Abstract

One of the most novel concepts that has been applied to companies in recent years is “Industry 4.0”. This is a wide term that implies a drastic change in the way companies operate. This paper reviews some of its existing literature in order to give an accurate definition of such a concept. A classification scheme based in two main pillars, on one hand the features which characterize that term and on the other hand the technologies and concepts that support their development is also defined. All results are based on a structured literature review.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Important advances in manufacturing technologies and communication, computing and information systems within recent years are enabling new ways to perform operations in industrial and service sectors.

This new paradigm is called “Industry 4.0” (term coined by “Industrie 4.0 Working Group and the “Plattform Industrie 4.0”) and seems to mark the future roadmap, leading to the fourth industrial revolution (Erol et al. 2016).

Industry 4.0 promotes, among other things, autonomous decision-making, interoperability, agility, flexibility, efficiency and cost reductions.

This is the reason by which many companies are aiming to implement the technologies and concepts related to “Industry 4.0”.

However, current research about “Industry 4.0” is diverse, limited and clearly insufficient regarding its implementation in operational levels of the production processes (Herman et al. 2015).

This lack of roadmaps and guides supporting its implementation, as well as its high complexity makes “Industry 4.0” too uncertain (Erol et al. 2016). Moreover, they are discouraging the early, orderly and effective implementation of the concept.

In addition to that, the many contributions of research centers, companies, universities and professionals are making the term “Industry 4.0” even more confuse.

Even the key promoters of the idea only describe the vision, the basic technologies the idea aims at, and selected scenarios but don’t provide a clear definition. As a result, a generally accepted definition of Industry 4.0 has not been published so far (Herman et al. 2015).

Maybe, one of the underlying causes is that too many different technologies and concepts are grouped under the wide term “Industry 4.0”, as it is stated by Herman et al. (2015): “Industrie 4.0 is a collective term for technologies and concepts of value chain organization”.

This paper aims to collect and organize all the relevant terms related to “Industry 4.0” in order to facilitate its implementation by different users such as companies, technologists, computer engineers and final users.

The paper is structured as follows: In Chap. 2 a brief summary of the literature review is presented. Then, in Chap. 3, a classification scheme is proposed. Finally, in Chap. 4 some conclusions are drawn.

2 Literature Review

First, a list of different characteristic features of “Industry 4.0” as well as different technologies and concepts which support that term were determined based on the frequency they were quoted in the literature review, composed by twelve main papers (Anon 2014; Herman et al. 2015; Lasi et al. 2014; Schlechtendahl et al. 2014; Lee et al. 2015; Shrouf et al. 2014; Atzori et al. 2010; Miorandi et al. 2012; Herčko et al. 2015; Pfohl et al. 2015; Stiel and Teuteberg 2015; Erol et al. 2016), selected from the initial search results.

Then, all the former papers were contrasted with other ones which aimed to propose classification schemes, as the ones of Herman et al. (2015) and Pfohl et al. (2015). This allowed to analyze in which extent the different features and technologies/concepts were taken into account and organized.

3 Proposed Classification Scheme

From the previous analysis, a classification scheme was proposed, leading to a better understanding of the concept “Industry 4.0”.

This classification scheme is based on two pillars: the features that characterize such a concept and the technologies or concepts that support them. Besides, the technologies or concepts that enable the development of the former individual features are also pointed out.

As a result, eight characterizing features were selected as the most representative ones, although a few other ones encountered in the literature were also added if they matched them. Their description is as follows:

-

1.

Virtualization: means that companies are able to monitor physical processes. These sensor data are linked to virtual plant models and simulation models. Thus, a virtual copy of the physical world is created (Herman et al. 2015). Another close feature is digitalization.

-

2.

Interoperability: means that all the systems, in and out the company are connected. Standards are a key success factor for communication (Herman et al. 2015). Other close features are socialization or network collaboration.

-

3.

Autonomization: “Industry 4.0” technologies and concepts are enabling machines and algorithms of future companies to make decisions and perform learning-activities autonomously. This autonomous decision-making and learning is based on man-made algorithms and enables whole factories and manufacturing facilities to work with minimum human-machine interaction (Pfohl et al. 2015). Another close feature is decentralization.

-

4.

Real-time availability: for organizational tasks it is necessary that data is collected and analyzed in real time. So, the status of the plant is permanently tracked and analyzed (Herman et al. 2015). Other close features are remote monitoring and mobility.

-

5.

Flexibility: due to new and more complex demands requirements, processes such as products development, products production processes or decision making procedures need to be performed faster (Lasi et al. 2014). Another close feature is mass-customization.

-

6.

Service Orientation: the services of companies over Internet can be utilized by other participants. They can be offered both internally and across company borders (Herman et al. 2015).

-

7.

Energy efficiency: climate change and scarcity of resources are megatrends that will affect to future industry players. These megatrends leverage energy decentralization for plants, triggering the need for the use of carbon-neutral technologies in manufacturing. Using renewable energies will be more financially attractive for companies (Anon 2014).

Secondly, a list of different technologies and concepts that support the future development of the concept of “Industry 4.0” was also considered.

For this purpose, a two-step approach was applied. In the first step, a list of technologies and concepts were extracted from the literature review. This list was too long, so it was attempted to reduce its complexity. For that, in the second step, four technologies/concepts that had the highest relevance and the widest scope were selected forming four groups: cyber-physical systems, Internet of Things/Services, Smart Data and Smart Factory. The remaining ones were then allocated in each of them. It is important to remark that the selected technologies/concepts overlap so that some concepts could have been allocated in different groups. In this work just the most representative one was chosen to allocate them.

In the following, the 4 selected technologies/concepts are reflected and described, jointly with those technologies/concepts related to them (Tables 1, 2, 3 and 4).

-

1.

Cyber-Physical Systems (CPS): is defined as transformative technologies for managing interconnected systems between its physical assets and computational capabilities. By integrating CPS with production, logistics and services in the current industrial practices, it would transform today’s factories into an Industry 4.0 factory with significant economic potential (Lee et al. 2015).

-

2.

Internet of Things/Services (IoT/IoS): IoT is a system a system where the physical items are enriched with embedded electronics (RFId tags, sensors…) and connected to the Internet. Thanks to IoT physical objects are seamlessly integrated into the information network where they can become active participants in business processes; communicate information about their status, surrounding environment, production processes, maintenance schedule and even more (Shrouf et al. 2014). IoS enables service vendors to offer their services via the internet. It consists of participants, an infrastructure for services, business models and the services themselves (Herman et al. 2015).

-

3.

Smart Data: data is often referred to as the raw material of the 21st century. Indeed, the amount of data available to businesses is expected to double every 1.2 years. A plant of the future will be producing a huge amount of data that needs to be saved, processed and intelligently analyzed. Innovative methods to handle big data and to tap the potential of cloud computing will create new ways to leverage information (Anon 2014).

-

4.

Smart Factory: it gives an overview of the firm as an interconnected global system on a microeconomic level. Outside the factory a 4.0 supplier network, resources of the future, new customer demands and the means to meet them are seen. Inside the factory, new production technologies, new materials and new ways of storing, processing and sharing data are envisioned (Anon 2014).

Finally, the proposed classification scheme aims to understand the relevance of the many interrelated technologies/concepts with respect to the achievement of the aforementioned “Industry 4.0” characterizing features.

For that, from the selected papers from the literature review, was analyzed how the different technologies/concepts were related to those features. Base on that, the contribution of all of them was individually collected and analyzed whether or not they enabled the virtualization, interoperability, autonomization, real-time availability, flexibility, service orientation and energy efficiency features.

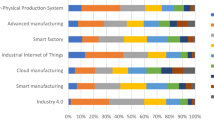

Table 5 shows the contribution of the different relevant technologies/concepts to the development of the features characterizing the “Industry 4.0”.

Due to space restrictions, only the most contributing technologies/concepts of each group (in bold in Tables 1, 2, 3 and 4) are briefly explained in the following:

-

1.

CPS

-

M2M: it is a broad label that can be used to describe any technology that enables networked devices to exchange information and perform actions without the manual assistance of humans. M2M communication is often used for remote monitoring.

-

-

2.

IoT/IoS

-

Sensors: it is a device that detects and responds to some type of input from the physical environment. The specific input could be light, heat, motion, moisture, pressure, or any one of a great number of other environmental phenomena. The output is generally a signal that is converted to human-readable display at the sensor location or transmitted electronically over a network for reading or further processing.

-

RFID: it is a technology that incorporates the use of electromagnetic or electrostatic coupling in the radio frequency (RF) portion of the electromagnetic spectrum to uniquely identify an object, animal, or person. It is coming into increasing use in industry as an alternative to the bar code. The advantage of this technology is that it does not require direct contact or line-of-sight scanning.

-

-

3.

Smart Data

-

Cloud Computing: it is a general term for the delivery of hosted services over the Internet. It enables companies to consume compute resources as a utility rather than having to build and maintain computing infrastructures in-house. It promises several attractive benefits for businesses and end users.

-

-

4.

Smart Factory

-

Smart Products: they are specializations of hybrid products with physical realizations of product categories and digital product descriptions that provide the following characteristics: personalized, adaptive, pro-active, business aware, location aware and network capable. Since smart products combine a physical product with additional services, they are a form of product service system.

-

4 Conclusions

Based on a structured literature review, the meaning of the so-popular and at the same time so wide concept “Industry 4.0” was understood. This was performed by proposing a classification scheme made up of two main inputs.

On one hand analyzing which features may better characterize the term “Industry 4.0”. It was stated that the main features were virtualization, interoperability, autonomization, real-time availability, flexibility, service orientation and energy efficiency. On the other hand analyzing which technologies and concepts may be classified under the term “Industry 4.0”. Many technologies and concepts were analyzed within the literature, grouping them into 4 relevant and representative ones: Cyber-Physical Systems (CPS), Internet of Things/Services (IoT/IoS), Smart Data, Smart Factory. Finally, it was stated how these technologies and concepts individually contributed to enable the achievement of the aforementioned characterizing features.

References

Anon (2014) Industry 4.0, Roland Berger Strategy Consultants

Atzori L, Iera A, Morabito G (2010) The Internet of things: a survey. Comput Netw 54(15): 2787–2805. Available at: http://www.sciencedirect.com/science/article/pii/S1389128610001568

Erol S, Schumacher A, Sihn W (2016) Strategic guidance towards Industry 4.0—a three-stage process model. In: International conference on competitive manufacturing, COMA’16

Herčko J, Slamková E, Hnát J (2015). INDUSTRY 4.0—New era of manufacturing. In: InvEnt 2015

Herman M, Pentek T, Otto B (2015) Design principles for industrie 4.0 scenarios: a literature review. Technische Universität Dortmund. Audi Stiftungslehrstuhl Supply Net Order Management

Lasi H et al. (2014) Industry 4.0. Bus Inf Syst Eng 6(4): 239–242. Available at: http://econpapers.repec.org/RePEc:spr:binfse:v:6:y:2014:i:4:p:239–242

Lee J, Bagheri B, Kao H-A (2015) A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf Lett 3:18–23

Miorandi D et al. (2012) Survey Internet of things: vision, applications and research challenges. Ad Hoc Netw 10(7):1497–1516. Available at: http://dx.doi.org/10.1016/j.adhoc.2012.02.016

Pfohl HC, Yahsi B, Kuznaz T (2015) The impact of Industry 4.0 on the supply chain. In: C.M.R.Wolfgang Kersten, Thorsten Blecker (ed) Proceedings of the Hamburg international conference of logistic (HICL)-20. Hamburgo: innovations and strategies for logistics an supply chain, pp 32–58

Schlechtendahl J et al. (2014). Making existing production systems Industry 4.0-ready. Prod Eng 9(1):143–148. Available at: http://dx.doi.org/10.1007/s11740-014-0586-3

Shrouf F, Ordieres J, Miragliotta G (2014) Smart factories in Industry 4.0: a review of the concept and of energy management approached in production based on the internet of things paradigm. In: 2014 IEEE international conference on industrial engineering and engineering management (IEEM), pp 697–701

Stiel F, Teuteberg F, (2015) Industry 4.0 business models in a sustainable society : challenges, competencies and opportunities. In: Issenschaftstagung 2015 der erich-gutenberg-arbeitsgemeinschaft köln e.v.: industrial internet of things—managerial challenges and organizational aspects. Nürnberg, pp 0–3

Acknowledgements

This research has been carried out in the framework of the project “Identificación de la información proporcionada por los nuevos sistemas de detección accesibles mediante internet en el ámbito de las-sensing enterprises- para la mejora de la toma de decisiones en la planificación de la producción” (GV/2014/010), funded by the Generalitat Valenciana.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Perales, D.P., Valero, F.A., García, A.B. (2018). Industry 4.0: A Classification Scheme. In: Viles, E., Ormazábal, M., Lleó, A. (eds) Closing the Gap Between Practice and Research in Industrial Engineering. Lecture Notes in Management and Industrial Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-58409-6_38

Download citation

DOI: https://doi.org/10.1007/978-3-319-58409-6_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58408-9

Online ISBN: 978-3-319-58409-6

eBook Packages: EngineeringEngineering (R0)