Abstract

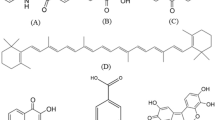

Synthesis of industrially important dye intermediates and dyes is presented. Industrial applications of dyes including textiles and non-textiles such as acid-base indicators, liquid crystal, color filters for displays and sensors, ink-jet, lasers, photographic, hairs, food, and biomedical are discussed.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Synthesis of industrially important dye intermediates and dyes is presented. Industrial applications of dyes including textiles and non-textiles such as acid-base indicators, liquid crystal, color filters for displays and sensors, ink-jet, lasers, photographic, hairs, food, and biomedical are discussed.

Manufacture of Dye Intermediates

This section provides an overview of the chemical reactions used in preparing the key intermediates employed in dye synthesis. The term “intermediates” refers to those compounds, which are prepared from the original coal tar constituents by various chemical reactions and which, in turn, can be converted into commercial dyes by relatively simple further transformations. A typical example is aniline, which is synthesized from benzene by various methods and can be converted into a wide variety of dyes. Thus, the raw materials used to synthesize organic dyes are commonly referred to as “dye intermediates.” Most of the intermediates entering into the preparation of commercial synthetic organic dyes are members of the aromatic series, which are mainly derivatives of benzene, naphthalene, and anthraquinone [1, 2].

There are three types of reactions involving substitution of the hydrogen atoms of the benzene nucleus, which differ in the nature of attacking reagent. The three types of attacking reagents are (1) electrophilic reagents (electron accepting or electron loving); (2) nucleophilic reagents (electron donating or nucleus loving); and (3) free radical reagents as given in Table 1.

Mechanism of Electrophilic Reagents

The electrophilic reagent is deficient in electrons, which reacts with the aromatic nucleus at a point of high electron density and establishes a bond by sharing an electron pair. After the initial fusion of the attacking group to the activated aromatic nucleus, the reaction is completed by the discharge of a proton and a return of the molecule from an unstable intermediate to a stable compound as shown in Scheme 1. The greater majority of the familiar reactions involving direct substitution on the aromatic hydrocarbon fall into this category.

Mechanism of Nucleophilic Reagents

The nucleophilic reagent possesses an unshared electron pair. In nucleophilic substitution reaction, hydrogen is seldom replaced. The replaced groups are ordinarily halogen atoms or other groups possessing reasonable stability as anions. The nucleophilic reagent may be either a charged particle or a neutral molecule, e.g., ammonia. The nucleophilic reagent attacks the aromatic system at a point of low electron density corresponding to positions which are unreactive to the more familiar electrophilic reagent. The nucleophilic substitution reactions involve replacement of groups which are activated through other substituents in the aromatic nucleus. Thus, the nitro group in the following example directs the attacking nucleophilic group (:OH) to the ortho position as shown in Scheme 2.

Most dye intermediates are prepared by reactions involving either electrophilic or nucleophilic substitution reactions.

Orientation Rules and Effects

The dye chemist is frequently faced with challenges of preparing new intermediates having a prescribed constitution and location of substituents. The solution to this challenge is made much easier by an accurate knowledge of all of the laws governing the positions taken by substituents, when they are introduced into the various aromatic ring systems.

Orientations in the Benzene Nucleus

The directing or orienting influence of the substituents can be divided into two classes. Class 1 includes alkyl, aryl (diphenyl), halogen, –OH, –OR, –O-acyl, –NH2, –NHR, NR2, –NH-acyl, –NR-acyl, and –N=N–. These groups direct an incoming substituent exclusively or nearly so to the ortho and para positions. Class 2 includes –NO2, –SO3H, –SO2Cl, –SO2R, –COOH, –COOR, –CONHR, –COR, –CHO, and –CN. These groups orient predominately, but seldom exclusively, to the meta position.Whether the ortho or para position is favored by the Class 1 substituents depends partly on the particular substituent present, but also to a large degree on the nature of the entering group and often on the reaction conditions, especially the temperature. The directing influence of primary, secondary, and tertiary amino groups is significantly reduced by the presence of large quantities of concentrated sulfuric acid. If there are already two substituents in the benzene ring, they may either direct the third entering group to the same position or work in opposition to each other. When substituents of the two classes are working in opposition, the influence of Class 1 groups usually predominates or completely masks the influence of the Class 2 groups.

Orientations in the Naphthalene Nucleus

The chemical structure and numbering of the naphthalene are given below

In the naphthalene series, two isomers, namely, α-isomer and β-isomer, are possible when only one substituent is present. Nitration and halogenation of naphthalene give only the α-compound. On the other hand, sulfonation with concentrated sulfuric acid always gives a mixture of two isomers; the relative amounts of the two depend on the sulfonation temperature. In cold, the chief product is α-sulfonic acid, while at temperatures above 120–130 °C, the β-sulfonic acid predominates.Groups of Class 1, which are strongly orienting (alkoxy, hydroxyl, amino, or acylamino groups in the absence of concentrated sulfuric acid), when present in the 1 position of the naphthalene nucleus, direct the entering substituent in ortho or para position (2 and 4 positions) similar to benzene nucleus. Groups of Class 1, which are less active (halogen and amino groups in the presence of concentrated sulfuric acid), when present in the 1 position of the naphthalene nucleus, often produce 5 isomer, instead of the 2 isomer, along with the 4-substituted compound. Groups of Class 1, when present in the 2 position of the naphthalene nucleus, direct partly to 1 position and partly to the positions in the other ring, especially the 8 position and then the 6 position. Groups of Class 2 favor the entrance of a second substituent into the other ring almost exclusively; the meta position of the same ring is usually entered only if there are other substituents already present in the other ring.

Orientations in the Anthraquinone Nucleus

The chemical structure and numbering of the anthraquinone are given below

In the anthraquinone series, the orientation is different from benzene and naphthalene. In contrast to benzene and naphthalene, anthraquinone is not easily sulfonated with concentrated sulfuric acid because the temperature is so high that the anthraquinone structure is destroyed. When anthraquinone is sulfonated with fuming sulfuric acid, the sulfo group enters almost exclusively in 2-position (β-position). If sulfonation is carried out in the presence of mercury salts, the first sulfo enters in 1-position (α-position) preferentially. If the sulfonation is further carried out, at least four isomers, 1,5-, 1,6-, 1,7-, and 1,8-isomers, are obtained. Nitration of anthraquinone proceeds in a manner analogous to sulfonation, except that the mercury salts have no effects on the orientation. Amination of anthraquinone is achieved either by replacing sulfo group by –NH2 group or by reducing nitro group. Halogenation of anthraquinone takes place only with difficulty but the hydroxyl and amino derivatives can be easily halogenated, particularly with bromine.

Fundamental Processes in Dye Chemistry

The modern dye industry is built upon the coal tar industry as its source of material and upon the Kekule benzene theory as its scientific basis. In this section, fundamental processes involved in dye chemistry are discussed. The fundamental processes include sulfonation, nitration, reduction, amination, hydroxylation, oxidation, halogenation, and diazotization/coupling.

Sulfonation

The introduction of a sulfonic acid group(s) (–SO3H) into a molecule is called sulfonation. Sulfonation is of the greatest importance in dye manufacture. Most of the water-soluble dyes owe their solubility to the presence of sulfonic acid groups. In addition, sulfonic acids are extremely important intermediates in the presence of phenols, especially in the naphthalene series. Sulfonation is carried out by using (1) concentrated sulfuric acid; (2) a combination of concentrated sulfuric acid and fuming sulfuric acid (sulfur trioxide (SO3)) (oleum); (3) sulfur trioxide in an inert solvent such as 1,2-dichloroethane or sulfur dioxide; (4) sulfur trioxide with ether or an organic base (pyridine); or (5) chlorosulfonic acid.

Sulfonic acid group can also be introduced (1) by replacing a halogen atom with the sulfonic acid group by means of sodium sulfite; (2) by the action of bisulfite on a nitro compound or on a quinone compound; (3) by oxidation of a disulfide, a mercaptan, or a sulfinic acid; or (4) by the introduction of the –CH2SO3H group by means of formaldehyde-bisulfite [3,4,5].

Sulfonation of Benzene

Benzene can be monosulfonated using excess of concentrated sulfuric acid; however, better results are obtained using oleum (7–8% SO3). Because of the high solubility of sulfonic acids in water, they are usually not isolated from aqueous solution in the free state, but are converted into and isolated as their sodium salts as given in Scheme 3.

Sulfonation of Toluene

The sulfonation of toluene with concentrated sulfuric acid at 100–120 °C results in the formation of toluene-p-sulfonic acid as the main product, accompanied by small amounts of the ortho and meta isomers, which can be easily removed by crystallization of the sodium salt of the para isomer in the presence of sodium chloride as shown in Scheme 4.

Sulfonation of Aniline

Aromatic aminosulfonic acids constitute an important class of dye intermediates particularly for azo dye chemistry. Aromatic amines are sulfonated by two methods: (1) direct and (2) indirect or baking process. The direct procedure is carried out at a comparatively low temperature with concentrated sulfuric acid or a combination of sulfuric acid and dissolved sulfur trioxide (oleum). The indirect or baking process involves a high-temperature baking of amine and sulfate. The indirect or baking process offers the advantage of giving products more nearly free of isomers and favors substitution in the para position when both ortho and para positions are available in the aromatic nucleus. Aniline is sulfonated by indirect or baking process using concentrated sulfuric acid at 260–280 °C giving aniline-4-sulfonic acid (sulfanilic acid) in 94.5% yield as shown in Scheme 5.

Sulfonation of Naphthalene

Sulfonation of naphthalene with concentrated sulfuric acid at lower temperatures (0–60 °C), often below 30 °C, almost exclusively gives naphthalene-1-sulfonic acid (the product of kinetic control), whereas sulfonation of naphthalene with concentrated sulfuric acid at about 160 °C for about 2 h yields largely naphthalene 2-sulfonic acid (the product of thermodynamic control). In both cases, the product is isolated as sodium salt as shown in Scheme 6.

Sulfonation of β-Naphthol

Sulfonation of β-naphthol presents a more complex picture in which the temperature, concentration, amount of sulfonating agent, and duration of the reaction all affect the identity and yield of the products. β-Naphthol with concentrated sulfuric acid at room temperature or under ice-cold conditions affords 2-naphthol-1-sulfonic acid (Oxy-Tobias acid), which on further treatment with concentrated sulfuric acid at 50–100 °C yields a mixture of 2-naphthol-8-sulfonic acid (crocein acid) and 2-naphthol-6-sulfonic acid (Schaeffer acid). Increasing the temperature gives increasing amounts of 2-naphthol-8-sulfonic acid (crocein acid), while at higher temperatures, 2-naphthol-6-sulfonic acid (Schaeffer acid) predominates. Increasing the acid concentration produces 2-naphthol-6, 8-disulfonic acid (G acid) and 2-naphthol-3, 6-disulfonic acid (R acid), which are very important azo dye intermediates, and finally 2-naphthol-3,6,8-trisulfonic acid as shown in Scheme 7.

Sulfonation of Anthraquinone

The sulfonation of anthraquinone in the presence of mercury salts and oleum gave anthraquinone-1-sulfonic acid. Further sulfonation of 1-monosulfonic acid in the presence of mercury salts and oleum gave anthraquinone-1,5-disulfonic acid and anthraquinone-1,8-disulfonic acid. In both cases, the product is isolated as sodium salt as shown in Scheme 8.

The carbonyl groups in anthraquinone deactivate the aromatic nucleus towards electrophilic attack and vigorous conditions for sulfonation such as oleum at about 160 °C are required. The product is largely anthraquinone-2-sulfonic acid. Further sulfonation of 2-monosulfonic acid in the presence of mercury salts and oleum gave anthraquinone-2,6-disulfonic acid and anthraquinone-2,7-disulfonic acid. In both cases, the product is isolated as sodium salt as shown in Scheme 9.

Nitration

The process of nitrating the benzene nucleus is one of the most important processes since the resulting nitro compounds can be readily reduced to the corresponding amines, which have broad applications in dye chemistry. Nitration process involves the introduction of one or more nitro groups (NO2) into the aromatic nucleus. Nitric acid (HNO3) in both aqueous and organic solvent systems can be used for nitrating more reactive compounds, whereas less reactive compounds require a combination of nitric acid (HNO3) and sulfuric acid (H2SO4), which is called as mixed acids. The sulfuric acid serves as a solvent for carrying out the reaction. In addition, it is effective in reacting with nitric acid molecule to form the nitronium ion (NO2 +), which is the actual nitrating agent [3,4,5]. The representative examples of nitration reactions are given below.

Nitration of Benzene

Benzene is nitrated with concentrated nitric acid and concentrated sulfuric acid yielded nitrobenzene as shown in Scheme 10.

Nitration of Toluene

When toluene is nitrated with concentrated nitric acid and concentrated sulfuric acid, a mixture of o-, p-, and m-nitrotoluene is obtained in 63%, 35%, and 2%, respectively, as shown in Scheme 11.

Nitration of Phenol

Phenol can be converted into a mixture of 2- and 4-nitrophenols by reaction with dilute nitric acid as shown in Scheme 12. The yield of 4-nitrophenol can be increased if a mixture of sodium nitrate and dilute sulfuric acid is employed.

Nitration of Naphthalene

Nitration of naphthalene proceeds readily by using mixed acids of lower concentration than in the case of benzene at 50–60 °C giving almost exclusively 1-nitronaphthalene in 95% yield and 2-nitronaphthalene in 5% yield. Further nitration gives first a mixture of 1,5- and 1,8-dinitronaphthalene and next principally, 1,4,5- and 1,3,8-trinitronaphthalene as shown in Scheme 13.

Nitration of 1-Naphthol and 2-Naphthol

The hydroxyl group of 1-naphthol directs nitro group into the 2- and 4-positions. Thus, nitration of 1-naphthol gave 2,4-dinitro-1-naphthol as shown in Scheme 14, while nitration of 2-naphthol in the cold in the presence of mercuric nitrate afforded good yield of 1-nitro-2-naphthol as shown in Scheme 15.

Nitration of 1-Naphthylamine and 2-Naphthylamine

1-Naphthylamine cannot be nitrated at the ordinary temperature without some decomposition. 1-Naphthylamine can be nitrated with nitric acid in a large excess of sulfuric acid below 0 °C yielding mainly the 5-nitro-1-naphthylamine and 8-nitro-1-naphthylamine as shown in Scheme 16. Similarly, 2-naphthylamine when nitrated with sulfuric acid gives mainly the 5-nitro-2-naphthylamine and 8-nitro-2-naphthylamine as shown in Scheme 17.

Nitration of Anthraquinone

The nitration of anthraquinone requires rather more drastic conditions than in the case of naphthalene or benzene. Since the reactivities of the two benzene rings in the anthraquinone molecule are largely independent of each other, exclusive mononitration is not possible. Anthraquinone undergoes nitration with sulfuric acid and nitric acid at about 80 °C, when 1,5-dinitroanthraquinone begins to separate, and the mixture is further heated at 125 °C for 2 h, when the separated yellow precipitate of 1,5-dinitroanthraquinone is filtered. The acid mother liquor contains 1,8-, 1,6-, and 1,7-dinitroanthraquinones, which have no technical value. Nitration of anthraquinone is given in Scheme 18.

Reduction

Most frequently encountered reduction by the dye chemist is the transformation of a nitro compound into an amino compound. However, there are several other reduction methods, which play a vital role in dye chemistry. This section covers the reduction of nitro and azo compounds into amino compounds. Some of the reducing agents employed are summarized below: (1) reduction with iron, water, and addition of a small amount of acid; (2) reduction with iron and addition of enough (a large amount of) acid; (3) reduction with zinc dust and acid or alkali; (4) reduction with ferrous hydroxide Fe(OH)2; (5) reduction with hydrogen sulfide and its salts; (6) reduction with hydrosulfite; (7) reduction with sulfur dioxide; (8) reduction with aluminum powder; (9) catalytic reduction with hydrogen; and (10) electrolytic reduction. In addition to the above-mentioned reducing agents, there are a wide variety of reducing agents [3,4,5].

Reduction of Nitrobenzene

For example, nitrobenzene reduced with tin and hydrochloric acid gave aniline as shown in Scheme 19.

Reduction of o-Nitroaniline

Compounds which are sensitive to acidic conditions may sometimes be successfully reduced to amines under alkaline condition. o-Nitroaniline reduced with zinc and sodium hydroxide gave o-phenylenediamine as shown in Scheme 20, which is an important key intermediate in dye chemistry.

Reduction of o-Nitrophenol

o-Nitrophenol can be readily reduced in good yield to o-aminophenol by sodium borohydride in aqueous methanol solution in the presence of a palladium-on-carbon catalyst as shown in Scheme 21.

Reduction of 1-Nitronaphthalene

A catalytic process for the reduction of 1-nitronaphthalene using hydrogen in the presence of nickel catalyst gave 1-naphthylamine as shown in Scheme 22.

Reduction of 1-Phenylazo-2-naphthol and Methyl Orange

It is interesting to note that azo compounds can be conveniently reduced either by tin (II) chloride (SnCl2) in hydrochloric acid or sodium dithionite. Thus, 1-phenylazo-2-naphthol is reduced to aniline and 1-amino-2-naphthol as shown in Scheme 23. Similarly, Methyl Orange is reduced to p-amino-N,N-dimethylaniline and sulfanilic acid as shown in Scheme 24.

Reduction of 1-Nitroanthraquinone

1-Nitroanthraquinone reduced with boiling sodium sulfide solution gave 1-aminoanthraquinone as shown in Scheme 25.

Amination

This section covers the replacement of a halogen by an amino group or the replacement of a phenolic hydroxyl group by an amino group [3,4,5].

Amination of Chlorobenzene

Aniline is prepared from chlorobenzene by treatment with sodamide in liquid ammonia as shown in Scheme 26. The reaction proceeds under vigorous conditions.

Amination of 2-Naphthol

Naphthalene intermediates containing amino groups can also be prepared by the replacement of a hydroxyl group with an amino group (Bucherer reaction). Thus, 2-naphthol is readily converted into 2-naphthylamine by heating with ammonium sulfite or ammonia at 150 °C in an autoclave as shown in Scheme 27.

Amination of Anthraquinone-1-sulfonic acid, Anthraquinone-2-sulfonic acid, 2-Chloroanthraquinone and 2,3-Dichloroanthraquinone

Anthraquinone-1-sulfonic acid is converted into 1-aminoanthraquinone by reacting with ammonia and arsenic pentoxide at 180 °C as shown in Scheme 28. Similarly, 2-aminoanthraquinone is prepared from anthraquinone-2-sulfonic acid using ammonia and sodium arsenate as shown in Scheme 29. 2-Chloroanthraquinone upon heating with ammonia and arsenic acid in an autoclave gave 2-aminoanthraquinone as shown in Scheme 30. 2,3-Diaminoanthraquinone, an important intermediate in dye chemistry, is synthesized by amination of 2,3-dichloroanthraquinone with ammonia as shown in Scheme 31.

Hydroxylation

The introduction of a hydroxyl group(s) (–OH) into a molecule is called hydroxylation. It is carried out by several methods such as (1) replacement of a sulfonic acid group by the hydroxyl group, via fusion of a sulfonic acid with alkali, e.g., sodium hydroxide or potassium hydroxide. When potassium hydroxide is used, the process is called “potash fusion”; (2) replacement of a labile halogen by the hydroxyl group; (3) replacement of a diazo group by the hydroxyl group; (4) heating an amine with acid or alkali under pressure [3,4,5].

Hydroxylation of Benzenesulfonic acid and Naphthalene-2-sulfonic acid

Alkali fusion that involves heating benzenesulfonic acid with either sodium hydroxide or potassium hydroxide in the presence of small amount of water to aid the fusion process gave phenol as shown in Scheme 32. Similarly, 2-naphthol is synthesized from naphthalene-2-sulfonic acid by alkali fusion with potassium hydroxide as shown in Scheme 33.

Hydroxylation of Anthraquinone-2-sulfonic acid

When sulfonic acid group is replaced by the hydroxyl group in the hydroxylation process, the oxidation products are occasionally formed. A particular example is the alkali fusion of anthraquinone-2-sulfonic acid, which results in 2-hydroxyanthraquinone, where the oxidation step is promoted by the deliberate introduction of potassium chlorate as an oxidant, where second hydroxyl group is introduced at 1-position forming the dyestuff, alizarin, as shown in Scheme 34.

Hydroxylation of 1-Chloro-4-nitrobenzene and 1-Chloro-2,4-dinitrobenzene

Direct nucleophilic displacement of the halogen in an aryl halide is difficult and the hydrolysis to phenols requires high temperatures and pressures. However, the presence of a nitro group in the ortho or para position makes the halogen more labile since electron withdrawal by the nitro groups in these positions stabilizes the intermediate anion by electron delocalization. For example, when 1-chloro-4-nitrobenzene was heated with 15% sodium hydroxide solution at about 150 °C, it gave 4-nitrophenol as shown in Scheme 35. When two activating nitro groups are present in ortho or para position, 1-chloro-2,4-dinitrobenzene is readily converted into 2,4-dinitrophenol as shown in Scheme 36.

Hydroxylation of m-Nitroaniline

Diazonium salts undergo a large number of reactions in which the diazo group is lost as molecular nitrogen and is replaced by a variety of other groups, such as OH, I, Br, Cl, F, CN, NO2, SO3H, H, and Ar, which becomes attached to the aromatic ring. When a solution of diazonium salt is heated, nitrogen is evolved as gas and the diazo group is replaced by a hydroxyl group. For example, m-nitroaniline is converted to m-nitrophenol as shown in Scheme 37. The diazonium sulfate is preferred over the diazonium chloride as the presence of chloride ions gives rise to small quantities of aryl chloride as by-product. The solution must be acidic in order to avoid the coupling reaction between the unreacted diazonium salt and the phenol.

Hydroxylation of 1-Naphthylamine and 2-Naphthylamine

1-Naphthylamine that is diazotized with sodium nitrite and sulfuric acid followed by reaction with aqueous sulfuric acid gave 1-naphthol as shown in Scheme 38. Similarly, 2-naphthol is obtained from 2-naphthylamine as shown in Scheme 39.

Oxidation

Most frequently encountered oxidation by the dye chemist is the transformation of a methyl group to carboxylic acid group (introduction of carboxylic acid group into aromatic system is called carboxylation) or conversion of –CH= group into keto (=C=O) group. Some of the oxidizing agents employed are summarized below: (1) air oxidation often in the presence of a catalyst; (2) chromic acid; (3) manganese dioxide (MnO2); (4) ferric chloride (FeCl3); (5) nitrosylsulfuric acid; (6) nitric acid; (7) lead peroxide; and (8) sodium hypochlorite. An alkyl group attached to the aromatic ring is oxidized to a carboxylic acid group via oxidation reaction [3,4,5].

Oxidation of 4-Nitrotoluene and 2-Chlorotoluene

For example, 4-nitrotoluene is oxidized with sodium dichromate in concentrated sulfuric acid to 4-nitrobenzoic acid as shown in Scheme 40. Another example of oxidation includes reaction of 2-chlorotoluene with aqueous potassium permanganate that yielded 2-chlorobenzoic acid as given in Scheme 41.

Oxidation of 2-Methylnaphthalene

2-Methylnaphthalene is oxidized by prolonged boiling with concentrated nitric acid (HNO3) to 2-naphthoic acid as shown in Scheme 42.

Oxidation of Naphthalene and Anthracene

Naphthalene that is oxidized by air in the presence of a catalyst, vanadium oxide, gave phthalic anhydride as shown in Scheme 43. In a similar fashion, anthracene that is oxidized by air in the presence of catalysts, sulfuric acid and chromic acid, yielded anthraquinone as given in Scheme 44.

Halogenation

Halogen atoms, usually chlorine or bromine (rarely fluorine or iodine), are generally introduced into the aromatic systems. It is often necessary to use a catalyst. The catalyst most commonly employed is iron or ferric chloride, sometimes iron with a trace of iodine and less frequently antimony, sulfur, or phosphorus compounds [3,4,5]. The chloro derivatives constitute the most important class of halogen-substituted intermediates of the benzene series.

Chlorination of Toluene

Chlorination of toluene with chlorine and ferric chloride as a catalyst resulted in approximately an equimolar mixture of o-chlorotoluene and p-chlorotoluene as given in Scheme 45.

Bromination of Benzene

Benzene does not react appreciably with chlorine or bromine in the cold, but in the presence of catalysts such as pyridine or iron reaction takes place readily, affording mono-halogenated product. Thus, benzene reacts with bromine in the presence of pyridine as the catalyst yielded bromobenzene as shown in Scheme 46. The function of the catalyst is to increase the electrophilic activity of the halogen.

Chlorination of Naphthalene

Naphthalene that is more readily chlorinated than benzene, in the presence of ferric chloride as a catalyst at 110–120 °C, gave 1-chloronaphthalene as the main product along with little of 2-chloronaphthalene as side product as given in Scheme 47.

Bromination of Naphthalene

Condensed aromatic hydrocarbons are more reactive towards electrophilic reagents. For example, naphthalene can be brominated readily with bromine in carbon tetrachloride solution, and without the need of a catalyst yielded 1-bromonaphthalene as illustrated in Scheme 48.

Chlorination of Anthraquinone, 2-Methylanthraquinone, and Bromination of 1-Aminoanthraquinone

The direct chlorination of anthraquinone in oleum cannot be controlled to yield a monochloro product but instead gave 1,4,5,8-tetrachloroanthraquinone as shown in Scheme 49. Careful chlorination of 2-methylanthraquinone with chlorine and sulfuric acid yielded 1-chloro-2-methylanthraquinone as given in Scheme 50. Further, 1-aminoanthraquinone that can be readily brominated with bromine in nitrobenzene yielded 1-amino-2,4-dibromoanthraquinone as shown in Scheme 51.

Diazotization and Coupling

Azo dyes represent the greatest production volume of dyestuff chemistry today and their relative importance may even be growing in the future. The great success of azo dyes is due to several factors such as the simplicity of the coupling reaction, immense possibilities for structural variations and adaptation to the needs of the most diverse applications for these dyes, and often very high molar extinction coefficients of the azo dyes. Thus, the diazotization and coupling are the most important reactions in dye chemistry [3,4,5,6,7,8,9,10].

Diazotization was discovered by Griess in 1858. It is a two-step process. The first step is the formation of a diazonium salt and the second step is the coupling reaction. The aqueous solution of primary aromatic or heteroaromatic amine is treated with mineral acid (HCl, H2SO4) and sodium nitrite (NaNO2) under ice-cold condition (0–5 °C) which gave diazonium salt as shown in Scheme 52. The use of two equivalents of acid is essential for a smooth reaction.

Depending on the basicity and solubility of the amine being diazotized, there are several types of diazotization as given below:

Direct Diazotization

The name “direct” is entirely arbitrary. The primary aromatic or heteroaromatic amine is dissolved or suspended in aqueous hydrochloric or sulfuric acid and aqueous solution of sodium nitrite is added. A temperature of 0–5 °C is maintained by adding ice and salt. Simplicity, speed, and cheapness are the advantages to be gained by its use, but it is not for isolation of the diazonium compounds in the solid form.

Inverted or Indirect Diazotization

The primary aromatic or heteroaromatic amines with carboxylic acid or sulfonic acid groups are often difficult to dissolve in dilute acid. Therefore, the amine is dissolved in water or weak alkali and calculated amount of sodium nitrite solution is added to this amine solution, which is stirred at 0–5 °C adding ice and salt. Thus, the reactivity of the amine is increased by alkali; hence, the method is called “inverted” or “indirect.” The acid can also be added to amine-nitrite mixture. Diazotization usually takes place instantly.

Diazotization of Weakly Basic Amines

When the basicity of an amine is so much reduced that it is no longer soluble in aqueous acids because its salts suffer complete hydrolytic dissociation, the use of such media for diazotization becomes impossible. Weakly basic amines are soluble only in concentrated acids and diazotization is carried out in such solution. Concentrated sulfuric acid is the most commonly employed solvent for this purpose. Thus, nitrosylsulfuric acid is prepared from solid sodium nitrite and concentrated sulfuric acid and used for diazotization. Weakly basic amines are dissolved in concentrated sulfuric acid and diazotized with nitrosylsulfuric acid.

Diazotization in Organic Solvents

The water-insoluble or sparingly soluble amine is dissolved in organic solvents (alcohol) or glacial acetic acid and diluted with water. After the addition of acid, it is diazotized in the usual manner with sodium nitrite solution.

Aromatic Diazo Components

Anilines, substituted anilines, naphthylamines, and substituted naphthylamines are used as aromatic diazo components. The representative examples of aromatic diazo components are aniline, substituted anilines, 1-naphthylamine, substituted 1-naphthylamines, 2-naphthylamine, and substituted 2-naphthylamines as shown below.

Heterocyclic Diazo Components

Dyes with heterocyclic diazo components have received much attention because of their high tinctorial power and excellent brightness. Heterocyclic diazo components are used in the preparation of acid dyes for polyamide carpet fibers, which demonstrated excellent leveling properties. Heterocyclic diazo components are also extensively used in the preparation of disperse dyes with outstanding dischargeability on cellulose acetate fibers. The success of new diazo components has been especially remarkable with disperse dyes as it has become possible to cover the whole shade range with monoazo dyes. These new monoazo blue dyes can now replace anthraquinones. The representative examples of heterocyclic diazo components are 2-aminothiazoles, 2-aminobenzothiazoles, 5-aminoisothiazoles, 3-amino-2,1-benzoisothiazoles, 2-amino-1,3,4-thiadiazoles, 5-amino-1,2,4-thiadiazoles, 2-aminoimidazoles, 5-aminopyrazoles, 2-aminothiophenes, 3-aminothiophenes, 2-aminothiazoles, and 2-aminobenzothiazoles [11] as shown below.

Coupling

Coupling was discovered by Kekule and Hidegh in 1870. The optimum coupling conditions depend on the nature of the diazo and coupling components used. The acidic diazonium salt solution is very slowly added (dropwise) to a solution of coupling component, either in acid or in alkali depending on the type of coupling component desired. The coupling reaction may be completed immediately after the components are mixed or after several hours. The monitoring and control of pH are extremely essential for coupling reaction. It is critical to maintain temperature at 0–5 °C by adding ice-salt mixture. The control of reaction temperature and pH is extremely necessary for the smooth coupling reaction. Coupling takes place in two ways, alkaline coupling and acidic coupling. In alkaline coupling, the diazonium salts couple to p-position of the hydroxyl group (or if p-position is occupied then it couples to o-position). In acidic coupling, the diazonium salts couple to p-position of the N,N-dialkyl-substituted aryl amines as shown in Scheme 53.

The coupling components include aromatic hydroxy compounds such as phenols, naphthols, naphtholsulfonic acids, aromatic amines such as anilines, diaminobenzenes, naphthylamines, naphthylaminesulfonic acids, aromatic aminophenols, aminophenolsulfonic acids, aminonaphtholsulfonic acids, aromatic N,N-dialkylsubstituted aryl amines, compounds with reactive methylene group (acetoacetarylides), and heterocyclic coupling components such as 5-hydroxypyrazoles, 5-aminopyrazoles, 6-hydroxypyridines, 6-aminopyridines, hydroxypyrido[1,2-a]benzimidazoles, aminopyrido[1,2-a]benzimidazoles, hydroxypyrimidines (barbituric acid), and hydroxyquinolines/hydroxyquinolones that are discussed below.

Aromatic Hydroxy Compounds

This group includes aromatic hydroxy compounds such as phenols, naphthols, and naphtholsulfonic acids, in which the coupling is carried out at the alkaline pH. Phenols mainly couple at the 4-position or at the 2-position if the 4-position is occupied. 1-Naphthols mainly couple at 4-position but 2- and 2,4-coupling products are also obtained, depending on the diazo component. 2-Naphthol couples at the 1-position. Similarly, the coupling of naphtholsulfonic acids is as shown below.

Aromatic Amines

This group includes aromatic amines such as anilines, diaminobenzenes, naphthylamines, and naphthylaminesulfonic acids, in which the coupling is carried out at the acidic pH. Anilines mainly couple at the 4-position or at the 2-position if the 4-position is occupied. 1-Naphthylamines mainly couple at 4-position but 2- and 2,4-coupling products are also obtained, depending on the diazo component. 2-Naphthylamine couples at the 1-position

Aromatic Aminophenols, Aminophenolsulfonic Acids, Aminonaphtholsulfonic Acids

In acidic medium, the coupling occurs at ortho or para position to amino group while the coupling occurs at ortho or para position to hydroxy group in alkaline medium. The preference of whether acidic or alkaline coupling occurs first depends on the other substituents on the aromatic nucleus as shown below. The representative examples of aromatic aminophenols, aminophenolsulfonic acids, and aminonaphtholsulfonic acids are m-aminophenol, I acid, γ acid, H acid, and K acid as shown below.

Aromatic N,N-Dialkylsubstituted Aryl Amines

The coupling occurs at p-position of N,N-dialkylsubstituted aryl amines under acidic conditions. The representative examples of aromatic N,N-dialkylsubstituted aryl amines are as shown below.

Compounds with Reactive Methylene Group

The coupling occurs at the reactive methylene group (>CH2). N-acetoacetyl derivatives of aromatic amine (acetoacetarylides) have the greatest industrial importance. Anilines substituted with halogen, alkyl, alkoxy, nitro, and acylamino groups are most commonly used as shown below.

Heterocyclic Coupling Components

As the great majority of the azo dyes are synthesized by the coupling reaction, the progress in azo dye chemistry has been largely determined by the technological progress in coupling. New azo coupling components and in particular new heterocyclic coupling components are of tremendous importance. The most commonly used heterocyclic coupling components with highest technical importance and for generating brightest dyes are discussed below. The representative examples of heterocyclic coupling components are 5-hydroxypyrazoles, 5-aminopyrazoles, 6-hydroxypyridines, 6-aminopyridines, hydroxypyrido[1,2-a]benzimidazoles, aminopyrido[1, 2-a]benzimidazoles, hydroxypyrimidines (barbituric acid), and hydroxyquinolines/hydroxyquinolones [12] as shown below.

Replacement of Diazo Group by Other Groups

Diazonium salts undergo a large number of reactions in which the diazo group is lost as molecular nitrogen and is replaced by a variety of other groups, e.g., OH, Cl, Br, I, CN, SH, and C6H5, which becomes attached to the aromatic ring as shown in Scheme 54.

Dyeing

It is difficult if not impossible to determine when mankind first systematically applied color to a textile substrate. The first colored fabrics were probably nonwoven felts painted in imitation of animal skins. The first dyeings were probably actually little more than stains from the juice of berries. Ancient Greek writers described painted fabrics worn by the tribes of Asia Minor. But just where did the ancient craft have its origins? Was there one original birthplace or were there a number of simultaneous beginnings around the world?

Although it is difficult to determine just when each respective civilization began to use dyes, it is possible to date textile fragments and temple paintings, which have survived the ensuing centuries. The ancient Egyptians wove linen as early as 5000 BC, and paintings on tomb walls infer that colored wall hangings were in use by 3000 BC. By 2500 BC, dyer’s thistle and safflower were used to produce red and yellow shades. Egyptian dyers developed a full range of colors by 1450 BC.

Another cradle of civilization was the Indian subcontinent where religious and social records dating to 2500 BC refer to dyed silk and woven brocades of dyed yarn. Cotton, first cultivated in the Indus valley of Pakistan, was woven as early as 2000 BC. A book written around 300 BC included a chapter on dyes. It is believed that systematic dyeing occurred in China as early as 3000 BC near the city of Xian in the Hoang (Yellow) River Valley, although there is no conclusive proof. Empress Si-Ling-Chi is credited with the discovery of silk about 2640 BC. Kermes and indigo were used as dyes as early as 2000 BC. Fragments of silk have been found in the corrosive patina of bronze swords of the Shang dynasty (1523–1027 BC), but most assuredly these samples are not the oldest [13].

The New World was similarly active in developing the textile art. With help from the desert climate in the high Andes of Peru, dyed samples of wool have been preserved and recovered from burial sites. These fragments have been dated to the millennium before the Christian era. The western and southwestern regions of the United States provided homes for the Anasazi, or ancient ones, who dwelt in the region of Mesa Verde National Park in southwestern Colorado, northern Arizona, New Mexico, and eastern Utah. Again the dry climate has helped to preserve samples from these early civilizations.

Very little in the nature of large, intact textile samples has survived in Europe. Remains of a large woolen robe, the Thorsberg Robe, found in northern Germany and dated prior to 750 BC, indicate a highly developed dyeing and weaving technology [14]. Indirect evidence is more plentiful: for example, a tombstone of a purpurarius, a Roman purple dyer, was found near Parma, northern Italy, and a dyer’s workshop excavated in Pompeii. This great center of the Roman Empire was destroyed by the eruption of Mount Vesuvius in 79 AD. Similar stone vats for dyeing have been excavated in the tells of Israel and in present-day Turkey.

The Dark Ages following the fall of the Roman Empire were dark indeed, with little development of the dyer’s art. The robes of a number of the monastic orders were brown and black, surely a dark age. By the end of the 1300s, however, civilization began making the swift and certain strides that have led to our present level of development. In 1371, the dyers of Florence, a city famous for its Renaissance art, formed a guild, or association of like merchants and craftsmen, which lasted for 11 years. Other guilds were being formed in other centers across Europe. Some of these guilds exist to this day. The Worshipful Company of Dyers was formed in 1471 in London. One of the legacies of this guild is a Publications Trust, which has underwritten the publication of a number of books on dyeing in cooperation with The Society of Dyers and Colourists.

The art and craft of dyeing were largely passed down from father to son or from craftsman to apprentice by word of mouth and example until the early 1500s. The Plictho of Gioanventura Rosetti, a Venetian armory superintendent, is believed to be the first published book on dyeing. It certainly is the oldest surviving European text to have come down to us in the twenty-first century. Five known Italian editions were published between 1548 and 1672. A French edition appeared in 1716. It is interesting that no known English translation was made until 1968 [15] when Sidney Edelstein of the Dexter Chemical Company and Hector Borghetty collaborated to reproduce a facsimile of the original 1548 edition along with a complete translation into English. During his extensive travels, Rosetti collected dyeing recipes and processes used in the flourishing city states of Venice, Genoa, and Florence. He published: Plictho de L’arte de Tentori che insegna tenger pani telle banbasi et sede si per larthe magiore come per la comune or Instructions in the Art of the Dyers, Which Teaches the Dyeing of Woolen Cloths, Linens, Cottons, and Silk by the Great Art as Well as by the Common or simply Instruction in the Art of Dyeing. The book was divided into four sections: the first and second sections were devoted to the dyeing of wool, cotton, and linen; the third to the dyeing of silk and the use of fugitive colors; and the fourth to the dyeing of leather and skins. Approximately 160 complete recipes were preserved in the first three sections. Edelstein and Borghetty labored diligently in determining the meanings of terms in recipes written in the dialect of sixteenth-century Italy.

Synthetic Dyes

The father of modern synthetic dyes was William Henry Perkin (1838–1907), who synthesized mauve, or aniline purple, in 1856. The story behind this great story bears telling. William’s father was a builder who wanted him to become an architect, but like many others, Perkin did not follow his father’s chosen profession. Perkin studied at the City of London School where he became interested in chemistry at the age of 12. A teacher, Mr. Hall, gave him work in the laboratory, which in turn inspired Perkin to follow his natural curiosity. At age 15, Perkin entered the Royal College of Science and listened to the lectures of the great German chemist, August Wilhelm von Hofmann (1818–1892). He was granted an assistantship under von Hofmann at age 17. Because his work did not allow time for his own research, he set up a separate laboratory at home and it was there that he discovered aniline purple, the first dyestuff to be commercially produced. Another dye, based on naphthalene, and prepared in collaboration with Arthur H. Church, actually preceded aniline purple, but was not commercially produced before aniline purple. Aniline purple was discovered at this home during Easter vacation while looking for quinine, an antimalarial drug. After oxidizing aniline with potassium dichromate and getting a black precipitate, extraction with ethanol gave a brilliant purple solution. Almost immediately, he sent a sample of this dye to a dyer in Perth with a request to dye silk fabric. The dyer’s report read: “If your discovery does not make the goods too expensive, it is decidedly one of the most valuable that has come out for a long time.” Trials on cotton were not as successful because the need for a mordant was not realized. Perkin later reported, “The value of mauve was first realized in France, in 1859. English and Scotch calico printers did not show any interest in it until it appeared on French patterns, although some of them had printed cloth for me with that colour [16].”

Since that beginning, thousands of dyes have been synthesized; some 1500–2000 are commercially successful today. Until 1884, however, all synthetic dyes required a mordant to give acceptable wash-fastness on the textile substrate. In 1884, Böttiger produced Congo red, which could dye cotton directly without a mordant. These dyes were commonly called direct dyes. In order to improve wash-fastness, the path taken in some synthetic dye chemistry was to build the dye from two or more components, directly in the fiber, or in situ. By building a large molecule without solubilizing groups within the fiber, wash-fastness was markedly improved. The first practical development along these lines was by A. G. Green who synthesized primuline, a dye that because of poor light-fastness was not commercially important but later led the way to many important commercial dyes. Table 2 lists a number of classes of dyes along with the date of discovery. Worldwide, 80% of all dyes go into textiles and 20% into paper, leather, food, and the like.

Development of US Dyestuff Industry

The natural dye industry was more than just a cottage industry in Colonial America. Indigo was a very important cash crop in South Carolina among the coastal islands and for some distance inland. Plantations existed well into the early 1900s despite the growth of the synthetic dyestuff industry.

The modern synthetic dye industry in the United States dates from World War I. However, in 1864, Thomas Holliday of Great Britain, and in 1868, the Albany (NY) Aniline Company with participation of Bayer of Germany began coal-tar dye manufacture. In the early 1900s, most synthetic dyes used in the United States were imported from Germany and Switzerland. With the outbreak of World War I, the British naval blockade of Germany prevented export of dyes from Europe. In spite of the blockade, the German submarine, Deutschland, ran the British blockade and sailed into American ports twice with dyestuffs and drugs. The Germans needed critical war material and export moneys; the United States and others needed dyes. Ironically, in 1914, German dyes were used by French dyers to dye the official French Army uniforms. The outbreak of war and ensuing blockade showed the United States how important dyes were to the American economy. Several companies began investigative work that would lead to dye synthesis; they found that dyestuffs were very difficult to make; the chemistry was much more complex than imagined. A real boost to the US industry came after World War I, when the German patents were given over to the Allies via the Alien Property Custodian. According to Lehner, DuPont reportedly spent $43 million, a tremendous sum of money in the early twentieth century, before ever showing a profit [17]. Obviously, only financially strong companies could afford to enter the business. The early pioneers included Allied (formed by merging five companies), American Cyanamid, and DuPont, to name only a few who survived to become major factors later in the twentieth century. In 1938, others included Dow, German-owned General Aniline and Film (GAF), and Swiss-owned Cincinnati Chemical Company (Ciba, Geigy, and Sandoz). In the 1960s, 50–60% of all US manufacturing was in the hands of four principal US companies:

-

Allied Chemical (later sold to Bayer of Germany and to independent investors as Buffalo Color, 1977)

-

American Cyanamid

-

GAF, the result of the break-up of the German cartel, I. G. Farben, which was nationalized during World War II and sold to BASF in 1978

-

DuPont (sold in 1980–1981 with various lines going to Crompton & Knowles, Ciba, and Blackman-Uhler)

Today, there are at least 42 dyestuff manufacturers, distributors, and repackaging agents in the United States [18]. Of the major companies, Swiss and German-based companies tend to dominate the US market. Those companies include:

-

Ciba, formerly Ciba-Geigy, Switzerland

-

Clariant (split off from Sandoz in 1995), Switzerland

-

DyStar, formed by the merger of Hoechst and Bayer (1995), acquisition of BASF textile colors which include the former Zeneca, and Mitsubishi of Japan

-

Crompton & Knowles sold to Yorkshire Group Plc and is now Yorkshire Americas

There is no major surviving US-based company. Raghavan [19] and Mock [20] give an interesting description of these mergers and the reasons behind them.

Most of the international companies have limited manufacturing facilities in the United States and major facilities in other countries where environmental laws are not as stringent or where the parent companies have a modern integrated low-pollution facility. These facilities in the United States minimize the tariffs paid and also allow quicker response to the marketplace. Ciba has a manufacturing facility in St. Gabriel, LA; Clariant in Martin, SC; DyStar near Charleston, SC; and Yorkshire Americas at Lowell, NC.

Today well over 1500 dyes are produced in commercial quantities, although only a select handful in each class are the true “workhorse” colors found in virtually every dyehouse dyeing a particular substrate for a particular end use. Approximately two-thirds of the dyes and pigments consumed in the United States are used by the textile industry. One-sixth of the dyes and pigments are used for coloring paper, and the rest are used chiefly in the production of organic pigments and in the dyeing of leather and plastics.

Dyes are catalogued and grouped under a set of rules established by the Colour Index committee, consisting of representatives from the Society of Dyers and Colourists (SDC), Bradford, England, and the American Association of Textile Chemists and Colorists (AATCC), Research Triangle Park, NC. Table 3 shows how over 9000 dyes are enumerated in the Colour Index. The Colour Index, now in its fourth edition, is updated periodically with newly released information and is available in book form and on CD-ROM. Volumes 1–3, published in 1971, contain the C.I. name and number, chemical class, fastness properties, hue indication, application, and usage. Volume 4, also published in 1971, contains the structures of all disclosed structures. Volume 5, last published as part of Volume 9 in 1993, contains the commercial names of all known dyes and pigments. Volumes 6–8 are supplements with updates to information in Volumes 1–4 up to 1976, 1981, and 1987, respectively. An online version of the Colour Index containing a significant number of new entries was made available in 2002.

In addition to the Colour Index, AATCC publishes a Buyer’s Guide annually in July [18]. Part A lists dyes, pigments, and resin-bonded pigment colors available from companies who choose to list this information.

The textile industry uses a large number of dyestuffs from each of the dye categories, the choice depending on the shade, fiber, and dyeing process; end use of the textile product; requirements for fastness; and economic considerations. To provide an understanding of the interrelationships that exist among the various dye classes and fiber types, a brief survey of the major fibers follows.

A review describes the textile dye industry in the United States. [21]. The market for dyes continued to shrink in the United States during the late 1990s. It seems clear that apparel production has essentially left the United States for the foreseeable future; over 80% are currently of foreign origin. Dyes will continue to be used in the United States in carpet, upholstery, bed linens, and home furnishings; however the non-textile uses of dyes continue to increase in the United States.

Textile Fibers

In this survey, commercially important textile fibers are grouped by their origin. First there are the natural fibers from plant sources, cotton and flax, and those from animal sources, wool and silk. A second group consists of those fibers that are regenerated or chemically modified natural materials, the rayon and acetate fibers. The final group consists of synthetic fibers, which include polyester, nylon, acrylics, polyolefins, and elastane.

Natural Fibers

Cotton. Cotton fibers are comprised mainly of cellulose, a long-chain polymer of anhydroglucose units connected by ether linkages. The polymer has primary and secondary alcohol groups uniformly distributed throughout the length of the polymer chain. These hydroxyl groups impart high water absorption characteristics to the fiber and can act as reactive sites. The morphology of the cotton fiber is a complex series of reversing spiral fibrils. The fiber in total is a convoluted collapsed tube with a high degree of twist occurring along the length of the fiber. This staple fiber occurs in nature in lengths of ½–2 in., depending on the variety and growing conditions. The diameter ranges from 16 to 21 μm (1 μm is 1 × 10−6 m).

Flax. Flax is also a cellulosic fiber but has a greater degree of crystallinity than cotton. The morphology of flax is quite different from that of cotton. Flax fibers have a long cylindrical shape with a hollow core. The fibers range in length from ½ to 2½ in., with a diameter of 12–16 μm. Flax staple is comprised of bundles of individual fibers. Historians believe that flax was among the first fibers to be used as a textile fiber. In recent years, its commercial importance as a textile fiber has decreased significantly.

Wool. Wool fibers are comprised mainly of proteins: the polypeptide polymers in wool are produced from some 20 alpha-amino acids. The major chemical features of the polypeptide polymer are the amide links, which occur between the amino acids along the polymer chain, and the cystine (sulfur to sulfur) cross-links, which occur in a random spacing between the polymer chains. The polymer contains many amine, carboxylic acid, and amide groups, which contribute in part to the water-absorbent nature of the fiber.

The morphology of wool is complex. There is an outer covering over the fiber, the cortical. There are also overlapping scales having a ratchet configuration that causes shrinkage and felting. The coefficient of friction in wool fibers is vastly different between the tip and the root, depending on which way the scales point. Wool can be made washable by chemically abrading the scales or coating the fibers with another polymer.

Wool fibers are not round but are oval in cross section. The cortical cells constitute the major component of the fiber, and are aligned along the axis of the fiber. There is a medulla section at the center region of the fiber. Each fiber has a bicomponent longitudinal crystalline arrangement. One side of the fiber contains alpha-keratin crystalline regions, and the other contains beta-keratin crystalline regions. Alpha-keratin and beta-keratin have different moisture absorption characteristics, and this difference is what gives wool fibers crimp and springiness. It is also the reason why wool fibers kink in conditions of high humidity.

Wool fibers are sheared from about 30 major sheep breeds. The length of the wool fibers varies from 1 to 14 in. and depends on the breed, climate, and location on the sheep’s anatomy. The fibers can be very fine to very coarse, ranging from 10 to 50 μm in diameter. The longer, coarser fibers normally are used for woolen fabrics, whereas the shorter finer ones are used for worsted fabrics.

Silk. Silk, like wool, is a protein fiber, but of much simpler chemical and morphological makeup. It is comprised of six alpha-amino acids, and is the only continuous-filament natural fiber. Historians claim that silk was discovered in China in 2640 BC. Silk fiber is spun by the silkworm as a smooth double strand, each part having a trilobal cross section. This configuration helps give silk its lustrous appearance. The fiber is unwound from the cocoon the silkworm spins as it prepares its chrysalis. The filaments are smooth and have no twists in their length, which can vary from 300 to 1800 yards. The diameter of silk is very fine, ranging from 2 to 5 μm. Because of the labor-intensiveness of sericulture and subsequent preparation of the fiber, silk remains a luxury fiber.

Regenerated Fibers

Rayon. Viscose rayon, like cotton, is comprised of cellulose. In the manufacturing process, wood pulp is treated with alkali and carbon disulfide to form cellulose xanthate. Subsequently, the reaction mass is forced through a spinneret and precipitated in an acid coagulation bath as it is formed into a continuous filament. The fiber has a round striated cross section. Rayon staple is made by “breaking” the continuous strands into staple-length fibers. Viscose rayon is conventionally produced in diameters varying from 9 to 43 μm.

Acetate. Triacetate and diacetate fibers are manufactured by the chemical treatment of cellulose obtained from refined wood pulp or purified cotton lint. Most of the hydroxyl groups are acetylated (esterified) by treating the cellulose with acetic acid. This determines the chemical configuration of triacetate. Acetate or diacetate is made by the saponification of one of the acetylated groups, thus restoring a hydroxyl to each cellulosic monomer unit. Theoretically, then, diacetate has two acetylated groups in each glycoside unit. The conversion of the hydroxyl groups causes these fibers to be hydrophobic and changes the dyeing characteristics drastically from those of the normal cellulosic fibers.

Triacetate fibers are spun by mixing the isolated reaction product (flake) with methylene chloride and alcohol. The spinning solution (dope) is forced through a spinneret and dry-spun into continuous filaments.

An alternate way of wet spinning is also possible. Acetate fibers are spun by mixing the isolated reaction product with acetone and water. The spinning solution is formed into filaments by evaporating the solvent and coagulating the acetate in a manner similar to that for triacetate (i.e., by the dry-spinning method).

Synthetic Fibers

Nylon. In 1939 the DuPont Company introduced the first truly synthetic textile fiber. Dr. Wallace Carothers invented nylon as a result of his basic research into polymer science. Chemically, nylon is a polyamide fiber. The two major types of nylon polymer are used in textiles: type 6,6 which is made by using hexamethylenediamine and adipic acid, and type 6, which is made by polymerizing ε-caprolactam. Nylon fibers are made by melt-spinning the molten polymer. The result is a continuous filament fiber of indeterminate length. It is spun in many deniers, with its diameter varying from 10 to 50 μm. The cross section usually is round, trilobal, or square with hollow channels when used as carpet fiber.

Polyester. Polyester is made by the polymerization reaction of a diol and a diester. The main commercial polymer is formed by a condensation reaction using ethylene glycol and terephthalic acid. Fibers are formed by melt-spinning. Commercially introduced in 1953 by the DuPont Company as Dacron, polyester fibers have high strength, and very low moisture absorbance. The fiber is usually spun with a round cross section. Polyester is the most used synthetic fiber around the world.

Acrylics. The DuPont Company introduced the first commercial acrylic fiber, Orlon, in 1950. Acrylics are made from the polymerization of acrylonitrile and other co-monomers to allow dyeability and to open the internal structure. The fibers are produced by either solvent-spinning (Orlon), or wet-spinning (Acrilan). In the solvent-spinning process, the polymer is dissolved in a low-boiling liquid solvent such as dimethyl formamide and extruded in a warm air chamber. In wet-spinning, the polymer is dissolved in a suitable solvent, extruded into a coagulation bath, dried, crimped, and collected. Although the acrylic fibers are extruded as continuous filaments, they subsequently are cut into staple-length fibers. Acrylics have found a niche market as a substitute for wool or in wool blends (blankets, sweaters, etc.) and in awnings and boat covers. The cross section of the filament varies among manufacturers, Orlon having a dog-bone configuration and Acrilan having a lima-bean shape. Acrylic fibers are quick drying and wrinkle resistant.

Polyolefins. Polyolefin fibers are produced from the polymerization of ethylene or propylene gas. The catalysis research of Ziegler and Natta led to the development of these polymers to form crystalline polymers of high molecular weight. Hercules Inc. produced the first commercial fibers in 1961. The fibers made from these polymers are melt-spun. The cross sections are round, and the fibers are smooth. They have extremely low dye affinity and moisture absorbance. Colored fiber is normally produced by mixing pigments in the melt polymer prior to extrusion.

Elastane. The DuPont Company commercialized the first manufactured elastic fiber, Lycra, in 1958. Originally categorized as a spandex fiber, the name “elastane” has become more common around the world. This specialty fiber is described as segmented polyurethane that contains “hard” and “soft” segments; their ratio determines the amount of stretch built into the fiber. Elastane fibers are formed by dry-spinning or solvent-spinning. The continuous filaments can be coalesced multifilaments or monofilaments, depending on the manufacturer. Because most dyeings are applied from water solutions or dispersions, the effect of water absorption by the fiber is an important criterion. Table 4 shows the hydrophobic/hydrophilic characteristics of the important fibers. The cellulosic and natural fibers are the most hydrophilic, and polyolefin is the most hydrophobic.

Microdenier Fibers. The first commercial production of microfiber in the United States was in 1989 by the DuPont Company. Today microfibers are produced in a variety of synthetic fibers (i.e., polyester, nylon, acrylic). A microfiber is a fiber that is less than one denier per filament. Yarns made from microdenier filaments are able to give silklike hand to fabrics.

Classification of Dyes

Dyes can be classified according to their usage or application method or according to chemical structure. In this chapter, the dyes are classified according to their usage or application method such as acid, basic (cationic), direct, disperse, reactive, solvent, sulfur, and vat dyes. Classification by usage or application is the principal system adopted by the Colour Index (CI). Traditional chemical classes of dyes such as azo, anthraquinone, phthalocyanine, and triphenylmethane are also included. With regard to the application of synthetic dyes to textiles, it is well known that dyeing of textile fibers from an aqueous dye bath involves four steps: exhaustion, diffusion, migration, and fixation. In step 1, individual dye molecules move from the dye bath to the fiber surface and in step 2, dye molecules move from the fiber surface into the amorphous regions of the fiber. In step 3, dye molecules move from regions of high concentration to regions of low concentration (i.e., migrate) to become uniformly distributed within the polymer matrix. In step 4, dye molecules interact with groups along the polymer chain via primary or secondary valency forces. Dye-polymer interactions can involve ionic bonding (e.g., acid dyes on nylon or wool), covalent bonding (e.g., reactive dyes on cotton), mechanical entrapment (e.g., vat dyes and sulfur dyes on cotton), secondary valency forces (direct dyes on cotton), or solid–solid solution (e.g., disperse dyes on polyester).

Acid Dyes

Acid dyes are used for dyeing polyamide, silk, and wool in the presence of an organic or inorganic acid (pH 2–6); hence they are called as acid dyes. Thus, the name “acid dye” is derived from the dyeing process. Acid dyes have sulfonic acid group, generally as sodium salt (R-SO3Na). When dissolved in water, they produce colored anions (RSO3 −) and colorless sodium cations (Na+) [22].

Acid dyes are divided into three groups based on their differences in affinity (which is primarily a function of the molecular size), their application, and wet fastness properties:

-

1.

Leveling Dyes Leveling acid dyes level well and their fastness is generally good. Leveling dyes for wool have low molecular weights and usually require a highly acidic dye bath for good exhaustion.Leveling dyes for nylon have high molecular weights and are applied at a neutral or weakly acidic pH. Leveling dyes are relatively small molecules, which form a salt-like bond with the protein fiber.

-

2.

Milling Dyes Milling acid dyes have better washing fastness than the leveling acid dyes but the shades generally lack brightness and good leveling power. Milling dyes are large-volume dye molecules, for which salt formation with fiber plays only a secondary role and the adsorption forces between the hydrophobic regions of the dye molecule and those of the protein fiber predominates.

-

3.

Super Milling Dyes Super milling acid dyes are applied from neutral solutions. They are not level dyeing and their application requires considerable care because of their comparatively high molecular weights. Super milling dyes with intermediate molecular size not only form a salt-like bond with the wool fiber but are also bonded to the fiber by intermolecular forces and have properties lying in an intermediate position between those of the leveling and milling dyes. Chemically, acid dyes are divided into various subclasses such as nitro, nitroso, monoazo, diazo, azine, ketone-imine, quinolone, triphenylmethane, xanthine, and anthraquinone.

Acid Monoazo Dyes

Acid monoazo dyes exhibit brilliance of shades, very good leveling power, and low cost and are used for dyeing wool. The representative examples of acid monoazo dyes having aromatic amines as coupling components are C.I. Acid Yellow 36 and C.I. Acid Blue 92 as shown below.

The representative examples of acid monoazo dyes having naphthols as coupling components are C.I. Acid Orange 7, C.I. Acid Red 88, and C.I. Acid Red 13 as shown below. C.I. Acid Orange 7 is a long-known, inexpensive acid monoazo dye and is used for dyeing wool, paper, and leather. C.I. Acid Red 88 and C.I. Acid Red 13 produce attractive red shades.

The representative examples of acid monoazo dyes having naphtholsulfonic acids as coupling components are C.I. Acid Orange 19 and C.I. Acid Red 14 as shown below. These dyes exhibit good fastness properties and are used for dyeing wool.

The representative examples of acid monoazo dyes having aminonaphtholsulfonic acids as coupling components are C.I. Acid Red 42, C.I. Acid Red 37, and C.I. Acid Violet 14 as shown below. These dyes show good light-fastness, wet-fastness, and good leveling power properties and are used for dyeing wool.

Further representative examples of acid monoazo dyes having aminonaphtholsulfonic acids as coupling components are C.I. Acid Red 32 and C.I. Acid Blue 117 as given below. These dyes exhibit very good wet-fastness and high leveling power properties and are used for dyeing wool. Another representative example of acid monoazo dye having aminonaphtholsulfonic acid as coupling components is C.I. Acid Brown 20 as shown below, which results in strong deepening shades and is used for dyeing silk and wool.

Acylation of the amino group of coupling component aminonaphtholsulfonic acids substantially improves light-fastness, wet-fastness, and leveling power. The representative examples of acid monoazo dyes having acylaminonaphtholsulfonic acids as coupling components are C.I. Acid Red 1 and C.I. Acid Red 138 as shown below. Incorporating long-chain hydrophobic hydrocarbon radical in C.I. Acid Red 138 results in very good wet-fastness properties and neutral affinity to wool.

Light-fast yellow shades can especially be achieved by using 1-phenyl-5-hydroxypyrazole as coupling components. 1-Aryl-3-methyl-5-hydroxypyrazole is preferred over corresponding 3-carboxy-5-hydroxypyrazole due to cost. These series generate a wide range of possible variations that the dyes extend from greenish yellow to reddish orange. The representative examples of acid monoazo dyes having 1-phenyl-5-hydroxypyrazole as coupling components are C.I. Acid Yellow 17 and C.I. Acid Yellow 76 as shown below. These dyes show good light-fastness and good milling-fastness properties and yield a clear, superbly light-fast yellow on wool.

Acid Disazo Dyes

Acid disazo dyes contain two azo groups. One of the most important representative examples of acid disazo dye is C.I. Acid Black 1 as given below. It exhibits good light-fastness, high affinity, good leveling power but moderate wet-fastness. It dyes wool in blue-black shades. Another representative example of acid disazo dye is C.I. Acid Yellow 38 as given below. It particularly provides excellent milling-fatness and dyes wool in bright yellow shades. Further representative example of acid disazo dye is C.I. Acid Yellow 56 as given below. It demonstrates good light-fastness, excellent wet-fastness, and usually neutral dyeing on wool.

Additional representative examples of acid disazo dyes are C.I. Acid Red 134 and C.I. Acid Red 154 as shown below. These dyes are used for dyeing polyamide and wool.

Further representative examples of acid disazo dyes are C.I. Black 24 and C.I. Acid Black 26 as shown below. These dyes give high yield, show very good wash-fastness and light-fastness, and are used for dyeing wool.

Acid Anthraquinone Dyes

Red and yellow acid anthraquinone dyes are of little importance. The majority of the commercially available acid anthraquinone dyes give bright blue shades as these are not obtained by azo dyes. Dyes of green shades can be achieved by combining blue and yellow dyes. The uniformly dyeing green dyes of the acid anthraquinone series are of special value. Acid anthraquinone dyes can be classified for particular applications according to their light-fastness, wash-fastness, and leveling characteristics. The representative examples of acid anthraquinone dyes containing 1-aminoanthraquinone-2-sulfonic acid are C.I. Acid Blue 25, C.I. Acid Blue 40, C.I. Acid Blue 62, and C.I. Acid Blue 129 as shown below.

The representative example of acid anthraquinone dyes containing diaminodihydroxy-anthraquinone sulfonic acids for dyeing wool is C.I. Acid Blue 43 as shown below.

The representative examples of acid anthraquinone dyes containing 1,4-diamino-anthraquinones with external sulfonic acid groups are C.I. Acid Green 25, C.I. Acid Green 41, and C.I. Acid Violet 42 as shown below. Further representative example of acid anthraquinone dyes containing 1-amino-4-hydroxyanthraquinones with external sulfonic acid groups is C.I. Acid Violet 43 as shown below.

Basic Dyes

Basic dyes are ionic dyes in which the colored part of the molecule is positively charged (cationic). For this reason, they are frequently referred as cationic dyes. They have good solubility in water. Basic dyes have high colored value and are among the brightest dyes available. Historically, basic dyes are important because the first synthetic dye, Mauve, synthesized by Perkin in 1856, is a basic dye. They have good fastness properties at a reasonable price. Basic dyes are applied to fibers made up of negatively charged polymer molecules. Bonds can be formed between the cation of the dye molecule and the anionic site in the fiber. Basic dyes are applied to cotton, silk, wool, acrylic fibers, paper, plastics, leather, and waxes [23,24,25,26].

In general, there are two important groups of cationic dyes:

-

1.

Localized or pendant cationic dyes: Those in which the positive charge is localized on one atom, usually a nitrogen atom.

-

2.

Delocalized cationic dyes: Those in which the positive charge is delocalized over the entire molecule (chromogen).

Localized or Pendant Cationic (Basic) Dyes

This group includes azo and anthraquinone dyes used for polyacrylonitrile fibers by the introduction of a pendant cationic group. These dyes are bright and show tinctorial strength.

The representative examples of localized or pendant cationic (basic) dyes are C.I. Basic Orange 1, C.I. Basic Orange 2, C.I. Basic Blue 54, and C.I. Basic Blue 22 as shown below.

Delocalized Cationic (Basic) Dyes

This group includes polymethine, triphenylmethane, oxazine, and thiazine (and their heterocyclic analogs) dyes. These dyes show exceptionally high tinctorial strength, high brightness, high fastness properties, and improved cost-effectiveness. The representative examples of delocalized cationic (basic) dyes are C.I. Basic Yellow 11, C.I. Basic Yellow 28, C.I. Basic Red 14, and C.I. Basic Blue 3 as shown below.

Direct Dyes

This class of dyes is called direct dyes because they dye cellulosic fibers directly without mordanting, which was necessary when trying to dye cellulosics with virtually all naturally occurring dyes. The first direct dye of this family was reported in 1884 and is called Congo red. Direct or substantive dyes are water-soluble anionic dyes, which when dyed from aqueous solution in the presence of electrolytes are substantive, i.e., have affinity for cellulosic fibers (cotton, viscose rayon, jute, hemp, linen, and ramie) [22, 27].

Direct dyes provide the simplest means of coloring cellulosic materials since they are normally applied from a neutral to slightly alkaline bath, at or near the boil, to which sodium chloride or sulfate is added in such quantities and at such intervals of time appropriate to the dyeing properties of individual dyes. The essential requirement of a dye in this group is its substantivity, i.e., its absorption from an aqueous salt-containing solution onto cellulosic materials. Absorption onto cotton takes place in a neutral or an alkaline medium and onto paper in a weakly acidic or neutral medium. The principal use of these dyes is the dyeing of cotton and regenerated cellulose, paper, leather, wool, silk, and to a lesser extent nylon. They are also used as pigments, indicators, and biological stains. Because of their ease of application and moderate price, direct dyes still represent one of the largest groups of azo dyes, although they have limited wet-fastness.

The majority of direct dyes belong to dis-, tris-, and polyazo classes, the remainder being monoazo, oxazine, stilbene, thiazole, triazine, and phthalocyanine compounds.

Direct Monoazo Dyes

The representative examples of direct monoazo dyes are C.I. Direct Yellow 27 and C.I. Direct Orange 75 as shown below.

Direct Disazo Dyes

The representative examples of direct disazo dyes containing benzidine nucleus are C.I. Direct Red 28, C.I. Direct Blue 84, and C.I. Direct Blue 1 as shown below.

The representative examples of direct disazo dyes containing a urea bridge are C.I. Direct Orange 26, C.I. Direct Red 23, and C.I. Direct Red 75 as shown below. The urea bridge increases the substantivity of the dyes.

Direct Trisazo Dyes

The trisazo dyes include in particular blue, green, and black shades. The representative example of direct trisazo dye is C.I. Direct Black 166 as shown below.

Direct Triazinyl Dyes

The direct triazinyl dyes include a triazine ring as a bridge to link two separate chromophoric systems. The triazine bridge increases the substantivity of the dyes, similar to urea group. The representative example of direct triazinyl dye is C.I. Direct Green 26 as shown below.

Disperse Dyes

Disperse dyes are substantially water insoluble, colloidally dispersed, nonionic dyes for application to hydrophobic fibers from aqueous dispersion. These dyes are used predominantly on polyesters and to a lesser extent on acrylic, cellulose, cellulose acetate, and nylon fibers. When the dye is applied from the aqueous medium, it is adsorbed from the molecularly dispersed aqueous solution onto the fiber surface and then diffuses into the interior of the fiber [28,29,30,31].

Chemically, disperse dyes are classified based on various chromophores such as azo, anthraquinone, quinaphthalone, methane, and nitro dyes.

Disperse Azo Dyes

Disperse azo dyes represent the largest group of disperse dyes because of the relatively simple process by which the dyes are produced and the ease with which an extraordinary number of combinations can be generated by varying the diazo and coupling components. Disperse azo dyes can be further divided into monoazo dyes and disazo dyes.

Disperse Monoazo Dyes

Disperse monoazo dyes derived from aromatic amines as coupling components and carbocyclic aromatic amines as diazo components are of greatest economic importance. The representative examples of disperse monoazo dyes derived from aromatic amines as coupling components and carbocyclic aromatic amines as diazo components are C.I. Disperse Orange 44, C.I. Disperse Red 72, C.I. Disperse Blue 366, and C.I. Disperse Blue 165 as shown below and are used for dyeing polyester.

Disperse monoazo dyes derived from heterocyclic amines as diazo components represent an important class of bright dyes. The representative examples of disperse monoazo dyes derived from heterocyclic amines as diazo components are C.I. Disperse Red 177 (with thiazole heterocycle as diazo component), C.I. Disperse Red 338 (with thiadiazole heterocycle as diazo component), C.I. Disperse Blue 284 (with thiophene heterocycle as diazo component), and C.I. Disperse Green 9 (with thiophene heterocycle as diazo component) as shown below and are used for dyeing polyester. The greatest commercial success achieved in the field of dyestuffs from Gewald chemistry is the synthesis of C.I. Disperse Blue 284 and C.I. Disperse Green 9 [32].

Disperse monoazo dyes derived from aromatic hydroxy compounds as coupling components are used for dyeing acetate and polyester fibers. The representative example of disperse monoazo dye derived from aromatic hydroxy compound as coupling component is C.I. Disperse Yellow 3 as shown below.