Abstract

Lactic acid bacteria (LAB) are known through ages for their wide applications in food, pharmaceutical and chemical industries. But recently LAB have aroused interest for their ability to secrete extracellular polysaccharides or glucans. These glucans have immense commercial value because of their industrially useful physico-chemical properties. The glucans derived from LAB play crucial role in improving rheology, texture, mouth feel of fermented food formulations and conferring beneficial physiological effects on human health, such as antitumour activity, immunomodulating bioactivity and anticarcinogenicity. The modulation of biochemical properties of glucans require a thorough understanding of its biosynthetic pathway and the relation between the structure of glucans and the functional effect provided by them after incorporation into the food matrix. LAB are employed in food industry for making yoghurt, cheese, sourdough bread, sauerkraut, pickles, beer, wine and other fermented foods and animal feeds like silage. LAB can also produce a variety of functional oligosaccharides that have applications as prebiotics, neutraceuticals, sweetners, humectants, drug against colon cancer and as immune stimulator. LAB are gram positive rods or cocci, non spore forming, acid tolerant, low GC containing, anaerobic or micro-aerophilic bacteria characterized by their ability to ferment sugar to lactic acid. The commonly known LAB genera are Lactobacillus, Leuconostoc, Pediococcus, Lactococcus and Streptococcus. Besides prolonging the shelf life, lactic acid enhances the gustatory and nutritional value, imparts appetizing flavour and texture to the food. Some LAB produce proteinaceous antimicrobial compounds called bacteriocins which inhibit the growth of Gram-positive pathogenic and spoilage bacteria and used as food additives. Lactic acid bacteria as probiotics have been proven effective against diarrhoea, irritable bowel disorder, allergies, stimulation of immunity, lactose intolerance.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Lactic acid bacteria are industrially important and beneficial microbes that have similar properties (gram positive and catalase negative) and all produce lactic acid as an end product of the fermentation process. The genera Carnobacterium, Enterococcus, Lactobacillus, Lactococcus, Lactosphaera, Leuconostoc, Melissococcus, Oenococcus, Pediococcus, Streptococcus, Tetragenococcus, Vagococcus and Weissella are recognized as LAB (Ercolini et al. 2001; Holzapfel et al. 2001). They are widespread in nature and are also found in our digestive systems. There are several potential healths or nutritional benefits possible from several species of lactic acid bacteria, among these are: improved nutritional value of food, control of intestinal infections, improved digestion of lactose, control of some type of cancer and control of serum cholesterol level. Although they are best known for their role in the preparation of fermented dairy products, they are also used for pickling of vegetables, baking, wine-making, curing fish, meats and sausages. Lactobacillus plantarum and Lactobacillus sanfrancisco are commercially available and widely used e.g. for the production of fermented milk products and for the preparation of sourdough (Sing 1977). LABs are also regarded as a major group of probiotic bacteria (Schrezenmeir and de Vrese 2001) i.e. they are a live microbial feed supplement which beneficially affects the host animal by improving its intestinal microbial balance. LAB produces various types of exopolysaccharide which has numerous application in food and pharmaceutical industry (Naessens et al. 2005; Purama and Goyal 2005) with the help of extracellular glucansucrase enzyme. These glucansucrase produce three types of glucans based on the types of the linkages present. They are dextran, mutan and alternan. The dexran is composed of mainly α(1 → 6) linkage and occasionally α(1 → 2), α(1 → 3) and α(1 → 4) linkage as branching points (Monchois et al. 1999). Mutan is a type of insoluble glucan having more than 50% α(1 → 3) linkages (Mooser 1992) and alternan composed of alternating α(1 → 6) and α(1 → 3) glucosidic linkages, with some degree of α(1 → 3) branching (Seymour and Knapp 1980; Cote and Robyt 1982). LAB can also produce a variety of functional oligosaccharides synthesized by glucansucrase as a result of acceptor reaction (Demuth et al. 2002) and can be used as used as neutraceuticals, stabilizers and prebiotics (Goulas et al. 2004; Naessens et al. 2005).

2 LAB in Food Industry

Lactic acid bacteria is used throughout the world to produce specialty foods, particularly in fermented milk products, including yoghurt, cheese, butter, buttermilk, kefir. Some of the traditional fermented food products and their associated lactic acid bacteria are listed in Table 33.1. LAB are either homofermentative or heterofermentative based on the organism’s metabolic pathway. Homofermentative bacteria such as Lactococcus and Streptococcus yield two lactates from one glucose molecule, whereas the heterofermentative bacteria such as Leuconostoc and Weissella transform a glucose molecule into lactate, ethanol and carbon dioxide (Kuipers et al. 2000). Lactic acid bacterial also produce acetic acid, aroma compounds, bacteriocins and exoplysaccharide and several important enzyme. For example acetaldehyde, provides the characteristic aroma of yoghurt, while diacetyl imparts a buttery taste to other fermented milks which improve the taste quality because at the fermentation process by lactic acid bacteria produce lactic acid in fermented milks which gives slightly tart taste. Some of the fermented foods produced by lactic acid bacteria are listed in Table 33.2 (Avonts et al. 2004).

3 Lactic Acid in Food Industry

Lactic acid is water soluble, non-volatile odorless and is classified as GRAS (generally regarded as safe) by FDA in the USA. Several lactic acid bacteria produce lactic acid at the end of carbohydrate fermentation. The presence of lactic acid, produced during the lactic acid fermentation is responsible for the sour taste and for the improved microbiological stability and safety of the food. Lactic acid is produced in the form of L(+) or D(−) lactic acid or as its racemic mixture. Organisms that form the L(+) form or D(−) form have two lactate dehydrogenases (LDH), which differ in their stereospecifity. Some Lactobacilli produce L(+) form, which on accumulation induces a racemase, which converts it into D(−) lactic acid until equilibrium is obtained. Lactobacillus plantarum produce both L(+) form or D(−) form. Of these L(+) form is of great application for its ability to tolerate high concentration of hydrogen ions and pure form of L(+) lactic acid is produced from Lactobacillus helvicticus by metabolic engineering (Nikkila et al. 2000).

Lactic acid is used as acidulant, flavorings and pH buffering agent or inhibitor of bacterial spoilage in a wide variety of processed foods. In contrast to other food acids it has a mild acidic taste. It is a very good preservative and pickling agent. Addition of lactic acid aqueous solution to the packaging of poultry and fish increases their shelf life. The esters of lactic acid are used as emulsifying agents in baking foods (stearoyl-2-lactylate, glyceryl lactostearate, glyceryl lactopalmitate). The manufacture of these emulsifiers requires heat stable lactic acid, hence only the synthetic or the heat stable fermentation grades can be used for this application (Sodegard 1998).

4 Glucans from LAB in Food Industry

Lactic acid bacteria produce a wide variety of food grade exopolysaccharides (EPS) with the help of glucosyltransferases that have nutritional and health applications. Glucansucrases are large extracellular enzymes capable of synthesizing various glucans from sucrose, such as dextran, mutan and alternan. These exopolysaccharides are potential therapeutic agents (Korakli and Vogel 2006) and are also used as viscosifying, stabilizing, emulsifying, sweetening, gelling or water-binding agents, in the food as well as in the non-food industries (Sutherland 1998; Welman and Maddox 2003). β-glucan consist of linear unbranched polysaccharides of linked β-(1 → 3) and β-(1→ 4)-D-glucopyranose units, and it is a natural water-soluble fiber that cannot be digested by human enzymes, but is degraded by bacteria in the colon into short-chain fatty acids (SCFAs). LAB strains belonging to the genera Pediococcus, Lactobacillus and Oenococcus isolated from cider and wine, produce a 2-substituted (1 → 3)-D-glucan (Dols-Lafargue et al. 2008). The plasmid gtf gene determinant for EPS production was cloned into Escherichia coli and determination of its DNA sequence revealed that it encodes a protein, named GTF glycosyltransferase. Cloning of the gtf gene and functional expression of its encoded glycosyltransferase in Streptococcus pneumoniae (Werning et al. 2006) and Lactococcus lactis revealed that this enzyme is indeed responsible for the synthesis of the β-D-glucan (Werning et al. 2008).

Glucan has several importances in food industry for its soluble nature which form viscous aqueous solutions and increases the viscosity of gut contents in the human alimentary tract. Now soluble fibers are very much concerned in human nutrition (Dols-Lafargue et al. 2008).

-

1.

Cholesterol lowering effect: it absorbed the cholesterol, helps in lowering the blood cholesterol level, thus reduce the risk of cardiovascular disease.

-

2.

Lowering effect of the glycaemic index: Glucans are very viscous in nature which makes the gastric content thicker and help in slowing down the absorption rate of glucose. ß-glucan thus spread glucose absorption over time (i.e. reduction of glycaemic index) and helps the body to fight against diabetes. In food industry, beside classical applications of polysaccharides as thickening agent, β-glucans have an increasing interest in the areas of edible film and as stabilizers in the manufacture of low-fat products such as salad dressings (Kontogiorgos et al. 2004), ice creams and yoghurts (Brennan et al. 2002) and cheese.

Four different genera of lactic acid bacteria, Streptococcus, Leuconostoc, Pediococcus and Lactobacillus are known to produce glucan. Glucan synthesis in lactic acid bacteria has been mainly studied from Leuconostoc spp. (Monsan et al. 2001; Majumder et al. 2009; Purama et al. 2009) with the help of glucansucrase enzyme. The culture condition of novel glucan and glucan producing glucansucrase from Leuconostoc spp. has been optimized by statistical approach method. Various types of glucan produced by Leuconostoc species and their source are given in Table 33.2. Glucansucrase (or also called dextransucrase) (E.C. 2.4.1.5) catalyzes the polymerization of the glucopyranosyl moieties of sucrose to form dextran (Purama and Goyal 2008). Dextran are used as viscosifying, texturizing or gelling agents in food formulations (Majumder and Goyal 2009), due to its non-ionic character and good stability under normal operating condition.

L. mesenteroides NRRL B-640 is shown to produce dextransucrase that gives highly linear and soluble dextran (Uzochukwu et al. 2002). A novel dextran produced by Leuconostoc dextranicum NRRL-B-18242 having a slushy, applesauce-like appearance with a particulate gel-like structure was described and the dextran in particulate or dried form is used in foods and other applications where texture is important (Pucci and Kunka 1990). Leuconostoc mesenteroides NRRLB-512 F is also used industrially to produce dextransucrase, which synthesize extracellular homopolysaccharide dextran (Purama and Goyal 2005).

The dextran is commercialized in a powder form and as a liquid with the following specifications

-

1.

For the powdered form (values in % of commercial product) carbohydrate 60 (with dextran 50, mannitol 0.5, fructose 0.3, leucrose 9.2), protein 6.5; lipid 0.5; lactic acid 10; ethanol traces; ash 13; moisture 10.

-

2.

For the liquid form (values in % of commercial product): carbohydrate 12 (with dextran 6.9; mannitol 1.1; fructose 1.85; leucrose 2.15); protein 2; lipid 0.1; lactic acid 2; ethanol 0.5; ash 3.4; moisture 80.

The solubility of dextran depends upon the branched linkage pattern. Presence of 95% linear linkages makes this dextran water-soluble, which makes it suitable for various applications (Leathers 2002).

The micro-organisms used for the production of dextran (Leuconostoc mesenteroides, Lactobacillus plantarum, Lactobacillus sanfrancisco) are currently used in food processing without any restriction. As a result of microbial activity, dextran occurs in small amounts in naturally fermented products such as sauerkraut and cucumber and in kefir where it probably plays a role in the thickening (Roller and Dea 1992). It has been reported that the glucan produced by Leuconostoc dextranicum NRRL B-1146, having α(1 → 4) and α(1 → 6) linkages, showed non-Newtonian pseudoplastic behaviour (Fig. 33.1) indicating its branched nature and also have unique rheological properties because of its potential of forming very viscous solution at low concentration and can be used as thickening or gelling agent in food.

The steady shear measurements for the semi-dilute glucan solution from Leuconostoc dextranicum NRRL B-1146 indicated that the viscosity (η) of the dilute polymer exponentially decreased with the increase in shear stress (τ) and exhibited a typical non-Newtonian psuedoplastic behavior (Majumder and Goyal 2009)

Further the Scanning Electron Micrograph (shown in Fig. 33.2) of the glucan produced by Leuconostoc dextranicum NRRL B-1146 showed small porous or web like structure, that facilitates its water holding capacity, thus can be used as a texturing agent in food industry (Majumder and Goyal 2009). The surface morphology of dried and powdered dextran from Leuconostoc dextranicum NRRL B-640 was also studied using Scanning Electron Microscopy and it revealed the cubical porous structure of dextran, as shown in Fig. 33.3. It was recently reported that the dextran from Pediococcus pentosaceus holds potential usage as gelling agent in food formulations and as drug delivery carriers (Patel et al. 2010).

Scanning Electron Micrograph of glucan showing surface morphology of Leuconostoc dextranicum NRRL B-1146 (Majumder and Goyal 2009)

Scanning Electron Micrograph of glucan showing surface morphology from Leuconostoc dextranicum NRRL B-640 (Purama et al. 2009)

The cytotoxicity test of dextran from Pediococcus pentosaceus was explored using human cervical cancer (HeLa) cell line and it is reported that there is no effect of dextran from P. pentosaceus on the viability of HeLa cells when observed for 72 h even at high concentration of 1,000 μg/ml (Fig. 33.4) (Patel et al. 2010). This revealed that the dextran is non-toxic and biocompatible, rendering it safe for drug delivery, tissue engineering and various other biomedical applications.

The indirect contact based in vitro cytotoxicity assay showing the cell viability was unaltered after treatment with various concentrations of dextran (10–1,000 μg/ml) from Pediococcus pentosaceus over a period of 24–72 h incubation (Patel et al. 2010)

5 Oligosaccharides from LAB in Food Industry

Certain oligosaccharides (e.g. fructooligosaccharides, isomaltooligosaccharides and lactulose) and polysaccharides (e.g. fructans) are used as prebiotic foods (Monsan and Paul 1995). These oligosaccharides contains high proportion of α(1 →6) glycosidic linkages that are partly or totally resistant to attack by human’s and animal’s digestive enzymes. Prebiotic oligosaccharides are noncarcinogenic, nondigestible and low calorific compounds stimulating the growth and development of gastrointestinal microflora described as probiotic bacteria such as Bifidobacteria and Lactobacilli (Kubik et al. 2004). They are not absorbed in small intestine and in the large intestine they are metabolized by the colonic bacterial flora and fermented into short chain fatty acids. The effects of prebiotics are principally due to stimulation of the growth of bifidobacteria (bifidogenic effect). The stimulation of this growth allows a reduction in the pH of the colon, an increase in the production of short chain fatty acids (SCFAs), in particular butyrate and propionate, a prevention of the installation of pathogenic microorganisms (barrier effect), an increase in the metabolization of potentially carcinogenic aminated compounds and the production of vitamin B.

Gluco-oligosaccharides have been produced by enzymatic synthesis using glucosyl donor and an accepter molecule (Iliev et al. 2008). Gluco-oligosaccharides production from glucan by microwave assisted hydrolysis from Leuconostoc mesenteroides NRRL B-742 has also been reported. The peak at ∼527 m/z value using MALDI-TOF-MS showed the presence of three glucose units of (m/z ∼180) and degree of polymerization of 3 (DP-3) for the oligosaccharide that was obtained from the glucan sample hydrolysed for 2 min.

The oligosaccharides are used widely in various food products such as soft drinks, cookies, cereals, candies and dairy products (Barreteau et al. 2006). For instance, galactooligosaccharides have shown very promising results increasing populations of both Lactobacilli and Bifidobacteria and increasing beneficial short chain fatty acids (Smiricky-Tjardes et al. 2003). A mixture of galacto-oligosaccharides and fructo-oligosaccharides added to standard infant formulas has also been shown to increase both Lactobacilli and Bifidobacteria species in human infants (Moro et al. 2002). Other applications for oligosaccharides such as an anticariogenic agent or a low-sweetness humectant have been explored (Chung and Day 2002).

6 Bacteriocin from LAB in Food Industry

A large number of ribosomally synthesized bacteriocins or bacteriocin-like substances are produced by lactic acid bacteria (LAB) have been identified and characterized in recent years due to their antimicrobial activity against foodborne pathogenic, as well as spoilage bacteria. The antibacterial spectrum frequently includes spoilage organisms and food-borne pathogens such as Listeria monocytogenes and Staphylococcus aureus. For these it has raised considerable interest for their application in food preservation that help to reduce the addition of chemical preservatives and/or the intensity of heat and other physical treatments, thus satisfying the demands of consumers for foods that are fresh tasting, ready to eat and lightly preserved. Bacteriocin can be added to foods in the form of concentrated preparations as food preservatives, shelf-life extenders, additives and ingredients (ex-situ) or they can be produced in situ by bacteriogenic starters, adjunct or protective cultures (Galvez et al. 2007). In situ bacteriocin production offers several advantages compared to ex situ production regarding both legal aspects and costs. Bacteriocins are usually inactivated by low pH, heat and from digestive enzyme such as proteases. Nisin, the product of some strains of Lactococcus lactis subsp. lactis, which was accorded GRAS (generally recognized as safe) status and approved for food use by the U.S. Food and Drug Administration, has already found a variety of applications in food preservation (Twomey et al. 2002). Till date only nisin and pediocins have been used as biopreservatives in food systems (Ray 1992; Rodríguez et al. 2002). Up to now, bacteriocins have been isolated from the commercial probiotic strains Lactobacillus casei Shirota and Lactobacillus johnsonii La1 (Avonts et al. 2004). Immobilized bacteriocins can also find application for developement of bioactive food packaging. The effectiveness of bacteriocins requires careful testing in the food systems for which they are intended to be applied against the selected target bacteria.

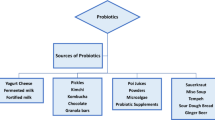

7 LAB as Probiotic

Lactic acid bacteria mainly Lactobacilli, Streptococci, Enterococci and Lactococci can be used as probiotic (Schrezenmeir and de Vrese 2001). They possess the property by which they can be considered as probiotic such as colonization or adhesion properties, good in vitro development, ability of cells to produce metabolites and enzymes, stability in bile and gastric juices, production of antimicrobial substances, antagonistic action against noted pathogenic bacteria and/or viruses and no adverse interactions with host especially, in terms of pathogenicity. LAB also potentially used as starter cultures for the manufacture of dairy-based probiotic foods (Saarela et al. 2002). Probiotic acidophilus is a naturally occurring antibiotic that helps enhance digestion produces vitamin B and brings down the risk of colon cancer. In addition, antimicrobial production by probiotic LAB might play a role during in vivo interactions occurring in the human gastrointestinal tract, hence contributing to gut health. Probiotics may regulate local and systemic immunity, thereby reducing allergic disease severity and susceptibilities of infants and children to allergies and atopic diseases (Hsieh and Versalovic 2008). There are several example of probiotic food that is commercially available shown in Table 33.3.

8 Polyols Produced by LAB

Several LAB produced polyols which are most commonly used as sugar replacement agents in food industry. Polyols are known as sugar alcohols and although they have the structure of alcohol, they mimic the sweetness of sugar when added to food. Sugar alcohols have a lower calorie count than true sugar because they are not entirely absorbed by the body and are often used in sugar-free or diet foods and drinks. One product that almost invariably contains sugar alcohols is chewing gum. They are added to gum because they are not broken down by either saliva or chewing action and therefore do not cause tooth decay. Some of the most common sugar alcohols are maltitol, sorbitol which are produced by LAB. Leuconostoc fructosum NRRL B-2041 produced manitol with maximum volumetric productivity of 2.36 g/l h when grown in supplemented carob syrup medium (Carvalheiro et al. 2010). All of these sugar alcohols produced by LAB have different ratings of sweetness. Sorbital is 60% as sweet as true glucose, while maltitol rates at 75%. Sorbitol is synthesised by an engineered Lactobacillus casei and Lactobacillus plantarum (Nissen et al. 2005; Ladero et al. 2007). Both homo- and heterofermentative lactic acid bacteria produce mannitol. Generally homofermentative lactic acid bacteria produce little amount of mannitol with the help of mannitol 1-phosphate dehydrogenase enzyme. Such as, in the presence of large amounts of glucose or sucrose, Streptococcus mutans, Lactobacillus leichmanii (Chalfan et al. 1975), Lactobacillus plantarum and Lactococus lactis (Neves et al. 2000) produce mannitol. Hetero fermentive lactic acid bacteria produce substantial amount of mannitol with the help of mannitol dehydrogenase enzyme. In the presence of fructose or sucrose, Leuconostoc (pseudo)mesenteroides produces high levels of mannitol (Grobben et al. 2001). Two other heterofermentative lactic acid bacteria, Lactobacillus sp. and Leuconostoc sp. also produced mannitol from fructose and sucrose (Saha and Nakamura 2003). The amount of mannitol produced under optimal culture conditions by Lactobacillus and Leuconostoc strains were 73 and 26 g/l from 100 g/l fructose with yields of 86% and 65%, respectively (Yun and Kim 1998).

9 Future Perspectives

Genome sequencing and functional genomic studies of a variety of LAB are rapidly providing insight into their diversity and evolution and revealing the molecular basis for important traits like flavour formation, sugar metabolism, stress response adaptation and interaction. LAB have been investigated using biotechnological techniques, including genetically modified organisms (GMOs) that contribute to the reliability of food fermentation and better process control. New properties can be introduced that enhance quality, taste, structure and wholesomeness of food and consequently bring benefit to the consumer. Also the use of LAB as probiotics in the treatment of many forms of diarrheal disease appears especially promising. The identification of glucan production gene is important for future challenges for the construction of strains of LAB that produce Glucan with novel properties that could be applied as food additives. The yield of glucans produced by the LAB depends on the composition of the medium, the LAB strain and growth conditions like temperature, pH, oxygen tension and incubation period. The need of the day is to improve the productivity of glucans from LAB, reduce the cost of production for commercial viability and to produce custom made glucans with the desired functionality. The modulation of biochemical properties of glucans require a thorough understanding of its biosynthetic pathway and the relation between the structure of glucans and the functional effect provided by them after incorporation into the food matrix. Several investigators are working on β glucans that can promote antitumor and antimicrobial activity by activating macrophages, dendritic cells and other leukocytes.

10 Conclusions

Several metabolites product produced by LAB including organic acids, fatty acids, hydrogen peroxide, carbon dioxide and bioactive peptides have antimicrobial effects. As biopreservatives are more preferred than chemical preservatives, there is an increased interest in prevention of food from spoilage through these metabolites produced by LAB because of their safe association with human fermented foods. The exopolysaccharides that are produced by LAB contribute to the specific rheology and texture of fermented milk products and also have applications in nondairy foods. When added to food products, polysaccharides function as thickeners, stabilizers, emulsifiers, gelling agents and water binding agents. Several oligosaccharides produced by LAB can act as prebiotic, increase the production of short chain fatty acid. Probiotic LAB strains might play a considerable role during in vivo interactions occurring in the human gastrointestinal tract, for instance towards H. pylori, E. coli and Salmolella. Bacteriocin-producing starter or co-cultures have been successfully produced on pilot-scale experiments in making cheese, fermented sausage, sourdough, etc., yielding food quality with food safety advantages.

References

L. Avonts, E. Van Uytven, L. De Vuyst, Cell growth and bacteriocin production of probiotic Lactobacillus strains in different media. Int. Dairy J. 14, 947–955 (2004)

H. Barreteau, C. Delattre, P. Michaud, Production of oligosaccharides as promising new food additive generation. Food Technol. Biotechnol. 44, 323–333 (2006)

C.S. Brennan, C.M. Tudorica, V. Kuri, Soluble and insoluble dietary fibres (non-starch polysaccharides) and their effects on food structure and nutrition. Food Ind. J. 5, 261–272 (2002)

F. Carvalheiro, P.C. Moniz, L.C. Duarte, M.P. Esteves, F.M. Girio, Mannitol production by lactic acid bacteria grown in supplemented carob syrup. J. Ind. Microbiol. Biotechnol. (2010). doi:10.1007/s10295-010-0823-5

Y. Chalfan, R. Levy, R.I. Mateles, Detection of mannitol formation by bacteria. Appl. Microbiol. 30, 476 (1975)

C.H. Chung, D.F. Day, Gluco-oligosaccharides from Leuconostoc mesenteroides B-742 (ATCC 13146): A potential prebiotic. J. Ind. Microbiol. Biotechnol. 29, 196–199 (2002)

G. Cote, J.F. Robyt, Isolation and partial characterization of an extracellular glucansucrase from Leuconostoc mesenteroides NRRL B-1355 that synthesizes an alterning (1–6), (1–3)-α-D Glucan. Carbohydr. Res. 101, 57–74 (1982)

K. Demuth, H.J. Jordening, K. Buchholz, Oligosaccharide synthesis by dextransucrase: New unconventional acceptors. Carbohydr. Res. 337, 1811–1820 (2002)

M. Dols-Lafargue, H.Y. Lee, C. Le Marrec, A. Heyraud, G. Chambat, A. Lonvaud-Funel, Characterization of gtf, a glucosyltransferase gene in the genomes of Pediococcus parvulus and Oenococcus oeni. Appl. Environ. Microbiol. 74, 4079–4090 (2008)

D. Ercolini, G. Moschetti, G. Blaiotta, S. Coppola, Behavior of variable V3 region from 16S rDNA of lactic acid bacteria in denaturing gradient gel electrophoresis. Curr. Microbiol. 42, 199–202 (2001)

A. Galvez, H. Abriouel, R.L. López, N.B. Omar, Bacteriocin-based strategies for food biopreservation. Int. J. Food Microbiol. 120, 51–70 (2007)

A.K. Goulas, D.A. Fisher, G.K. Grimble, A.S. Grandison, R.A. Rastall, Synthesis of isomaltoligosaccharides and oligodextrans by the combined use of dextransucrase and dextranase. Enz. Microb. Technol. 35, 327–338 (2004)

G.J. Grobben, S.W.P.G. Peters, H.W. Wisselink, R.A. Weusthuis, M.H.N. Hoefnagel, J. Hugenholtz, G. Eggink, Spontaneous formation of a mannitol-producing variant of Leuconostoc pseudomesenteroides grown in the presence of fructose. Appl. Environ. Microbiol. 67, 2867–2870 (2001)

W.H. Holzapfel, P. Haberer, R. Geisen, J. Bjorkroth, U. Schillinger, Taxonomy and important features of probiotic microorganisms in food nutrition. Am. J. Clin. Nutr. 73, 365S–373S (2001)

M.H. Hsieh, J. Versalovic, The human microbiome and probiotics: Implications for pediatrics. Curr. Probl. Pediatr. Adolesc. Health Care 38, 309–327 (2008)

I. Iliev, T. Vassileva, C. Ignatova, I. Ivanova, T. Haertlé, P. Monsan, J.M. Chobert, Gluco-oligosaccharides synthesized by glucosyltransferases from constitutive mutants of Leuconostoc mesenteroides strain Lm28. J. Appl. Microbiol. 104, 243–250 (2008)

V. Kontogiorgos, C.G. Biliaderis, V. Kiosseoglou, G. Doxastakis, Stability and rheology of egg-yolk-stabilized concentrated emulsions containing cereal b-glucans of varying molecular size. Food Hydrocolloids 18, 987–998 (2004)

M. Korakli, R.F. Vogel, Structure/function relationship of homopolysaccharide producing glycansucrases and therapeutic potential of their synthesized glycans. Appl. Microbiol. Biotechnol. 71, 790–803 (2006)

C. Kubik, B. Sikora, S. Bielecki, Immobilization of dextransucrase and its use with soluble dextranase for glucooligosaccharides synthesis. Enz. Microb. Technol. 34, 555–560 (2004)

O.P. Kuipers, G. Buist, J. Kok, Current strategies for improving food bacteria. Res. Microbiol. 151, 815–822 (2000)

V. Ladero, A. Ramos, A. Wiersma, P. Goffin, A. Schanck, M. Kleerebezem, J. Hugenholtz, E.J. Smid, P. Hols, High-level production of the low-calorie sugar sorbitol by Lactobacillus plantarum through metabolic engineering. Appl. Environ. Microbiol. 73, 1864–1872 (2007)

T.D. Leathers, Biopolymers, in Polysaccharides I: Polysaccharides from Prokaryotes, ed. by E.J. Vandamme, S. DeBaets, A. Steinbüchel (Wiley-VCH, Weinheim, 2002), pp. 229–321

A. Majumder, A. Goyal, Rheological and gelling properties of a novel glucan from Leuconostoc dextranicum NRRL B-1146. Food Res. Int. 42, 525–528 (2009)

A. Majumder, A. Singh, A. Goyal, Application of response surface methodology for glucan production from Leuconostoc dextranicum and its structural characterization. Carbohydr. Polym. 75, 150–156 (2009)

V. Monchois, R.M. Willemot, P. Monsan, Glucansucrases: Mechanism of action and structure -function relationships. FEMS Microb. Rev. 23, 131–151 (1999)

P. Monsan, F. Paul, Enzymatic synthesis of oligosaccharides. FEMS Microbiol. Rev. 16, 187–192 (1995)

P.F. Monsan, S. Bozonnet, C. Albenne, G. Joulca, R.M. Willemot, M. Remaud-Simeon, Homopolysaccharides from lactic acid bacteria. Int. Dairy J. 11, 675–685 (2001)

G. Mooser, Glycosidases and glycosyltransferases. Enzymes 20, 187–221 (1992)

G. Moro, I. Minoli, M. Mosca, S. Fanaro, J. Jelinek, B. Stahl, G. Boehm, Dosage-related bifidogenic effects of galacto- and fructooligosaccharides in formula-fed term infants. J. Pediatr. Gastroenterol. Nutr. 34, 291–295 (2002)

M. Naessens, A. Cerdobbel, W. Soetaert, E.J. Vandamme, Leuconostoc dextransucrase and dextran: production, properties and applications. J. Chem. Technol. Biotechnol. 80, 845–860 (2005)

A.R. Neves, A. Ramos, C. Shearman, M.J. Gasson, J.S. Almeida, H. Santos, Metabolic characterization of Lactococcus lactis deficient in lactate dehydrogenase using in vivo 13 C-NMR. Eur. J. Biochem. 267, 3859–3868 (2000)

K.K. Nikkila, H. Mervi, L. Matti, P. Airi, Metabollic engineering of Lactobacillus helvicticus CNRZ32 for production of pure, L(+) Lactic acid. Appl. Environ. Microbiol. 66, 3835–3841 (2000)

L. Nissen, G. Pérez-Martínez, M.J. Yebra, Sorbitol synthesis by an engineered Lactobacillus casei strain expressing a sorbitol-6-phosphate dehydrogenase gene within the lactose operon. FEMS Microbiol. Lett. 249, 177–183 (2005)

S. Patel, N. Kasoju, U. Bora, A. Goyal, Structural analysis and biomedical applications of dextran produced by a new isolate Pediococcus pentosaceus screened from biodiversity hot spot Assam. Biores. Technol. 101, 6852–6855 (2010)

M.J. Pucci, B.S. Kunka, Novel dextran produced by Leuconostoc dextranicum NRRL B-18242, United States Patent 4,933,191, 1990

R.K. Purama, A. Goyal, Dextransucrase production by Leuconostoc mesenteroides. Indian J. Microbiol. 2, 89–101 (2005)

R.K. Purama, A. Goyal, Identification, effective purification and functional characterization of dextransucrase from Leuconostoc mesenteroides NRRL B-640. Biores. Technol. 99, 3635–3642 (2008)

R.K. Purama, P. Goswami, A.T. Khan, A. Goyal, Structural analysis and properties of dextran produced by Leuconostoc mesenteroides NRRL B-640. Carbohydr. Polym. 76, 30–35 (2009)

B. Ray, Bacteriocins of starter culture bacteria as food biopreservative, in Food Biopreservatives of Microbial Origin, ed. by B. Ray, M. Daeschel, vol. 8 (CRC Press, Florida, 1992), pp. 177–205

J.M. Rodríguez, M.I. Martínez, J. Kok, Pediocin PA-1, a wide-spectrum bacteriocin from lactic acid bacteria. Crit. Rev. Food Sci. Nutr. 42, 91–121 (2002)

S. Roller, I.C.M. Dea, Biotechnology in the production and modification of biopolymers for foods. Crit. Rev. Biotechnol. 12(3), 261 (1992)

M. Saarela, Lahteenaki, R. Crittenden, S. Salminen, T. Mattila-Sandholm, Gut bacteria and health foods – The European perspective. Int. J. Food Microbol. 78, 99–117 (2002)

B.C. Saha, L.K. Nakamura, Production of mannitol and lactic acid by fermentation with Lactobacillus intermedius NRRL B-3693. Biotechnol. Bioeng. 82, 864–871 (2003)

J. Schrezenmeir, M. de Vrese, Probiotics, prebiotics, and synbiotics – Approaching a definition. Am. J. Clin. Nutr. 73, 361S–364S (2001)

F.R. Seymour, R.D. Knapp, Structural analysis of dextrans from strains of Leuconostoc and related genera, that contain 3-O-a glucosylated-D-glucopyranosyl residues at the branched points or in consecutive linear position. Carbohydr. Res. 81, 105–129 (1980)

E.L. Sing, Culture of Sour Dough Bacteria, United States Patent 4,021,581 (1977)

M.R. Smiricky-Tjardes, C.M. Grieshop, E.A. Flickinger, L.L. Bauer, G.C. Fahey Jr., Dietary galactooligosaccharides affect ileal and total-tract nutrient digestibility, ileal and fecal bacterial concentrations, and ileal fermentative characteristics of growing pigs. J. Anim. Sci. 81, 2535–2545 (2003)

A. Sodegard, Preparation of poly (L-lactide-graft-acrylic acid) by pre-irradiation grafting. Polymer Preparation 39, 215–216 (1998)

I.W. Sutherland, Novel and established applications of bacterial polysaccharides. Trends Biotechnol. 16, 41–46 (1998)

D. Twomey, R.P. Ross, M. Ryan, B. Meaney, C. Hill, Lantibiotics produced by lactic acid bacteria: Structure, function and applications. Antonie Van Leeuwenhoek 82, 165–185 (2002)

S. Uzochukwu, E. Balogh, R.T. Loefler, P.O. Ngoddy, Structural analysis by13C nuclear magnetic resonance spectroscopy of glucan extracted from natural palm wine. Food Chem. 76, 287–291 (2002)

A.D. Welman, I.S. Maddox, Exopolysaccharides from lactic acid bacteria: Perspectives and challenges. Trends Biotechnol. 21, 269–274 (2003)

M.L. Werning, I. Ibarburu, M.T. Dueñas, A. Irastorza, J. Navas, P. López, Pediococcus parvulus gtf gene encoding the GTF glycosyltransferase and its application for specific PCR detection of D-glucan-producing bacteria in foods and beverages. J. Food Prot. 69, 161–169 (2006)

M.L. Werning, M.A. Corrales, A. Prieto, P. Fernandez de Palencia, J. Navas, P. López, Heterologous expression of a 2-substituted-(1,3)-D-glucan in Lactococcus lactis. Appl. Environ. Microbiol. 74, 5259–5262 (2008)

J.W. Yun, D.H. Kim, A comparative study of mannitol production by two lactic acid bacteria. J. Ferm. Bioeng. 85, 203–208 (1998)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media B.V.

About this chapter

Cite this chapter

Das, D., Goyal, A. (2012). Lactic Acid Bacteria in Food Industry. In: Satyanarayana, T., Johri, B. (eds) Microorganisms in Sustainable Agriculture and Biotechnology. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-2214-9_33

Download citation

DOI: https://doi.org/10.1007/978-94-007-2214-9_33

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-2213-2

Online ISBN: 978-94-007-2214-9

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)