Abstract

The effects of cementation gel among particles of soil by permeating grouting on the unconfined compressive strength of soft clay soil have been studied in this work. The soil sample obtained from Al-Jadriah district in Baghdad city which can be classified as soft clayey soil of low plasticity (CL). The soil samples were improved by grouting gel of cement/water with three weight percentages. The percentages of grouting gel are measured in terms of cement to water as; 0.1 C:0.9 W, 0.2 C:0.8 W and 0.3 C:0.7 W. In addition to the grouting get, the soil samples improved with silica fume, where silica fume added in two percentages of 2 and 4%. The improved soil samples were dehydrated after grouting for three periods of time 1, 3, and 7 days. The results of tests indicated increasing the unconfined compression strength and decreasing the axial strain with increasing the percentage of grouting gel. The addition of silica fume to the soft clayey soil improved by cementing agent resulted in significant increase in the unconfined compression strength and significant decrease in axial strain.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Portland cement is used as a grout to fill the voids of the soil media and improve the strength and elastic properties of soil [1,2,3]. Most grouts with Portland cement required to add small amounts of additives, that is used for specific purposes such as increasing fluidity, retarding sedimentation, and controlling on the set times [4,5,6,7,8]. In the present study, three percentages of grouting gel of cement-water and two percentages of silica fume are used to improve the undrained shear strength of soft soil. Also, the effects of curing period on the growing of undrained shear strength have been studied.

2 Soil and Used Materials

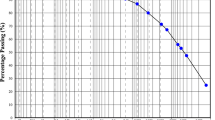

The physical properties of soil sample used in the present work are given in Table 1, measured according to ASTM [9]. The specifications of Portland cement used in the present work are: the specific surface is 2250 cm2/g and the initial and final hardening times are 1 and 10 h respectively. The compressive strength of cement mortar is150 kg/cm2 after 3 days and 240 kg/cm2 after 7 days. In addition, the tensile strength of cement is 21 kg/cm2. The used silica fume (Sika Fume-HR) contains extremely fines of (0.1 μm) reactive dioxide of silicon. The soil mixture becomes extremely soft and workable when using silica fume, also, the reactions of silica fume generates a chemical bond with the free calcium components present in the clayey soil. The color of used silica fume is a light gray powder of density 0.65 kg/l.

3 Stabilization with Grouting Cement Gel and Silica Fume

Grouting gel mixtures are used to improve the unconfined shear strength of soil. The grouting gel is mixture of water/cement, added in three ratios of soil mass (0.9:0.1, 0.8:0.2, and 0.7:0.3) %. The natural soil sample was dried in the oven at 110 °C, then mixed with the optimum moisture content, then placed in layers in the compaction mold. Each layer was compacted with 25 blows distributed uniformly on the surface of a soil sample to achieve the required maximum dry density. From the mold of compaction, a soil sample of dimensions 38.5 mm diameter and 76.8 mm height was extracted. The treatment method can be summarized by injection 1 cm3 of the grouting gel by needle into the soil sample at different locations and reach to the middle height of sample. Then, the mold covered with a polyethylene layer to control the moisture content of soil sample and left for rehydration. The suggested curing periods were 1, 3, and 7 days to measure the effects of curing period on the acquired undrained shear strength. Also, two soil samples are mixed with 2 and 4% of silica fume before injection the grouting gel and curried for 1 day.

4 Results and Discussion

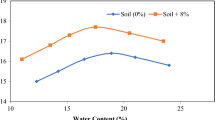

Generally, there was an increase in the undrained shear strength of soil stabilized with grouting gel of cement until the maximum strength reached, and then there was a slight reduction in the strength of the soil as shown in Figs. 1 and 2. The increase in magnitude of unconfined compressive strength ranged from 7 to 82% for the three percentages of grouting mixture and three periods of curing. Increasing the ratio of cement in the grouting mixture causes increasing the undrained strength, but the significant effect is related to the period of curing. Also, there was no change in the axial strain at failure for soil samples treated with grouting gel only. In addition, the unconfined compressive strength increases with increasing the relative compaction and curing time [10]. The delay in mixing and compaction causes decreasing the undrained shear strength of soil. The mixing of soft soil with silica fume before injection the grouting gel causes increasing the undrained shear strength by 32 to 72% after one day of curing. Increasing the cement ratio in the grouting gel causes significant increase in the undrained shear strength. Also, the mixing of soil with silica fume causes a significant decrease in the axial strain ranged 35 to 44%. The low ratios of silica fume alone make the mixture of soil unstable chemically and give negative effects through increasing the moisture content required to produce a homogenous mixture, which causes a decrease in the unconfined compressive strength [11]. The summary of undrained shear strength and axial strains are given in Tables 2 and 3.

5 Conclusions

The undrained shear strength of soft clayey soil increased with increasing the ratio of cement in the grouting gel and the more significant increase was noticed with increasing the curing period from 1 to 7 days. There was slight change in the axial strain when the soil samples treated with grouting gel of cement and water. The mixing of soil with silica fume then grouted with cement gel causes significant increase in the undrained shear strength and significant decrease in the axial strain. Silica fume accelerate the chemical reactions between soil and grouting gel which gives the hardening to soft soil.

References

Karol, R.: Chemical Grouting and Soil Stabilization, 3rd edn. Revised and Expanded. Marcel Dekker Inc., Basel (2003)

U.S. Army Corps of Engineers: 1984. Grouting technology. Publication No. EM 1110-2-3506 (2017). http://www.publications.usace.army.mil/Portals/76/Publications/EngineerManuals/EM_1110-2-3506.pdf

Sinroja, J.M., Joshi, N.H., Shroff, A.V.: Ground improvement technique using microfine slag cement grouts. In: Proceeding of IGC, Chennai, pp. 661–664 (2006)

Warner, J.: Practical Handbook of Grouting: Soil, Rock, and Structures. Wiley, New York (2004)

Dano, C., Hicher, P.Y., Tailliez, S.: Engineering properties of grouted sands. J. Geotech. Geoenviron. Eng. ASCE 130(3), 328–338 (2004)

Akbulut, S., Saglamer, A.: Estimating the groutability of granular soils: a new approach. Tunneling Undergr. Space Technol. 17, 371–380 (2002)

Kazemian, S., Huat, B.B.K.: Assessment and comparison of grouting and injection method in geotechnical engineering. Eur. J. Sci. Res. 27(2), 234–247 (2009)

Santhosh Kumar, T.G., Benny, M.A., Sridharan, A., Babu, T.J.: Bearing capacity improvement of loose sandy foundation soils through grouting. Int. J. Eng. Res. Appl. (IJERA) 1(3), 1026–1033 (2011)

Annual book of ASTM standards, Soil and Rock; Building; Stone; Peats (2003)

Karkush, M.O., Ali, H.A: Improvement of unconfined compressive strength of soft clayey soil by using glass wool fibers. In: The Iraqi Journal for Mechanical and Material Engineering, Special Volume, Babylon First International Engineering Conference Issue (B) (2016)

Onyelowe, K.C., Onuoha, I.C., Ikpemo, O.C., Okafor, F.O., Maduabuchi, M.N., Kalu-Nchere, J., Aguwa, P.: Nanostructured clay (NC) and the stabilization of lateritic soil for construction purposes. EJGE 22(10), 4177–4196 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Switzerland AG

About this paper

Cite this paper

Karkush, M.O., Ali, H.A., Ahmed, B.A. (2018). Improvement of Unconfined Compressive Strength of Soft Clay by Grouting Gel and Silica Fume. In: Wu, W., Yu, HS. (eds) Proceedings of China-Europe Conference on Geotechnical Engineering. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-319-97112-4_122

Download citation

DOI: https://doi.org/10.1007/978-3-319-97112-4_122

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97111-7

Online ISBN: 978-3-319-97112-4

eBook Packages: EngineeringEngineering (R0)