Abstract

CNC milling is widely used in manufacturing complex parts of aerospace fields, and the development of the intelligent tool wear monitoring can improve the utilization of the tool during the milling process while ensuring the surface quality of the processed parts. In this paper, a novel method based on wavelet packet analysis and RBF neural network was proposed for monitoring the tool wear condition during milling. Firstly, cutting force signals were measured during milling, and filtered by filter function. Secondly, the cutting vibration signals caused by tool wear were separated by the wavelet packet decomposition from initial data, and the energy of the reconstructed signals was characterized for analyzing tool wear during the milling process. Then, the filtered cutting force and the cutting vibration features were trained by RBF neural network. Fifteen groups of features were trained by RBF neural network, and three groups of features were used to test RBF neural network. Finally, the results show that the method can accurately monitor the flank wear of milling cutter within a short time, which provides a theoretical basis and experimental scheme for further implementing the on-line tool wear monitoring.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As an important part of advanced manufacturing technology, online tool condition monitoring technology has become a research topic in recent years [1]. The tool, a direct implementation of the cutting process, inevitably exists wear, breakage and other conditions during the cutting process. Changes in the tool condition directly lead to the increase of cutting force and cutting temperature, the rise of workpiece surface roughness, workpiece size out of tolerance, cutting color change and cutting chatter [2]. Therefore, there has an urgent need to monitor the tool wear condition. Tool wear condition monitoring means that the computer acquires a variety of sensor signal changes during the product processing process, real-time predicts the tool wear or breakage through data fusion method, and uses the alarm devices to accurately prompt the tool change time. Research shows that CNC machine tools with tool monitoring system can reduce downtime by 75%, improve production efficiency by 10–60%, and increase machine tool utilization by 50% [3].

The intelligent monitoring of tool wear condition is generally divided into two steps: features extraction and features recognition. Referring to the feature extraction methods there are three types: time domain analysis, frequency domain analysis, time-frequency domain analysis. Time domain analysis is a method of signal processing directly in time domain. Haber et al. [4] extracted the mean and peak value of the vibration signal as the features, so as to predict the tool wear. However, the use of time domain signal as features extraction is often affected by the noise signal or the signal changes. As for frequency domain analysis, it transforms the signal from time domain to frequency domain by Fourier series or Fourier transform. Kopac and Sali [5] measured the sound pressure at 0.5 mm from the cutting area by a condenser microphone and analyzed in the frequency domain from 0 to 22 kHz. However, while transforming from time domain to frequency domain using Fourier transform, signals from all the time domain has to be used. The time-frequency domain analysis method can be used to describe the time domain and frequency domain of the signal, which can clearly describe the change of signal frequency with time. Zhu et al. [6] introduced the wavelet analysis method and applied it in tool condition monitoring. Li [7] proposed the wavelet packet analysis of the AE signal during the rotation of the tool. The above research has demonstrated that the time-frequency analysis method can accurately be used for signal time-frequency analysis, the signal in time domain and frequency domain can achieve high resolution.

In recent years, neural network has been widely used in data fusion and recognition. Wang [8] proposed a method for monitoring tool wear based on automatic combined neural network. Elanayar and Shin [9] proposed a dynamic model for tool wear monitoring. Pai et al. [10] proposed a method using a radial basis function network to predict the rake wear in end milling operation. It is found that the prediction results for tool wear using RBF neural network is more robust and high accuracy than resource allocation network. All of these methods are based on fuzzy algorithm and neural network algorithm, choosing the appropriate recognition algorithm plays an important role in improving the recognition convergence speed and improving the local minima during the fitting process.

The above reference only uses the wavelet packet analysis algorithm to divide the signal into time-frequency domain, so as to filter out the noise signal or the environmental signal which is not related to the main signal. In this paper, the wavelet packet analysis algorithm is used to extract the cutting force signals due to vibration which related to tool wear except the cutting force signal, which is the contribution of this paper. The wavelet packet is used to segment the frequency of the cutting force signal in the time-frequency domain. In addition to the cutting force signal at the low frequency, the reconstructed signal energy value of the intermediate frequency band is also related to the tool wear, and the signal is extracted as a vibration signal related to the tool wear. And then this paper adopts RBF neural network to make data fusion for input feature, in a short period of time to predict the tool wear accurately. In Sect. 2, the mathematical model of wavelet packet analysis and RBF neural network are discussed. In Sect. 3, the cutting force signal in the machining process is measured by the milling experiment, and the signal value of the cutting force signal due to vibration in the cutting force signal is separated by wavelet packet as the feature. These two types of characteristic signals are input into the RBF neural network, and the network output is the tool flank wear. In Sect. 3.2, from the analysis data, the tool wear monitoring method can accurately monitor the tool wear in time. Finally, Sect. 4 contains the conclusions.

2 Mathematical Model of Tool Wear Monitoring

In this paper, the theory of wavelet packet analysis and RBF neural network are used to monitor the tool wear. Firstly, the wavelet packet theory is used to analyze the relevant signals in the process, and then the signal energy related to tool wear is extracted as features and input of the RBF neural network model according to the prior knowledge, so as to effectively identify and predict the tool wear. In this section, the wavelet packet theory analysis model and RBF neural network model are discussed.

2.1 A Mathematical Model of Energy Feature Extraction Based on Wavelet Packet Analysis

Wavelet packet theory analysis.

In the wavelet packet analysis, the scale function of a standard orthogonalization \( \psi \left( x \right) \) is used, and with the help of two scale difference recursive equations, functions are generated as formula (1) called orthogonal wavelet packet of \( \psi \left( x \right) \)

.

where \( w_{0} = \psi \left( x \right) \), \( h_{k} ,g_{k} \) are respectively a pair of conjugate quadrature filter coefficients derived from \( \psi \left( x \right) \). In theory, according to the observation signal \( {\text{s}}\left( t \right) \in L^{2} \left( R \right) \), the discrete orthogonal wavelet packet transform is defined as the projection coefficient of \( {\text{s}}\left( t \right) \) on the orthogonal wavelet packet base \( \left\{ {w_{n,j,k} \left( t \right)} \right\}_{{n \epsilon Z/Z^{ - } ,j \epsilon Z,k \epsilon Z}} \) [11], namely:

where \( \left\{ {P_{s} \left( {n,j,k} \right)} \right\}_{k \epsilon Z} \) is the wavelet packet transform coefficient sequence of \( s\left( t \right) \) on the orthogonal wavelet packet space \( U_{j}^{n} \). In fact, according to a certain observation signal \( s\left( t \right) \), set up a group of low and high conjugate quadrature filter coefficients of \( \left\{ {h_{k} } \right\}_{k \epsilon Z} \) and \( \left\{ {g_{k} } \right\}_{k \epsilon Z} \), then the wavelet packet transform coefficients can be expressed as the following recursive formula [11]:

In order to overcome the shortcomings of traditional wavelet transform, wavelet packet transform is used to divide the signal at the time-frequency domain. The wavelet packet can be improved with the increase of resolution \( 2^{j} \), and the broadened spectrum window has the fine quality of further segmentation. For a given signal, the signal can be divided into any frequency band by a group of low- and high-pass combinatorial quadrature filters H, G, which has high time resolution and frequency resolution in low frequency and high frequency [11]. Firstly, the three-layer wavelet packet decomposition is carried out to process the cutting force signal. The cutting force signal and the cutting force signal due to vibration which related to the wear are extracted from the reconstructed wavelet packet, details about three-layer wavelet packet decomposition process is shown as follows, j is the number of layers (Fig. 1).

Extraction of the signal eigenvalues related to tool wear using wavelet packet analysis.

In the wavelet packet decomposition process, each time the conjugate quadrature filter is used, the signal length is shortened by half. Suppose that the original signal \( s\left( t \right) \) is decomposed by \( {\text{L}} \)-layer wavelet packet. If the original data length is \( 2^{N} \), after the decomposition of the L layer, the length of each signal becomes \( 2^{N - L} \). Using the wavelet packet, the signal can be decomposed into the corresponding frequency band according to the characteristics of any time-frequency resolution (which satisfies the Heisenberg uncertainty principle), and the signals in different frequency bands are decomposed into the corresponding frequency range, according to the effective frequency of prior knowledge extraction, the signal is reconstructed to restore the signal length to \( 2^{N} \). At this point, the energy distribution \( E\left( {j,n} \right) \) of the reconstructed signal in the time-frequency domain is defined as follows:

In the formula, the discrete numerical calculation of the wavelet packet transform coefficients \( P_{s} \left( {n,j,k} \right) \) is obtained by using the recursive algorithm of formula (3). The key components of the orthogonal wavelet packet space are selected, the principle of which is to select the orthogonal wavelet packet space with relatively concentrated energy. This method can make full use of prior information, so that the main wavelet packet energy eigenvalues of the original signal can be enhanced, and the dimension of the eigenvalue can be reduced. Of course, if the prior information is uncertain or the feature dimension can reduce the classification and recognition ability of the model, it is necessary to retain the wavelet packet energy eigenvalue as the final feature vector. In this paper, the reconstruction signal energies of cutting force signals and the cutting force signals due to vibration which related to tool wear are extracted as features to identify subsequent neural network. The cutting force fluctuation signals are decomposed from the original cutting force by wavelet packet method.

2.2 A Mathematical Model for Identifying Tool Wear Based on RBF Neural Network

Artificial neural network (ANN) is a nonlinear dynamic network system which is based on the research of modern neurophysiology and psychology. As a new method of knowledge processing, it has been widely used in many fields. Among them, when the input signal near the radial basis function of the central range, the hidden layer node will produce a larger output, so the radial basis function neural network (RBFNN) has the capacity of local approximation, and the response speed and recognition accuracy is also better than that of BP neural network. Figure 2 is the structure of the RBF neural network, it is a three-layer feedforward network including the input layer, hidden layer and output layer [12].

In the RBF neural network, RBF is used as the excitation function in the hidden layer and the output layer is a simple linear function [13]. The input layer to the hidden layer is nonlinear transmission, and the clustering learning algorithm is adopted. The output layer is trained by least squares algorithm [14,15,16]. The role of the hidden layer node is to analyze some local areas of the input signal. The important parameter of the hidden layer node is the center and the width of the radial basis function, which are denoted by \( c \) and \( \upsigma \), as shown in Eq. (5). When the input vector is closest to the center of a hidden layer node, the output of the hidden layer node is the largest, and the output of the hidden layer node will decrease with the distance between the vector and the radial center.

where \( \left| {\left| {x - c_{j} } \right|} \right|^{2} = \sum\nolimits_{i = 1}^{n} {\left( {x_{i} - c_{ji} } \right)^{2} } \), \( x \) is the input vector, \( c_{j} \) is the clustering center of the jth Gaussian function in the \( n \)-dimensional vector, and can be randomly selected according to the input vector. \( \sigma_{j}^{2} \) is the normalized scale parameter, which is equivalent to the variance. \( R_{j} \) represents the output of the hidden layer function. The output of the hidden layer node is passed to the output layer linearly by weight ω, and the corresponding function expression is shown in formula (6).

where \( w_{i} \) is the output weight, and \( {\text{y}} \) is the expected output of the RBF neural network. In this paper, the energy value of the reconstructed signal of the cutting force signal and the cutting force fluctuation signals due to vibration are extracted by wavelet packet analysis as the input feature vector. The output layer is the tool flank wear.

3 Experimental Validation and Discussion

3.1 Experimental Setup

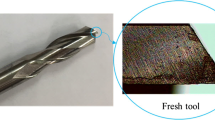

The experiments were carried out for up milling, and a Kistler 9123C rotating dynamometer was used to measure the force during the milling process Tool wear was measured with a non-contact optical measurement equipment Alicona InfiniteFocus. And the cutting parameters of this experiment are:

To avoid the influence of cutter runout, only one insert was installed, and the machining process was dry cutting. For each cutting parameters group, the same cutting experiments were carried out repeatedly until the tool wear reaches 0.3 mm (Fig. 3).

3.2 Results and Discussion

With the increase of cutting length (L), tool wear gradually increased. In this experiment, 18 appropriate groups are carried out for tool flank wear measurement. The experimental data are shown in Table 1.

Feature extraction of tool wear based on cutting force.

In the actual machining process, the signal of cutting force, vibration and acoustic emission will change significantly with the increase of tool wear. However, the acquisition of all relevant signals will increase the cost and complexity of the device. Therefore, this paper proposes to collect only the cutting force signal during the cutting process. By analyzing the original force signal using the wavelet packet analysis, the signal related to the tool vibration is decomposed. The eigenvalues related to tool wear are extracted from these two kinds of signals, which are used to identify the tool wear. The following are specific analysis of how to extract the tool wear eigenvalues.

The spectrum transform of cutting force based on fast Fourier transform.

Firstly, the cutting force of three cycles is described by MATLAB. Secondly, the spectrum analysis is carried out by Fourier transform to transform the signal from the time domain to frequency domain. The fast Fourier transform is used to shift the frequency of unequal Fourier transform data, and the frequency range becomes: \( - {\text{fs}}/2\sim {\text{fs}}/2 \). As shown in Figs. 4 and 5.

Extraction of the cutting force fluctuation energy values related to tool wear.

According to the analysis of the frequency spectrum, the cutting force signal amplitude is high at low frequency, and the signal amplitude decreases with the increase of frequency. When the frequency is greater than 1.2 kHz, the signal amplitude is small enough to be ignored. According to the experiment, when number N is 8, the time domain waveform becomes smooth, and the frequency characteristic is also good, so choosing the db8 as the wavelet packet basis is more appropriate. According to the results of the spectrum analysis, the 0~1.2 kHz signal is decomposed into 8 frequency bands by using db8 wavelet packet decomposition, and the width of each frequency band is 150 Hz, and then the signal is reconstructed for each band. Figure 6 shows the reconstruction of the decomposition of the 8 bands.

As shown in Fig. 6, the signal reconstruction of the \( 0\sim 150\,{\text{Hz}} \) frequency band is regarded as cutting force signal. The energy values of these reconstructed signals by frequency band are analyzed. It is found that except that the energy of the reconstructed signal in the energy spectrum of \( 0\sim 150\,{\text{Hz}} \) is related to the tool wear condition in the energy spectrum of the tangential force \( f_{t} \), the energy value of the reconstructed signal of the second band \( \left( {150\sim 300\,{\text{Hz}}} \right) \) is also related to the tool wear condition. The frequency band signal can be identified as the cutting force fluctuation signal energy value, denoted by \( V_{t} \). In the energy spectrum of the radial force \( f_{r} \), the energy value of the reconstructed signal in the fourth band (\( 450\sim 600\,{\text{Hz}} \)) is also related to the tool wear condition. The frequency band is identified as the energy value of the cutting force fluctuation signal in the radial force, denoted by \( V_{r} \). Figure 7 shows the trend of changes of the signal energy in the frequency band with the increase of the tool wear.

In order to facilitate the training and testing of RBF neural network model, the above 18 groups of data need to be normalized.

where \( x_{max} \) and \( x_{min} \), respectively, are the maximum and minimum values of the data, and \( x_{i}^{{\prime }} \) is the result of the normalized data.

Tool wear prediction based on RBF neural network.

According to the general description about the mathematical model of RBF neural network in Sect. 2, the number of neuron nodes at the input of neural network is determined by the type of features. The number of hidden neuron nodes can be determined by the empirical formula method (8). The number of output neuron nodes is determined by the expected output value.

In this paper, the input node are the features associated with the tool wear, and there are 4 features, which are the tangential and radial cutting forces in the cutting process, as well as the cutting force fluctuation signals due to vibration peeling off from the tangential and radial cutting forces (the cutting force fluctuation signal is represented by the symbol V), and the output node is the tool flank wear (denoted by VB). The cutting tool is machined 58 times on the workpiece flank side, and the tool flank wear of the 18 groups were measured as the output values of the neural network (L represents the number of the same tool machined times). The statistics of input vectors and output data are shown in Table 2.

According to the data of the 18 groups in Table 2, the model is first normalized, and the model is trained and predicted by MATLAB RBF neural network toolbox. Set the input layer neural network element number 4. The number of output layer is 1. The number of hidden layer is automatically selected by the network, and the neural network diffusion coefficient is 0.3. 19L, 31L, 52L three groups are used to test, and the other tool wear data are for RBF neural network training, as shown in Figs. 8 and 9.

According to the analysis results of RBF neural network in Sect. 3, the prediction error of the flank wear is calculated by the formula (9). The error analysis results are shown in Table 3.

Among them, VB represents tool flank wear, \( VB_{m} \) on behalf of RBF neural network predictive value. The error of the tool wear prediction shows that the average error of the flank wear of the three groups is 5.36%, and the average time used to predict the three groups using the MATLAB RBF neural network toolbox is 0.13 s. The error can meet the tool wear monitoring accuracy requirements, and the average time can also achieve the effect of on-line monitoring of tool flank wear.

4 Conclusions

In this paper, the wavelet packet analysis and RBF neural network are used to monitor the flank wear of milling cutter. The wavelet packet analysis is used to analyze the signal features related to tool wear from the original cutting force signal, the cutting force signal and the cutting vibration signal which related to the tool wear are extracted, and the energy of the reconstructed signal is taken as the extracted eigenvalue. For the extracted features, the data fusion is carried out by RBF neural network, and then accurately identify the flank wear of milling cutter within a short period of time, which provides theoretical support for the real-time on-line monitoring of the subsequent tool wear. Based on the above research, the article is summarized as follows:

-

1.

The method of wavelet-packet analysis is used to extract the cutting vibration signal related to tool wear in the cutting force signal, which is the contribution of this paper. The wavelet packet is used to segment the frequency of the cutting force signal in the time-frequency domain. In addition to the cutting force signal at the low frequency, the reconstructed signal of the intermediate frequency band is also related to the tool wear, and the signal is extracted as a vibration signal related to the tool wear. This method avoids the measurement of tool vibration signal in the process of machining, which reduces the cost and complexity of the experimental.

-

2.

Three groups of data for RBF test are selected during the process of tool wear, and the collected cutting force signal can be transformed into the input features for RBF neural network entry through software, and then use the trained RBF neural network to output tool wear, so as to achieve on-line monitoring of tool wear.

-

3.

In this paper, RBF neural network is used to identify two kinds of features of tool wear. The method can quickly and effectively identify the flank wear of the milling cutter. The average recognition time can reach 0.13 s, and the average recognition error is 5.36%, which provides a good theoretical basis and experimental scheme for further accurate tool wear monitoring.

References

Ertunc, H.M., Loparo, K.A.: A decision fusion algorithm for tool wear condition monitoring in drilling. Int. J. Mach. Tools Manufact. 41(9), 1347–1362 (2001)

Li, X.: A brief review: acoustic emission method for tool wear monitoring during turning. Int. J. Mach. Tools Manufact. 42(2), 157–165 (2002)

Rehorn, A.G., Jiang, J., Orban, P.E.: State-of-the-art methods and results in tool condition monitoring: a review. Int. J. Adv. Manufact. Technol. 26(7–8), 693–710 (2005)

Haber, R.E., Jiménez, J.E., Peres, C.R., et al.: An investigation of tool-wear monitoring in a high-speed machining process. Sens. Actuators A Phys. 116(3), 539–545 (2004)

Kopač, J., Šali, S.: Tool wear monitoring during the turning process. J. Mater. Process. Technol. 113(1), 312–316 (2001)

Zhu, K., San, W.Y., Hong, G.S.: Wavelet analysis of sensor signals for tool condition monitoring: A review and some new results. Int. J. Mach. Tools Manufact. 49(7), 537–553 (2009)

Wang, G., Cui, Y.: On line tool wear monitoring based on auto associative neural network. J. Intell. Manufact. 24(6), 1085–1094 (2013)

Elanagar, V.T.S., Shin, Y.C.: Design and implementation of tool wear monitoring with radial basis function neural networks. In: Proceedings of the 1995 American Control Conference, vol. 3, pp. 1722–1726. IEEE (1995)

Srinivasa, P., Nagabhushana, T.N., Rao, P.K.R.: Flank wear estimation in face milling based on radial basis function neural networks. Int. J. Adv. Manufact. Technol. 20(4), 241–247 (2002)

Wu, Y., Du, R.: Feature extraction and assessment using wavelet packets for monitoring of machining processes. Mech. Syst. Sig. Process. 10(1), 29–53 (1996)

Rothweiler, J.: Polyphase quadrature filters–a new subband coding technique. In: IEEE International Conference on Acoustics, Speech, and Signal Processing, vol. 8, pp. 1280–1283, ICASSP 1983. IEEE (1983)

Elanayar, S., Shin, Y.C.: Robust tool wear estimation with radial basis function neural networks. Trans. Am. Soc. Mech. Eng. J. Dyn. Syst. Measure. Control 117, 459–467 (1995)

Dimla, D.E., Lister, P.M., Leighton, N.J.: Neural network solutions to the tool condition monitoring problem in metal cutting—a critical review of methods. Int. J. Mach. Tools Manufact. 37(9), 1219–1241 (1997)

Kuo, R.J., Cohen, P.H.: Multi-sensor integration for on-line tool wear estimation through radial basis function networks and fuzzy neural network. Neural Netw. 12(2), 355–370 (1999)

Panda, S.S., Chakraborty, D., Pal, S.K.: Flank wear prediction in drilling using back propagation neural network and radial basis function network. Appl. Soft Comput. 8(2), 858–871 (2008)

Yao, Y., Li, X., Yuan, Z.: Tool wear detection with fuzzy classification and wavelet fuzzy neural network. Int. J. Mach. Tools and Manufact. 39(10), 1525–1538 (1999)

Acknowledgements

This project is supported in part by National Basic Research Program of China (Grant No. 2013CB035802) and National Natural Science Foundation of China (Grant No. 51575453).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Li, T., Zhang, D., Luo, M., Wu, B. (2017). Tool Wear Condition Monitoring Based on Wavelet Packet Analysis and RBF Neural Network. In: Huang, Y., Wu, H., Liu, H., Yin, Z. (eds) Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science(), vol 10464. Springer, Cham. https://doi.org/10.1007/978-3-319-65298-6_36

Download citation

DOI: https://doi.org/10.1007/978-3-319-65298-6_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65297-9

Online ISBN: 978-3-319-65298-6

eBook Packages: Computer ScienceComputer Science (R0)