Abstract

The self-association force of water on the surface of a composite polymeric material is a physicochemical process dominated by cohesive forces and van der Waals-type interactions existing below the material surface. Perturbations in the chemical potential of water, brought about by the interaction between it and a polymeric surface, induce compensatory structural changes. Thus, the structure of water on the surface of a composite polymeric material reveals the hydrogen bond interactions taking place beneath it, which are key to understanding the properties of thermoplastic starch (TPS) materials. In the literature, there is a broad consensus based on empirical results that a contact angle (θ) greater than 65° defines a hydrophobic surface. These findings suggest that there are at least two different types of water structures that exist as a response to interactions occurring within the composite polymers. One of these is formed when there is a low density of “Lewis sites”, and the other when there is a high density of “Lewis sites” on the surface of the thermoplastic materials. This second scenario produces the collapse of the water structure, i.e., the collapse of the hydrogen-bonded network. In spite of the physicochemical response of water to the intra- and intermolecular interactions that occur on composite materials, these have not been studied as a means to modify the surface behavior of TPS materials. This could be achieved by incorporating natural fillers that have a plasticizer or crosslinking effect on their structure. In this chapter, we analyze the surface properties of starch-based composite materials as an indirect measure of the interactions that occur within them, mainly as regards plasticizing effects and crosslinking reactions.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The surface properties of thermoplastic starch (TPS) used to pack food are key variables for food packaging designers and engineers as they influence product shelf life, appearance, and quality control.

Materials made using TPS often contain fillers such as nanoparticles, microcapsules, cellulose, and clay, among others, which have all been extensively studied (Trache et al. 2017; Voicu et al. 2016; Miculescu et al. 2016). Because they are highly susceptible to humidity, the starches used are usually modified in order to improve their physicochemical properties (Wang et al. 2016). However, although there have been many efforts made to develop materials from biomacromolecules, especially starch, their surface properties have received relatively little attention.

Surface composition and morphology are commonly determined by means of several techniques such as electron spectroscopy for chemical analysis (ESCA or XPS), secondary ion mass spectrometry (SIMS), scanning electron microscopy (SEM), atomic force microscopy (AFM), and contact angle (Peeling et al. 1976; Varma 1984; Russell et al. 1987; Baldwin et al. 1997, 1998; Michalska-Pożoga et al. 2016). In particular, this last technique is increasingly being used in the academic and scientific worlds, as well as at an industrial level, since the table-top equipment now on offer can cost as little as 150 dollars. The instruments are also more portable and robust (Fig. 1a) than more traditional equipment (Fig. 1b) and can produce higher quality images (Fig. 1c, d).

The contact angle (θ) is defined as the angle formed by the intersection of the tangent lines of the liquid and solid surfaces at the three-phase boundary between these two phases and the third surrounding phase (generally air or vapor) (Wong et al. 1992). A schematic representation of a contact angle (θ) is shown in Fig. 2. One of the primary characteristics of any immiscible two- or three-phase system made up of two condensed phases, at least one of which is a liquid, is the contact angle of that liquid on the other condensed phases (solid or liquid surfaces) (Ghanbarzadeh et al. 2013). These phases can be as follows:

-

liquid–vapor–solid: for example, water on an edible film.

-

liquid–liquid–solid: for example, water–oil–protein in an emulsion.

-

liquid–liquid–vapor: for example, an oil drop on a water surface.

To summarize, the contact angle is the angle, conventionally measured through the liquid, where a liquid–vapor interface meets a solid surface. It quantifies the wettability of a solid surface by a liquid via the Young equation (Fig. 2). Any solid, liquid, and vapor system at a given temperature and pressure will have a unique equilibrium contact angle. However, in practice, contact angle hysteresis is observed, ranging from the so-called advancing (maximal) contact angle to the receding (minimal) contact angle. The equilibrium contact lies between these values and can be calculated from them. The equilibrium contact angle reflects the relative strength of the liquid, solid, and vapor molecular interaction. Contact angles are extremely sensitive to contamination: values reproducible to less than a few degrees are generally only obtained under laboratory conditions with purified liquids and very clean solid surfaces. If the liquid molecules are strongly attracted to the solid molecules, then the liquid drop will completely spread out on the solid surface, giving a contact angle of 0°.

In essence, the contact angle may be explained as the physicochemical response of a pure solvent drop on a surface. This is related to the surface tension produced by the unbalanced forces of the liquid molecules on that surface (Fig. 3). Wettability studies of a surface are usually performed by determining contact angles using distilled and deionized water. In this regard, there is a broad consensus in the literature, based on empirical results, than a contact angle (θ) greater than 65° defines a hydrophobic surface when water is used as a solvent (Fig. 4) (Vogler 1998). It is well known that the contact angle of water increases with an increase in surface hydrophobicity (Ojagh et al. 2010). Karbowiak et al. (2006) suggested that an increase in the water contact angle of biopolymers could be due to strong intermolecular hydrogen bonding under the film surface. The most polar sites (Lewis sites) would be affected by these interactions, thus generating a reduction in the surface polarity of biopolymer films. Starch film surfaces with higher contact angles do not contain the energy required to break the cohesive force of water (Vogler 1998). Thus, a droplet with high surface tension resting on a low-energy solid tends to adopt a spherical shape due to the establishment of a high contact angle with the surface. Conversely, when the surface energy of the solid exceeds the liquid surface tension, the droplet tends to adopt a flatter shape due to the establishment of a low contact angle with the surface (Fig. 5).

Interestingly, this kind of water structure requires that the hydrogen bond network of water directly adjacent to a nonpolar surface is interrupted yielding “dangling hydrogen bonds”. These dangling hydrogen bonds have been theoretically predicted (Lee et al. 1984) and spectroscopically resolved from hydrogen bonds in bulk water (Du et al. 1993, 1994a, b).

Contact angles have also been associated with the surface characteristics of starchy materials through the well-known Wenzel equation (Wenzel 1936):

In Wenzel’s equation, the roughness factor (r) acts to amplify the surface chemistry-determined term cosθ. Thus, small changes in θ translate to larger changes in θ W, provided complete contact is maintained between the liquid and the solid (Fig. 6). The importance of θ = 90° is the changeover in the sign of the cosine term. When θ < 90, the effect of increasing roughness (r) is to further reduce the Wenzel contact angle toward 0. However, when θ > 90, the effect of increasing r is to further increase the Wenzel contact angle toward 180. Thus, Wenzel roughness emphasizes the intrinsic tendency of a surface to have either complete wetting or complete non-wetting properties.

Conversely, a liquid may form bridges between surface features and no longer penetrate through the spaces separating them; a simplified example of a flat-topped surface is shown in Fig. 7. In this example, it is assumed that the liquid only makes contact with the flat parts of the surface and that the meniscus below the drop is flat. This implies that the gaps between the features are much smaller than the curvature of the meniscus due to the weight of the liquid and the pressure exerted by the top meniscus. As the contact line advances by ΔA only a fraction, f sΔA, of the solid makes contact with the liquid, and the remainder (1 − f s)ΔA is the area bridged between surface features in contact with the air. Thus, this remainder involves the creation of a liquid vapor interface. The surface free energy change is given by Eq. 2:

Based on these concepts, in this chapter, we discuss the surface properties of TPS materials reinforced with natural fillers as an indirect measure of interactions in starch-based composite materials, mainly with regard to plasticizing effects and crosslinking reactions.

2 Effect of the Amylose/Amylopectin Ratio on the Surface Properties of TPS

Starch is a polysaccharide composed of the essentially (1-4)-linked linear amylose and the extensively (1-6)-branched amylopectin, and occurs naturally in plants in the form of granules. The film formation process is important for film structure and crystallinity. Previous studies undertaken by Stading et al. (2001) and Rindlav-Westling et al. (2002) have shown that amylopectin films are totally amorphous without any visible structure, and this is reflected by a smooth surface. In contrast, amylose films are semicrystalline (Stading et al. 2001, Rindlav-Westling et al. 2002) giving rise to a rougher surface.

Rindlav-Westling and Gatenholm (2003) analyzed the surfaces of starch solution cast films prepared from amylose and amylopectin by scanning electron microscopy (SEM), atomic force microscopy (AFM), electron spectroscopy for chemical analysis (ESCA), and time-of-flight secondary ion mass spectrometry (ToF-SIMS). They found that the surface (as visualized by SEM) of amylopectin films was very smooth, whereas that of amylose films was rougher. A possible explanation for this is the higher crystallinity of the amylose films due to starch retrogradation, which affects their topography (Fig. 8). Moreover, the amylopectin films appeared to be flat even at the high magnifications obtained with atomic force microscope (AFM). Using this technique, small protrusions were also observed on top of the surface structures of the much rougher amylose films.

The authors also examined the starch films using a light microscope and found that most showed phase separation. This result could be related to the fact that under certain conditions, amylose and amylopectin are incompatible in aqueous solutions (Kalichevsky and Ring 1987) producing phase separation during film formation (Rindlav-Westling et al. 2002). In addition, differences in the crystalline structures of the films also appeared to influence their surface topography.

As an initial conclusion, we can say that the surfaces of starch films reflect the effects of retrogradation and phase separation. Smooth surfaces are associated with amylopectin films, whereas amylose film surfaces are much rougher.

The topic of wetting has sparked a great deal of interest both from the fundamental and the applied point of view (Yuan and Lee 2013). Wettability studies usually involve the measurement of contact angles as the primary data, as this indicates the degree of wetting when a solid and a liquid interact. Small contact angles (≪90°) correspond to high wettability, while large contact angles (≫90°) denote low wettability.

Phan et al. (2005) prepared edible films made from agar (AG), cassava starch (CAS), normal rice starch (NRS), and waxy (glutinous) rice starch (WRS), and tested them for their potential use as edible packaging or coatings. Among other properties, the surface hydrophobicity and wettability of these films were investigated using the sessile drop contact angle method. SEM micrographs of the cross sections of the prepared films showed an irregular and rough topography, suggesting a heterogeneous structure due to the retrogradation and partial crystallization of the gelatinized starch before the formation of the films. The water vapor permeability (WVP) of the films was directly proportional to their amylopectin content. Similar results on the better barrier properties of amylose films compared with those of amylopectin films were reported by Stading et al. (1998). It can thus be said that films with poor water vapor barrier properties will show high hydrophilicity. Stading et al. (1998) evaluated the sensitivity of films to liquid moisture transfer by determining the adsorption rate of water droplets, finding that, in general, a higher contact angle indicated a lower adsorption rate. Nevertheless, this characteristic might be affected by the evaporation of excess water during the measurement period. Gutiérrez and González (2016) prepared edible films from cassava (Manihot esculenta C.) and taro (Colocasia esculenta L. Schott) starch plasticized with glycerol, as packaging materials. A comparison of these two starches revealed that the taro starch had a lower amylose content than the cassava starch (15.1 and 19.9%, respectively). Weak amylopectin–glycerol interactions facilitate water absorption, which could explain the higher moisture content of the taro starch films. Under weak starch–glycerol interactions, water can act as a plasticizer, a phenomenon commonly known as moisture plasticization. Glycerol–amylose interactions produce a reduction in the intra- and intermolecular interactions between the starch macromolecules increasing the movement and rearrangement of the chains. XRD diffraction patterns have shown that the areas under the crystalline peaks are larger in cassava starch films than in taro starch films, which correlates with the higher amylose content of cassava starch. In addition, SEM images showed that the cassava starch films had more compact structures, possibly associated with their high amylose content (Miles et al. 1985a, b). It has been previously established that a more compact structure leads to lower water adsorption as it makes interactions between the starch–glycerol and water less likely, leading to a decrease in the polar glycerol–starch character of the films (García-Tejeda et al. 2013; Pelissari et al. 2013) (Fig. 8).

Gutiérrez and González (2016) studied the color of cassava and taro starch films and found that that the indexes evaluated were higher for the cassava films than the taro films. They also found that cassava starch films were whiter and more opaque than taro starch films, confirming that materials with a lower amylose content are more transparent.

Following on from this, AFM studies showed that films made from cassava starch (with a higher amylose content) have a rougher surface than those made from taro starch. This agrees with the luminosity data: films with a high roughness profile are more opaque, i.e., less transparent (Reyes 2013). Apparently, the greater tendency to retrogradation of starch-based films with a higher amylose content creates torsional forces on the macromolecules, which generates a rougher surface.

Regarding wettability, the contact angles of the cassava starch films were higher than those of the taro starch films, which can be associated with their higher surface hydrophobicity (Ojagh et al. 2010). An increase in the water contact angle of biopolymers has been related to stronger intermolecular hydrogen bonding under the film surface (Karbowiak et al. 2006). Thus, a decrease in the number of Lewis sites could generate a decrease in the surface polarity of biopolymer films. This produces dry cassava starch film surfaces, since they do not contain enough energy to break the cohesive force of water (Vogler 1998). Gutiérrez and González (2016) claim that films derived from starches with a lower amylose content show a lower plasticizer–polymer compatibility. This allows the plasticizer to migrate toward the surface of the film, thereby increasing the number of Lewis sites and reducing the water contact angle (Fig. 8b). Higher contact angle values are thus recorded for films with a higher amylose content (Fig. 9). A diagrammatic summary of the surface properties of TPS films associated with their amylose content effects is provided in Fig. 10.

3 Effect of Exposure to Pulsed Light on the Surface Properties of TPS

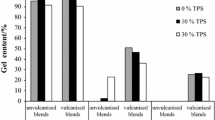

Crosslinking technologies have been used to modify TPS and other starch-based blends in order to improve their physical and mechanical properties (Zhou et al. 2009). As regards UV photo-crosslinking, photo-sensitizers or photo-initiators are generally incorporated into the materials during processing to produce reactive radicals that subsequently initiate crosslinking reactions under UV irradiation. This treatment generally produces a reduction in surface hydrophilicity and improved water resistance (Gutiérrez and González 2016).

Zhou et al. (2009) prepared crosslinked surfaces from TPS/PVA blends by applying ultraviolet (UV) irradiation, and using sodium benzoate as a photosensitizer. They then analyzed several physical properties of the films, such as the water contact angle, moisture absorption, degree of swelling, and water solubility. Mechanical properties were also measured to characterize the influence of the photo-crosslinking modification on the film surface. These authors observed that crosslinking considerably reduced the hydrophilic character of the TPS/PVA film surfaces, as well as enhancing water resistance. The tensile strength and Young’s modulus also increased, but the elongation at break of the films was lowered. These results were attributed to the increase in the crosslinking density of the macromolecular chains on the surface of the films.

Zhou et al. (2009) also found a direct correlation between the surface contact angle and surface roughness. In addition, the orientation of the polar hydroxyl groups on the contact surface had a significant influence on the contact angle measurements. An increase in the water contact angle indicates an enhancement of the hydrophobic character of the surface and a lower value for the polar component of the surface energy.

These same authors found that after surface photo-crosslinking, the water contact angle of the TPS/PVA films, jumped significantly and continued to rise with an increasing UV irradiation dose until 20 J/cm2. In contrast, a decrease in the water contact angle as a function of the UV irradiation dose was observed on the photo-crosslinked surface of corn starch sheets (Zhou et al. 2008). These authors proposed that as the crosslinking reaction progresses, more and more hydroxyl groups on the surface layer, either from TPS or PVA molecular chains, are consumed and are thus not available to water. In addition, they found that as the UV irradiation dose increased, the resulting crosslinked structure caused both the degree of swelling and the water solubility to decrease, thus these crosslinking points restrict the molecular mobility of the polymer chains.

Gutiérrez and González (2016) evaluated the effects of pulsed light (PL) treatment, as a crosslinking method, on some properties of edible films derived from cassava (Manihot esculenta C.) and taro (Colocasia esculenta L. Schott) starch plasticized with glycerol, relevant to their use as packaging materials. They found that samples deteriorated after PL treatment compared to control films as demonstrated by an increase in the contact angle, roughness, and crystallinity, and a decrease in the tensile strength, transparency, and water content regardless of the amylose content of the starch used to develop the films. In addition, the degree of crystallinity of the films exposed to PL was slightly higher than that of the untreated ones, a phenomenon that can be associated with the retrogradation of starch during aging or by the deterioration process, which reduces chain mobility (García-Tejeda et al. 2013, Bertuzzi et al. 2007). They also found that films treated with PL showed a significant reduction in the moisture content, possibly due to the crosslinking caused by the UV radiation on the films treated with PL (Andrady et al. 1998, Cui et al. 2013). After PL treatments, the films displayed a more compact structure reflecting their lower moisture content. It is worth noting that the molecular weight of the cassava starch-based films (with a higher amylose content) decreased, whereas the molecular weight of the taro starch films (with less amylose content) slightly increased. Based on this, Gutiérrez and González (2016) suggested that the crosslinking reaction in taro starch films produced a slightly more pronounced increase in the water contact angle than the cassava starch films. In the cassava starch films, the decrease in their molecular weight suggests the de-polymerization of their biopolymer chains. This exposes the amylose chains resulting in a less conspicuous increase in the contact angle (Fig. 11). A diagrammatic summary of the properties of TPS films modified by PL is provided in Fig. 12.

4 Effect of the Chemical Modification of Starch on the Surface Properties of TPS

Two of the main advantages starch has over other materials are its low cost and availability in very large amounts from renewable resources. These aspects, together with the fact that starch may be used in thermoplastic formulations, make it one of the best options for preparing biodegradable polymers. However, the use of starch as a substitute for conventional petroleum-based plastics has been limited by its brittleness and hydrophilicity (Shogren et al. 1998). This has meant that TPS compositions developed thus far cannot be used for many applications, including packaging, and intensive work has been done to overcome these drawbacks (Dufresne and Vignon 1998, Averous et al. 2000, 2001; Curvelo et al. 2001, Carvalho et al. 2005). Several strategies have been attempted in order to widen the usability of starch as a biodegradable thermoplastic material suitable for packaging applications. One possibility is to modify the starch. Chemical modification involves the introduction of functional groups into the starch molecule by phosphation, acetylation, and oxidation, among others. Starches can also be physically modified by heat-moisture treatment and annealing. Chemical modification causes changes in the molecular structure or introduces functional groups, thus improving the applicability of plant-derived materials in both the food and non-food industries (Xia et al. 2005; Bertolini 2010; Nafchi et al. 2013).

Carvalho et al. (2005) prepared TPS films plasticized with 20 and 30 wt% glycerol. The materials obtained were treated with various reagents (phenyl isocyanate (PhNCO), a phenol blocked polyisocyanate of trimethylol propane and toluene diisocyanate (TMP-TDI-Phenol), a styrene-co-glycidyl methacrylate (PS-GMA) copolymer and stearoyl chloride (StCl)) in order to make their surfaces less sensitive to moisture. In addition, two different techniques were used to produce the modifications: (a) suspension at room temperature and (b) dipping in the reactant solution followed by heating under reflux.

Carvalho et al. (2005) found that the polar contribution was drastically reduced in the modified polymers, indicating that the surfaces had become more hydrophobic. The treatment with phenyl isocyanate in xylene proved the most effective.

In addition, all the chemical treatments carried out produced an increase in the contact angle values with water, together with a decrease in the purely dispersive liquids, confirming that coupling reactions took place. In particular, the phenyl isocyanate produced some excellent results, probably because of the very high reactivity of this compound, which gave rise to the formation of a densely packed monolayer of phenyl moieties on the surface. Treatment with stearoyl chloride also gave some interesting results (very low values for the polar component). However, the formation of HCl in the coupling reaction with the OH groups might limit its practical use.

Carvalho et al. (2005) concluded that the use of these polymeric reagents offers a further advantage in that a given macromolecule can couple with OH groups coming from both the starch and the glycerol simultaneously, thus immobilizing the latter species. The dipping + heating treatment was found to be the most appropriate for practical applications.

Gutiérrez and González (2017) prepared films from plantain flour with the incorporation of different concentrations of Aloe vera (Av) gel. They found that the Av gel produced crosslinking of the starch found in the flour, resulting in films that were smoother, more transparent, more rigid and plastic, dryer, and with increased hydrophobicity (Fig. 13).

As already mentioned, the Av gel produced a decrease in the moisture content of the plantain flour films. This could be associated with strong starch–glycerol interactions, which inhibit water absorption (Cyras et al. 2006; Flores et al. 2007; Hu et al. 2009; Gutiérrez et al. 2015). In addition, color testing (opacity of the film) revealed that films with a lower Av gel content showed a tendency to retrograde. AFM studies also showed that the surface roughness of films made from plantain flour with a higher Av gel content tended to decrease, which is consistent with the luminosity results (high roughness profiles were more opaque, i.e., less transparent). In addition, the contact angle increased as a function of Av content, which agrees with all the previous results, and also with the fact that the organic acids present in Av gel produce stronger hydrogen bond interactions between the starch and the glycerol, probably due to the crosslinking of the former. The SEM images were also consonant with the other results: the plantain flour-based films with higher Av gel content had the most closed structures, which act as a physical barrier to water.

Similarly, the incorporated Av gel had a positive effect on all the mechanical parameters measured: films with higher Av gel content were markedly more rigid, showed a greater strain at break, and had higher enthalpy (ΔH) and glass transition temperatures (T g). This last is further evidence of the crosslinking of the starch in the presence of the Av gel: crosslinking limits the movement of the molecular segments, resulting in an increase in T g. A diagrammatic summary of the properties of chemically modified TPS films is provided in Fig. 14.

5 Effect of Plasticizers on the Surface Properties of TPS

In general, plasticization refers to a change in the thermal and mechanical properties of a given polymer which involves the following:

-

A decrease in stiffness at room temperature.

-

A decrease in the temperature at which substantial deformations can be produced with moderate forces.

-

An increase in the elongation to break at room temperature.

-

An increase in the toughness (impact strength) at the lowest serviceable temperature.

These effects can be achieved by combining the polymer of interest with a low molecular weight compound or another polymer, or by introducing a co-monomer into the original polymer to reduce crystallinity and increase chain flexibility.

Medina et al. (2015) prepared cassava starch-based films with different amounts of yerba mate (Y) extract as an antioxidant (0–20 wt%). They found that films with 5 wt% of the extract (TPS-Y5) showed a lower loss of antioxidant than films with 20 wt% (TPS-Y20). In addition, the incorporation of the Y extract led to increased values of surface roughness and contact angle, indicating an increase in the hydrophobicity of the film surface. This was confirmed by a decrease in water vapor permeability and water content values. The greater hydrophobicity of the Y extract-containing films is due to the fact that covalent and hydrogen interactions between the polysaccharide network and the polyphenol compounds limit the availability of the hydrogen groups to form hydrophilic bonds, thus reducing the affinity of the films to water (Siripatrawan and Harte 2010). Previous studies have positively correlated the surface roughness of a material with its hydrophobicity (Erbil et al. 2003). The contact angle of a material is also related to the roughness and hydrophobicity: a rougher surface increases the contact angle and therefore, the hydrophobicity of the material (Erbil et al. 2003). This is because a rougher surface increases the fraction of trapped air and thereby the water contact angle (Kim et al. 2014). Regarding mechanical properties, Medina et al. (2015) found that the addition of the Y extract resulted in a decrease in the elastic modulus and tensile strength, but a significant increase in the strain at break values. This resulted in more flexible materials as the relaxation processes took place at lower temperatures compared to the matrix without Y extract. Other mechanical properties of the extract-containing films were also typical of plasticized films. Finally, cassava starch films containing Y appear promising as coatings for retarding the oxidation of food products, thus increasing their shelf life. In addition, according to Medina et al. (2016), films with a smoother surface are apparently more biodegradable.

Gutiérrez et al. (2016a) prepared films from native and modified plantain flour, plasticized with glycerol, with or without the addition of beet flour. Analysis of the prepared flours showed that the fiber content of the modified plantain flour increased by about 20%, possibly as a result of the leaching of proteins and fatty material during its modification. The phosphorus content, degree of substitution (DS), and apparent amylose content also decreased by about 50% in the modified flour, due to the crosslinking of the amylose.

Gutiérrez et al. (2016a) observed that the incorporation of beet flour resulted in an increase in water solubility that became significant when combined with the modified flour. This behavior was associated with the sugars contained in beet flour, which conferred a more polar character to the films. In contrast, native plantain flour-based films exhibited higher contact angles, reflecting an increase in surface hydrophobicity. The surface of these films was dryer as they do not have enough energy to break the cohesive force of water (Vogler 1998). These types of hydrophobic surfaces require Lewis sites for surface wetting to occur. In addition, their higher amylose content gives them a closed structure (observed by SEM) resulting in a further, physical impediment to wetting. Conversely, phosphated plantain flour-based films showed a lower contact angle. This could be related to the addition of phosphate groups that strengthen the polar character of the surface, increasing the density of Lewis sites. These sites would be close to the hydrogen bond network of water, and would thus compete with the cohesive forces, leading to the collapse of water structure on the hydrophilic surface and decreasing the contact angle. The incorporation of beet flour produced a decrease in the contact angle for both native and modified plantain flour as a consequence of the polar character of the sugars contained within it.

Gutiérrez et al. (2016a) found that the incorporation of beet flour also enabled the preparation of intelligent films sensitive to alkaline pH changes. In addition, they demonstrated that betalains found in the beet flour interacted more efficiently with the phosphated plantain flour, limiting its immediate response to pH changes.

In addition, other components (proteins and sugars) in the beet flour produced more flexible films (an increase in the elongation at break: plasticizing effect). This can be associated with hydrogen bond interactions between these components and the plantain flours, which could explain the decrease in the contact angle together with the increase in the thickness and solubility of these films.

Furthermore, Gutiérrez et al. (2016b) found that beet flour incorporated into edible films prepared from native and phosphate-modified plantain flour acted as a plasticizer, producing smoother, wetter, and more transparent films. The beet flour also improved the transmittance of the films and their thermodynamic stability. According to the results obtained from differential scanning calorimetry (DSC), the addition of beet flour destroys the intra- and intermolecular interactions between starch–starch chains, thus strengthening hydrogen bonding interactions between the hydroxyl groups of the starch chains and the polar compounds of the beet flour. This enables the starch chains to become more mobile and produces a reduction in the T g confirming the plasticizer effect. The increase in the transmittance of the films (more evident in the case of the phosphate-modified plantain flour) produced by the plastizicing effect of the beet flour could be related to an increase in the degrees of freedom of the OH groups, which itself is a consequence of the greater mobility of the starch chains (Medina et al. 2016). Thus, an increase in transmittance is related to a decrease in the T g. The SEM images taken were consistent with these results and revealed the plasticizer effect of the beet flour, which inhibited the recrystallization of the starch. AFM images showed that films made from native plantain flour (with a higher amylose content) displayed greater surface roughness than those made from phosphated plantain flour: a rougher surface gives more opaque (less transparent) films. This is probably due to the fact that a rougher surface texture does not permit the reflection of light which is thus absorbed by the film (Reyes 2013, Gutiérrez and González 2016, 2017). The incorporation of the beet flour generated a smoother surface due to its plasticizing effect. This inhibited starch retrogradation thereby avoiding the creation of holes. Similarly, a smoother surface was related to an increase in the transparency of these systems (Fig. 15).

Gutiérrez et al. (2016a, b) also showed that modified plantain flour crosslinked with sodium trimetaphosphate produced more transparent, smoother, more plastic, and biodegradable films. The decrease in the moisture content of the phosphated plantain flour films was associated with the strong hydrogen bond interactions between the phosphated flour and the plasticizer, which limits possible water adsorption by these polar compounds (Gutiérrez et al. 2015). XRD results also suggest an increase in the number of hydrogen bond interactions, caused by the plasticizer effect of beet flour (Gutiérrez et al. 2016b).

After analyzing their results, Gutiérrez et al. (2016a, b) concluded that the minor interaction between the starch–starch chains produced more transparent, less crystalline, smoother, more plastic, and biodegradable films. A diagrammatic summary of the effects of plasticizers on the surface properties of TPS films is provided in Fig. 16.

6 Effect of Composites on the Surface Properties of TPS

TPS on its own often cannot meet all the requirements of a packaging material. However, the incorporation of environmentally acceptable reinforcing materials has proved an effective method to obtain starch-based biocomposites with improved physical and mechanical properties (Cyras et al. 2008). In this section, we discuss the surface properties of TPS materials with added fillers.

6.1 Effect of Clay/Starch Composite Materials

The incorporation of clays has been reported as a good approach to improve polysaccharide-based film properties. Kaolinite, smectite, and sepiolite are the most frequently used clays in polymer nanocomposite studies. These clays are environmentally friendly, naturally abundant, and economical. Smectites, in particular, are often chosen for the preparation of polymer-based nanocomposites. The most widely studied smectite clay filler is montmorillonite (Mnt) (de Azeredo 2009). Mnt is a hydrated alumina-silicate-layered clay consisting of two-dimensional layers, 1 nm thick, made up of two silica tetrahedrals fused to an edge-shared octahedral sheet of either aluminum or magnesium hydroxide (Ray and Bousmina 2005). The imbalance of the negative surface charges is compensated by exchangeable cations (typically Na+ and Ca+2). The parallel layers are stacked together by weak electrostatic forces leading to a regular van der Waals gap between the layers called the interlayer or gallery. As the forces that hold the stacks together are relatively weak, the intercalation of small molecules between the layers is straightforward. Thus, in addition to their low cost, high surface area, and large aspect ratio, the rich intercalation chemistry of these clays enables them to be easily chemically modified.

In order to obtain nanocomposites with improved final properties, the clay layers must be highly dispersed in the polymer matrix (intercalated or exfoliated) as opposed to being aggregated as tactoids (Ray and Okamoto 2003). The major problem in preparing these composites is thus to separate the layers of the clay as they are initially agglomerated. The most significant challenges in the development of well-dispersed clay/polymer nanocomposites are as follows (Ollier et al. 2014):

-

The maximization of chemical compatibility between the clay surface and the polymer matrix, i.e., how to make the clay more compatible with starch, which facilitates the dispersion of the clay layers.

-

The selection of the most appropriate processing method in order to provide optimal conditions for the dispersion of the clay platelets.

The presence of exfoliated clay layers in polymer structures has been shown to greatly improve barrier properties since they obstruct diffusion gases and water molecules forcing them to follow a tortuous path, and thus minimizing one of the main limitations of biopolymer films (de Azeredo 2009). The clay layers also induce changes in the molecular mobility of the polymer matrix, which may enhance its thermal and mechanical properties as well as oxidation stability, among other advantages. It is important to mention that all these improvements can be achieved with low amounts of Mnt (below 10 wt%).

Mnt has been extensively employed to reinforce native starch (Slavutsky et al. 2012), derivative starch (Gao et al. 2012), carboxymethyl cellulose (CMC) (Gutiérrez et al. 2012), starch/CMC (Almasi et al. 2010; Ghanbarzadeh et al. 2013), and starch/chitosan films (Ghani et al. 2013). However, very few of the studies concerned with clay/starch nanocomposites have analyzed in detail the surface properties of these materials.

Aouada et al. (2013) prepared Mnt/TPS bionanocomposite films. They employed a pristine Mnt and focused on the processing procedure of the materials. The composites were prepared by intercalation from solution followed by melt processing, with 1 and 5 wt% Mnt. The authors affirmed that the intercalation/exfoliation of the clay into TPS is achieved when the shear rate increases. Additionally, swelling may expand the clay galleries, thus facilitating their dispersion (Paul and Robeson 2008). Measurements of water absorption confirmed the stability of the nanocomposites and showed that the addition of natural Mnt reduced the bulk hydrophilicity of the TPS matrix. A decrease in water absorption after increasing the clay content of the TPS matrix was associated with the following phenomena: (1) the migration of a fraction of the glycerol plasticizer to the clay phase, which reduces the glycerol content of the polymeric matrix and (2) the reinforcement effect of the clay due to high interaction between the clay and the TPS matrix, which makes the matrix three-dimensionally more stable with limited expansion. Furthermore, water contact angle measurements showed that the addition of clay also reduced the surface hydrophilicity of the nanocomposites. The authors associated this improvement with the novel methodology used to prepare the TPS bionanocomposites. Cyras et al. (2008) observed a different behavior when they dispersed Mnt into TPS by the casting method. In their case, the clay nanolayers formed an intercalated structure but not complete exfoliation. The nanocomposites were also more hydrophilic than the neat starch due to their high surface polarity, as measured by the contact angle. This can be attributed to the non-exfoliated structure of the clay in the starch matrix, which causes lower hydrogen bonding interactions compared to materials developed by Aouada et al. (2013) (obtained by a different processing protocol). However, maximum water absorption as well as the rate of water absorption was reduced by the addition of clay to the TPS. This behavior was attributed to the formation of a tortuous pathway due to the presence of the clay layers.

Wilpiszewska et al. (2015) prepared carboxymethyl starch (CMS)-based biodegradable films with calcium-rich montmorillonite (Ca-Mnt) by the casting method; glycerol and citric acid were used as the plasticizer and crosslinking agents, respectively. CMS is a derivative starch obtained by the Williamson process, by which ionic substituents are introduced into the starch structure through reactions with monochloroacetic acid sodium salt (Yanli et al. 2009). The intercalated structure of Ca-Mnt was observed in all composites; however, the most efficient clay platelet dispersion was noted for the 5 wt% Ca-Mnt/CMS film. The introduction of Ca-Mnt into CMS produced an increase in the water contact angle from 70° for the neat CMS films, to 107° for the films containing 5 wt% Ca-Mnt/CMS, i.e., the surface became more hydrophobic. A lower contact angle value for the 7 wt% Ca-Mnt/CMS films compared to the 5 wt% Ca-Mnt/CMS films indicated that clay dispersion was less effective in the former. This was confirmed by XRD. In addition, there was a negative correlation between clay content and water absorption. The higher Ca-Mnt content in this composite could lead to stronger hydrogen bonding between the hydroxyl groups of the starch, and the hydroxyl or carboxylic groups of the CMC and −OH of the clay layers (Huang et al. 2004). This would result in a stronger structure with fewer active sites for water absorption.

Although clays are naturally compatible with starch, they can be chemically modified to obtain composites with improved properties. Kampeerapappun et al. (2007) prepared Mnt/cassava starch composite films, with chitosan, a natural cationic polysaccharide, as a compatibilizing agent for Mnt modification and glycerol as a plasticizer. Chitosan is compatible with the starch matrix as it has amine and hydroxyl groups which can interact via hydrogen bonding, as well as being ion-exchangeable with clay (Darder et al. 2003). As a result, the average particle size of chitosan-treated Mnt was notably smaller than that of pristine Mnt/starch film. Improvements in the physical properties include reduced surface wettability and a decrease in the water vapor transmission rate and moisture absorption. An interesting finding was that the addition of neat Mnt did not affect film surface hydrophobicity. However, at a fixed clay content, an increase in the percentage of added chitosan produced a significant increase in the water contact angle values of the composite films. Moreover, chitosan content had a significant effect on the moisture uptake values (which is related to the bulk hydrophobicity) of the composite films compared with neat Mnt composites. The authors suggested that the contribution of chitosan to the surface and bulk hydrophobicity was associated with the role of available hydrophobic acetyl groups present in the structure of incompletely deacetylated chitosan chains. In addition, the tensile properties of the composite films were improved by the addition of both chitosan and Mnt.

Abreu et al. (2015) developed Mnt modified with a quaternary ammonium salt C30B/starch nanocomposite (C30B/ST-NC), silver nanoparticles/starch nanocomposite (Ag-NPs/ST-NC), and both silver nanoparticles/C30B/starch nanocomposites (Ag-NPs/C30B/ST-NC) films by the solution casting procedure. The silver nanoparticles (Ag-NPs) were incorporated and synthesized in situ by the chemical reduction method. The incorporation of both types of nanoparticles, Ag-NPs and C30B, had a synergetic effect, resulting in a material with greater homogeneity and better clay dispersion, as demonstrated by SEM and XRD. In addition, the Ag-NPs/C30B/ST-NC film exhibited an increase in the storage modulus value (calculated from DMA measurements) compared to the starch film. It is known that the effect of clay in polymer matrices is to increase the modulus or stiffness via reinforcement mechanisms described by composite theories (Fornes and Paul 2003). The incorporation of C30B by itself, however, caused a significant decrease in the water contact angle value. This suggests that there was an increase in the polarity, which can be attributed to the incorporation of more hydrophilic groups in the clay. More hydrophobic surfaces were achieved when both nanoparticles were added. Abreu et al. (2015) also found that the composite films they obtained showed antimicrobial activity against Staphylococcus aureus, Escherichia coli, and Candida albicans. Furthermore, the migration of components from the nanostructured starch films was minor and under the legal limits. Thus, according to the authors, starch films loaded with C30B and Ag-NPs have the potential to be used as nanostructured packaging materials.

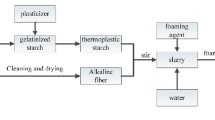

6.2 Effect of Natural Fibers/Starch Composite Materials

Adding natural fibers to starch-based composites in order to obtain more resistant and stable films has given some promising results. Moreover, natural fibers provide positive environmental benefits regarding ultimate disposability and the use of raw materials (Singha and Thakur 2008a, b, c; Thakur et al. 2013a, b, c, d). Generally speaking, the properties of natural fibers, such as a high aspect ratio, low cost, renewability, biodegradability, high specific strength and modulus, low density, and reactive surface sites that facilitate grafting chemical species to achieve other useful surface properties, make them a very attractive alternative (Singha and Thakur 2009a, b, c, d; Faruk et al. 2012, López et al. 2015). Several types of natural fibers such as cotton, hemp, sisal, jute, flax, ramie, coir, and cellulose have been explored (Faruk et al. 2012; Pappu et al. 2016). Natural fibers can be processed in different ways to yield reinforcing elements with different properties (Corobea et al. 2016).

Cellulose is a very abundant natural polysaccharide, composed of linear chains of β-1,4 linked glucopyranose units. These polymer chains are associated by hydrogen bonds forming bundles of fibrils, also called microfibrillar aggregates, with high axial stiffness. Within cellulose microfibrils there are highly ordered regions (crystalline phases) alternating with disordered domains (amorphous phases) (Azizi Samir et al. 2005). The crystalline regions contained within the cellulose microfibrils can be extracted by various methods, resulting in cellulose nanocrystals (Moon et al. 2011).

Cao et al. (2008) prepared nanocomposite films made from plasticized starch (PS) reinforced with hemp cellulose nanocrystals (HCNs). Loadings were between 0 and 30 wt%, and prepared by casting from aqueous suspensions. A homogeneous distribution of the HCNs in the PS matrix was observed, indicating strong adhesion between the fillers and matrix. The uniform distribution of the fillers in the matrix played an important role in improving the mechanical performance of the resulting nanocomposite films. With the incorporation of HCN fillers into the PS matrix, the contact angle of the nanocomposites significantly increased. This behavior was associated with the highly crystalline hydrophobic cellulose compared with the hydrophilic starch. Moreover, the presence of HCNs caused a reduction in the rate of water adsorption by the PS/HCN nanocomposites. The authors concluded that the improvements in the performance of the nanocomposites were due to chemical similarities between the starch and cellulose, the nanometric size effect of the HCNs, and the hydrogen bonding interactions between the fillers and the matrix.

Spiridon et al. (2013) prepared starch–cellulose composite materials from modified starch microparticles, synthesized from starch previously crosslinked by reaction with tartaric acid. These starch–cellulose materials were then used as fillers within a glycerol plasticized-corn starch matrix prepared by the casting technique. Cellulose fibers, obtained from bleached birch industrial pulp, were also incorporated into the polymeric matrix. The crosslinked starch microparticles produced an increase in the water contact angle due to the fact that −OH groups on the surface of the material were less available to establish hydrogen bonds with the water molecules. The addition of cellulose fibers increased the hydrophobic properties of the starch-based films even further. This effect was limited to low cellulose contents, but at high cellulose contents, poor wetting properties of the films were observed. The presence of the cellulose fibers also enhanced the water resistance of the films although there was a slight decrease in transparency. Although cellulose is a hydrophilic polymer, the high degree of crystallinity and tight structure of the microfibrils within the fibers tended to decrease the water adsorption capacity of the composite compared with that of amorphous starch. The hydrogen bonding interactions between the starch and cellulose stabilized the starch matrix even when it was placed in a highly moisturized environment. Due to the strong intermolecular hydrogen bonds, the thermal stability and mechanical properties of the starch–cellulose composite films were improved compared with the neat matrix. The T g increased with increasing amounts of cellulose in the composites. This was associated with the anti-plasticization of amylopectin-rich domains by the presence of the cellulose fibers.

López et al. (2015) prepared biocomposite films from TPS containing 0.5% w/w fibrous residue obtained from Pachyrhizus ahipa starch extraction (PASR) by melt-mixing and compression molding. PASR is mainly constituted by the remaining cell walls and natural fibers. Chemical analysis of the residue indicated that fiber and starch were the principal components. A continuous PASR-TPS interface was observed by SEM, confirming the good adhesion of the fibrous residue to the starch matrix. SEM micrographs of the TPS surfaces revealed the presence of some non-molten starch granules and micropores, as well as numerous superficial micro-cracks. Films containing PASR showed fewer superficial cracks than neat TPS, but their fracture surfaces were more irregular. Films with the filler also showed far fewer non-molten starch granules. The authors associated this effect with the fact that starch granular fusion was affected by the presence of the fibers during the thermo-plastic processing of the TPS (Ma et al. 2005; Luna et al. 2009), i.e., the filler had an effect on the plasticization of the corn starch (Martins et al. 2009). Based on previous research, the authors mentioned that the presence of the filler during thermo-mechanical processing lead to improved melting of the starch granules. AFM images also demonstrated the effect of PASR on starch melting and plasticization during TPS processing. In addition, the presence of PASR increased the surface roughness of the starch films, due to randomly oriented fiber agglomerates, and PASR-TPS films showed significantly lower water vapor permeability values. Finally, the PASR filler increased the maximum tensile strength and Young’s modulus of the TPS films, indicating that these matrices were more resistant.

In conclusion, we can say that the strong hydrogen bonding interactions between fillers and TPS prevent phase separation with the plasticizer. This decreases the number of Lewis sites on the surface of these materials, since the plasticizer cannot migrate to the surface. The water contact angle is thus increased, and the surface roughness decreased (Fig. 17).

7 Conclusions and Future Perspectives

Up until now, the surface properties of TPS have been little studied with regard to the inter- and intramolecular interactions that occur within biopolymer films, although theoretical information on this topic is available in the literature. Nevertheless, interest in the surface effects of these types of materials is surging, since they can serve as a support for biocatalysts (enzymes). This line of research could enable the development of innovative active packaging systems, which can remove substrates such as lactose. Thus, lactose-free products, for example, could be obtained by the use of active packaging with the appropriate surface properties. With this in mind, our research group is currently developing a standard methodology based on the measurement of the contact angle of starch-based materials. This would enable us to determine the degree of aging in these types of materials, and the extent of the loss of their surface properties during storage. This could help to rapidly evaluate these materials in an easy and economical way that would also be applicable at an industrial scale. Finally, the study of the surface properties of TPS materials is promising for the development of other products that will surely have a major impact on future society.

References

Abreu AS, Oliveira M, de Sá A, Rodrigues RM, Cerqueira MA, Vicente AA, Machado AV (2015) Antimicrobial nanostructured starch based films for packaging. Carbohyd Polym 129:127–134

Almasi H, Ghanbarzadeh B, Entezami AA (2010) Physicochemical properties of starch-CMC-nanoclay biodegradable films. Int J Biol Macromol 46:1–5

Andrady AL, Hamid SH, Hu X, Torikai A (1998) Effects of increased solar ultraviolet radiation on materials. J Photochem Photobiol, B 46(1):96–103

Aouada FA, Mattoso LH, Longo E (2013) Enhanced bulk and superficial hydrophobicities of starch-based bionanocomposites by addition of clay. Ind Crops Prod 50:449–455

Averous L, Fringant C, Moro L (2001) Plasticized starch–cellulose interactions in polysaccharide composites. Polymer 42(15):6565–6572

Averous L, Moro L, Dole P, Fringant C (2000) Properties of thermoplastic blends: starch–polycaprolactone. Polymer 41(11):4157–4167

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromol 6(2):612–626

Baldwin PM, Adler J, Davies MC, Melia CD (1998) High resolution imaging of starch granule surfaces by atomic force microscopy. J Cereal Sci 27(3):255–265

Baldwin PM, Melia CD, Davies MC (1997) The surface chemistry of starch granules studied by time-of-flight secondary ion mass spectrometry. J Cereal Sci 26(3):329–346

Bertolini AC (2010) Trends in starch applications. Starches: characterization, properties, and applications. Taylor and Francis Group, LLC, Abingdon, pp 1–20

Bertuzzi MA, Vidaurre EC, Armada M, Gottifredi JC (2007) Water vapor permeability of edible starch based films. J Food Eng 80(3):972–978

Cao X, Chen Y, Chang PR, Stumborg M, Huneault MA (2008) Green composites reinforced with hemp nanocrystals in plasticized starch. J Appl Polym Sci 109(6):3804–3810

Carvalho AJF, Curvelo AAS, Gandini A (2005) Surface chemical modification of thermoplastic starch: reactions with isocyanates, epoxy functions and stearoyl chloride. Ind Crops Prod 21(3):331–336

Cui H, Hanus R, Kessler MR (2013) Degradation of ROMP-based bio-renewable polymers by UV radiation. Polym Degrad Stab 98(11):2357–2365

Curvelo AAS, De Carvalho AJF, Agnelli JAM (2001) Thermoplastic starch–cellulosic fibers composites: preliminary results. Carbohyd Polym 45(2):183–188

Corobea MC, Muhulet O, Miculescu F, Antoniac IV, Vuluga Z, Florea D et al. (2016) Novel nanocomposite membranes from cellulose acetate and clay-silica nanowires. Polym Adv Technol 27(12):1586–1595

Cyras VP, Tolosa Zenklusen MC, Vazquez A (2006) Relationship between structure and properties of modified potato starch biodegradable films. J Appl Polym Sci 101(6):4313–4319

Cyras VP, Manfredi LB, Ton-That MT, Vázquez A (2008) Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohyd Polym 73(1):55–63

Darder M, Colilla M, Ruiz-Hitzky E (2003) Biopolymer-clay nanocomposites based on chitosan intercalated in montmorillonite. Chem Mater 15(20):3774–3780

de Azeredo HM (2009) Nanocomposites for food packaging applications. Food Res Int 42(9):1240–1253

Du Q, Freysz E, Shen YR (1994a) Surface vibrational spectroscopic studies of hydrogen bonding and hydrophobicity. Science 264(5160):826–828

Du Q, Freysz E, Shen YR (1994b) Vibrational spectra of water molecules at quartz/water interfaces. Phys Rev Lett 72(2):238

Du Q, Superfine R, Freysz E, Shen YR (1993) Vibrational spectroscopy of water at the vapor/water interface. Phys Rev Lett 70(15):2313

Dufresne A, Vignon MR (1998) Improvement of starch film performances using cellulose microfibrils. Macromolecules 31(8):2693–2696

Erbil HY, Demirel AL, Avcı Y, Mert O (2003) Transformation of a simple plastic into a superhydrophobic surface. Science 299(5611):1377–1380

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Flores S, Famá L, Rojas AM, Goyanes S, Gerschenson L (2007) Physical properties of tapioca-starch edible films: influence of filmmaking and potassium sorbate. Food Res Int 40(2):257–265

Fornes TD, Paul DR (2003) Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 44(17):4993–5013

Gao W, Dong H, Hou H, Zhang H (2012) Effects of clays with various hydrophilicities on properties of starch–clay nanocomposites by film blowing. Carbohyd Polym 88:321–328

García-Tejeda YV, López-González C, Pérez-Orozco JP, Rendón-Villalobos R, Jiménez-Pérez A, Flores-Huicochea E, Solorza-Feria J, Bastida CA (2013) Physicochemical and mechanical properties of extruded laminates from native and oxidized banana starch during storage. LWT Food Sci Technol 54(2):447–455

Ghanbarzadeh B, Almasi H, Oleyaei SA (2013) A novel modified starch/carboxymethyl cellulose/montmorillonite bionanocomposite film: structural and physical properties. Int J Food Eng 10:121–130

Ghani SWA, Bakar AA, Samsudin SA (2013) Mechanical properties of chitosan modified montmorillonite filled tapioca starch nanocomposite films. Adv Mat Res 686:145–154

Gutiérrez MQ, Echeverría I, Ihl M, Bifani V, Mauri AN (2012) Carboxymehtylcellulose-montmorillonite nanocomposite films activated with murta (Ugni molinae Turcz) leaves extract. Carbohyd Polym 87:1495–1502

Gutiérrez TJ, González G (2016) Effects of exposure to pulsed light on surface and structural properties of edible films made from cassava and taro starch. Food Bioproc Tech 9(11):1812–1824

Gutiérrez TJ, González, G (2017) Effect of cross-linking with Aloe vera gel on surface and physicochemical properties of edible films made from plantain flour. Food Biophys 12(1):11–22

Gutiérrez TJ, Guzmán R, Medina C, Famá L (2016a) Effect of beet flour on films made from biological macromolecules: native and modified plantain flour. Int J Biol Macromol 82:395–403

Gutiérrez TJ, Suniaga J, Monsalve A, García NL (2016b) Influence of beet flour on the relationship surface-properties of edible and intelligent films made from native and modified plantain flour. Food Hydrocoll 54:234–244

Gutiérrez TJ, Morales NJ, Pérez E, Tapia MS, Famá L (2015) Physico-chemical properties of edible films derived from native and phosphated cush-cush yam and cassava starches. Food Packag Shelf Life 3:1–8

Hu G, Chen J, Gao J (2009) Preparation and characteristics of oxidized potato starch films. Carbohyd Polym 76(2):291–298

Huang MF, Yu JG, Ma XF (2004) Studies on the properties of montmorillonite-reinforced thermoplastic starch composites. Polymer 45:7017–7023

Kalichevsky MT, Ring SG (1987) Incompatibility of amylose and amylopectin in aqueous solution. Carbohyd Res 162(2):323–328

Kampeerapappun P, Aht-ong D, Pentrakoon D, Srikulkit K (2007) Preparation of cassava starch/montmorillonite composite film. Carbohyd Polym 67(2):155–163

Karbowiak T, Debeaufort F, Champion D, Voilley A (2006) Wetting properties at the surface of iota-carrageenan-based edible films. J Colloid Interface Sci 294(2):400–410

Kim SI, Lee BR, Lim JI, Mun CH, Jung Y, Kim JH, Kim SH (2014) Preparation of topographically modified poly(l-lactic acid)-b-poly(ɛ-caprolactone)-b-poly(l-lactic acid) tri-block copolymer film surfaces and its blood compatibility. Macromol Res 22(11):1229–1237

Lee CY, McCammon JA, Rossky PJ (1984) The structure of liquid water at an extended hydrophobic surface. J Chem Phys 80(9):4448–4455

López OV, Versino F, Villar MA, García MA (2015) Agro-industrial residue from starch extraction of Pachyrhizus ahipa as filler of thermoplastic corn starch films. Carbohyd Polym 134:324–332

Luna G, Villada H, Velasco R (2009) Fique’s fiber reinforced thermoplasticstarch of cassava: preliminary. Dyna 159:145–151

Ma X, Yu J, Kennedy JF (2005) Studies on the properties of naturalfibers-reinforced thermoplastic starch composites. Carbohyd Polym 62(1):19–24

Martins IMG, Magina SP, Oliveira L, Freire CSR, Silvestre AJD, Neto CP, Gandini A (2009) New biocomposites based on thermoplastic starch and bacterial cellulose. Compos Sci Technol 69(13):2163–2168

Medina C, González P, Goyanes S, Bernal C, Famá L (2015) Biofilms based on cassava starch containing extract of yerba mate as antioxidant and plasticizer. Stärke 67(9–10):780–789

Medina C, Gutiérrez TJ, Goyanes S, Bernal C, Famá L (2016) Biodegradability and plasticizing effect of yerba mate extract on cassava starch edible films. Carbohyd Polym 151:150–159

Miles MJ, Morris VJ, Orford PD, Ring SG (1985a) The roles of amylose and amylopectin in the gelation and retrogradation of starch. Carbohyd Res 135(2):271–281

Miles MJ, Morris VJ, Ring SG (1985b) Gelation of amylose. Carbohydr Res 135(2):257–269

Miculescu M, Thakur VK, Miculescu F, Voicu SI (2016) Graphene-based polymer nanocomposite membranes: a review. Polym Adv Technol 27(7):844–859

Michalska-Pożoga I, Tomkowski R, Rydzkowski T, Thakur VK (2016) Towards the usage of image analysis technique to measure particles size and composition in wood-polymer composites. Ind Crops Prod 92:149–156

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994

Nafchi AM, Tabatabaei RH, Pashania B, Rajabi HZ, Karim AA (2013) Effects of ascorbic acid and sugars on solubility, thermal, and mechanical properties of egg white protein gels. Int J Biol Macromol 62:397–404

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122(1):161–166

Ollier R, Lanfranconi M, Alvarez V (2014) Chemical modifications of natural clays: strategies to improve the polymeric matrix/clay compatibility. In: Wythers Maryann C (ed) Advances in materials science research. Nova Science Publishers, Hauppauge, NY, pp 55–82

Paul DR, Robeson LM (2008) Polymer nanotechnology: nanocomposites. Polymer 49:3187–3204

Pappu A, Saxena M, Thakur VK, Sharma A, Haque R (2016) Facile extraction, processing and characterization of biorenewable sisal fibers for multifunctional applications. J Macromol Sci Part A 53(7):424–432

Peeling J, Clark DT, Evans IM, Boulter D (1976) Evaluation of the ESCA technique as a screening method for the estimation of protein content and quality in seed meals. J Sci Food Agric 27(4):331–340

Pelissari FM, Andrade-Mahecha MM, do Amaral Sobral PJ, Menegalli FC (2013) Comparative study on the properties of flour and starch films of plantain bananas (Musa paradisiaca). Food Hydrocoll 30(2):681–690

Phan TD, Debeaufort F, Luu D, Voilley A (2005) Functional properties of edible agar-based and starch-based films for food quality preservation. J Agric Food Chem 53(4):973–981

Ray SS, Bousmina M (2005) Biodegradable polymers and their layered silicate nanocomposites: in greening the 21st century materials world. Prog Mater Sci 50(8):962–1079

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28(11):1539

Reyes LR (2013) Caracterización de dispersiones filmogénicas a base de almidón de maíz y ácido oleico en nanoemulsión con capacidad de formación de recubrimientos comestibles activos. Tesis de Maestría. Facultad de Química. Universidad Autónoma de Querétaro, México

Rindlav-Westling Å, Gatenholm P (2003) Surface composition and morphology of starch, amylose, and amylopectin films. Biomacromol 4(1):166–172

Rindlav-Westling Å, Stading M, Gatenholm P (2002) Crystallinity and morphology in films of starch, amylose and amylopectin blends. Biomacromol 3(1):84–91

Russell PL, Gough BM, Greenwell P, Fowler A, Munro HS (1987) A study by ESCA of the surface of native and chlorine-treated wheat starch granules: the effects of various surface treatments. J Cereal Sci 5(1):83–100

Shogren RL, Lawton JW, Tiefenbacher KF, Chen L (1998) Starch–poly (vinyl alcohol) foamed articles prepared by a baking process. J Appl Polym Sci 68(13):2129–2140

Siripatrawan U, Harte BR (2010) Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll 24(8):770–775

Singha AS, Thakur VK (2008a) Synthesis and characterization of Grewia optiva fiber-reinforced PF-based composites. Int J Polym Mater Polym Biomater 57(12):1059–1074

Singha AS, Thakur VK (2008b) Synthesis and characterization of pine needles reinforced RF matrix based biocomposites. J Chem 5(S1):1055–1062

Singha AS, Thakur VK (2008c) Fabrication and study of lignocellulosic hibiscus sabdariffa fiber reinforced polymer composites. BioResources 3(4):1173–1186

Singha AS, Thakur VK (2009a) Fabrication and characterization of H. sabdariffa fiber-reinforced green polymer composites. Polym Plast Technol Eng 48(4):482–487

Singha AS, Thakur VK (2009b) Grewia optiva fiber reinforced novel, low cost polymer composites. J Chem 6(1):71–76

Singha AS, Thakur VK (2009c) Mechanical, thermal and morphological properties of grewia optiva fiber/polymer matrix composites. Polym Plast Technol Eng 48(2):201–208

Singha AS, Thakur VK (2009d) Study of mechanical properties of urea-formaldehyde thermosets reinforced by pine needle powder. BioResources 4(1):292–308

Slavutsky AM, Bertuzzi MA, Armada M (2012) Water barrier properties of starch-clay nanocomposite films. Braz J Food Technol 15:208–218

Spiridon I, Teacă CA, Bodîrlău R, Bercea M (2013) Behavior of cellulose reinforced cross-linked starch composite films made with tartaric acid modified starch microparticles. J Polym Environ 21(2):431–440

Stading M, Hermansson AM, Gatenholm P (1998) Structure, mechanical and barrier properties of amylose and amylopectin films. Carbohyd Polym 36(2):217–224

Stading M, Rindlav-Westling Å, Gatenholm P (2001) Humidity-induced structural transitions in amylose and amylopectin films. Carbohyd Polym 45(3):209–217

Thakur VK, Thakur MK, Gupta RK (2013a) Graft copolymers from cellulose: synthesis, characterization and evaluation. Carbohydr Polym 97:18–25

Thakur VK, Thakur MK, Gupta RK (2013b) Rapid synthesis of graft copolymers from natural cellulose fibers. Carbohydr Polym 98:820–828

Thakur VK, Singha AS, Thakur MK (2013c) Synthesis of natural cellulose-based graft copolymers using methyl methacrylate as an efficient monomer. Adv Polym Technol 32(S1):E741–E748

Thakur VK, Thakur MK, Gupta RK (2013d) Graft copolymers from natural polymers using free radical polymerization. Int J Polym Anal Charact 18(7):495–503

Trache D, Hazwan Hussin M, Mohamad Haafiz MK, Kumar Thakur V (2017) Recent progress in cellulose nanocrystals: sources and production. Nanoscale 9(5):1763–1786

Varma AJ (1984) Photoelectron spectroscopic studies of cellulose, starch and their oxidation products, in powdered form. Carbohyd Polym 4(6):473–479

Voicu SI, Condruz RM, Mitran V, Cimpean A, Miculescu F, Andronescu C, Thakur VK (2016) Sericin covalent immobilization onto cellulose acetate membrane for biomedical applications. ACS Sustain Chem Eng 4(3):1765–1774

Vogler EA (1998) Structure and reactivity of water at biomaterial surfaces. Adv Colloid Interface 74(1):69–117

Wang B, Mireles K, Rock M, Li Y, Thakur VK, Gao D, Kessler MR (2016) Synthesis and preparation of bio-based ROMP thermosets from functionalized renewable isosorbide derivative. Macromol Chem Phys 217(7):871–879

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28(8):988–994

Wilpiszewska K, Antosik AK, Spychaj T (2015) Novel hydrophilic carboxymethyl starch/montmorillonite nanocomposite films. Carbohyd Polym 128:82–89

Wong DWS, Gastineau FA, Gregorski KS, Tillin SJ, Pavlath AE (1992) Chitosan-lipid films: microstructure and surface energy. J Agric Food Chem 40:540–544

Xia X, Hu Z, Marquez M (2005) Physically bonded nanoparticle networks: a novel drug delivery system. J Control Release 103(1):21–30

Yanli W, Wenyuan G, Xia L (2009) Carboxymethyl Chinese yam starch: synthesis, characterization, and influence of reaction parameters. Carbohyd Res 344:1764–1769

Yuan Y, Lee TR (2013) Contact angle and wetting properties. In: Bracco G, Holst B (eds) Surface science techniques. Springer, Berlin, pp 3–34

Zhou J, Ma Y, Ren L, Tong J, Liu Z, Xie L (2009) Preparation and characterization of surface crosslinked TPS/PVA blend films. Carbohyd Polym 76(4):632–638

Zhou J, Zhang J, Ma Y, Tong J (2008) Surface photo-crosslinking of corn starch sheets. Carbohyd Polym 74(3):405–410

Acknowledgements

The authors would like to thank National Council of Scientific and Technical Research (CONICET) (Postdoctoral fellowship internal PDTS-Resolution 2417) and National University of Mar del Plata (UNMdP) for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Gutiérrez, T.J., Ollier, R., Alvarez, V.A. (2018). Surface Properties of Thermoplastic Starch Materials Reinforced with Natural Fillers. In: Thakur, V., Thakur, M. (eds) Functional Biopolymers. Springer Series on Polymer and Composite Materials. Springer, Cham. https://doi.org/10.1007/978-3-319-66417-0_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-66417-0_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-66416-3

Online ISBN: 978-3-319-66417-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)