Abstract

In microsystem technology research a material with such a diversity and significance like silicon in microelectronics has not been established for the last 20 years. Recently in microfluidics and in special imaging systems hydrogels get ready to take this place. Here we present a review on hydrogel based microsystems with actuator or sensor-actuator functionalities. Automatic microfluidic systems based on the sensor-actuator properties of hydrogels offer functionalities which have not been yet realised with other systems or actuators. The functional principles of the basic elements are described on the example of hydrodynamic transistors, pumps and tunable microlenses. In the field of microelectromechanical microfluidic systems hydrogels provide a unique multi-functionality. We describe the basic principles applied on an electronic control for hydrogel actuators and also on the basic components for microfluidics: microvalve, micropump and hydrodynamic transistors. Furthermore, the first hydrogel-based highly integrated microsystem, a high-resolution tactile display containing 4,225 individually controllable actuator pixels, is reviewed. In the last two Sections we discuss essential physical phenomena und design rules, which have to be considered to avoid malfunctions of the designed devices.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Originally there was the expectation that stimuli-responsive hydrogels would provide a new type of actuator, the so called “artificial muscle” (Kuhn et al. 1948; Kuhn and Hargitay 1951). Hydrogels show properties similar to the natural muscle (Table 1). Therefore, they were intended as propulsion for robotic applications. Research groups developed spectacular applications such as “gel fish” (Osada and Gong 1998a; Kurauchi et al. 1991), “artificial elbow” (Suzuki 1991), “gel hand” (Kurauchi et al. 1991), and rotatory “gel motor” (Mitsumata et al. 1998; Mitsumata et al. 2000). However, due to the time-consuming swelling process of centimetre-sized gel components (Table 1, Sect. 3.2) and to the limited electronic controllability the present generation of hydrogels is not yet ready for the robotic “artificial muscle” or other macroscopic actuator applications. Nevertheless, to realise low dynamic applications such as medical pumps (Richter et al. 2004a) or automatic decubitus mattresses (Richter et al. 2005), hydrogels offer interesting properties.

Here, we report about the high potential of stimuli-responsive hydrogels as active materials for a platform technology of monolithic integrated microsystems. Similar to the computer science and to the electronics which are commonly using microprocessors consisting of integrated circuits in future medicine, biotechnology and chemistry could benefit from highly integrated fluidic circuits, such as the so-called microfluidic processors or lab-on-a-chip devices, which can significantly reduce the operating time, the reagent volume and the required sample volume (Janasek et al. 2006; Dittrich and Manz 2006). In few commercial applications the advantages of large-scale integrated devices containing hundreds or thousands of valves are impressively demonstrated by micro-pneumatic multilayer soft-lithographic systems (Unger et al. 2000; Thorsen et al. 2002; http://www.fluidigm.com/products/biomark-chips.html, date: 25.06. 2008) based on the elastomer polydimethylsiloxane (PDMS). Due to the complex pneumatic control and to the limitation to only one basic functionality, which is a pneumatic displacement valve, the micro-pneumatics is not generally applicable.

Unlike the pure PDMS, stimuli-responsive hydrogels are active materials capable to change their properties, such as the volume. Hydrogels show excellent micro fabrication capability that allows a monolithic chip design as well as the largest known actuator effect of solid state actuators and within the sub-millimetre size a response time in the range from milliseconds to few seconds. As shown on the example of poly(N-isopropylacrylamide) (PNIPAAm) gels provide the realisation of all active components in microfluidics including valves (Richter et al. 2003; Yu et al. 2003a; Wang J et al. 2005), adjustable hydrodynamic transistors (Richter et al. 2007a), pumps (Richter et al. 2009a) and liquid sensors with only one required type of hydrogel material [19, Chap. 5]. The only known material with a comparable multi-functionality is silicon in the field of microelectronics. An integration technology providing the fabrication and the individual addressing of thousands of active hydrogel components on a single chip is demonstrated on the example of an artificial skin (Richter and Paschew 2009). Here, we report about the fundamentals of two general applications of hydrogel-based microfluidic systems, automatic (Sect. 2) and microelectromechanical systems (Sect. 3) and as a third application, high-resolution tactile display devices (Sect. 4).

2 Automatic Microfluidic Systems

The control of the concentration of certain chemical substances in mixtures is a key problem of fluidic processes. Current systems, which automatically regulate a chemical or physical condition of a liquid, are expensive and consist of sensors, data processing and actuator units. However, stimuli-responsive polymers combine the properties of a chemical sensor and of an actuator by a reversible and reproducible change of their volume in response to small alterations of certain chemical (Tanaka 1978; Li et al. 2002; Arndt et al. 1999; Kataoka et al. 1998; Miyata et al. 1999) or energy-based (Arndt et al. 2001; Suzuki and Tanaka 1990; Tanaka et al. 1982; Osada and Gong 1998b) conditions of the liquids. They provide the probably simplest automatic closed-loop control systems. Besides the chemical control systems devices are of particular relevance, which are able to regulate biochemical substances, because systems substituting body functions like that of the pancreas, could be realised. In the future the sensor-actuator functionality of hydrogel could be the base of integrated automatic microfluidic systems performing event-sensitive microfluidic processing.

2.1 Hydrodynamic Transistors

The simplest functionality to regulate a liquid flow is provided by a throttle valve. To the best of my knowledge, the idea to use hydrogels in chemomechanical valves was presented in 1981 by Y. Osada for the first time (Osada and Takeuchi 1981). To realise this device the hydrogel-based sensor-actuatorFootnote 1 controls the size of the channel cross-section by swelling or shrinking. Due to its automatic flow control depending on the ion and solvent concentrations this apparatus is, ultimately, a chemostat valve (greek: chem(o) = chemistry; -stat = regulating) or due to its equivalency to the electronic model a hydrodynamic transistor. Table 2 gives an overview of such devices described in the literature.

2.1.1 Directly Acting Hydrogel Component

The hydrodynamic transistors shown in Table 2 can be classified in two types distinguished by the function of the gel actuator. The actuator of type B acts as servo drive actuating the valve seat. The actuator of type B is directly placed within the flow channel. Therefore, the stimulant, which is typically a component of the process medium, directly controls the sensor-actuator element. The hydrogel swells or shrinks by absorption or release of the process medium and regulates the channel cross-section. Figure 1 shows two examples of such hydrodynamic transistors.

2.1.2 Hydrogel as Servo Drive

By swelling or shrinking the actuator of the “type B” valve moves a flexible membrane (Fig. 2a) or a boss (Fig. 2b) closing or opening the valve seat. At the valve seat the hydrogel has no direct contact with the medium. It is possible to use one process circuit (channel 1) containing the hydrogel element regulating a second process circuit (channel 2, Fig. 2a).

2.1.3 Normally Closed and Normally Open Valves

It is essential that the swelling behaviour of the hydrogel can be alternatively used for both normally closed and open valves, respectively (Richter et al. 2007b). This valve function can be defined by the way the hydrogel moves the valve seat. To realise a normally closed (NC) valve the hydrogel is directly placed inside the flow channel. (Fig. 3a). After the hydrogel swelling the valve chamber is completely filled and thereby the valve is closed. Shrinking of the gel opens the valve.

As shown in Fig. 3b a normally open (NO) valve can be designed to keep the conic valve seat open by the swollen hydrogel. The valve seat is closed after shrinking of the gel.

Zhang et al. (Zhang et al. 2008) describe an antagonism for bimorph hydrogel-based flap valves. Depending on the layer arrangement by hydrogel swelling the flap valve closes if the gel layer is on the top of the supporting strip or opens if it is below.

2.1.4 Mechanical Adjustability of the Regulation Point

The fixed regulation point, predefined by the type of the used hydrogel and by the valve design, is an essential problem of the hydrodynamic transistors. It is practically impossible to adapt the hydrogel element to each application. However, the adaption for applications is much easier if the device is designed adjustable (Richter et al. 2007b).

The actuation point of the NO valve (Fig. 4b) is designed to be adjustable by the possibility to vary the distance x. It is possible to assign a regulation point to each swelling state of the hydrogel by a variable displacement of the complete servo drive unit.

Mechanically adjustable hydrodynamic transistors. (a) Normally closed and (b) normally open hydrodynamic transistors according to (Richter et al. 2007b)

The regulation point of the NC valve (Fig. 4a) can be adjusted by a varying the size of the valve chamber, e.g. by using a thread. Thereby the regulation point condition is adjustable, at which the valve chamber volume equals the hydrogel volume (at a defined pressure resistance of the valve). In Fig. 5 a thermostat function of a NC valve based on the thermo-sensitive hydrogel PNIPAAm is presented. PNIPAAm shows lower critical solution temperature behaviour (LCST) (Fig. 5a). The hydrogel shrinks and opens the valve at higher temperatures or swells and closes the valve at lower temperatures. Adjusting the chamber size to a volume equal to the swelling degree of the hydrogel material at a defined temperature, the precise valve-opening or -closing temperature point can be predefined.

Regulation point adjustment of a normally closed hydrodynamic transistor. (a) Swelling characteristics of PNIPAAm in aqueous solution depending on the temperature. (b) Temperature control point of the hydrodynamic transistor as function of the valve chamber length d (according to (Richter et al. 2007b))

The standard deviation or control accuracy of the thermostat is 0.75 K. The range of regulation point adjustment is restricted to the volume phase transition range of the hydrogel (Fig. 5b). Above and below that range the volume change is too small.

In the meantime hydrodynamic transistors are ready for practical use. Their regulation precision (temperature ± 0.75 K, contents of alcohol ± 1 wt.-% (Richter et al. 2007b)) already has the required accuracy for many applications. The valve performance comprises an adjustable pressure resistance up to 18 MPa (Peters et al. 1997). The reported response time of the valves varies within the range of seconds or minutes which should be sufficient for most applications, because changes of liquid concentrations are typically processes with low dynamics. The possibility to adjust the hydrodynamic transistor control point is implemented which was a missing key feature required for the diversity of practical applications.

Devices that are able to regulate biochemical substances are of particular relevance for the implementation of systems substituting body functions, like that of the pancreas (Baldi et al. 2003).

2.2 Fluidic Propulsion

The sensor-actuator properties of hydrogels can also be used to generate a liquid flow or a pressure. Adapting the fundamental principle of the “osmotic pump” of Theeuwes and Yum (Theeuwes and Yum 1976) so far two types of pumps are described.

2.2.1 Chemostat Pumps

These pumps use the volume phase transition behaviour of gels to move small amounts of liquid. The characteristic feature of stimuli-sensitive hydrogels to change their volume absorbing or releasing aqueous solution has been used to realise displacement free valves. However, this gel property is inappropriate for the direct hydrogel actuator use in pumps. Therefore, the hydrogel swelling moves an elastic membrane into a fluid reservoir (pump chamber) and displaces the liquid (Fig. 6). Displacement pumps controlled by energetic quantities such as temperature require a special swelling agent reservoir (e.g. the water reservoir in Fig. 6a) (Suzuki et al. 2002). The hydrogel elements of pumps, which can be stimulated by special substances, need a direct contact to the process medium (Fig. 6b).

The pumps can be additionally equipped with a separate chemostat valve (Eddington and Beebe 2004). Compared to other pumps hydrogel-based chemostat pumps provide a medium performance (Nguyen et al. 2002; Laser and Santiago 2004). Beebe et al. report a flow rate of 2 μl min-1 generated by the pump and a maximal back pressure of 35 kPa (Eddington and Beebe 2004). For a fast bolus release the valve has to be opened after the swelling of the pump actuator. After valve opening the generated pressure releases the content of the pump chamber within a few seconds at an average flow rate of 540 μl min-1. However, these investigations are of limited informational value, because these were performed by a practically not relevant switching condition from strong acidic liquids (pH 2) towards strong basic pH 12. Investigations of the chemostat pump performance at application-relevant pH variation in the order of 1 or 2 pH units or a few mass percent should be subjects of future investigations.

2.2.2 Autonomous Pumps

These pumps are intended as disposable, portable and inexpensive devices performing the pumping completely autonomously. Here, the hydrogel component does not act as a control element but as fluidic propulsion which does not need an external power supply. Autonomous hydrogel-based pumps can perform complete task sequences. The insulin pump described in (Richter et al. 2004a) (Fig. 7a) was developed for the treatment of the Dawn phenomenon of diabetes mellitus patients. Using the special possibilities to influence the swelling kinetics and the actuator dynamics, respectively, such as the variation of the swelling distance, defined counter-forces and limitations of the swelling agent supply (see Section 6), the pump realises a four task sequence.

The pump is activated by switching on f the swelling agent supply (Fig. 7a). The trigger can open the supply unit or the swelling agent reservoir, respectively. A spring generates a permanent hydrostatic pressure within the swelling agent reservoir and provides a position independent swelling agent supply. The hydrogel swells and stretches a foil. At first, the actuator has to displace a friction piston. The length of the displacement is adjustable by the adjusting screw providing the adjustability of the time between the pump initialisation and the start of the drug release. After a time-delay the gel actuator presses the drug ampoule to the opener to open the sterile ampoule. In the last step the hydrogel actuator displaces the ampoule content and the pump releases the drug.

The pump shown in Fig. 7b can be initialised by a droplet of water (Good et al. 2007).

Disposable autonomous pumps do not require hydrogels with volume phase transition behaviour. Here, the strong swelling superabsorbers can be used, which are mostly more powerful than stimuli-responsive gels.

The performance of the autonomous pumps can be defined by the size of the actuator and the material. The actuator used in (Richter et al. 2004a) provides a maximal pressure of 200 kPa and is designed to release 500 μl insulin within 2 h.

2.3 Tunable Micro-Lenses

Due to the rapid development of optical imaging systems, optical communications, optical analytics and optical monitoring, the necessity to realise very compact and miniaturised micro-optical systems drastically increases. The adaptive lens is a key element of the micro-optics.

The outstanding transparency of hydrogels inspired the group of Lyon to develop tunable microlenses based on stimuli-responsive hydrogels (Kim et al. 2004, 2005a, b; Ehrick et al. 2007). By swelling or shrinking a planoconvex hydrogel structure bonded on the substrate deforms and changes its curvature (Fig. 8a). This leads to a tunability of the focal length of the lens.

The groups of Jiang and Beebe developed a liquid micro-lens consisting of a ring made of stimuli-responsive hydrogel which is filled with water (Fig. 8b). When the hydrogel is stimulated to change its volume the expansion or contraction of the ring regulates the shape of the oil-water interface and tunes the focal length of the micro-lens (Dong et al. 2006, 2007). The focal length is adjustable by thermal stimulation in a range between 3.3 mm and + ∞ at a response time of about 18 s.

3 Microelectromechanical Microfluidic Systems

For the last 20 years scientists have been vainly searching for a material which is able to fulfil a task in the microsystem technology comparable to the one of silicon in microelectronics. At the beginning of the 1990s stimuli-responsive hydrogels were discussed as such candidates, because these materials can be stimulated to perform the volume phase transition by light (Suzuki and Tanaka 1990) and electric field quantities (Tanaka et al. 1982). However, these effects are not really suitable for practical use in actuator devices. Therefore, in topical reviews on microfluidics or microsystem technology hydrogels are not considered at all (Stone et al. 2004; Whitesides 2006; Dittrich et al. 2006; Haeberle and Zengerle 2007).

For the last 10 years the fundamentals of a MEMS technique based on temperature-sensitive polymers have been developed by our group at the Technische Universität Dresden. In 2008 the first highly integrated hydrogel-based MEMS named “artificial skin” was presented (Richter and Paschew 2009).

In the following we introduce two key solutions of our platform technology, a concept able to control highly integrated systems containing hundreds or thousands of active polymeric elements and active microfluidic basic components.

3.1 Electrothermic and Optoelectrothermic Interface

Temperature-sensitive hydrogels with actuator properties show a LCST behaviour. They are swollen at low temperatures and shrink by exceeding of the volume phase transition temperature T t. The best known hydrogel with LCST behaviour is PNIPAAm (Fig. 9).

The probably simplest controllable basic functionality consists of a thermo-sensitve hydrogel and a directly attached resistive heater (Fig. 10a) (Richter et al. 2003; Arndt et al. 2000). As a function of the electrical power per Joule heat the hydrogel can be heated above its volume phase transition temperature.

(a) Electrothermic and (b,c) optoelectrothermic interfaces for the control of temperature-sensitive hydrogels based (a) on resistive heaters according to (Richter et al. 2003; Arndt et al. 2000), (b) on a laser beam according to (Wünschmann et al. 2002) and (c) on controlled light projection according to (Richter and Paschew 2009)

As resistive heating elements of this electrothermic interface thin film platinum resistors and surface mount technology (SMT) resistors are used (Richter et al. 2003, 2009a). The hydrogel components can be heated and cooled also by Peltier elements (Yu et al. 2003b; Luo et al. 2003a).

A similar effect can be obtained with an optoelectrothermic interface. Here, the hydrogel component is illuminated with high-energetic light, e.g., light of a laser source or a halogen lamp (Fig. 10b) (Wünschmann et al. 2002; Chen et al. 2008). It is recommendable to incorporate light-absorbing materials inside the gel matrix or to realise a light-absorbing interface of the hydrogel, which can be the supporting substrate (Wünschmann et al. 2002).

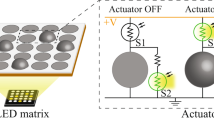

In the past it was expected that the electrothermic interface only allows a limited potential, because the physical and technological restrictions limit actuator density and large scale integration (Sugiura et al. 2007). This was proved to be a wrong estimation. In (Richter and Paschew 2009) an optoelectrothermic control of large-scale-integrated hydrogel-based MEMS is described. This control principle is possible since the temperature difference necessary to switch a PNIPAAm actuator from the fully swollen to the completely shrunken state is only 6 K. Furthermore, exceeding heat can be dissipated by an active cooling. The principle of the optoelectrothermic control is illustrated in Fig. 10c. The hydrogel actuators are placed onto a light absorbing black substrate. They are controlled by a commercial business video projection system. The illuminated areas are heated above the volume phase transition temperature of the gel. An active tempering keeps a constant temperature below the T t on the bottom side of the substrate and in areas which are not illuminated. This system is suitable for individual addressing of each single actuator up to an actuator density of 566 elements per cm². A common video projector with additional optics could control approximately 100 actuators per cm² (Richter and Paschew 2009).

3.2 Microvalves

Microvalves are the simplest hydrogel-based components. The gel actuator is directly placed within a valve chamber (Fig. 11a). The thermo-sensitive PNIPAAm is swollen at room temperature and closes the valve. For opening the attached resistive heater has to be activated. Exceeding the volume phase transition temperature of approximately 34°C the gel shrinks and opens the valve seat.

As pointed up in Table 3 hydrogel-based microvalves show several excellent properties. They are miniaturisable, very pressure resistant, extremely particle permissive and show no leakage.

Wang et al. (Wang J et al. 2005) use microvalves in a polymerase chain reaction (PCR) chip, and the valves of Richter et al. are commercialised as single component or within microscopy chips (Gast et al. 2006).

3.3 Micropumps

Integrable micropumps which act as fluidic propulsions or pressure sources are key elements of integrated microfluidic processors. Two types are described in the literature:

3.3.1 Diffusion Pumps

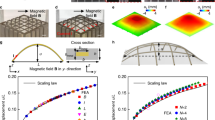

The characteristic feature of stimuli-sensitive hydrogels to change their volume absorbing or releasing aqueous solution has been used as advantage to realise displacement-free valves. However, this gel property is inappropriate for their use as direct-acting actuators of pumps. Therefore, the hydrogel actuator of the diffusion pump uses its swelling pressure to deform an elastic membrane which acts as pressure accumulator (Fig. 12a) (Richter et al. 2009a). If the swollen actuator is sequentially heated above its phase transition temperature by the heating meanders beginning outlet-sided then the actuator shrinks releasing the swelling agent. The released solution is immediately pushed to the outlet by the pressure of the elastic membrane because the inlet is sealed by a swollen actuator segment. To re-load the pump the heating meander has to be switched-off incipient inlet-sided. The gel cools down below the phase transition temperature and swells by absorbing liquid.

Diffusion micropump. (a) Schematic set-up. (b) Operating principle. (c) Pump characteristics; (1) peristaltic mode, (2) pulsatile mode. Reproduced from (Richter et al. 2009a) by permission of The Royal Society of Chemistry

The pump can operate in two different modi (Fig. 12b). A peristaltic operation provides a continuous and relatively homogeneous pumping while a pulsatile operation of the pump is realised by a complete emptying of the pump chamber.

The pump provides a flow rate in the peristaltic mode of (0.54 ± 0.016) μl min-1 and in the pulsatile mode of (2.80 ± 0.350) μl within one minute. The maximum pressure is 1.28 kPa.

3.3.2 Displacement Micropumps

This pump type adapts the principle of the osmotic pump similar to chemostat pumps (Theeuwes and Yum 1976). The hydrogel actuator is placed in the actuator chamber which is located within a separate layer (Fig. 13a). This layer contains a swelling agent supply and is placed above the channel structure involving the pump chamber.

Displacement micropump. (a) Schematic set-up. (b) Operating principle. (c) Pump characteristics. Reproduced from (Richter et al. 2009a) by permission of The Royal Society of Chemistry

Unlike diffusion devices the displacement micropump pumps at increasing actuator volume (Fig. 13b) and fills the pump chamber at hydrogel shrinkage. The flow direction of the pump is defined by the valves placed inlet- and outlet-sided.

The pumping pressure of the displacement pump is generated by the swelling force of the hydrogel actuator. Besides the elastic membrane the back pressure of the system counteracts the swelling pressure. Increasing back pressure decreases the flow rate of the device (Fig. 13c, pump 1). Maximal values of the pumping parameters are 4.5 μl min-1 at 0.5 kPa back pressure and 5 kPa at 0.2 μl min-1. The pumping pressure can be increased by an increase of the actuator’s thickness (Fig. 13c, pump 2). Generally, the correlation between the pumping pressure and the actuator thickness is a linear scaling law. The threefold thicker actuator of pump 2 pumps 0.6 μl min-1 at a back pressure of 15 kPa.

Compared to other micropumps hydrogel-based devices can be classified as pumps with small dead volume suitable for low- (diffusion micropump) and medium-performance (displacement micropump) applications (Nguyen et al. 2002; Laser and Santiago 2004).

3.4 Hydrodynamic Microtransistors

In presence of certain substances, the phase transition temperature of thermo-sensitive hydrogels is altered. This phenomenon is used to design electrothermically adjustable hydrodynamic microtransistors, which are also called chemostat microvalves (Richter et al. 2007a). The valve seat of the device (Fig. 14a) is tempered by a heater and an integrated temperature sensor is used for a closed-loop control. The volume phase transition temperature of PNIPAAm decreases with increasing alcohol content in water (Fig. 14b, solid symbols). Therefore, each critical alcohol concentration or volume phase transition correlates with one characteristic isotherm. Tempered at a particular isotherm the valve switches at a certain concentration (Fig. 14b, open symbols).

Electronically controllable hydrodynamic microtransistor. (a) Schematic set-up. (b) Volume phase transition temperature of microgel determined by DSC measurements (solid symbols) as well as operating point of the transistor device (open symbols) for different alcohol concentrations in water. Reproduced with permission from (Richter et al. 2007a) p. 1109-1110, copyright Wiley-VCH Verlag GmbH & Co. KGaA.

At a certain alcohol concentration the PNIPAAm actuator loses its temperature-sensitivity due to the good solubility of the polymer chains in the solvent alcohol. This critical alcohol concentration is 11.7 mol l-1 for methanol, 4.1 mol l-1 for ethanol and 1.75 mol l-1 for 1-propanol. This device can be precisely adjusted to 60 mmol l-1 (methanol), 25 mmol l-1 (ethanol) and 15 mmol l-1 (1-propanol) concentration steps by a temperature alteration of 0.1 K.

In presence of other substances PNIPAAm does not lose its LCST behaviour. Here, the adjustability and the control range are only restricted by the solubility or by the miscibility of the substances.

4 High Resolution Tactile Displays

Besides microfluidics the human-machine interaction, especially the imaging systems, could enormously benefit from the availability of large-scale integrated actuator systems. Such systems could provide an additional mechanical data channel intended for the sense of touch of the human, which is a very sensitive aesthesia. A first impression about the performance of a high-resolution tactile display gives the “artificial skin” (Fig. 15a).

Artificial skin consisting of 4,225 actuators at an area of (37 x 37) mm2. (a) Photograph. (b) The skin maps the sharp outlines of a dolphin. The length of the dolphin from mouth to tail is 14.5 mm. Reproduced with permission from (Richter and Paschew 2009), copyright Wiley-VCH Verlag GmbH and Co. KGaA.

This system contains an actuator array consisting of 4,225 PNIPAAm actuators at a pitch of 580 μm (Richter and Paschew 2009). Each actuator pixel is individually switchable using the optoelectrothermic control based on a commercial business video projection system.

The artificial skin displays different types of information. Immediately after heating above the phase transition temperature of about 34 °C the PNIPAAm actuators change their colour from transparent to opaque. The artificial skin displays monochrome visual information. After the end of the shrinking process the artificial skin maps the dolphin with single pixel accuracy (Fig. 15b). The palpable information is based on changes in the actuator height from 500 μm at the swollen state to about 250 μm at the shrunken state and on the variation of the softness. A smooth surface of the skin’s cover displays preferably differences in softness. Transferable impressions reach from the softness of fatty tissue at the swollen PNIPAAm state to the wood-like surfaces displayed by shrunken gel.

Because differences in height are hardly palpable on the soft hydrogel surface, the display is covered with a foil equipped with knobs which enhance the palpable edges.

The artificial skin would allow physical–auditory interaction with the virtual world of simulators and game engines by mapping of the computer-generated data. If the device is combined with image-based diagnostics such as computer tomography or ultrasonography then the artificial skin would provide new features in teleoperations and in diagnostics due to the virtual tactile access to inaccessible regions. The palpable recognition of objects inside the human body without the necessity to open it would improve diagnoses and allow preliminary simulation of surgical operations.

5 Influence of Material and Phase Transition Phenomena on the Operational Characteristics of Hydrogel Elements

5.1 Effects at the Initialisation of Gel Elements

After the synthesis of the active hydrogel components these are often not immediately ready to operate and show an unsatisfying behaviour. During the design process the causes of malfunctions have to be considered to avoid inoperative devices.

5.1.1 Conditioning Effect

During the first operation hydrogel elements often shows a poor repeatability and a drift of the parameters. This is caused by changes in the microscopic structure of the polymer network. By swelling and shrinking the too short polymer chains have to be cracked and the chains in general have to find their optimal moving way and position.

By performing a number of conditioning cycles the polymer network is “warmed up” and the repeat accuracy significantly increases. The conditioning process typically requires between six and thirty swelling cycles (Richter et al. 2004b). A detailed description of an initial gel conditioning procedure of a sensor is provided in Sect. 5.2.4.

5.1.2 Softening Effect

This effect is important if the hydrogel component operates between the dry state and the swollen state. The beginning of the swelling process of polymer networks with a high glass transition temperature T g (higher than the operating temperature) can be delayed. Because of the high T g the polymer network is glassy and the movement of the polymer chains, which is necessary for the swelling process, is disabled. Due to the self-diffusion the swelling agent penetrates the network and decreases T g of the polymer. Now, the polymer chains are much more elastic and the polymer network begins to swell. The softening effect could be avoided using a hydrogel with a low T g (Richter et al. 2004b).

5.1.3 Volume Change After Polymerisation

After the synthesis hydrogels significantly reswell. By adequate investigation this effect can be regarded during the design of the device. If neglected then this can lead to an irreversible malfunction or to a damage of the device, especially in components synthesised using in-situ polymerisation.

5.2 Phenomena at the Volume Phase Transition of Gels

5.2.1 Intrinsic Shrinkage Barrier Effect

The shrinkage process of hydrogels during the volume phase transition is sometimes affected by irregularities. A fast change of the stimulus leads to a rapid formation of a collapsed outer layer, while the rest of the hydrogel is still in the swollen state. This phenomenon is the so-called shrinkage barrier effect. After the additional collapsing of a substantial thicker layer, which is surrounding the hydrogel body beneath the thin already collapsed skin, this layer acts as shrinkage barrier preventing the swelling agent release. Therefore, the hydrogel core remains swollen. (see also Sect. 3.3.2). This effect leads to a malfunction of the device.

The shrinkage barrier effect was observed on hydrogels with porous structure stimulated by solvents and on homogeneous gels by temperature stimulation. However, this phenomenon depends on the dimensions of hydrogel. For structures with less than 200 µm in size no shrinkage barrier effect is observable. The shrinkage barrier effect is avoidable using optimised hydrogels (size and homogeneity) (Richter et al. 2004b).

5.2.2 Extrinsic Shrinkage Barrier Effect

An effect similar to the shrinkage barrier effect can be observed at particle- or microgel-based actuators. This effect occurs more frequently than the intrinsic shrinkage barrier effect. It appears in packed particle actuators, when the first particle layer swells too fast and significantly decreases the swelling agent supply of the further layers similar to a valve (Fig. 16). The extrinsic shrinkage barrier effect depends on the used type of hydrogel but also on the load (particle-compressing counterforce). This can be avoided by a hydrogel material with optimised particle size which can be above or below the critical particle size.

5.2.3 Two-Step Mechanism of the Volume Phase Transition

As already described in Sect. 3.2.4 and 3.3.2, the volume phase transition takes place in two steps. At first, a fast phase separation of polymer chains occurs towards polymer-rich and polymer-poor zones. This effect can be observed in experiments as a prompt change of the Young´s modulus of the hydrogel. Following, the hydrogel shrinking process starts. The hydrogel shrinking is slower and takes place in a second step after the phase separation. This mechanism influences the behaviour of the hydrogel elements during the operations.

For example, the prompt increase of the Young’s modulus at the beginning of the shrinking process of hydrogel actuators leads to a small pressure peak. After initiation of the swelling process the Young’s modulus of the hydrogel actuator abruptly decreases with a decrease of the actuator’s pressure. Both phenomena are observable as discontinuities of the flow rate of valves and pumps (Richter et al. 2004b).

5.2.4 Screening Effect

Especially pH-sensitive hydrogels show a distinctive hysteretic swelling behaviour (Fig. 17) (Arndt et al. 1999). The transition from basic to acidic conditions is quite different from the acidic-to-basic curve. This is reflected in mechanical and optical hydrogel properties (Richter et al. 2008b). Suzuki explains that phenomenon with both a replacement of the H+ counterion by an adequate ion such as Na+ and with an excess of these ions inside the gel causing a shielding or screening of the ionised gel groups (Suzuki and Suzuki 1995).

As shown in the inset of Fig. 17, the hysteresis can be significantly lowered by a restriction to a very small operation range within the phase transition range.

5.2.5 Material Enrichment Inside the Hydrogel

In solutions with high ionic strength hardly soluble complexes or salts can be accumulated inside the hydrogels resulting in an irreversible malfunction of the sensor. Such agglomerates can appear within a few hours. This can be avoided if the hydrogel element is regularly purged and stored in deionised water. Only very thin hydrogel films do not tend to such effects. A correctly maintained hydrogel-based device can be used for several years.

6 Design and Performance

6.1 Response Time

6.1.1 Effective Diffusion Length

The swelling kinetics of stimuli-responsive hydrogels is described by the theory of cooperative diffusion (Sect. 3.2.2 and 3.2.3, (Tanaka and Fillmore 1979)). Besides the cooperative diffusion constant, which is specific for each solvent–polymer network combination (see Eq. (3.2.9)), the time behaviour of active hydrogel components can be as well influenced by further design-dependent aspects (Richter 2006, 2008b).

Due to the diffusion process hydrogel components with dimensions in the millimetre range or larger are very slow. To obtain fast hydrogel components different approaches are investigated. First, synthesis of porous hydrogels o minimises the effective diffusion length of the swelling agent inside the hydrogel (see Chap. 2 and Sect. 3.2.5). Unfortunately, the usability of this method is restricted because an increasing porosity of the gel significantly decreases the mechanical stability.

Furthermore, short effective diffusion lengths can be achieved by fragmentation of a large hydrogel component into many small particles (Fig. 18). Using microgels and hydrogel particles, respectively, the effective diffusion length is reduced from d A to approximately r P. A similar effect can be obtained with photolithographically patterned hydrogel posts (Beebe et al. 2000). Using the fragmentation method a time reduction of one or two orders of magnitude can be realised.

Influence of the effective diffusion length on the response time of a hydrogel component. (a) Bulk hydrogel component. The effective diffusion length is d A. (b) Component with hydrogel particles. The component volume equals with that of the bulk component. The effective diffusion length is approximately r P

6.1.2 Swelling Agent Supply

Limitations of the swelling agent supply have a strong impact on the swelling kinetics. A decrease of the channel area A C can increase the flow resistance to a value at which the hydrogel is restricted and can get only a fractional amount of the swelling agent volume flow which it would take in the case of free swelling. Therefore, the hydrogel swells remarkably slower than possible (Fig. 19a).

Swelling characteristics of hydrogel components at (a) different channel cross-sections A C and (b) various counterforces. As hydrogel a poly(vinyl alcohol) / polyacrylic acid network is used (Arndt et al. 1999)

6.1.3 Counterforces

The theory of Tanaka and Fillmore (Tanaka and Fillmore 1979) describes only the unloaded case. For actuator applications this case is almost impossible.

Practical investigations show that the time behaviour of the hydrogel components is strongly influenced by the counteracting forces during the swelling process of the gel. Increasing the counter-force significantly increases the response time and decrease the amplitude of the swelling degree (Fig. 19b). The shrinking process can be accelerated by counterforces.

6.1.4 Recirculation of Process Media

Inside microfluidic channels the flow is laminar. Due to the absence of turbulences different media do not mix or mix only spontaneously and very slowly. Automatic elements can only operate correct in the presence of sufficient process medium. Otherwise, in the absence of stimulation, the control functionality can not be performed. Therefore, inside microfluidic channel networks the realisation of a recirculation is recommended which can provide an independency from the state (open or closed) of the active hydrogel components.

6.2 Pressure Resistance and Particle Tolerance

Hydrogel is a soft material. However, hydrogel-based valves are outstandingly pressure-resistant (Richter et al. 2004b). The pressure resistance correlates with a maximal closing pressure which is mainly depending on the mechanical properties of the hydrogel and on the design parameters of the device. The pressure resistance of particle-based valves can be predefined by a variation of the filling degree of the actuator chamber with hydrogel. The back pressure of the valve increases with increasing filling degree. However, the filling degree also influences the switching time of the valve. Small filling degrees provide a fast opening but a slow closing time. A high filling degree leads to a fast closing and a slow opening time (Fig. 20). The pressure resistance of monolithic valves can be defined by the length of the valve (Yu et al. 2003b).

Maximal back pressure without leakage flow and switching time of a microvalve in dependence on the filling degree VGel/VC of the valve chamber. The valve chamber (800 μm × 800 μm × 200 μm) is filled with dry PNIPAAm MBAAm 4 particles; particle size 82.5 ± 5 μm (according to (Richter et al. 2004b)). V Gel bulk volume of dry hydrogel particles, V C valve chamber volume

Due to its softness hydrogel elements are extremely particle permissive. This feature is important especially for valves. If a particle is present inside the valve seat during the closing process then the swelling hydrogel encloses it without any disturbance of the valve function.

Notes

- 1.

In this chapter the sensor-actuator functionality is sometimes described as actuator according to terms used in the literature. Please note that a sensor-actuator transforms non-mechanical energy into mechanical energy, whereas an actuator is typically controlled by electrics or electronics.

Abbreviations

- LCST:

-

Lower critical solution temperature

- MBAAm:

-

N, N´-methylenebis(acrylamide)

- NC:

-

Normally closed

- NO:

-

Normally open

- n.s.:

-

Not specified

- PCR:

-

Polymerase chain reaction

- PNIPAAm:

-

Poly(N-isopropylacrylamide)

- A C :

-

Cross-section area of channel

- c Alcohol :

-

Content of alcohol in aqueous solution

- c EtOH :

-

Content of ethanol in aqueous solution

- c Glucose :

-

Content of glucose in aqueous solution

- c HxOH :

-

Content of hexanol in aqueous solution

- c MeOH :

-

Content of methanol in aqueous solution

- c NaCl :

-

Content of sodium chloride in aqueous solution

- c PrOH :

-

Content of 1-propanol in aqueous solution

- d :

-

Valve chamber length

- d A :

-

Effective diffusion way of a bulk actuator

- pH:

-

pH value

- pk a :

-

pk value of acid

- r P :

-

Particle radius

- T :

-

Temperature

- T g :

-

Glass transition temperature

- T t :

-

Volume phase transition temperature

- T Control :

-

Control temperature of hydrodynamic transistor

- t:

-

Time

- V :

-

Swollen volume of hydrogel

- V 0,V dry :

-

dry volume of hydrogel

- V C :

-

Valve chamber volume

- V Gel :

-

Bulk volume of dry hydrogel particles

- x:

-

Distance

- Δd :

-

Difference of valve chamber length

- ΔpH:

-

Difference of pH value

- ΔT :

-

Temperature difference

- Δx :

-

Displacement

- Δd :

-

Difference of valve chamber length

- ΔpH:

-

Difference of pH value

- ΔT :

-

Temperature difference

- Δx :

-

Displacement

- λ:

-

Wavelength of light

References

Arndt KF, Richter A, Ludwig S, Zimmermann J, Kressler J, Kuckling D, Adler HJ (1999) Poly(vinyl alcohol)/poly(acrylic acid) hydrogels: FT-IR spectroscopic characterization of crosslinking reaction and work and transition point. Acta Polym 50:383–390

Arndt KF, Kuckling D, Richter A (2000) Application of sensitive hydrogels in flow control. Polym Adv Technol 11:496–505

Arndt KF, Schmidt T, Reichelt R (2001) Thermo-sensitive poly(methyl vinyl ether) micro-gel formed by high energy irradiation. Polymer 42:6785–6791

Baldi A, Gu Y, Loftness PE, Siegel RA, Ziaie B (2003) A hydrogel-actuated environmentally sensitive microvalve for active flow control. J Microelectromech Syst 12:613–621

Beebe DJ, Moore JS, Bauer JM, Yu Q, Liu RH, Devadoss C, Jo BH (2000) Functional hydrogel structures for autonomous flow control inside microfluidic channels. Nature 404:588–590

Chen G, Svec F, Knapp DR (2008) Light-actuated high pressure-resisting microvalve for on-chip flow control based on thermo-responsive nanostructured polymer. Lab Chip 8:1198–1204

Dittrich PS, Manz A (2006) Lab on a chip: microfluidics in drug discovery. Nature Rev Drug Disc 5:210–218

Dittrich PS, Tachikawa K, Manz A (2006) Micro total analysis systems. Latest advancements and trends. Anal Chem 78:3887–3907

Dong L, Agarwal AK, Beebe DJ, Jiang H (2006) Adaptive liquid microlenses activated by stimuli-responsive hydrogels. Nature 442:551–554

Dong L, Agarwal AK, Beebe DJ, Jiang H (2007) Variable-focus liquid microlenses and microlens arrays actuated by thermoresponsive hydrogels. Adv Mater 19:401–405

Eddington DT, Beebe DJ (2004) A valved responsive hydrogel microdispensing device with integrated pressure source. J Microelectromech Syst 13:586–593

Ehrick JD, Stokes S, Bachas-Daunert S, Moschou EA, Deo SK, Bachas LG, Daunert S (2007) Chemically tunable lensing of stimuli-responsive hydrogel microdomes. Adv Mater 19:4024–4027

Gast FU, Dittrich PS, Schwille P, Weigel M, Mertig M, Opitz J, Queitsch U, Diez S, Lincoln B, Wottawah F, Schinkinger S, Guck J, Käs J, Smolinski J, Salchert K, Werner C, Duschl C, Jäger MS, Uhlig K, Geggier P, Howitz S (2006) The microscopy cell (MicCell), a versatile modular flowthrough system for cell biology, biomaterial research, and nanotechnology. Microfluid Nanofluid 2:21–36

Gerlach G, Günther M, Sorber J, Suchaneck G, Arndt KF, Richter A (2005) Chemical and pH sensors based on the swelling behavior of hydrogels. Sens Actuat B 111–112:555–561

Good BT, Bowman CN, Davis RH (2007) A water-activated pump for portable microfluidic applications. J Colloid Interface Sci 305:239–249

Haeberle S, Zengerle R (2007) Microfluidic platforms for lab-on-a-chip applications. Lab Chip 7:1094–1110

Harmon ME, Tang M, Frank CW (2003) A microfluidic actuator based on thermoresponsive hydrogels. Polymer 44:4547–4556

http://www.fluidigm.com/products/biomark-chips.html, date: 25.06.2008

Janasek D, Franzke J, Manz A (2006) Scaling and the design of miniaturized chemical-analysis systems. Nature 442:374–380

Kataoka K, Miyazaki H, Bunya M, Okano T, Sakurai Y (1998) Totally synthetic polymer gels responding to external glucose concentration: their preparation and application to on-off regulation of insulin release. J Am Chem Soc 120:12694–12695

Kim D, Beebe DJ (2007) A bi-polymer micro one-way valve. Sens Actuat A 136:426–433

Kim J, Serpe MJ, Lyon LA (2004) Hydrogel microparticles as dynamically tunable microlenses. J Am Chem Soc 126:9512–9513

Kim J, Nayak S, Lyon LA (2005a) Bioresponsive hydrogel microlenses. J Am Chem Soc 127:9588–9592

Kim J, Serpe MJ, Lyon LA (2005b) Photoswitchable microlens arrays. Angew Chem Int Ed 44:1333–1336

Kuckling D, Arndt KF, Richter A (2003) Temperature and pH dependent swelling behavior of poly(N-isopropylacrylamide)-copolymer hydrogels and their use in flow control. Macromol Mater Eng 288:144–151

Kuhn W, Hargitay B (1951) Muskelähnliche Arbeitsleistung künstlicher hochpolymerer Stoffe. Z f Elektrochemie 55:490–502

Kuhn W, Künzle O, Katchalsky A (1948) Denouement de molecules en chaines polyvalentes par des charges electriques en solution. Bull Soc Chim Belg 57:421–431

Kurauchi T, Shiga T, Hirose Y, Okada A (1991) Deformation behaviors of polymer gels in electric field. In: D. DeRossi, K. Kajiwara, Y. Osada, A. Yamauchi (ed): Polymer gels: Fundamentals and biomedical applications. Plenum Press New York, 2

Laser DJ, Santiago JG (2004) A review of micropumps. J Micromech Microeng 14:R35–R64

Li W, Zhao H, Teasdale PR, John R, Zhang S (2002) Synthesis and characterisation of a polyacrylamide-polyacrylic acid copolymer hydrogel for environmental analysis of Cu and Cd. React Funct Polym 52:31–41

Liu RH, Yu Q, Beebe DJ (2002) Fabrication and characterization of hydrogel-based microvalves. J Microelectromech Syst 11:45–53

Liu C, Park JY, Xu Y, Lee SH (2007) Arrayed pH-responsive microvalves controlled by multiphase laminar flow. J Micromech Microeng 17:1985–1991

Luo Q, Mutlu S, Gianchandani YB, Svec F, Fréchet JMJ (2003a) Monolithic valves for microfluidic chips based on thermoresponsive polymer gels. Electrophoresis 24:3694–3702

Luo Q, Mutlu S, Gianchandani YB, Svec F, Fréchet JMJ (2003b) Monolithic valves for microfluidic chips based on thermoresponsive polymer gels. Electrophoresis 24:3694–3702

Mitsumata T, Ikeda K, Gong JP, Osada Y (1998) Solvent-driven chemical motor. Appl Phys Lett 73:2366–2368

Mitsumata T, Ikeda K, Gong JP, Osada Y (2000) Controlled motion of solvent-driven gel motor and its application as a generator. Langmuir 16:307–312

Miyata T, Asami N, Uragami T (1999) A reversibly antigen-responsive hydrogel. Nature 399:766–769

Nguyen NT, Huang X, Chuan TK (2002) MEMS-micropumps: a review. Transact ASME 124:384–392

Osada Y, Gong JP (1998a) Soft and wet materials: Polymer gels. Adv Mater 10:827–837

Osada Y, Gong JP (1998b) Soft and wet materials: Polymer gels. Adv. Mater. 10:827–837

Osada Y, Takeuchi Y (1981) Water and protein permeation through polymeric membrane having mechanochemically expanding and contracting pores - Function of chemical valve-. J Polym Sci, Polym Lett Ed 19:303–308

Park JY, Oh HJ, Kim DJ, Baek JY, Lee SH (2006) A polymeric microfluidic valve employing a pH-responsive hydrogel microsphere as an actuating source. J Micromech Microeng 16:656–663

Peters EC, Svec F, Frechét JMJ (1997) Thermally responsive rigid polymer monoliths. Adv Mater 9:630–633

Richter A (2006) Hydrogel-based µTAS. In C.T. Leondes: MEMS/NEMS Handbook: Techniques and Applications. Vol. 2: Fabrication Techniques, Chapter 5, Springer, New York

Richter A, Paschew G (2009) Optoelectrothermic control of polymer-based highly integrated MEMS applied in an artificial skin. Adv Mater 21:979–983

Richter A, Arndt KF, Krause W, Kuckling D, Howitz S (2001) Devices for flow control based on smart hydrogels. 7th Pacific polymer Conference, Oaxaca, Dec 3–7, 2001, p. 312

Richter A, Kuckling D, Howitz S, Gehring T, Arndt KF (2003) Electronically controllable microvalves based on smart hydrogels: magnitudes and potential applications. J Microelectromech Syst 12:748–753

Richter A, Klenke C, Arndt KF (2004a) Adjustable low dynamic pumps based on hydrogels. Macromol Symp 210:377–384

Richter A, Howitz S, Kuckling D, Arndt KF (2004b) Influence of volume phase transition phenomena on the behaviour of hydrogel-based valves. Sens Actuat B 99:451–458

Richter A, Krause W, Lienig J, Arndt KF (2005) Polymer networks as actuator and sensor systems to be used for automation of biomedical devices. Biomed Technik 50:66–68

Richter A, Türke A, Pich A (2007a) Controlled double-sensitivity of microgels applied to electronically adjustable chemostats. Adv Mater 19:1109–1112

Richter A, Wenzel J, Kretschmer K (2007b) Mechanically adjustable chemostats based on stimuli-responsive polymers. Sens Actuat B 125:569–573

Richter A, Klatt S, Paschew G, Klenke C (2009a) Micropumps operated by swelling and shrinking of temperature-sensitive hydrogels. Lab Chip 9:613–618

Richter A, Paschew G, Klatt S, Lienig J, Arndt KF, Adler HJ (2008b) Review on hydrogel-based pH sensors and microsensors. Sensors 8:561–581

Sershen SR, Mensing GA, Ng M, Halas NJ, Beebe DJ, West JL (2005) Independent optical control of microfluidic valves formed from optomechanically responsive nanocomposite hydrogels. Adv Mater 17:1366–1368

Stone HA, Stroock AD, Ajdari A (2004) Engineering flows in small devices: microfluidics towards a lab-on-a-chip. Annu Rev Fluid Mech 36:381–411

Sugiura S, Sumaru K, Ohi K, Hiroki K, Takagi T, Kanamori T (2007) Photoresponsive polymer gel microvalves controlled by local light irradiation. Sens Actuat A 140:176–184

Suzuki M (1991) Amphoteric poly(vinyl alcohol) hydrogel and electrodynamic control method for artificial muscles. In: D. DeRossi, K. Kajiwara, Y. Osada, A. Yamauchi (ed): Polymer gels: Fundamentals and biomedical applications. Plenum Press New York, 221-236

Suzuki A, Suzuki H (1995) Hysteretic behavior and irreversibility of polymer gels by pH change. J Chem Phys 103:4706–4710

Suzuki A, Tanaka T (1990) Phase-transition in polymer gels induced by visible-light. Nature 346:345–347

Suzuki H, Tokuda T, Kobajashi K (2002) A disposable “intelligent mosquito” with a reversible sampling mechanism using the volume-phase transition of a gel. Sens Actuat B 83:53–59

Tanaka T (1978) Collapse of gels and critical endpoint. Phys Rev Lett 40:820–823

Tanaka T, Fillmore DJ (1979) Kinetics of swelling of gels. J Chem Phys 70:1214–1218

Tanaka T, Nishio I, Sun ST, Ueno-Nishio S (1982) Collapse of gels in an electric field. Science 218:467–469

Theeuwes F, Yum SI (1976) Principles of the design and operation of generic osmotic pumps for the delivery of semisolid or liquid drug formulations. Annals Biomed Eng 4:343–353

Thorsen T, Maerkl SJ, Quake SR (2002) Microfluidic large-scale integration. Science 298:580–584

Unger MA, Chou HP, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288:113–116

Wang J, Chen Z, Mauk M, Hong KS, Li M, Yang S, Bau1 HH (2005) Self-actuated, thermo-responsive hydrogel valves for lab on a chip. Biomed Microdev 7: 313–322

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442:368–373

Wünschmann W, Richter A, Dierigen HJ, Howitz, S, Kuckling D, Keller, M, Arndt KF, Taktile Anzeigeeinheit. German Patent Application DE 102 26 746.4, filing date 14/06/2002

Yu C, Mutlu S, Selvaganapathy P, Mastrangelo CH, Svec F, Fréchet JMJ (2003a) Flow control valves for analytical microfluidic chips without mechanical parts based on thermally responsive monolithic polymers. Anal Chem 75:1958–1961

Yu C, Mutlu S, Selvaganapathy P, Mastrangelo CH, Svec F, Fréchet JMJ (2003b) Flow control valves for analytical microfluidic chips without mechanical parts based on thermally responsive monolithic polymers. Anal Chem 75:1958–1961

Zhang Y, Kato S, Anazawa T (2008) A microchannel concentrator controlled by integral thermoresponsive valves. Sens Actuat B 129:481–486

Acknowledgments

The author gratefully acknowledges the support for this work from the Deutsche Forschungsgemeinschaft (Collaborative Research Centre SFB 287 “Reactive Polymers”, Heisenberg fellowship). G. Paschew is thanked for carefully proof-reading the manuscript.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Richter, A. (2009). Hydrogels for Actuators. In: Gerlach, G., Arndt, KF. (eds) Hydrogel Sensors and Actuators. Springer Series on Chemical Sensors and Biosensors, vol 6. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-75645-3_7

Download citation

DOI: https://doi.org/10.1007/978-3-540-75645-3_7

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-75644-6

Online ISBN: 978-3-540-75645-3

eBook Packages: EngineeringEngineering (R0)