Abstract

This paper describes a DEM investigation of the formation of sandpiles and the angle of repose by focusing on the effect of particle shape. Special efforts are made to quantitatively analyze the particle arrangements and interactions, which are essential to the explanation of angle of repose from a micromechanical perspective. The DEM simulation results show that the angle of repose decreases with the increase of the shape parameter (aspect ratio and circularity). The intensities of fabric anisotropy described by particle and contact orientations both exhibit a negative correlation with the shape parameter. The principal anisotropy directions of contact orientations for the left and right parts of sandpiles deviate increasingly away from the vertical direction as the shape parameter is increased. A characteristic aspect ratio AR = 0.6 has been identified for the fabric anisotropy of particle orientations, at which the principal anisotropy directions for the left and right parts of sandpiles reach a compromise state and lie in the horizontal direction. Furthermore, the repose angle is found to be closely linked with the fabric anisotropy, with the sum of the repose angle α and deviation angle Δϕn (the angle formed between principal anisotropy direction of contact orientations and the vertical direction) being approximately a constant, regardless of the effect of particle shape. The arching effect in the sandpile is also examined through a statistical analysis of the distribution of forces at the bottom, and the mechanism underlying the formation of sandpiles is thus clarified.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Discrete Element Method

- Fabric Anisotropy

- Discrete Element Method Simulation

- Particle Orientation

- Contact Orientation

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Granular materials such as sand and gravels are ubiquitous in our daily life, and the understanding of such materials are of utmost interest to a number of practical issues ranging from landslides to industrial processes. One of the simplest presence form of dry granular materials is the sandpile which is constructed by pouring sand particles from a point source onto a horizontal plane. The slope of the sandpile is termed as “angle of repose” . In terms of this conceptually simple granular system, one may intuitively think that the maximum pressure at the bottom would occur right under the apex of the sandpile. However, a variety of experimental studies reveal that a local pressure dip exists under the apex of the sandpile [1–6]. To understand this interesting phenomenon, some researchers developed theoretical models to explore the origin of sandpiles [7–9]. Such theoretical studies, which were conducted in the framework of continuum mechanics, have shed some light on the interesting phenomena observed in sandpiles such as arching in the force network and pressure dip at the bottom.

But, it is worth noting that the macroscopic angle of repose and its associated phenomena in fact originate from the discrete nature of granular media [10–12]. Thus the grain-scale modeling such as molecular dynamics (MD) and discrete element method (DEM) are preferred by researchers in the investigation of sandpiles. Lee and Herrmann [13], Luding [14], Zhou et al. [15] and Goldenberg and Goldhirsch [16] performed the MD or DEM simulations to examine the effect of inter-particle friction on the angle of repose. Liffman et al. [17] and Li et al. [18] used idealized spherical particles to mimic the formation of sandpile and examine the force distribution in or underneath the pile. Alternatively using irregular-shaped particles to build up numerical models, Matuttis [19], Matuttis et al. [20], Zhou and Ooi [21] and Zhou et al. [22] studied the effect of particle shape on the formation of the sandpile and scrutinized its related phenomena such as arching and pressure dip .

The MD and DEM simulations have to some extent provided a fundamental understanding into the origin of sandpile , whereas most of these numerical studies tended to reproduce the characteristic responses observed in the experiments or predicted by the theoretical models, and make a qualitative and phenomenological interpretation. Few studies have been carried out to probe an effective quantitative relationship between the macroscopic angle of repose and micromechanical indices characterizing the microstructures and inter-particle force network. Thus no satisfactory explanation has been achieved to account for the formation of sandpile and the origin of angle of repose from a micromechanical perspective.

This paper describes an DEM study of the formation of sandpile and angle of repose by focusing on the effect of particle shape. The sandpiles are created with clumped particles of different aspect ratios or circularities. The effect of particle shape on the angle of repose is discussed. Particular attention has been given to a complete quantitative analysis of the microstructures in the sandpile by taking into consideration the effect of particle shape. An attempt has also been made to explore a quantitative link between the macroscopic angle of repose and the micromechanical parameters, such that the angle of repose is clarified from a microscopic perspective.

2 Numerical Implementation

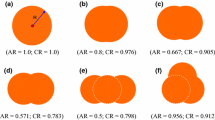

The DEM program PFC2D [23] was used in current study to mimic the formation of sandpiles comprising particles of different shapes. In total six particle shapes, as described in Fig. 1, were considered, including the disk-shaped particle (Fig. 1a), elongated-shaped particle (Figs. 1b–e), and triangular-shaped particle (Fig. 1f). Except for the disk-shaped particle, the particles of other shapes were generated by clumping two or three disks to form a rigid integrated entity which cannot be broken apart. The particle size of clumped particles was measured by the diameter of circular particles which have the same area as those clumped ones, with the cumulative size distribution curve given in Fig. 2. The indices of aspect ratio (AR) and circularity (CR) were employed to characterize the shape of particles. The aspect ratio of a particle is here defined to be the ratio of the length of its minor axis over that of its major axis [24–27], and the circularity is expressed to be [28–30]:

where R is the radius of an equivalent particle having the same area; Ap and P are the particle area and perimeter, respectively. The values of the two shape parameters for the concerned particle shapes are given in Table 1.

The particle density is 2.65 g/cm3. The contact behavior between particles is governed by the linear elastic contact model built-up in PFC2D, with the normal and tangential stiffness of particles specified to be 1.0 × 109 N/m. The stiffness of bottom wall in both normal and tangential directions is also given to be 1.0 × 109 N/m. The inter-particle and particle-wall friction coefficients are both set to be 0.5.

In this numerical study, the sandpiles are constructed by pouring the particles which are initially generated within a narrow domain, onto a bottom wall, as schematically described in Fig. 3. The narrow rectangular domain in fact serves as a point source, with the dimension being 0.14 × 1.6 m2. After the particles have fallen and rested on the bottom wall, the narrow domain is moved upward, with a clearance of about 50 dm left between this domain and the apex of sandpile, where dm is the mean particle size. Then a new batch of particles are generated within this updated domain, and the pouring of particles is once again executed to create another layer of particles in the sandpile. This process is repeated in total thirteen times, such that each sandpile consists of thirteen layers, and each layer has 200 particles. With the omission of the particles finally settling at a certain position off the main part of sandpile, each sandpile contains about (slightly less than) 2600 particles.

The description of fabric anisotropy relating respectively to the contact and particle orientations follows that of Dai et al. [31, 32].

3 Results and Discussions

3.1 Effect of Particle Shape on the Angle of Repose

The angles of repose for both left and right parts of sandpiles are plotted respectively against the aspect ratio AR and circularity CR, as given in Fig. 4. It is shown that the angle of repose decreases with the increase of both AR and CR, implying that the more irregular particle shape is, the larger the angle of repose is. As indicated in Table 1, the angle of repose of shape A (disk shaped) is on the average the smallest and that of shape E (three-particle clumped) is the largest. It is also noted that the angle of repose is correlated better with the circularity CR, as compared with the aspect ratio AR, which has in fact been verified by the root mean square deviations shown in Fig. 4.

3.2 Micromechanical Analysis

-

(a)

Contact orientations

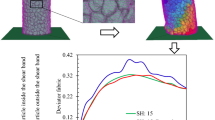

Figure 5 describes the relations between the shape parameters and the fabric anisotropy of contact orientations for both left and right parts of sandpiles. It is seen that the anisotropy magnitude an shows a negative correlation with AR and CR, and an is the lowest for the disk-shaped case (shape A). Figure 6 plots the deviation angle Δϕn of the principal anisotropy direction relative to the vertical direction, against the angle of repose α. It is seen that Δϕn decreases with the angle of repose α. It is also interesting to find that there seems to exist a linear relationship between Δϕn and α, in which the summation of Δϕn and α approximates to a constant 47º.

-

(b)

Particle orientations

Figure 7 depicts the relations of the fabric anisotropy of particle orientations with the aspect ratio. Figure 7a shows that the anisotropy magnitude a0 decreases with the increase of AR. That is, the more irregular particle shape is, the more intense the fabric anisotropy of particle orientations tends to be. In the meantime the principal anisotropy direction ϕ0 for the left part of the case shape B, as can be seen in Fig. 7b, is a negative value, referring to a direction below the horizontal plane (in the fourth quadrant of Cartesian coordinate system). As particle shape becomes more irregular, ϕ0 increases with the decrease of AR, and ϕ0 for the left part of the case Shape E has even become a positive value denoting a direction above the horizontal plane (in the first quadrant). On the contrary the principal anisotropy direction for the right part of sandpiles transits from a direction above the horizontal plane (the shape B) to a direction beneath it (the shape E) as the aspect ratio AR decreases.

Of great interest is the observation that the two best fit lines cross at the point (0.6, 0). It can be thus inferred that with the aspect ratio AR varying, the two principle anisotropy directions respectively for the left and right parts of sandpiles are expected to reach a compromise state where both left and right parts share the same principal anisotropy direction, and that this characteristic state takes place at AR = 0.6, with the common principal anisotropy direction being ϕ0 = 0º ̶ the horizontal direction.

-

(c)

Bottom response

The average normal and friction forces are plotted against the relative positions, as given in Fig. 8. Obviously, a pressure dip is observed at the middle of sandpile for the distribution of normal forces. Correspondingly, the friction force at the middle is nearly zero.

4 Conclusions

-

(a)

The angle of repose decreases as the aspect ratio AR (or circularity CR) increases, and its correlation with CR seems to be better than that with AR.

-

(b)

The fabric anisotropy magnitude an of contact orientations in both left and right parts of sandpiles shows a negative correlation with AR (or CR), with the disk-shaped case being the smallest and the case shape E being the largest. The angle of repose is found to be dependent on the fabric anisotropy, with its summation with the deviation angle Δϕn being a constant 47º in this study.

-

(c)

It is revealed that the more irregular particle shape is, the more intense the fabric anisotropy of particle orientations tends to be. The principal anisotropy direction for both left and right parts of sandpiles will experience rotations as the shape parameter AR varies. A characteristic aspect ratio AR = 0.6 has thus been identified, at which the left and right parts of sandpiles share the same principal anisotropy direction ̶ the horizontal direction.

-

(d)

A pressure dip and the zero friction response are observed at the middle of sandpiles, which agrees well with previous laboratory observations.

References

Brockbank, B., Huntley, J.M., Ball, R.C.: Contact force distribution in beneath a three-dimensional granular pile. J. Phys. II France 7, 1521–1532 (1997)

Vanel, L., Howell, D.W., Clark, D., Behringer, R.P., Clément, E.: Memories in sand: experimental tests of construction history on stress distributions under sandpiles. Phys. Rev. E 60, R5040–R5043 (1999)

Geng, J., Longhi, E., Behringer, R.P., Howell, D.W.: Memory in two-dimensional heap experiments. Phys. Rev. E 64, 060301 (2001)

Mueggenburg, N.W., Jaeger, H.M., Nagel, S.R.: Stress transmission through three-dimensional ordered granular arrays. Phys. Rev. E 66, 031304 (2002)

Atman, A.P.F., Brunet, P., Geng, J., Reydellet, G., Claudin, P., Behringer, R.P., Clément, E.: From the stress response function (back) to the sand pile “dip”. Eur. Phys. J. E 13, 93–100 (2005)

Zuiguel, L., Mullin, T., Rotter, J.M.: The effect of particle shape on the stress dip under a sandpile. Phys. Rev. Lett. 98, 028001 (2007)

Liu, C.H., Nagel, S.R., Schecter, D.A., Coppersmith, S.N., Majumda, S., Narayan, O., Witten, T.A.: Force fluctuation in beads packs. Science 269, 513–515 (1995)

Coppersmith, S.N., Liu, C.H., Majumda, S., Narayan, O., Witten, T.A.: Model for force fluctuation in bead packs. Phys. Rev. E 53, 4673–4685 (1996)

Wittmer, J.P., Claudin, P., Cates, M.E., Bouchaud, J.P.: An explanation for the central stress minimum in sand piles. Nature 382, 336–338 (1996)

Jaeger, H.M., Nagel, S.R., Behringer, R.P.: Granular solids, liquids, and gases. Rev. Mod. Phys. 68, 1259–1273 (1996)

Duran, J.: Sand, Powders, and Grains: An Introduction to the Physics of Granular Materials. Springer, New York (1999)

Aranson, I.S., Tsimring, L.S.: Patterns and collective behavior in granular media: theoretical concepts. Rev. Mod. Phys. 78, 641–692 (2006)

Lee, J., Herrmann, H.J.: Angle of repose and angle of marginal stability: molecular dynamics of granular particles. J. Phys. A: Math. Gen. 26, 373–383 (1993)

Luding, S.: Stress distribution in static two-dimensional granular model media in the absence of friction. Phys. Rev. E 55, 4720–4729 (1997)

Zhou, Y.C., Xu, B.H., Yu, A.B., Zulli, P.: Numerical investigation of the angle of repose of monosized spheres. Phys. Rev. E 64, 021301 (2001)

Goldenberg, C., Goldhirsch, I.: Friction enhances elasticity in granular solids. Nature 435, 188–191 (2005)

Liffman, K., Nguyen, M., Metcalfe, G., Cleary, P.: Forces in piles of granular materials: an analytic and 3D DEM study. Granular Matter 3, 165–176 (2001)

Li, Y., Xu, Y., Thornton, C.: A comparison of discrete element method simulations and experiments for ‘sandpile’ composed of spherical particles. Powder Technol. 160, 219–228 (2005)

Matuttis, H.G.: Simulation of the pressure distribution under a two-dimensional heap of polygonal particles. Granular Matter 1, 83–91 (1998)

Matuttis, H.G., Luding, S., Herrmann, H.J.: Discrete element simulations of dense packing and heaps made of spherical and non-spherical particles. Powder Technol. 109, 278–292 (2000)

Zhou, C., Ooi, J.Y.: Numerical investigation of progressive development of granular pile with spherical and non-spherical particles. Mech. Mater. 41, 707–714 (2009)

Zhou, Z.Y., Zou, R.P., Pinson, D., Yu, A.B.: Angle of repose and stress distribution of sandpiles formed with ellipsoidal particles. Granular Matter 16, 695–709 (2014)

Itasca: User’s manual for PFC2D. Itasca Consulting Group, Inc., Minneapolis, USA (2005)

Cavarretta, I., Coop, M., O’Sullivan, C.: The influence of particle characteristics on the behaviour of coarse grained soils. Géotechnique 60, 413–423 (2010)

Yang, J., Luo, X.D.: Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids (2015). doi:10.1016/j.jmps.2015.08.001

Yang, J., Wei, L.M.: Collapse of loose sand with the addition of fines: the role of particle shape. Géotechnique 62, 1111–1125 (2012)

Yang, Y., Wang, J.F., Cheng, Y.M.: Quantified evaluation of particle shape effects from micro-to-macro for non-convex grains. Particuology (2015). doi:10.1016/j.partic.2015.01.008

Wadell, H.: Volume, shape, and roundness of rock particles. J. Geol. 40, 443–451 (1932)

Wadell, H.: Volume, shape, and roundness of quartz particles. J. Geol. 43, 250–280 (1935)

Robinson, D.A., Friedman, S.P.: Observations of the effects of particle shape and particle size distribution on avalanching of granular media. Phys. A 311, 97–110 (2002)

Dai, B.B., Yang, J., Luo, X.D.: A numerical analysis of the shear behavior of granular soil with fines. Particuology 21, 160–172 (2015)

Dai, B.B., Yang, J., Zhou, C.Y., Luo, X.D.: DEM investigation on the effect of sample preparation on the shear behavior of granular soil. Particuology 25, 111–121 (2016)

Acknowledgments

The authors thank the financial support provided by the National Natural Science Foundation of China (51209237; 51428901; 41530638; 51408381) and the Fundamental Research Funds for the Central Universities (No. 13lgpy05).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this paper

Cite this paper

Dai, BB., Yang, J., Zhou, CY., Zhang, W. (2017). Effect of Particle Shape on the Formation of Sandpile. In: Li, X., Feng, Y., Mustoe, G. (eds) Proceedings of the 7th International Conference on Discrete Element Methods. DEM 2016. Springer Proceedings in Physics, vol 188. Springer, Singapore. https://doi.org/10.1007/978-981-10-1926-5_79

Download citation

DOI: https://doi.org/10.1007/978-981-10-1926-5_79

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1925-8

Online ISBN: 978-981-10-1926-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)