Abstract

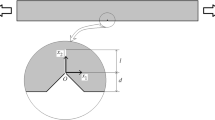

Catastrophic failure in polycrystalline ceramics results from stressed cracks growing to critical dimensions which can span a range of size scales. As critical flaw dimensions increase in size from a scale less than characteristic micro-structure dimensions to a size which encompasses many grain diameters, the resistance to fracture increases, in certain polycrystals, by a factor of 5–10. This increase represents the difference between the fracture resistance of the polycrystal and that of its individual constituent single crystals. In this chapter, we: (1) show how relatively small variations in grain size and shape affect the fracture toughness — crack size relationship (R-curve behaviour); (2) briefly review several microstructural mechanisms suggested to be responsible for both the high fracture energy of polycrystals and the rising resistance to fracture with crack extension; (3) present the results of in-situ microscopy observations of subcritically propagating cracks which lend support to crack-interface traction as an important fracture resistance mechanism; and (4) examine the complicating influence that the traction mechanism has on prediction of time-dependent failure from flaws propagating under the influence of stress-enhanced chemical reactions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Chantikul, P., G. R. Anstis, B. R. Lawn, & D. B. Marshall 1981. A critical analysis of indentation techniques for measuring fracture toughness: II, strength method. J. Am. Ceram. Soc. 64, 539–43.

Davidge, R. W., J. W. McLaren, & G. Tappin 1973. Strength-probability-time (STP) relationships in ceramics.J. Mat. Sci. 8, 1699–705.

Evans, A. G. 1972. A method for evaluating the time-dependent failure characteristics of brittle materials and its application to polycrystalline alumina.J. Mat. Sci. 7, 1137–46.

Evans, A. G. & K. T. Faber 1984. Crack growth resistance of microcracking materials. J. Am. Ceram. Soc. 67, 255–60.

Evans, A. G., D. B. Marshall & N. H. Burlingame 1981. Transformation toughening in ceramics. In Advances in ceramics, vol. 3, A. H. Heuer & L. W. Hobbs (eds), 202–16. Columbus, Ohio: American Ceramic Society.

Faber, K. T. & A. G. Evans 1983a. Crack deflection processes: I, theory. Acta Metall. 31, 565–76.

Faber, K. T. & A. G. Evans 1983b. Crack deflection processes: II, experiment. Acta. Metall. 31, 577–84.

Freiman, S. W., L. Chuck, J. J. Mecholsky, D. L. Shelleman & L. J. Storz 1986. Fracture mechanisms in lead zirconate titanate ceramics. In Fracture mechanics of ceramics, vol. 8, R. C. Bradt, A. G. Evans, D. P. H. Hasselman & F. F. Lange (eds), 175–85. New York: Plenum.

Fuller, E. R., B. R. Lawn & R. F. Cook 1983. Theory of fatigue for brittle flaws originating from residual stress concentrations. J. Am. Ceram. Soc. 66, 314–21.

Hellmann, J. R., J. Matsko, S. W. Freiman & T. L. Baker 1986. Microstructure-mechanical property relationships in 94% alumina ceramics. In Tailoring multiphase and composite ceramics, R. E. Tressler, G. L. Messina, C. G. Pantano & R. E. Newnham (eds), 367–79. New York: Plenum Press.

Hoagland, R. G., J. D. Embury & D. J. Green 1975. On the density of microcracks formed during the fracture of ceramics. Scripta Metall. 9, 907–9.

Knehans, R. & R. Steinbrech 1982. Memory effect of crack resistance during slow crack growth in notched Al2O3 bend specimens. J. Mat. Sci. Lett. 1, 327–9.

Li, V. C. & E. Liang 1986. Fracture processes in concrete and fiber reinforced cementitious composites. J. Engng. Mech. 112, 566–86.

Mai, Y.-W. & B. R. Lawn 1987. Crack-interface grain bridging as a fracture resistance mechanism in ceramics: II. Theoretical fracture mechanics model.J. Am. Ceram. Soc. 70, 289–94.

Meredith, P. G. 1989. Fracture and failure of brittle polycrystals: an overview. This volume, 5–47.

Michalske, T. A. & S. W. Freiman 1983. A molecular mechanism for stress corrosion in vitreous silica. J. Am. Ceram. Soc. 66, 284–8.

Rice, R. W. & S. W. Freiman 1981. Grain size dependence of fracture energy in ceramics, II: a model for non-cubic materials. J. Am. Ceram. Soc. 64, 350–4.

Rice, R. W., S. W. Freiman & J. J. Mecholsky 1980. The dependence of strength controlling fracture energy on the flaw size to grain size ratio. J. Am. Ceram. Soc. 63, 129–36.

Shah, S. P. (ed.) 1985. Applications of fracture mechanics to cementitious composites. Boston: Martinus Nijhoff.

Steinbrech, R., R. Knehans & W. Schaarwachter 1983. Increase of crack resistance during slow crack growth in Al2O3 bend specimens. J. Mat. Sci. 18, 265–70.

Swain, M. V. & L. R. F. Rose 1984. Toughening of ceramics. Proc. Sixth Int. Conf. on Fracture 1, 473–94.

Swanson, P. L. 1987. Tensile fracture resistance mechanisms in brittle polycrystals: An ultrasonics and in-situ microscopy investigation.J. Geophys. Res. 92, 8015–36.

Swanson, P. L. 1988. Crack-interface traction: a fracture-resistance mechanism in brittle polycrystals. In Advances in ceramics, 22, 135–55. Columbus, Ohio: Am. Ceram. Soc.

Swanson, P. L., C. J. Fairbanks, B. R. Lawn, Y.-W. Mai, & B. J. Hockey 1987. Crack-interface grain bridging as a fracture resistance mechanism in ceramics: I. Experimental study on alumina. J. Am. Ceram. Soc. 70, 279–89.

Wiederhorn, S. M. 1984. Brittle fracture and toughening mechanisms in ceramics. Ann. Rev. Mat. Sci. 14, 373–403.

Wieninger, H., K. Kromp & R. F. Pabst 1986. Crack resistance curves of alumina and zirconia at room temperature. J. Mat. Sci. 21, 411–18.

Rights and permissions

Copyright information

© 1990 D. J. Barber, P. G. Meredith & contributors

About this chapter

Cite this chapter

Freiman, S.W., Swanson, P.L. (1990). Fracture of polycrystalline ceramics. In: Deformation Processes in Minerals, Ceramics and Rocks. The Mineralogical Society Series, vol 1. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-6827-4_4

Download citation

DOI: https://doi.org/10.1007/978-94-011-6827-4_4

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-011-6829-8

Online ISBN: 978-94-011-6827-4

eBook Packages: Springer Book Archive