).

The factors to be taken into account for microalgae product extraction are cell disruption method, type of solvent, solvent-to-biomass ratio, and extraction time. These factors should be studied altogether, so the extraction process can be optimized, by minimizing costs and maximizing yield (Moraes et al. 2010). A set of factors have a simultaneous effect on a process. Design of experiments is the most effective tool to identify and optimize the most significant factors with the least experimental runs (Sharif et al. 2014). These designs are divided into two categories: screening (full factorial, fractional factorial, and Plackett-Burman designs) and optimization (central composite or Box-Behnken design) (da Silva et al. 2016).

This chapter reviews the existing methods for the extraction of biodiesel and other metabolites from microalgal biomass, at a laboratory and large scales, in order to aid researchers with the selection of a suitable technique for specific metabolites in their studies.

2 Microalgae Products: Biofuels and Metabolites of Nutritional Value

The role of lipids in the microalgae cell is critical for cellular function. In cyanobacteria and microalgae, lipids can be classified according to their potential applications as fatty acids for biofuels (suitable for transesterification) and lipids with nutritional value, like polyunsaturated fatty acids and carotenoids (Fig. 11.1).

Microalgae produce lipids through the conversion of carbon dioxide emissions into glucose, which in turn is converted to fatty acids for membrane synthesis. Under stress conditions, fatty acids are converted into lipids for biodiesel production. Total oil productivity depends on the oil content of the biomass and growth rate (Aarthy et al. 2018).

2.1 Biodiesel

Biodiesel is a fuel produced by transesterification of triacylglycerides (TAGs) usually obtained from plant oils with high amounts of fatty acid methyl esters (FAMEs) and also is produced by some cyanobacteria from CO2 and sunlight. Particularly for biodiesel production, three important factors have been identified when using photosynthetic microorganisms for bulk production: lipid productivity, fatty acid profile, and harvesting potential. Cyanobacteria present different advantages over microalgae since they provide high biomass concentration and grow under relatively harsh environments; also, they can be easily harvested by flotation or filtration (Griffiths et al. 2012). The utilization of organisms such as cyanobacteria and microalgae for biofuels has many advantages over fossil fuels and plants: higher growth rate compared to plants, availability of genetic tools and sequenced genome, and their ability to grow in areas where crop fuels cannot (Machado and Atsumi 2012).

Since a few decades ago, intensive research has been carried out on biofuel production with Synechocystis and Synechococcus and in a minor extent with Anabaena and Cyanothece (a nitrogen-fixing strain). “Omics” techniques have been extensively used in the introduction of pathways for ethanol, butanol, fatty acids, and other organic acids, all focused on biofuel bulk production (Wijffels et al. 2013). Recently, genetic engineering techniques have been applied to Synechocystis sp. to increase the intracellular concentration of fatty acids, reaching up to 197 mg/L (Machado and Atsumi 2012).

The discovery of new strains with higher fatty acid production is another approach. Cyanobacterial isolates of the genera Synechococcus, Trichormus, Microcystis, Leptolyngbya, and Chlorogloea have been investigated regarding quantity and quality of lipid feedstock. Their biomass productivity ranged from 3.7 to 52.7 mg/L-day, and the lipid productivity varied between 0.8 and 14.2 mg/L-day. The most promising species were the ones of genera Synechococcus and Microcystis; they also showed similar fatty acid profiles to those of seeds already used for biofuel production (Da Rós et al. 2013). Strains of Pseudanabaena sp., Synechococcus sp., and Nodosilinea sp. were isolated and exhibited lipid contents from 7.4% to 15.66% (dry cell weight), being Synechococcus sp. the strain with maximal biomass and lipid productivity. These strains were then subjected to mixotrophic cultivation with ostrich oil as a carbon source, resulting in a high content of palmitoleic, palmitic, linoleic, linolenic, and oleic acids (Modiri et al. 2015).

An important and simplest approach, other than genetic engineering, to increase the number of fatty acids in cyanobacteria is the modification of culture conditions such as nutrients and light intensity. Synechocystis sp. cultures were optimized for nutrient supply and light intensity, showing lipid productivities of 722 mg/L after 12-day cultivation (Monshupanee and Incharoensakdi 2014).

It has been reported that for biomass and lipid productivity, mixed cultures possess higher potential than single cultures. Cyanobacteria Synechocystis salina was co-cultured with three different species of microalgae to assess their potential to remove nitrogen and phosphorus from wastewater and lipid productivity. Lipid productivities determined for single cultures ranged from 4.39 to 7.13 mg/L-day, whereas for dual-species cultures, these values ranged from 7.76 to 11.10 mg/L-day (Gonçalves et al. 2016). Leptolyngbya sp. was co-cultured with Chlorella vulgaris in heterotrophic and mixotrophic conditions. Mixotrophic cultures with sodium acetate produced the highest biomass and neutral lipid productivity (156 g/m3-day and 24.07 g/m3-day, respectively) (Silaban et al. 2014).

Enrichment of the culture media with sodium carbonate (Na2CO3) and high light intensities also resulted in an increase in unsaturated fatty acids (particularly linoleic acid) in Synechococcus sp. (Silva et al. 2014). Recently, lipid droplet (inclusions of neutral lipids) location and identification have been studied because of their content of TAGs for biodiesel. Nostoc punctiforme lipid droplet locations were identified to assess new possible ways to increase their presence (Peramuna and Summers 2014).

2.2 Polyunsaturated Fatty Acids

Polyunsaturated fatty acids are 18–22 hydrocarbon chains and are classified as omega-3 and omega-6 fatty acids. PUFAs are reported to have a positive impact on health such as reduction of the risk for cardiovascular disease, neurological disorder, inflammation, and cancer. By overexpression of endogenous and exogenous genes encoding for PUFA desaturases in the blue-green algae Synechocystis sp., the accumulation of α-linolenic acid (ALA, 18:3n-3) and stearidonic acid (SDA, 18:4n-3) was increased (Chen et al. 2014). Synechocystis aquatilis is one strain of cyanobacteria that has high CO2 uptake and has been tested for lipid production in batch and continuous culture. The extracted fatty acids were mostly composed of saturated acid (palmitic acid) as well as polyunsaturated fatty acids (linoleic and a-linolenic acid) (Kaiwan-arporn et al. 2012). Genetic engineering has also been used in the cyanobacteria Synechococcus sp. to include desaturase enzymes, resulting in 5.4 times greater accumulation of ALA compared to the wild-type strain and production of both GLA (gamma-linoleic acid) and SDA (Dong et al. 2016b).

2.3 Carotenoids

Carotenoids are a group of isoprenoid compounds comprising a wide range of structures; they possess high antioxidant and pigmentation properties. In Arthrospira platensis the carotenoids β-carotene, β-cryptoxanthin, zeaxanthin, and astaxanthin have been identified (Esquivel-Hernández et al. 2017). β-Carotene is a worldwide used carotenoid with industrial applications in cosmetic and food industry (Malik et al. 2012; Havaux 2014). Cyanobacteria have been studied in regards of carotenoid production; recombinant DNA technology has been applied to strains of Synechocystis to increase the number of carotenoids in the cell, resulting in different metabolic pathway studies (Al-Haj et al. 2016).

3 Methods for the Extraction of Microalgae Products

Algae biomass can be submitted to different processes in order to extract different compounds. There are several conversion processes; some of the most important are the mechanical-based treatments (Cherubini et al. 2009). After microalgae cultures reach the stationary phase of growth, the biomass is concentrated, and the products of interest can be extracted by using dry or wet biomass. For the first case, a dewatering process can be performed by centrifugation and is followed by a cell disruption process with the objective to break the cellular walls and favor the release of microalgae components that are not secreted outside the cell. The methodologies used involve disruption, breakage, or disintegration (Dong et al. 2016a). On the other hand, to get dry biomass after the process of dewatering, it undergoes a thermal drying process that usually produces a paste-like biomass, with a dry weight above 85% (Xu et al. 2011).

The pretreatment of microalgae biomass is a very important step for the recovery of lipids and other valuable products, as a tool to improve extraction yields (Karemore and Sen 2016). Microalgae cell walls consist of a fibrillar matrix and crystalline polymers, and the proportion varies between species, so it is necessary to develop a specific pretreatment method (Aarthy et al. 2018).

3.1 Solvent Extraction

Most of the solvent-based extraction techniques used for extraction of lipids from microalgae are based on the traditional methods used for plant oil extraction, like organic solvent extraction, Folch method, Soxhlet, and others. Organic solvents are absorbed within the cell wall, where they cause swelling and rupture of the microalgae cell, making the cell contents available to be separated on the following step (Molina Grima et al. 2013). The main parameters to consider in the choosing of a solvent for the extraction of lipids from microalgae are polarity or extractability, lipid solubility, water miscibility (ability for two-phase systems), and low toxicity (Bensalem et al. 2018).

3.1.1 Folch Method

Lipid extraction by the Folch method relies on the use of a 2:1 chloroform-methanol mixture for extraction of intracellular lipids and is the basis of many solvent extraction methods used nowadays. First, a cell homogenate is equilibrated with 25% volume of saline solution and stirred. This mixture is left to stand until biphasic separation, so the lipids settle on the upper layer (Ranjith Kumar et al. 2015). After, the organic phase is recovered and is evaporated under nitrogen flux. The lipids are weighed, and the lipid content is calculated as the ratio of the weight of lipids and the weight of total microalgae biomass (Fig. 11.2).

Since this method was originally designed for animal cells and tissues, a previous step of disruption of microalgae cell walls has to be included (Molina Grima et al. 2013).

3.1.2 Soxhlet Extraction

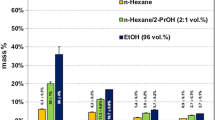

Soxhlet extraction (SE) is a process in which partially soluble components of a solid sample are transferred to a liquid phase (solvent), by means of a Soxhlet extractor. This technique employs nonpolar solvents, like hexane, to obtain neutral lipids. The extraction consists of the placement of the solid sample in a filter paper thimble into the main chamber of the Soxhlet apparatus. Then the solvent is heated to reflux and travels into the main chamber, so the less soluble compounds are recovered by the solvent (Royal Society of Chemistry 2018). As the extraction solvent polarity increases, a higher extraction yield of microalgae can be achieved, due to recovery of complex lipids and pigments (Baumgardt et al. 2016). This is an important consideration since total lipid extracts with polar solvents are complex and other metabolites different than lipids are present. Soxhlet extraction parameters include a choice of solvent, sample particle size, and extraction time (Sharif et al. 2014). A modified methodology for microalgal lipid extraction is presented in Fig. 11.3 (Molina Grima et al. 2013).

Soxhlet extraction is usually carried out in laboratory scale, requires high solvent consumption and long extraction time. After, the total fatty acid methyl esters (FAMEs) are measured to evaluate the efficiency of the extraction procedure (Baumgardt et al. 2016).

3.1.3 Other Solvent-Based Methods: Bligh and Dyer Method

The Bligh and Dyer method consists in the simultaneous lipid extraction and partitioning, with protein precipitation in the interface between two liquid phases, similar to the Folch method. However, the solvent mixture composition and ratios are different (Fig. 11.4).

First, the lipids from a cell homogenate are extracted with 1:2 chloroform/methanol, and the chloroform phase (lipid-rich) is recovered. Microalgae lipids are extracted and measured by gravimetry. This procedure is employed in the pilot- and large-scale operations (Ranjith Kumar et al. 2015).

An improvement of this method is the addition of 1 M NaCl, instead of water, in order to avoid binding of acidic lipids to denatured lipids. Shorter separation times have been achieved by the addition of 0.2 M phosphoric acid and HCl. Increased recovery of acidic phospholipids has been achieved by the addition of 0.5% acetic acid (v/v) (Ranjith Kumar et al. 2015).

Organic solvent extraction remains as one of the main strategies for the recovery of valuable products from microalgae. Solvents should be chosen based on the polarity of the target compounds. For instance, TAGs are nonpolar molecules and the main lipid target for biodiesel production; hence a nonpolar solvent is a suitable choice for extraction.

3.2 Mechanical Methods

Cell disruption methods include solid shear, cavitation and collapse, pulsed electric fields, chemical hydrolysis, enzymatic digestion, subcritical water extraction, and high-pressure homogenization and bead milling.

3.2.1 Milling

Bead milling consists in disrupting cell walls of microalgae by grinding and agitation of the cells on a solid surface of glass beads (Ghasemi Naghdi et al. 2016). The size of the beads for an effective disruption is in the range of 0.3–0.5 mm. The beads can be made up of zirconia-silica or zirconium oxide. The process efficiency is determined by the biomass concentration, flow rate, agitator movement type and speed, and temperature.

The process of milling can be done in shaking vessels or through agitated beads. In the shaking vessel method, the culture vessel is under shake by using a vibrating platform, allowing the beads to move the microalgae cells and forcing them to collide with each other. The highest recovery of lipids through this method was performed by Ryckebosch and collaborators, recovering 40% of lipids from a culture of Phaeodactylum tricronutum (Ryckebosch et al. 2012). On the other hand, Zheng and collaborators extracted 11% of lipids from a culture of Chlorella vulgaris, using a bead milling vessel (Zheng et al. 2012). In the case of agitated beads, a method in which the beads and the culture are agitated by a rotatory agitator inside the culture vessel at the same time provides heat that helps in the disruption process, as reported by Lee and collaborators. The authors used this methodology and obtained an oil yield inside the range of 7.9–8.1 g/L, using cultures of Botryococcus sp., Chlorella vulgaris, and Scenedesmus sp. (Lee et al. 2010).

3.2.2 Pressing

The use of presses is one of the classical methods used to perform the extraction of value-added products from many sources. This method is based on the mechanical crushing of materials with a very low content of moisture. First of all, dried biomass is submitted to high mechanical pressure for crushing and breaking the cells and then squeezing the oil out of the biomass. The extraction efficiency can be improved by variations in the pressure force used, the algal strain used, and configuration of the press and pistons used. In the gel-press alternative, algae are first washed before carbohydrate extraction using diluted alkali. Centrifugation separates residues, followed by filtration through porous silica and concentration by evaporation. The material recovered is extruded through spinnerets into a cold solution of potassium chloride, and the gelled threads are then dewatered by pressure (Amin 2009).

Shear-based devices such as French press and Hughes press use high pressures to force a biomass solution through a small aperture. Usually, the oil recovery is in the range of 70–75%. Sometimes for enhanced oil recovery, mechanical crushing is used in addition with chemical methods. The principal drawbacks of this method are the requirement of high-cost maintenance and less efficiency compared to other methods (Ranjith Kumar et al. 2015).

Different products produced by microalgae, including lipids, proteins, and pigments, have been extracted by means of mechanical extraction. Table 11.1 shows the relation of mechanical extraction used and the yield obtained in different studies.

3.3 Freeze-Thaw Method

The freeze-thaw method favors lipid extraction from microalgae biomass, since it decreases to a minimum the loss of volatile lipids due to evaporation. This method consists of the crystallization of the intracellular water by freezing the wet biomass at a temperature near −80 °C. After, the samples are thawed, so the frozen cells are lysed by the expansion of the ice crystals. This method is usually employed in combination with another method, such as ultrasonication, microwave-assisted extraction, or bead milling, with the purpose to increase yield efficiency (Aarthy et al. 2018). However, freeze-thawing cycles must be carefully managed. A study of the metabolic profile of marine microalgae after freeze-thawing under standard freeze-storage temperatures (−20 °C and −78 °C), for 1 and 2 cycles of 7 days each, reports that unfrozen samples showed a decrease of 10% in reproducibility after 1 cycle and decreased 7% further after the second cycle (Chr. Eilertsen et al. 2014).

3.4 Enzymatic Methods

In enzymatic extraction processes, a combination of enzymes is employed to break down the algal cell wall, expel lipid bodies outside the cell, and separate the lipid fraction from the lipid/protein matrix (Sierra et al. 2017). Enzymatic lysis is an alternative to mechanical cell disruption. The lytic enzymes have to be specific for the microalgae species, the most common being cellulase and lipase, due to the presence of polysaccharides, like cellulose and hemicellulose, in algal cell walls and lipids, contained in a sac surrounded by phospholipids (Aarthy et al. 2018).

Aqueous enzymatic assisted extraction (AEAE) is a cell disruption technique for the extraction of lipids from microalgae. Remarkable features include high selectivity, mild reaction conditions (neutral pH, incubation from 25 to 37 °C), and absence of intensive drying steps (Sierra et al. 2017). A report from Chen and collaborators presents an improved method for enzymatic lysis coupled with thermal treatment for extraction of lipids from N. oceanica, finding the optimal extraction parameters at 37 °C, pH 5.0, 1.3% of cellulase, liquid/solid ratio 15 mL/g, and 5 h. These conditions yielded up to 28.8% of lipids (Chen et al. 2016).

The main steps for enzymatic extraction of lipids from microalgae include biomass harvesting, conditioning and addition of enzymes, stirred incubation for disruption of algal cell walls, addition of solvent (if needed), centrifugation, and lipid fraction recovery (Sierra et al. 2017). Furthermore, enzymatic digestion can be used as means for saccharification of the carbohydrate biomass, for bioethanol production, after the removal of lipids (Heo et al. 2017).

The main microalgae products of interest obtained by enzymatic methods are lipids, carbohydrates, and proteins and are presented in Table 11.2.

3.5 Supercritical Fluid Extraction

Supercritical fluid extraction (SFE) employs the solvating properties of a supercritical fluid, by applying pressure and temperature above the critical point of a compound or mixture. The tunable parameters to consider for SFE include solvent, temperature, pressure, extraction time, solvent flow rate, sample size, use of the modifier, and particle size (Sharif et al. 2014).

Supercritical fluid extraction with carbon dioxide (SFE-CO2) has been employed as an alternative green extraction technique, to spare the use of toxic solvents (Hernández et al. 2014). The advantages of SFE-CO2 consist of the low critical point of CO2 at near room temperature at relatively low pressure (30.9 °C and 73.9 bar) and it being generally recognized as safe (GRAS) by the Food and Drug Administration (FDA) and environmentally friendly (Reverchon and De Marco 2006; Esquivel-Hernández et al. 2016). Moreover, CO2 becomes gaseous after depressurization, thus separated from the sample without residual traces of solvent, can be collected for recycling for subsequent extractions, which in itself brings economic and environmental benefits. In Fig. 11.5, a diagram of a semi-batch SFE system is shown (Laitinen 1999).

Schematic diagram of a semi-batch supercritical fluid extraction apparatus. Reproduced from Laitinen 1999.

Particularly useful for biodiesel extraction, supercritical CO2 is highly selective for nonpolar lipids, such as triglycerides, and does not solubilize phospholipids (Hernández et al. 2014). Other solvents used in SFE include hydrocarbons (hexane, pentane, butane), nitrous oxide, sulfur hexafluoride, and fluorinated hydrocarbons (Reverchon and De Marco 2006).

3.6 Microwave-Assisted Extraction

Microwave-assisted extraction (MAE) relies on the contact of a dielectric polar substance (water, for instance) and a fast oscillating electric field, produced by microwaves, that generates heat due to the friction caused by inter- and intramolecular movements. The heat induces the formation of water vapor in the cell, which eventually causes rupture and further leakage and release of intracellular components, led by an electroporation effect (Ghasemi Naghdi et al. 2016). Thus, MAE is regarded as a rapid, simple, safe, effective, and economical method for the extraction of lipids that does not require the previous dewatering of samples (Ranjith Kumar et al. 2015). Furthermore, microalgae pretreated by microwaves present multiple micro-fissures within the cell wall, which yields higher bio-oil recoveries (Šoštarič et al. 2012).

Besides extraction, microwaves can be employed for transesterification of oils into biodiesel and represent an attractive option since it requires short reaction time (15–20 min), low operational cost, and efficient extraction of algal oils. One important drawback of this method is the high maintenance cost in commercial scale settings (Ranjith Kumar et al. 2015).

For MAE the main parameters to be taken into account include extraction time, temperature, dielectric properties of the process mixture, solid/liquid ratio, and type and concentration of solvent (Ghasemi Naghdi et al. 2016).

3.7 Ultrasound-Assisted Extraction

Ultrasonic-assisted extractions (UAE) can recover oils from microalgae cells through cavitation (Harun et al. 2010). During the low-pressure cycle, high-intensity small vacuum bubbles are created in the liquid. When the bubbles attain a certain size, they collapse violently during a high-pressure cycle. During the implosion very high pressures and high-speed liquid jets are produced locally, and the resulting shear forces break the cell structure mechanically, favoring the extraction of algal lipids (Wei et al. 2008). Ultrasonic waves produce high-pressure cycles that allow the diffusion of solvents, like hexane, into the algal cell wall. The transfer of lipids from the cell into the solvent is aided by ultrasound through the mechanical breakage of the cell wall due to the cavitation shear force (Cravotto et al. 2008).

Lipid recovery can be enhanced by increasing the exposure time and by using mixtures of polar and nonpolar solvents. Also, UAE favors the release of cell contents into the solvent, through mass transfer and penetration of solvent within the cell. UAE can be performed at low temperatures, an ideal feature when dealing with the extraction of thermally sensitive molecules (Ghasemi Naghdi et al. 2016).

3.8 Other Methods

Microalgae are composed of single cells surrounded by an individual cell wall, which includes “unusual” lipid classes and fatty acids that differ from those in higher animals and plants (Guschina and Harwood 2006). In some cases, for extraction of lipids from microalgae, regular extraction methods may not be applicable (Ryckebosch et al. 2012). Extracting and purifying oil from algae is considered challenging due to its energetic and economically intensive nature (Fajardo et al. 2007; Mercer and Armenta 2011).

3.8.1 Pressurized Liquid Extraction

The wet lipid extraction process uses wet algae biomass by using solvent proportionately (Sathish and Sims 2012). This method resembles the solvent extraction process but varies with the nature of biomass (wet). The advantage of the process includes the elimination of a drying step; the interference of moisture content with the extraction solvents and lack of wide applicability to all kinds of solvents are the major limitations of this extraction procedure.

Hydrothermal liquefaction is a process in which biomass is converted in hot compressed water to a liquid biocrude (Brown et al. 2010; Biller et al. 2012). Processing temperatures range from 200 to 350 °C with pressures of around 15–20 MPa, depending on the temperature, because the water has to remain in the subcritical region to avoid the latent heat of vaporization (Biller et al. 2012). At these conditions, complex molecules are broken down and repolymerized to oily compounds (Peterson et al. 2008). This procedure is ideal for the conversion of high-moisture-content biomass such as microalgae because the drying step of the feedstock is not necessary.

3.8.2 Osmotic Pressure

Osmotic shock or osmotic stress is a sudden change in the solute concentration around a cell, causing a rapid change in the movement of water across its cell membrane (Fajardo et al. 2007). This shock causes a release in the cellular contents of microalgae. The method is more applicable for the strains cultivated in marine environments (e.g., Nannochloropsis sp.). Osmotic shock is also induced to release cellular components for biochemical analysis (Larach 2010). This method is also applied for Halorubrum sp. isolated from saltern ponds. The results showed increased lipid productivities and variations in lipid compositions (Lopalco et al. 2004).

3.8.3 Pulsed Electric Field Technologies

Pulsed electric field (PEF) processing is a method for processing cells by means of brief pulses of a strong electric field (Guderjan et al. 2007). Algal biomass is placed between two electrodes and the pulsed electric field is applied. The electric field enlarges the pores of the cell membranes and expels its contents (Guderjan et al. 2005).

4 Concluding Remarks

Extraction of lipids is a key aspect involved in the biomass-to-biodiesel production; the selected method directly influences the potential lipid productivity of the process. So far, several methods have been employed for extracting the cellular contents (lipids) of microalgae. Each method has its own advantages and disadvantages for practical applicability. Among the processes described, solvent extraction is suitable for extracting lipids from mass cultures, but requires large volumes of solvent. The Soxhlet extraction method is applicable only when a single solvent is used and is not suitable for binary solvent applications. On the other hand, recovery and reusability of the solvent are possible with this method. The ultrasonic-assisted extraction can perform well when coupled with the enzymatic treatment, but both methods lack cost-effectiveness and feasibility for large-scale applications. Supercritical carbon dioxide extraction (SFE-CO2), pulsed electric fields, osmotic shock, hydrothermal liquefaction, and wet lipid extraction require more optimization efforts for large-scale applications. A suitable method that is operable with both binary and single solvents, applicable at large scales and yielding higher lipid productivities, is yet to be optimized to achieve enhanced microalgae lipid yields for biofuels and metabolite extraction.

References

Aarthy A, Kumari S, Turkar P, Subramanian S. An insight on algal cell disruption for biodiesel production. Asian J Pharm Clin Res. 2018;11:21. https://doi.org/10.22159/ajpcr.2018.v11i2.22481.

Al-Haj L, Lui Y, Abed R, et al. Cyanobacteria as chassis for industrial biotechnology: progress and prospects. Life. 2016;6:42. https://doi.org/10.3390/life6040042.

Amin S. Review on biofuel oil and gas production processes from microalgae. Energy Convers Manag. 2009;50(7):1834–40. https://doi.org/10.1016/j.enconman.2009.03.001.

Baumgardt FJL, Filho AZ, Brandalize MV, et al. Lipid content and fatty acid profile of Nannochloropsis oculata before and after extraction with conventional solvents and/or compressed fluids. J Supercrit Fluids. 2016;108:89–95. https://doi.org/10.1016/j.supflu.2015.11.003.

Bensalem S, Lopes F, Bodénès P, et al. Understanding the mechanisms of lipid extraction from microalga Chlamydomonas reinhardtii after electrical field solicitations and mechanical stress within a microfluidic device. Bioresour Technol. 2018;257:129–36. https://doi.org/10.1016/j.biortech.2018.01.139.

Biller P, Ross AB, Skill SC, et al. Nutrient recycling of aqueous phase for microalgae cultivation from the hydrothermal liquefaction process. Algal Res. 2012;1:70–6. https://doi.org/10.1016/j.algal.2012.02.002.

Brasil B dos SAF, de Siqueira FG, Salum TFC, et al. Microalgae and cyanobacteria as enzyme biofactories. Algal Res. 2017;25:76–89. https://doi.org/10.1016/j.algal.2017.04.035.

Brown TM, Duan P, Savage PE. Hydrothermal liquefaction and gasification of Nannochloropsis sp. Energy Fuel. 2010;24:3639–46.

Chen G, Qu S, Wang Q, et al. Transgenic expression of delta-6 and delta-15 fatty acid desaturases enhances omega-3 polyunsaturated fatty acid accumulation in Synechocystis sp. PCC6803. Biotechnol Biofuels. 2014;7:1–10. https://doi.org/10.1186/1754-6834-7-32.

Chen L, Li R, Ren X, Liu T. Improved aqueous extraction of microalgal lipid by combined enzymatic and thermal lysis from wet biomass of Nannochloropsis oceanica. Bioresour Technol. 2016;214:138–43. https://doi.org/10.1016/j.biortech.2016.04.031.

Cherubini F, Jungmeier G, Wellisch M, et al. Toward a common classification approach for biorefinery systems. Biofuels Bioprod Biorefin. 2009;3:534–46. https://doi.org/10.1002/bbb.172.

Chr. Eilertsen H, Huseby S, Degerlund M, et al. The effect of freeze/thaw cycles on reproducibility of metabolic profiling of Marine microalgal extracts using direct infusion high-resolution mass spectrometry (HR-MS). Molecules. 2014;19:16373–80. https://doi.org/10.3390/molecules191016373.

Cravotto G, Boffa L, Mantegna S, et al. Improved extraction of vegetable oils under high-intensity ultrasound and/or microwaves. Ultrason Sonochem. 2008;15:898–902. https://doi.org/10.1016/j.ultsonch.2007.10.009.

Cuellar-Bermudez SP, Aguilar-Hernandez I, Cardenas-Chavez DL, et al. Extraction and purification of high-value metabolites from microalgae: essential lipids, astaxanthin and phycobiliproteins. Microb Biotechnol. 2015;8:190–209. https://doi.org/10.1111/1751-7915.12167.

Da Rós PCM, Silva CSP, Silva-Stenico ME, et al. Assessment of chemical and physico-chemical properties of cyanobacterial lipids for biodiesel production. Mar Drugs. 2013;11:2365–81. https://doi.org/10.3390/md11072365.

da Silva RPFF, Rocha-Santos TAP, Duarte AC. Supercritical fluid extraction of bioactive compounds. TrAC Trends Anal Chem. 2016;76:40–51. https://doi.org/10.1016/j.trac.2015.11.013.

Dong T, Knoshaug EP, Davis R, et al. Combined algal processing: a novel integrated biorefinery process to produce algal biofuels and bioproducts. Algal Res. 2016a;19:316–23. https://doi.org/10.1016/j.algal.2015.12.021.

Dong X, He Q, Peng Z, et al. Production of γ-linolenic acid and stearidonic acid by Synechococcus sp. PCC7002 containing cyanobacterial fatty acid desaturase genes. Chin J Oceanol Limnol. 2016b;34:772–80. https://doi.org/10.1007/s00343-016-4369-x.

Esquivel-Hernández DA, López VH, Rodríguez-Rodríguez J, et al. Supercritical carbon dioxide and microwave-assisted extraction of functional lipophilic compounds from Arthrospira platensis. Int J Mol Sci. 2016;17:658. https://doi.org/10.3390/ijms17050658.

Esquivel-Hernández DA, Rodríguez-Rodríguez J, Cuéllar-Bermúdez SP, et al. Effect of supercritical carbon dioxide extraction parameters on the biological activities and metabolites present in extracts from Arthrospira platensis. Mar Drugs. 2017;15:1–18. https://doi.org/10.3390/md15060174.

Fajardo AR, Cerdán LE, Medina AR, et al. Lipid extraction from the microalga Phaeodactylum tricornutum. Eur J Lipid Sci Technol. 2007;109:120–6. https://doi.org/10.1002/ejlt.200600216.

Ghasemi Naghdi F, González González LM, Chan W, Schenk PM. Progress on lipid extraction from wet algal biomass for biodiesel production. Microb Biotechnol. 2016;9:718–26. https://doi.org/10.1111/1751-7915.12360.

Gonçalves AL, Pires JCM, Simões M. Biotechnological potential of Synechocystis salina co-cultures with selected microalgae and cyanobacteria: nutrients removal, biomass and lipid production. Bioresour Technol. 2016;200:279–86. https://doi.org/10.1016/j.biortech.2015.10.023.

Griffiths MJ, van Hille RP, Harrison STL. Lipid productivity, settling potential and fatty acid profile of 11 microalgal species grown under nitrogen replete and limited conditions. J Appl Phycol. 2012;24:989–1001. https://doi.org/10.1007/s10811-011-9723-y.

Grimi N, Dubois A, Marchal L, et al. Selective extraction from microalgae Nannochloropsis sp. using different methods of cell disruption. Bioresour Technol. 2014;153:254–9. https://doi.org/10.1016/j.biortech.2013.12.011.

Guderjan M, Töpfl S, Angersbach A, Knorr D. Impact of pulsed electric field treatment on the recovery and quality of plant oils. J Food Eng. 2005;67:281–7. https://doi.org/10.1016/j.jfoodeng.2004.04.029.

Guderjan M, Elez-Martínez P, Knorr D. Application of pulsed electric fields at oil yield and content of functional food ingredients at the production of rapeseed oil. Innov Food Sci Emerg Technol. 2007;8:55–62. https://doi.org/10.1016/j.ifset.2006.07.001.

Guschina IA, Harwood JL. Lipids and lipid metabolism in eukaryotic algae. Prog Lipid Res. 2006;45:160–86. https://doi.org/10.1016/j.plipres.2006.01.001.

Harun R, Danquah MK, Forde GM. Microalgal biomass as a fermentation feedstock for bioethanol production. J Chem Technol Biotechnol. 2010;85:199–203. https://doi.org/10.1002/jctb.2287.

Havaux M. Carotenoid oxidation products as stress signals in plants. Plant J. 2014;79:597–606. https://doi.org/10.1111/tpj.12386.

Heo YM, Lee H, Lee C, et al. An integrative process for obtaining lipids and glucose from Chlorella vulgaris biomass with a single treatment of cell disruption. Algal Res. 2017;27:286–94. https://doi.org/10.1016/j.algal.2017.09.022.

Hernández D, Solana M, Riaño B, et al. Biofuels from microalgae: lipid extraction and methane production from the residual biomass in a biorefinery approach. Bioresour Technol. 2014;170:370–8. https://doi.org/10.1016/j.biortech.2014.07.109.

Jung FW, Wilson GP. Effluent of different fermented animal wastes. Bull Environ Contam Toxicol. 1981;159:151–9.

Kaiwan-arporn P, Hai PD, Thu NT, Annachhatre AP. Cultivation of cyanobacteria for extraction of lipids. Biomass Bioenerg. 2012;44:142–9. https://doi.org/10.1016/j.biombioe.2012.04.017.

Karemore A, Sen R. Downstream processing of microalgal feedstock for lipid and carbohydrate in a biorefinery concept: a holistic approach for biofuel applications. RSC Adv. 2016;6:29486–96. https://doi.org/10.1039/C6RA01477A.

Laitinen A. Supercritical fluid extraction of organic compounds from solids and aqueous solutions. Espoo: VTT Publications; 1999. p. 1–48.

Larach MC. Hydrodynamic extraction of oils from photosynthetic cultures. J Chromatogr A. 2010;1217:6134–42.

Lee JY, Yoo C, Jun SY, et al. Comparison of several methods for effective lipid extraction from microalgae. Bioresour Technol. 2010;101:S75–7. https://doi.org/10.1016/j.biortech.2009.03.058.

Lopalco P, Lobasso S, Babudri F, Corcelli A. Osmotic shock stimulates de novo synthesis of two cardiolipins in an extreme halophilic archaeon. J Lipid Res. 2004;45:194–201. https://doi.org/10.1194/jlr.M300329-JLR200.

Machado IMP, Atsumi S. Cyanobacterial biofuel production. J Biotechnol. 2012;162:50–6. https://doi.org/10.1016/j.jbiotec.2012.03.005.

Malik K, Tokkas J, Goyal S. Microbial pigments: a review. Int J Microb Res Technol Accept. 2012;41:361–5.

Mata TM, Martins AA, Caetano NS. Microalgae for biodiesel production and other applications: a review. Renew Sust Energ Rev. 2010;14:217–32. https://doi.org/10.1016/j.rser.2009.07.020.

Mazard S, Penesyan A, Ostrowski M, et al. Tiny microbes with a big impact: the role of cyanobacteria and their metabolites in shaping our future. Mar Drugs. 2016;14:E97.

Mercer P, Armenta RE. Developments in oil extraction from microalgae. Eur J Lipid Sci Technol. 2011;113:539–47.

Modiri S, Sharafi H, Alidoust L, et al. Lipid production and mixotrophic growth features of cyanobacterial strains isolated from various aquatic sites. Microbiology. 2015;161:662–73. https://doi.org/10.1099/mic.0.000025.

Molina Grima E, Acién Fernández FG, Robles Medina A. Downstream processing of cell mass and products. In: Richmond A, Hu Q, editors. Handbook of microalgal culture. 2nd ed. Chichester: Wiley Blackwell; 2013. p. 267–309.

Monshupanee T, Incharoensakdi A. Enhanced accumulation of glycogen, lipids and polyhydroxybutyrate under optimal nutrients and light intensities in the cyanobacterium Synechocystis sp. PCC 6803. J Appl Microbiol. 2014;116:830–8. https://doi.org/10.1111/jam.12409.

Moraes CC, De Medeiros Burkert JF, Kalil SJ. C-phycocyanin extraction process for large-scale use. J Food Biochem. 2010;34:133–48. https://doi.org/10.1111/j.1745-4514.2009.00317.x.

Nie C, Pei H, Jiang L, et al. Growth of large-cell and easily-sedimentation microalgae Golenkinia SDEC-16 for biofuel production and campus sewage treatment. Renew Energy. 2018;122:517–25. https://doi.org/10.1016/j.renene.2018.02.005.

Olaizola M. Commercial production of astaxanthin from Haematococcus pluvialis using 25,000-liter outdoor photobioreactors. J Appl Phycol. 2000;12:499–506. https://doi.org/10.1023/A:1008159127672.

Peramuna A, Summers ML. Composition and occurrence of lipid droplets in the cyanobacterium Nostoc punctiforme. Arch Microbiol. 2014;196:881–90. https://doi.org/10.1007/s00203-014-1027-6.

Peterson AA, Vogel F, Lachance RP, et al. Thermochemical biofuel production in hydrothermal media: a review of sub- and supercritical water technologies. Energy Environ Sci. 2008;1:32. https://doi.org/10.1039/b810100k.

Prabakaran P, Ravindran AD. A comparative study on effective cell disruption methods for lipid extraction from microalgae. Lett Appl Microbiol. 2011;53:150–4. https://doi.org/10.1111/j.1472-765X.2011.03082.x.

Ranjith Kumar R, Hanumantha Rao P, Arumugam M. Lipid extraction methods from microalgae: a comprehensive review. Front Energy Res. 2015;2:1–9. https://doi.org/10.3389/fenrg.2014.00061.

Reverchon E, De Marco I. Supercritical fluid extraction and fractionation of natural matter. J Supercrit Fluids. 2006;38:146–66. https://doi.org/10.1016/j.supflu.2006.03.020.

Royal Society of Chemistry. Soxhlet extraction. Chem Methods Ontol. 2018.; http://www.rsc.org/publishing/journals/prospect/ontology.asp?id=CMO:0001609&MSID=C1EE01213D. Accessed 5 Apr 2018.

Ryckebosch E, Muylaert K, Foubert I. Optimization of an analytical procedure for extraction of lipids from microalgae. J Am Oil Chem Soc. 2012;89:189–98. https://doi.org/10.1007/s11746-011-1903-z.

Sathish A, Sims RC. Biodiesel from mixed culture algae via a wet lipid extraction procedure. Bioresour Technol. 2012;118:643–7. https://doi.org/10.1016/j.biortech.2012.05.118.

Sharif KM, Rahman MM, Azmir J, et al. Experimental design of supercritical fluid extraction – a review. J Food Eng. 2014;124:105–16. https://doi.org/10.1016/j.jfoodeng.2013.10.003.

Shen Y, Yuan W, Pei Z, Mao E. Heterotrophic culture of Chlorella protothecoides in various nitrogen sources for lipid production. Appl Biochem Biotechnol. 2010;160:1674–84. https://doi.org/10.1007/s12010-009-8659-z.

Shokrkar H, Ebrahimi S, Zamani M. Bioethanol production from acidic and enzymatic hydrolysates of mixed microalgae culture. Fuel. 2017;200:380–6. https://doi.org/10.1016/j.fuel.2017.03.090.

Sierra LS, Dixon CK, Wilken LR. Enzymatic cell disruption of the microalgae Chlamydomonas reinhardtii for lipid and protein extraction. Algal Res. 2017;25:149–59. https://doi.org/10.1016/j.algal.2017.04.004.

Silaban A, Bai R, Gutierrez-Wing MT, et al. Effect of organic carbon, C:N ratio and light on the growth and lipid productivity of microalgae/cyanobacteria coculture. Eng Life Sci. 2014;14:47–56. https://doi.org/10.1002/elsc.201200219.

Silva CSP, Silva-Stenico ME, Fiore MF, et al. Optimization of the cultivation conditions for Synechococcus sp. PCC7942 (cyanobacterium) to be used as feedstock for biodiesel production. Algal Res. 2014;3:1–7. https://doi.org/10.1016/j.algal.2013.11.012.

Šoštarič M, Klinar D, Bricelj M, et al. Growth, lipid extraction and thermal degradation of the microalga Chlorella vulgaris. New Biotechnol. 2012;29:325–31. https://doi.org/10.1016/j.nbt.2011.12.002.

Wei F, Gao GZ, Wang XF, et al. Quantitative determination of oil content in small quantity of oilseed rape by ultrasound-assisted extraction combined with gas chromatography. Ultrason Sonochem. 2008;15:938–42. https://doi.org/10.1016/j.ultsonch.2008.04.003.

Wijffels RH, Kruse O, Hellingwerf KJ. Potential of industrial biotechnology with cyanobacteria and eukaryotic microalgae. Curr Opin Biotechnol. 2013;24:405–13. https://doi.org/10.1016/j.copbio.2013.04.004.

Xu L, Wim Brilman DWF, Withag JAM, et al. Assessment of a dry and a wet route for the production of biofuels from microalgae: energy balance analysis. Bioresour Technol. 2011;102(8):5113–22. https://doi.org/10.1016/j.biortech.2011.01.066.

Zheng H, Yin J, Gao Z, et al. Disruption of Chlorella vulgaris cells for the release of biodiesel-producing lipids: a comparison of grinding, ultrasonication, bead milling, enzymatic lysis, and microwaves. Appl Biochem Biotechnol. 2011;164:1215–24. https://doi.org/10.1007/s12010-011-9207-1.

Zheng G, Li C, Guo L, et al. Purification of extracted fatty acids from the microalgae Spirulina. J Am Oil Chem Soc. 2012;89:561–6. https://doi.org/10.1007/s11746-011-1956-z.

Acknowledgments

This research was supported by Tecnologico de Monterrey Mexico. The financial support provided by CONACYT (Mexican Council of Science and Technology) under the project Phycopigments (grant number 268792) is thankfully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Salinas-Salazar, C., Saul Garcia-Perez, J., Chandra, R., Castillo-Zacarias, C., Iqbal, H.M.N., Parra-Saldívar, R. (2019). Methods for Extraction of Valuable Products from Microalgae Biomass. In: Alam, M., Wang, Z. (eds) Microalgae Biotechnology for Development of Biofuel and Wastewater Treatment. Springer, Singapore. https://doi.org/10.1007/978-981-13-2264-8_11

Download citation

DOI: https://doi.org/10.1007/978-981-13-2264-8_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2263-1

Online ISBN: 978-981-13-2264-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)