Abstract

This chapter introduces the role of enzymes in the biomass degradation, namely sugarcane bagasse and straw, leading to the formation of fermentable sugars and second-generation ethanol. The chapter begins with a retrospective of the structuring of the ethanol production chain and then presents current aspects where the deficit of production and its consequences in business can be seen. Subsequently, we list the role of enzymes involved in the biomass hydrolysis, the commercial cocktails, and the proposal of our laboratory in this context. On the other hand, the efficiency of enzymes on the biomass is increased when the bagasse and straw are pretreated. Thus, some technologies that may facilitate the enzymatic hydrolysis and the formation of fermentable sugars are described. Lastly, recent analytical methods that enable a better analysis of the composition and viewing of fiber in the sugarcane biomass are presented.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

This chapter provides an overview of the production of second-generation ethanol regarding the enzymes that degrade the cell walls of sugarcane. Also, there is an overview of the pretreatments that can be carried out on the straw and bagasse of sugarcane, and the current techniques that could further elucidate details of the structure of the lignocellulolytic biomass . In this context, initially, a retrospective and the actual scenario of production of the sugarcane in Brazil is described, since it is one of the main plant species cultivated in this country, and the Southeastern and Midwestern regions are the most important areas for it. After that, this chapter describes how sugarcane by-products such as straw and bagasse could be used to enhance the production of bioethanol .

Despite many advances in the area of enzymology related to bioenergy, it should be remembered that in order to maintain the efficiency of converting cellulose and hemicellulose into glucose and xylose, it is necessary to (a) reduce the cost of the enzyme production, (b) use nonpathogenic microorganisms, (c) pretreat biomass, (d) avoid the inhibition of the enzymes by their own products of the assay, and (e) not allow interferences of the lignin degradation products in the microorganism growth. Additionally, a detailed description of the action of each enzyme involved in the hydrolysis of the sugarcane cell wall, the efficiency of commercial enzymatic cocktails and the goals of our laboratory are presented.

Furthermore, a section with a brief explanation of some of the pretreatment technologies used with sugarcane bagasse, in order to improve the access of hydrolytic enzymes in the macromolecules of the cell wall, is presented. It includes some physical, physicochemical, chemical, and biological pretreatments. Finally, in the last section, some methods for characterization of sugarcane bagasse, depolymerase activity, hydrolysis products, and inhibitors are described. Alternative analyses of cellulose and hemicellulose hydrolysis products are addressed and a synergistic view of the hydrolytic enzymatic capacities on sugarcane cell wall and the methodologies of analysis of biomass are discussed.

2 Retrospective and Current Deficit of Ethanol Production

The sugarcane crops were brought to Brazil in 1532 and the cultivation of this crop was the economic basis for the increase in population, mainly in the State of São Paulo and in Northeastern Brazil by Portuguese and the Dutch immigrants, respectively. According to Miranda (2010), scientific and detailed studies indicate that during the period of the Portuguese royalty, the average of annually cultivated area of sugarcane was 9000 ha, reaching as much as 16,000 ha at the beginning of the Empire. The total deforestation for the production of sugar for more than 220 years, during the years of struggle for the independence from Portugal, was around 140,000 ha. Currently, in just 1 year, Brazil produces more sugarcane than it did during the whole Imperial Age.

The advent in the 1970s of the Federal Program entitled “Pro-Alcohol” placed Brazil in the vanguard of the world scenario in the production of renewable fuels. This program led to the establishment of a large number of industrial bioethanol plants based on the sugarcane industry already established with existing sugarcane-processing mills (De Souza et al. 2014), that was a time when an energy crisis was lived, which was intensified in the conferences on the environment (Soccol et al. 2010). Although Brazil has invested in the bioethanol production from sugarcane, it is still based exclusively on the “first-generation technologies,” where their main product, e.g., sucrose, is subjected to the fermentation process. However, this source of energy is only 1/3 of the energy content of sugarcane, and much more bioethanol can be produced if all energy from biomass is utilized.

Although with great potential, the sugar and alcohol sector suffered a strong decline over the recent years, which is causing a significant deficit of bioethanol in the fuel market. Since 2008, the Brazilian ethanol market is showing a growing disconnection between the actual supply and the potential demand for this product. On the demand side, biofuel car sales, according to ANFAVEA (n.d.) (National Association of Automobile Manufacturers ), increased by about 11% per year between 2008 and 2010 (BNDES 2015). As for the ethanol, the supply was almost stagnant during the same period. While in 2008 27.1 billion liters of the fuel were produced, and in 2010 27.9 billion liters were produced, which means an increase of only 1.5% per year (BNDES 2015). Figure 5.1 illustrates the timeline of ethanol production since 1970 until 2012.

Currently, data available from Brazilian Sugarcane Industry Association (Unica 2015) shows that the quantity of sugarcane processed in 2015/2016 referents at harvest in the South-Central region of Brazil reached 620,830 thousand tons and the ethanol production totaled 28,363 thousand m3—with 17,692 thousand m3 of anhydrous ethanol and 10,671 thousand m3 of hydrous ethanol.

Bearing in mind the predicted rising in bioethanol demand due to the increase of flexible-fuel vehicles, and the fact that it is necessary to avoid the competition for land with food crops, i.e., rice, beans, corn, soybeans, coffee, or pastures, it is plausible to state that rational alternatives, incentives, and accurate public policies are necessary to increase the bioethanol production from sugarcane in Brazil. The current global trend is to use bagasse from sugarcane not only for the production of heat and the generation of the power necessary for the production process of bioethanol from sugarcane, the factor that makes a positive energy balance in the ethanol production, but also as an energy source for the second-generation bioethanol production. In Brazil, this strategy would help to supply, or at least to mitigate the bioethanol production deficit trends that have been observed in the last 8 years.

Brazil is a country with a great potential for the generation of renewable resources, which places it in a privileged position to develop technologies related to the use of biomass. The wide area with fertile soils, the intense solar radiation, the abundant water supply, and the diversity of weather and soil (Bon et al. 2008) are factors that favor Brazil to produce biomass. Thus, not only sugarcane bagasse and straw, but also other biomasses such as agro-industrial and forest residues might be used for “second-generation” biofuel production in this country.

Regarding the generation of biomass as sugarcane bagasse, it is important to consider that between 2010 and 2011 Brazil harvested about 200 million tons of bagasse as residue (CONAB 2011, cited in Rocha 2011). This material has been used mainly in burning processes for power generation within the sugar and ethanol industry. However, this product has been pursued to increase the production of alcohol fuel through the degradation of its cell wall, which is rich in complex polysaccharides that can be hydrolyzed and fermented into ethanol. However, for this process to be effective, accurate studies of its cell wall structure/organization are necessary, as well as studies to understand the main cell wall deconstruction mechanisms involved in the bioethanol production (Santos et al. 2012; De Souza et al. 2013).

The advancement and the success of second-generation bioethanol industries are highly dependent on the enzyme production. Although there is plenty of research involved in the production of enzymes from microorganisms that have potential application in the production of bioethanol, the enzyme production remains as one of the major bottlenecks to overcome cell wall recalcitrance.

3 Enzymatic Hydrolysis of Sugarcane Cell Wall: Cellulases and Hemicellulases—Concepts and Updates

Biomass is defined as the renewable resource of all organic material (plant or animal) that can be used for energy production. The most abundant biomass in nature is lignocellulosic materials, which are composed of agro-industrial materials, municipal waste, and the wood of angiosperms and gymnosperms (Segato et al. 2014). The main sources of lignocellulosic residues produced by the global agribusiness are sugarcane, corn, rice, and wheat (De Souza et al. 2013).

Cell walls of straw and bagasse of sugarcane are composed of a recalcitrant polymeric structure with 31–48.6% cellulose , 25–32% hemicellulose, 17–24% lignin , and 1.2–7% ashes/extractives, as the main components (De Souza et al. 2013). Cellulose and hemicellulose (represented mainly by xylan) must be degraded into glucose and xylose, respectively, using acid treatment or enzymatic hydrolysis. After that, these monomeric sugars are fermented by yeast to ethanol. Acid treatment results in several problems such as the corrosion of materials used in the process and the presence of acids in the effluents. The enzymatic hydrolysis of lignocellulosic biomass aiming at the production of fermentable sugars is the best alternative, but it is also considered as a bottleneck during the production of bioethanol .

Based on the evolutionary expression of cell wall formation, Buckeridge and De Souza (2014) suggested the inclusion of cell wall polysaccharide as part of sugar code, named for them by Glycomic Code . This code is the assumption that the composition and function of cell walls in plant tissues and organs are derived from the communication mechanism between biosynthesis and degradation of polysaccharides. In addition, they suggest that different combinations of polymers with unique fine structures arrange themselves within the wall creating a code. In this way, comprehending the Glycomic Code will enable the emergence of new hydrolysis technologies for the plant cell wall polysaccharide degradation (Buckeridge and De Souza 2014; Tavares and Buckeridge 2015; Buckeridge et al. 2015).

Because of the complexity and recalcitrance of cell walls, the major difficulty in the saccharification process is related to hydrolysis. To be efficient, the use of lignocellulosic material to cellulosic ethanol production requires a controlled hydrolysis of all insoluble polysaccharides present in this biomass. In addition, to enhance the biomass saccharification, the cellulosic ethanol industry has been using a variety of strategies, such as physical and chemical pretreatments (Soccol et al. 2010). Although these processes promote the lignin extraction, they might increase the cellulose crystallinity, hindering the saccharification process (Driemeier et al. 2011). Only after the lignin removal and elimination of the enzymatic inhibitors, such as furfural and hydroxymethylfurfural, biomass is ready for the enzymatic saccharification.

Some of the most important enzymes applied in this process are the cellulases and hemicellulases , i.e., hydrolases working synergistically to release sugars. They attack the remaining polysaccharides producing sugars (C5 or C6) that can be directly converted into ethanol by yeasts in the fermentation process (Castro and Pereira 2010; Hu et al. 2013).

3.1 Cellulases

Cellulose is the major structural constituent of plant cell wall and it is composed by the linear homopolysaccharide formed by d-glucose units joined by glycosidic bonds of the β-1,4 type. Its role is structural, providing mechanical protection to the cell (Segato et al. 2014).

The enzymes responsible for the cellulose breakdown are cellulases, a group of hydrolases that cleave β-1,4 O-glycosidic bonds . They are classified into three groups, according to the site where they act on their substrate molecules: (a) endoglucanases (EnG ) or endo-β-1,4-glucanases (EC 3.2.1.4), which cleave the internal bonds of cellulose fibers present in the amorphous part of cellulose, releasing cello-oligosaccharides; (b) exoglucanases (ExG ), or cellobiohydrolases (CBH ) (EC 3.2.1.91, EC 3.2.1.176), which act on the external region of cellulose, releasing cellobiose from the reducing- (CBH I) or nonreducing ends (CBHII); and (c) β-glucosidases or cellobiases (EC 3.2.1.21) hydrolyze soluble oligosaccharides and cellobiose up to glucose (Zhang et al. 2006; Castro and Pereira 2010). Figure 5.2 (first part) illustrates the action mechanism of the main cellulases by showing the action of enzymes on cellulose.

Action mechanism of the main holocellulolytic enzymes. The second part is an adaptation of Dodd and Cann (2009)

Two catalytic residues are responsible for the hydrolysis: a proton donor (generally acid) and a nucleophile/base. Hydrolysis occurs depending on the residue spatial catalytic position, either by the retention or the inversion of the anomeric configuration. Cellulases retain the same configuration after a double-displacement hydrolysis with two glycosylation/deglycosylation steps of the anomeric C bond. On the other hand, the “inverting” cellulases invert their configuration after a single nucleophilic displacement hydrolysis (Zhang et al. 2006; Payne et al. 2015). Thus, different action mechanisms of this group of enzymes enhance catalytic efficiency with different substrates increasing the hydrolytic properties and thereby promoting the conversion of oligomers to be used in the fermentative process for the production of second-generation ethanol (Vuong and Wilson 2010).

In order to efficiently deconstruct cellulose polymer, cellulolytic enzymes attack the substrate in a synergistic way. This synergism results in an increase of efficiency by the action of two or more components of the system as compared to the action of each one separately.

Transmission electron microscopy, X-ray diffraction, and atomic force microscopy techniques have been used to determine the three-dimensional structure of cellobiohydrolases. The results showed that these enzymes possess two distinct domains, one catalytic domain and one carbohydrate-binding domain (CBD ) linked by a flexible region rich in threonine, proline, or serine residues, called hinge (Gilkes et al. 1991). Although the CBD is not essential for the catalytic activity of the enzyme, it modulates the specific enzymatic activity in soluble and insoluble cellulolytic substrates. CBD binds on crystalline cellulose , weakening the hydrogen bonds among microfibrils, helping in their separation and favoring the enzyme progression (Segato et al. 2012; Pakarinen et al. 2014).

Another group of enzymes closely related to the cellulases is the lytic polysaccharide monooxygenases (LPMO ) (GH61/CBM33), copper-dependent enzymes recently reclassified as AA9 (fungal enzymes) and AA10 (bacterial enzymes). LPMOs act on the cellulose backbone using an oxidative mechanism, improving the degradation of this recalcitrant polymer into oligosaccharides, and consequently bursting the cellulosic ethanol production. The exact mechanism of action of these enzymes is unclear, but some studies assume the interaction between the flat face of the active site and the substrate, with copper acting as the cofactor of the oxidation reaction (Hemsworth et al. 2013, 2014; Kjaergaard et al. 2014; Lo Leggio et al. 2015).

3.2 Hemicellulases

Hemicellulose is a group of a heterogeneous polymers organized into two main cores, i.e., the backbone and branches. This complex can be formed by hexoses (β-d-glucose, β-d-mannose and α-d-galactose), pentoses (β-d-xylose and α-l-arabinose), and some acid sugars (α-d-glucuronic, α-d-4-O-methyl-galacturonic, and α-d-galacturonic acid) (Gírio et al. 2010).

The variable structure and organization of hemicellulose require the action of many enzymes for its complete deconstruction such as xylanases, arabinanases, arabinofuranosidases, ferulic and coumaric acid esterases, acetyl xylan esterases, glucuronidases, mannanases, xylosidases, galactosidases, and others (De Vries and Visser 2001; Polizeli et al. 2005; Gírio et al. 2010).

Segato et al. (2014), in a recent review, suggested that hemicellulases can be divided into three groups: (1) enzymes that hydrolyze backbones; (2) enzymes that remove side chains; (3) accessory enzymes that remove substituted residues, such as acetyl groups. A detail explanation about these enzymes is described below.

-

1.

Enzymes that hydrolyze backbones:

-

(a)

Endo-1,4-β-xylanases (EC 3.2.1.8): These are responsible for cleaving internal glycosidic linkages of xylan backbone, initially forming xylooligosaccharides, or forming xylotriose, xylobiose, and xylose in further steps. Two families belong to this group of enzymes, i.e., GH10 and GH11. While the GH10 family is able to hydrolyze xylan chains closer to the branching points, the GH11 family is able to cleave this polymer in more distant regions of the side chains (Dodd and Cann 2009; Pollet et al. 2010). Thus, branching residue distribution throughout the polymer seems to interfere in the action of these endo-cleaving enzymes on the xylan backbone (Polizeli et al. 2005; Nacke et al. 2012).

-

(b)

β- d-xylosidases : (EC 3.2.1.37): These enzymes hydrolyze small xylooligosaccharides and xylobiose from their nonreducing ends, releasing free xylose. They are usually not able to hydrolyze xylan, but can cleave artificial substrates such as p-nitrophenyl β-d-xylopyranoside (Kurakabe et al. 1997; Polizeli et al. 2005).

-

(c)

Mannanase (EC 3.2.1.78): They act on the galacto (gluco) mannan skeleton, releasing predominantly mannobiose and mannotriose (Buckeridge 2010; Segato et al. 2014).

-

(d)

β-Mannosidases (EC 3.2.1.25): These enzymes are exo-hydrolases working on nonreducing ends of mannan-oligosaccharides (MOS), releasing mannose (Buckeridge 2010; Segato et al. 2014).

-

(a)

-

2.

Enzymes that remove side chains:

-

(a)

Arabinanases (EC 3.2.1.99): They act on the linear arabinan. They do not exhibit activity on the synthetic substrate p-nitrophenyl α-l-arabinofuranoside (Segato et al. 2014).

-

(b)

Arabinofuranosidases (EC 3.2.1.55): These act on the branched arabinans, removing residues substituted at positions 2 and 3 of xylan. They are active on the synthetic substrate p-nitrophenyl α-l-arabinofuranoside (Gírio et al. 2010; Segato et al. 2014, see Chap. 6).

-

(c)

Xyloglucanases (EC 3.2.1.151): These enzymes are able to hydrolyze xyloglucan backbone (glucose β-1,4 linkages) in glucose residues (Buckeridge 2010; Segato et al. 2014).

-

(d)

α-Glucuronidases (EC 3.2.1.139): They hydrolyze the α-1,2 linkages between glucuronic acid and xylose residues in glucuronoxylan (Tenkanen and Siika-aho 2000; Gírio et al. 2010).

-

(e)

α-Galactosidase (EC 3.2.1.22) and β-galactosidase (EC 3.2.1.23): These are enzymes acting on d-galactose residues. β-Galactosidase releases galactose from side chains of pectin galactan, whereas the α-galactosidase removes galactose from mannose residues in the galacto (gluco) mannan skeleton (Buckeridge et al. 2000; Gírio et al. 2010).

-

(a)

-

3.

Accessory enzymes that remove substituted residues, such as acetyl groups:

-

(a)

Acetyl xylan esterases (EC 3.1.1.72): These remove O-acetyl substituents from the position C2 and/or C3 of xylose residues in acetyl xylan (Caufrier et al. 2003; Polizeli et al. 2005). They are important enzymes involved in the xylan saccharification , since they facilitate the endoxylanase action on the xylan backbone (Gírio et al. 2010; Segato et al. 2014, see Chap. 6).

-

(b)

Feruloyl esterases (EC 3.1.1.73) and p-coumaric acid esterases (EC 3.1.1.): These are esterases able to cleave ester linkages in xylan, between the arabinose side chains and ferulic acid, and from arabinose and p-coumaric acid, respectively (Crepin et al. 2004; Polizeli et al. 2005; Gírio et al. 2010; Segato et al. 2014). Figure 5.2 (second part) illustrates the action mechanism of the main hemicellulases by showing the action of enzymes on arabinoxylan.

-

(a)

Due to the insolubility and recalcitrance of plant cell wall, many hemicellulases are modular proteins, and besides their catalytic domain, they possess other functional modules. The catalytic modules present in the hemicellulases are glycoside hydrolase (GHs ). They are responsible for the hydrolysis of glycosidic linkages. Another domain is the carbohydrate esterase (ECs), which hydrolyzes ester bonds of acetate groups or ferulic acid. These modules are constructed based on the homology of their primary sequence, conservation of tertiary and secondary structure, and molecular mechanisms of catalysis (Henrissat and Davies 2000; Cantarel et al. 2009).

3.3 Commercial Enzymes : Current State of the Art

The most important step in producing cellulosic ethanol is the enzymatic hydrolysis of the biomass, which aggregates high cost to the saccharification process (De Souza et al. 2013; Gírio et al. 2010). Thus, several strategies to decrease the enzyme cost in this process have been adopted over the years. Scientists around the world have been developing approaches to improve enzyme performance to make the cellulosic ethanol industry worthy. In this scenario, one of the most important procedures is the prospection of enzymes capable of performing the deconstruction of plant cell walls. The GH61 or LPMO is an example of how the introduction of new enzymes in the current commercial cocktails might help to increase the efficiency of cell wall hydrolysis. Many experiments with this enzyme have shown that it can increase the cellulose conversion yield, and reduce the amounts of other enzymes necessary to saccharify biomass (Cannella et al. 2012).

The final goal for the production of cellulosic ethanol is the conversion of polymers in monomers especially by glucosidases. Nonetheless, this type of enzyme is usually inhibited by the substrate. Thus, the prospection of glucosidases resistant to the substrate inhibition, or their genetic manipulation, is a sine qua non step for the saccharification process (Rani et al. 2014).

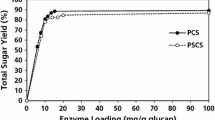

In the past years, commercial enzyme companies have made significant progress in producing new-generation cocktails with enzymes presenting higher specific activities and lower cost using different biotechnology processes and engineering approaches, especially after signing a contract with the US Department of Energy (DOE), whose main goal was to decrease the enzymatic production cost approximately 20-fold (McMillan et al. 2011). Since then, Novozymes and Genencor have been working in launching efficient enzymatic preparations to improve the sugar conversion. Thus, the newest generations of cocktails that can be cited are the Cellic Ctec® and Htec® family from Novozymes, and Accellerase from Genencor (de Paula et al. 2016; Kallioinen 2014; DuPont 2013; Novozymes 2012).

Cellic Ctec 3® , the last family launched by Novozymes, is a cellulose and hemicellulase complex able to convert pretreated lignocellulosic materials into fermentable sugars. In addition, Htec3 from the same company is only a hemicellulase complex that can supplement other cocktails aiming at the deconstruction of biomasses rich in hemicellulose. On the other hand, Accellerase 1500® , the last complex launched by Genencor, is an enzyme complex that contains exoglucanase, endoglucanase, hemicellulase, and β-glucosidase, which can also work in a variety of pretreated biomass (de Lucas et al. 2016; de Paula et al. 2016; Li et al. 2015; DuPont 2013; Canella et al. 2012; Novozymes 2012).

The large effort of industries around the world working in decreasing the enzymatic production costs, elevating the enzymatic efficiency, generating a large amount of sugars, and consequently producing ethanol from biomass is also a big step to reduce the impact caused by residues constantly thrown in nature, aggregating value to this product (Fig. 5.3).

Surface chemical imaging of sugarcane bagasse. The sample was introduced directly into the TOF-SIMS instrument without further preparation. The analysis was conducted using a 30 keV Bi3+ primary ion beam scanned over a 500 × 500 μm raster upon the surface for a measurement time of 100 s. Secondary ions emitted from the sample surface were analyzed according to mass and elemental/molecular ion images produced by synchronization with the primary ion beam position. (a) Sugarcane sample in natura with aluminum packaging. (b) TOF-SIMS ion image showing sulfur (green) distribution upon the treated sugarcane surface. (c) Milled sugarcane sample in natura with aluminum packaging. (d) TOF-SIMS ion image showing the presence of fluorine (red) distribution upon the treated sugarcane surface. Illustrations obtained from TOF.SIMS 5–100 instrument operation. The pictures were obtained from TOF.SIMS 5–100 instrument operation. We thank the efforts of Dr. Reinhard Kersting, at TASCON GmbH, Münster, Germany, and Fellipy Ferreira, at dpUNION Instrumentação Analítica e Científica Ltda, São Paulo, Brazil

In this perspective, scientists around the world have been really contributing with studies on the elucidation of the enzymatic way of action involved in biomass deconstruction and the discovering of new enzymes and new potential microorganisms. In addition, with recent methodology sources such as molecular biology, they are developing great catalysts that can be used in enzymatic cocktails applied in plant cell wall hydrolysis.

In Brazil, the Laboratory of Microbiology and Cell Biology from the São Paulo University, in Ribeirao Preto city, coordinated by Dr. Polizeli, has reached significant advances in the enzymology field. This group is responsible for prospecting more than 1000 new environmental filamentous fungi that can demonstrate high enzymatic secretion potential, especially enzymes applied in industrial processes. For that, they run a rigorous screening of their samples and also perform biochemical characterization of their catalysts, such as determination of temperature and pH effects on stability and enzyme activity, effect of glycosylation, determination of kinetic constants, mass spectrometry analysis, molecular modeling, immobilization, and effect of salts, inhibitors, solvents, chelate, and reducing composts on enzyme activity.

Recently, using protein heterologous expression and enzymatic immobilization on different chemical supports, Dr. Polizeli’s group is trying to improve the performance of the most promising enzymes that were already screened. Another methodology recently applied by our research group is the secretome, an important source to better understand the enzymatic requirement by the fungi according to a different kind of biomass employed as its growing source. Using this methodology, it might be possible to explain, for instance, how enzymes work together and which enzymes are necessary to deconstruct the plant cell wall. Also, the information obtained from secretome can help to construct an efficient enzymatic cocktail directed to a specific biomass such as sugarcane. Borin et al. (2015) studying the secretome from Aspergillus niger and Trichoderma reesei verified that these fungi use different enzymatic sequences to degrade the same biomass, which corroborate with the hypothesis already explained here that for the construction of an efficient enzymatic cocktail it is important to verify how these fungi act when grown on different types of biomass, which kind of enzymes they produce, and, the most important, which sequence of these catalysts are necessary to deconstruct the biomass.

Table 5.1 shows some of the recent advances from Dr. Polizeli’s group in the production of enzymes involved in the hydrolysis of holocellulosic biomass and their contribution to the global scientific community. With regard to the second-generation ethanol, many of these enzymes mentioned in Table 5.1 are now being tested in order to evaluate their ability in converting biomass into oligomers, and, consequently, the publications are still ongoing and the results achieved until now are promising.

4 Pretreatment Technologies

The recalcitrant nature of plant cell walls makes the pretreatment of lignocellulosic biomass essential for efficient and cost-effective saccharification of their macromolecules to fermentable sugars by cellulolytic and hemicellulolytic enzymes (Soccol et al. 2010).

Pretreatment technologies can be categorized as physical, physicochemical, chemical, or biological and more information about these treatments is described in Table 5.2. The goals of all pretreatment technologies are to improve the access of hydrolytic enzymes to cell wall polysaccharides while minimizing degradation of sugars and formation of fermentation inhibitors. However, lignocellulose pretreatments have a detrimental effect of releasing a wide range of compounds such as phenolics, weak acids, and furan derivatives, which are inhibitory to fermenting microorganisms and/or cellulolytic enzymes.

5 Inhibition and Deactivation of Cellulases : Challenges and Perspectives

Enzymatic hydrolysis of lignocellulosic biomass for the production of fermentable sugars has been extensively investigated, being reported as a critical step during the production of biofuels and other bio-based products (Zhang and Lynd 2004; Lynd et al. 2008). As mentioned before this step represents the major contributor to the total cost of producing ethanol from biomass. Therefore, it is critical to minimize the use of enzymes while maintaining the efficiency of converting cellulose to glucose through enzymatic hydrolysis.

The cost of enzymes coupled with the large amounts required to obtain commercially viable yields is by far the main economic barrier posed to the large-scale production of biofuels. A significant contributor to the high-dose demands is that hydrolysis rates decrease when reaction proceeds in a much faster way than can be explained by substrate consumption alone for a typical enzymatic hydrolysis (Yang et al. 2006). Several factors, including enzyme inhibition and deactivation, a drop in substrate reactivity, or nonproductive binding of enzyme to lignin , could be responsible for the loss of enzyme effectiveness with time (Eriksson et al. 2002; Qing et al. 2010).

Lignin-derived inhibitors, frequently released during the pretreatment steps, are a major obstacle because they prevent the enzymatic hydrolysis of cell wall polysaccharides, especially with softwood lignocellulosic materials. However, the exact mechanisms of lignin-derived inhibition are not fully understood. It is known that lignin physically hinders the access of enzymes to cellulose (Donohoe et al. 2008; Ishizawa et al. 2009; Rollin et al. 2011; Rahikainen et al. 2011) due to adsorption of cellulase to lignin (Berlin et al. 2006; Nakagame et al. 2010), and also inhibits or deactivates cellulases due to the presence of phenols produced from lignin degradation (Jing et al. 2009; Ximenes et al. 2010, 2011).

Several works have studied the effect of these inhibitors on the enzymatic activity. For example, Ximenes et al. (2010, 2011, see Chap. 6), and Kim et al. (2011, 2013), identified phenolic compounds from lignin as the major enzyme inhibitors and/or deactivators. The amount and type of phenolic compounds depend on the biomass source, and methods and conditions of pretreatment used. The strength of the inhibition or deactivation effect, however, depends mainly on three factors: (1) the type of enzyme; (2) the microorganism from which the enzyme was derived, and (3) the type of phenolic compounds.

The inhibitory effect of several phenolic compounds on Trichoderma reesei cellulases has been known since 1975, when Highley (1975) showed that simple phenols such as vanillin, caffeic acid, and catechol lead to inhibition of cellulase activities. Ximenes et al. (2011) observed that β-glucosidase from Aspergillus niger was the most resistant enzyme to the inhibition and deactivation by phenolic compounds, requiring about five- and tenfold higher concentrations, respectively, for the same levels of inhibition or deactivation when compared with enzymes from Trichoderma reesei.

Regarding the type of phenolics, tannic, gallic, hydroxycinnamic, and 4-hydroxybenzoic acids, as well as vanillin and syringaldehyde (see Chap. 4), reduced the cellulase activities, including the β-glucosidase activity. Tannic acid had the most severe effect, causing both deactivation and reversible loss (inhibition) on all activities of enzymes tested (Ximenes et al. 2011). Furthermore, Tejirian and Xu (2011) found that tannic acid as low as 1 mM caused significant inhibition with approximately 70–80% decrease in cellulose hydrolysis and initial hydrolysis rate.

Kim et al. (2011, 2013) also evaluated the effect of soluble inhibitors on cellulase activity and found that both phenolic compounds and xylo-oligosaccharides were the most important factors, leading to a decrease in cellulase activity. They showed that a total phenolic compound concentration as low as 1.3 g/L strongly inhibited cellulase by the precipitation and deactivation of β-glucosidase. Xylose (21 g/L) resulted in 10% lower glucose yield and 10% lower initial hydrolysis rate compared to the control, and xylo-oligomers were stronger inhibitors than xylose. At a concentration of 8 g/L, the initial rate was approximately 40% lower, and final glucose yield was 20% lower than the control. Enzymatic hydrolysis of the xylo-oligosaccharides to xylose (21 g/L) resulted in a moderate relief of inhibition, improving hydrolysis yield by 10%. To overcome the negative effects of residual hemicellulose on enzymatic hydrolysis, other authors have used hemicellulases to boost the cellulose saccharification through (1) removal of the remaining hemicellulose and the enlarged contact area between the cellulose and the enzyme and/or (2) conversion of xylan and xylo-oligomers to the less inhibitory xylose (Romaní et al. 2014). Although sugar oligomers are cellulase inhibitors, phenolic compounds exert the dominant effect for the process of relevant conditions, unless they are removed or transformed into non-inhibitory compounds.

Michelin et al. (2016) have shown that both cellulases and hemicellulases were inhibited and/or deactivated by phenolics obtained from pretreatment of sugarcane bagasse by liquid hot water. They also highlighted that the removal or mitigation of inhibitor effects must be considered in order to improve the efficiency of cellulose hydrolysis and particularly to avoid the cascade of inhibitory effects that result when β-glucosidase or β-xylosidase activities are deactivated. Kim et al. (2011) improved the final sugar yield by 20% through the removal of phenolic compounds. Inhibition by xylose and sugar oligomers is reversible, meaning that inhibition can be reversed if sugar oligomers are removed, for example, through hydrolysis and pentose fermentation. Kumar and Wyman (2009) also showed that xylo-oligomers inhibited cellulase action and that both glucose and xylose release could be significantly enhanced by supplementation with β-xylosidase and xylanase. Other authors have reported the inhibitory effect of hemicelluloses on cellulase activity, particularly in the form of oligomers that presents a more inhibitory effect than xylan and xylose (Qing et al. 2010; Qing and Wyman 2011).

On the other hand, some phenolic compounds are known to inhibit cellulase by irreversible binding and precipitation (Kim et al. 2011; Ximenes et al. 2011). Thus, mitigating phenolic-induced inhibition/deactivation would be critical for the development of cost-efficient cellulose hydrolysis.

A number of physical and chemical methods have been developed for the removal of these inhibitory compounds including dilution, solvent extraction, precipitation, adsorption (e.g., activated charcoal), and the use of ion-exchange resins (Larsson et al. 1999; Mussatto and Roberto 2004; Carter et al. 2011). However, these detoxification methods have some drawbacks such as high cost and generation of additional waste streams. An alternative detoxification method is the use of microorganisms or their enzymes such as laccases, to remove phenolic compounds. This approach can offer improvements compared to physical and chemical methods since, in addition to other advantages (e.g., mild condition, low cost, high degradation efficiency, low energy consumption), little waste is generated (Parawira and Tekere 2011; Lee et al. 2012; Cao et al. 2013; He et al. 2016). For example, Lee et al. (2012) removed phenolic compounds from biomass slurries using a novel laccase (YlLac) from yeast Yarrowia lipolytica , which alleviated the cellulase inhibition and subsequently increased saccharification yield of rice straw. This detoxification method has proved to be a promising approach for improving the efficiency of biorefineries.

6 Directions for Enzyme Kinetic Analysis

The current research on substrate-related depolymerase activities must deal with the gap of knowledge among substrate structure, enzyme structure analysis, and their relationships to the enzyme kinetics, such as binding constants, processivity, and catalytic efficiency. The state of the art of sugarcane analysis and protein structure was heavily reviewed and is under the scope of these chapters (Driemeier et al. 2011; Yang et al. 2011; Foston and Ragauskas 2012; De Souza et al. 2013). Currently, the works of De Souza et al. (2013) and Driemeier et al. (2011) form a methodological scaffold and reference work for the study of sugarcane biomass. Here we present directions for a deep understanding of enzyme catalysis to couple it to structural studies, such as the origin and structural related controls of reaction rates, binding order, and enzyme efficiency.

6.1 Characterization of Enzyme Mechanisms Involved in Degradation Processes

Integrated enzyme studies related to reaction kinetics and protein dynamics are far from a comprehension of enzyme action linked to structural properties of sugarcane bagasse to better efficacy during depolymerization processes. Among these enzyme properties, the enzyme efficiency, endurance, processivity, distributivity, and dig capacity are the most valuable information to transpose the academic knowledge to the industrial sector. However, the lack of a statistical method capable of overcoming the gap among substrate structure, enzyme properties, and process yield imposes an obstacle for substrate-enzyme-yield integration. Thus, the Methods in Enzymology remains the mandatory source of information to develop new methods to study enzymes related to depolymerization of polysaccharides in sugarcane feedstock.

Enzyme efficiency and endurance are among the major goals to be achieved for utilization in the industrial environment. The investigation of enzyme efficiency and usability is related to its kinetic, chemical, and dynamic mechanisms, a demanding task for depolymerizing enzymes. The initial-rate kinetics is the first tool for analyzing enzyme catalysis (Segel 1993). This step determines catalytic rates and constants, substrate specificity and side reactions, product inhibition and competitive inhibition—both used to analyze substrate binding order—determination of pKs of catalytic groups by pH kinetics, and analysis of the involvement of amino acid residues during catalysis by site-direct mutagenesis.

The chemical studies consider the reaction stereochemistry (NMR, X-ray crystallography); detection of tightly bound coenzymes (NMR, MS, X-ray crystallography); and metal ions (X-ray crystallography, NMR, ICP-MS) necessary to develop a specific enzyme reaction determining all organic and inorganic components necessary to develop higher reaction rates. The detection of covalent intermediates by rapid kinetic strategies and spectroscopic or MS analysis reveals the reaction course used by an enzyme, which can be integrated with its structural analysis. In turn, the identification of active-site residues involved in the binding and reaction course by affinity labelling provides information for enzyme engineering. Powerful mechanistic tools include the time-resolved Laue X-ray crystallography and video absorption spectroscopy (Purich 2010, see Chap. 6), which are useful for determining structure-function relationships in enzymes and between enzymes and substrates.

Isotope kinetics is used to investigate substrate binding order, which is extremely important to analyze and coordinate enzyme reaction events at the catalytic site. For these analyses, an enzymologist employs partial exchange reaction analysis and substrate exchange at equilibrium. Isotope kinetics is also used to study reaction “stickiness” by isotope trapping and partition kinetics, but also to identify reaction intermediates using positional isotope exchange and kinetic isotope effects (Segel 1993; Purich 2010). The use of a liquid scintillation counter and chromatographic instruments coupled to mass spectrometers or radiation counters must be employed in isotope kinetic studies.

Fast reaction kinetics is used to discriminate partial kinetic constants and reaction order to deeply understand the reaction events at the catalytic site, determining the time-dependent bottleneck events during the reaction course of a processing enzyme. The design of experiments for enzymes acting on polymeric substrates is challenging. These studies employ special equipment, and encompass the continuous, stopped-flow, and mix/quenching techniques, the temperature-jump and pressure-jump relaxation techniques, and the cryoenzymology. These techniques are used to obtain data about reaction steps on a shorter timescale inferior to 1 s. While stopped-flow devices are useful at 5–10 ms, faster reactions require the use of relaxation techniques, cryotemperatures, or even NMR and photon-activated experiments.

Depolymerases acting by processive or distributive mechanisms generally possess “hidden” nonproductive interactions in steady-state treatments or shifted binding behavior at high substrate concentration, a problem for process efficiency studies. Many exopolymerases were listed as highly processive (Purich 2010), remaining attached to their polymeric substrate during several catalytic rounds. The higher the processivity of the enzyme, the greater is its permanence in the substrate holding productive interactions, yielding monosaccharides for fermentation. Distributive mechanisms are characterized by the release of enzyme molecules after each catalytic cycle. In turn, these enzymes are capable of fragmenting the substrate, a typical behavior of endoglucanases. Monitoring these activities are conclusive kinetic studies to identify an exopoligalacturonase or endopoligalacturonase and its catalytic efficiencies. Protocols to determine processivity were presented by McClure and Chow (1980). The basic analytic tool measures discrete product lengths, which are studied using the Kuhn distribution law. Random scission kinetics of some endo-depolymerases (Purich 2010) can be analyzed using a modification of the protocol of Thomas (1956) analyzing the DP of cleavage products by means of GPC or MS. Purich (2010) presented an initial source of mathematical treatments to analyze nonproductive interactions and shifted binding behavior. In turn, the dig of cell walls, an important mechanism to access the deep layers of the cell wall by depolymerases, can be image measured using ATM, SEM, or electron tomography. The current lack of these knowledge is the main reason for failures in operational plants for bioethanol production.

7 Concluding Remarks

Sugarcane has emerged as a leading culture in Brazil for the development of new technologies for biofuels in order to ensure the energy demand in a sustainable manner (see Chap. 10 for further details).

Currently, a second-generation ethanol production plant is operating in Brazil, the Bioflex 1 from GranBio with a production capacity of 82 million liters of ethanol per year (Elabora Consultoria 2014). Internationally, the major players in cellulosic ethanol are INEOS Bio, KiOR, Novozymes, Petrobrás, Dupont, Raysen-CTC, and POET. Logen Corporation and Beta Renewables are responsible for pretreatment of biomass in the Brazilian industries of cellulosic ethanol. Their income with current substrate variability or high production costs will be of fundamental importance to guide research on the development of processes of pretreatments .

Besides these aspects, the relevance of the sugarcane bioenergy for the social and economic development of Central America, South America, and sub-Saharan Africa is immense (see Chap. 11). These regions are extremely favorable for the sustainable expansion of bioenergy, since there is no land available for the substantial production of bioenergy and food in other regions. The proper land management can result in production capacity of more than 24 EJ of liquid biofuels without compromising food production (Souza et al. 2015). Thus, the assurance of the energy security of our century includes the development of emerging or underdeveloped countries with potential impact on the eradication of poverty.

References

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

ANFAVEA (n.d.) Associação Nacional dos Fabricantes de Veículos automotores, Brasil. Dados estatísticos disponíveis em http://www.anfavea.com.br

Berlin A, Balakshin M, Gilkes N, Kadla J, Maximenko V, Kubo S, Saddler J (2006) Inhibition of cellulase, xylanase and beta glucosidase activities by softwood lignin preparations. J Biotechnol 125:198–209

BNDES (2015) O Déficit de Produção de etanol no Brasil entre 2012 e 2015: determinantes, consequências e sugestões de política. Milanez AY, Nyko D, Garcia JLF, Reis BLSFS. http://www.bndes.gov.br/bibliotecadigital. Accessed Mar 2015

Bon EPS, Gírio F, Pereira N Jr (2008) Enzimas na produção de etanol. In: Bon EPS, Ferrara MA, Corvo ML, Vermelho AB, Paiva CLA, Alencastro RB, Coelho RRR (eds) Enzimas em Biotecnologia Produção, Aplicações e Mercado. Editora Interciência, Rio de Janeiro (Chapter 10)

Borin GP, Sanchez CC, De Souza AP, Santana ES, Souza AT, Leme AFP, Squina FM, Buckeridge MS, Goldman GH, Oliveira JVC (2015) Comparative secretome analysis of Trichoderma reesei and Aspergillus niger during growth on sugarcane biomass. PLoS One 10(6):e0129275

Brodeur G, Yau E, Badal K, Collier J, Ramachandran KB, Ramakrishnan S (2011) Chemical and physicochemical pretreatment of lignocellulosic biomass: a review. Enzyme Res 2011:1–17

Buckeridge MS (2010) Seed cell wall storage polysaccharides: models to understand cell wall biosynthesis and degradation. Plant Physiol 154:1017–1023

Buckeridge MS, De Souza AP (2014) Breaking the “Glycomic Code” of cell wall polysaccharides may improve second-generation bioenergy production from biomass. Bioenergy Res 7:1065–1073

Buckeridge MS, Santos HP, Tiné MAS (2000) Mobilisation of storage cell wall polysaccharides in seeds. Plant Physiol Biochem 38:141–156

Buckeridge MS, Santos WD, Tiné MS, De Souza AP (2015) The cell wall architecture of sugarcane and its implications to cell wall recalcitrance. In: Lam E, Carrer H, Silva JA (eds) Compendium of bioenergy plants: sugarcane. CRC Press, Boca Raton, p 125

Cannella D, Hsieh CW, Felby C, Jørgensen H (2012) Production and effect of aldonic acids during enzymatic hydrolysis of lignocellulose at high dry matter content. Biotechnol Biofuels 5(1):26

Cantarel BL, Coutinho PM, Rancurel C, Bernard T, Lombard V, Henrissat B (2009) The Carbohydrate-Active EnZymes database (CAZy): an expert resource for glycogenomics. Nucleic Acids Res 37:233–238

Cao G, Ximenes E, Nichols NN, Zhang L, Ladisch M (2013) Biological abatement of cellulase inhibitors. Bioresour Technol 146:604–610

Carter B, Squillace P, Gilcrease PC, Menkhaus TJ (2011) Detoxification of a lignocellulosic biomass slurry by soluble polyelectrolyte adsorption for improved fermentation efficiency. Biotechnol Bioeng 108:2053–2060

Castro MD, Pereira N Jr (2010) Produção, propriedades e aplicação de celulases na hidrólise de resíduos agroindustriais. Quím Nova 33:181–188

Caufrier F, Martinou A, Dupont C, Bouriotis V (2003) Carbohydrate esterase family 4 enzymes: substrate specificity. Carbohydr Res 338(7):687–692

Crepin VF, Fauld CB, Connerton IF (2004) Functional classification of the microbial feruloyl esterases. Appl Microbiol Biotechnol 63(6):647–652

Damasio ARL, Silva TM, Almeida FBDR, Squina FM, Ribeiro DA, Leme AFP, Segato F, Prade RA, Jorge JA, Terenzi HF, Polizeli MLTM (2011) Heterologous expression of an Aspergillus niveus xylanase GH11 in Aspergillus nidulans and its characterization and application. Process Biochem 46:1236–1242

Damasio ARL, Pessela BC, Segato F, Prade RA, Guisan JM, Polizeli MLTM (2012a) Improvement of fungal arabinofuranosidase thermal stability by reversible immobilization. Process Biochem 47(12):2411–2417

Damasio ARL, Polizeli MLTM, Guisan JM, Prade RA, Pessela BC, Mateo C, Segato F (2012b) Immobilization of a recombinant endo-1,5-arabinanase secreted by Aspergillus nidulans strain A773. J Mol Catal B: Enzym 77:39–45

Damasio ARL, Ribeiro LFC, Ribeiro LF, Furtado GP, Segato F, Almeida FB, Crivellari AC, Buckeridge MS, Souza TA, Murakami MT, Ward RJ, Prade RA, Polizeli MLTM (2012c) Functional characterization and oligomerization of a recombinant xyloglucan-specific endo-β-1,4-glucanase (GH12) from Aspergillus niveus. Biochim Biophys Acta 1824:461–467

Damasio ARL, Pessela BC, Silva TM, Guimaraes LH, Jorge JA, Guisan JM, Polizeli MLTM (2013) Co-immobilization of fungal endo-xylanase and α-l-arabinofuranosidase in glyoxyl agarose for improved hydrolysis of arabinoxylan. J Biochem 154:275–280

De Lucas RC, Cereia M (2016) Mycology: current and future developments. In: Chapter 1. Large scale production of cellulases for biomass degradation. Bentham Science, Sharjah, vol 1, pp 316–328

De Paula RG, Antoniêto ACC, Silva RN (2016) Mycology: current and future developments. In: Chapter 1. The panorama for biofuels biotechnology: present and future. Bentham Science, Sharjah, vol 1, pp 3–22

De Souza AP, Leite DCC, Pattathil S, Hahn MG, Buckeridge MS (2013) Composition and structure of sugarcane cell wall polysaccharides: implications for second-generation bioethanol production. Bioenergy Res 6:564–579

De Souza AP, Grandis A, Leite DCC, Buckeridge MS (2014) Sugarcane as a bioenergy source: history, performance, and perspectives for second-generation bioethanol. Bioenergy Res 7:24–35

De Vries RP, Visser J (2001) Aspergillus enzymes involved in degradation of plant cell wall polysaccharides. Microbiol Mol Biol Rev 65(4):497–522

Dodd D, Cann IK (2009) Enzymatic deconstruction of xylan for biofuel production. Glob Change Biol Bioenergy 1(1):2–17

Donohoe BS, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2008) Visualizing lignin coalescence and migration trough maize cell walls following thermochemical pretreatment. Biotechnol Bioeng 101:913–925

Driemeier C, Pimenta MTB, Rocha GJM, Oliveira MM, Mello DB, Maziero P, Gonçalvess AR (2011) Evolution of cellulose crystals during prehydrolysis and soda delignification of sugarcane lignocellulose. Cellulose 18:1509–1519

DuPont (2013) Acellerase 1500®: cellulase enzyme complex for lignocellulosic biomass hydrolysis. http://accellerase.dupont.com/fileadmin/user_upload/live/accellerase/documents/DUP-00413_ProdSheet_1500_web.pdf

Elabora Consultoria (2014) Renewable fuels and chemicals. Elabora Editora, Sao Paulo

Eriksson T, Karlsson J, Tjerneld F (2002) A model explaining declining rate in hydrolysis of lignocellulose substrates with cellobiohydrolase I (Cel7A) and endoglucanase I (Cel7B) of Trichoderma reesei. Appl Biochem Biotechnol 101:41–60

Foston M, Ragauskas AJ (2012) Biomass characterization: recent progress in understanding biomass recalcitrance. Ind Biotechnol 8(4):191–208

Furtado GP, Santos CR, Cordeiro RL, Ribeiro LF, de Moraes LAB, Damasio ARL, Polizeli MLTM, Lourenzoni MR, Murakami MT, Ward RJ (2015) Enhanced xyloglucan-specific endo-β-1,4-glucanase efficiency in an engineered CBM44-XegA chimera. Appl Microbiol Biotechnol 99(12):5095–5107

Gilkes NR, Henrissat B, Kilburn DG, Miller RC Jr, Warren RAJ (1991) Domains in microbial beta-1-4-glycanases: sequence conservation, function, and enzyme families. Microbiol Rev 55:303–315

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101(13):4775–4800

He H, Zhang J, Bao J (2016) Acceleration of biodetoxification on dilute acid pretreated lignocellulose feedstock by aeration and the consequente ethanol fermentation evaluation. Biotechnol Biofuels 9:19

Hemsworth GR, Taylor EJ, Kim RQ, Gregory RC, Lewis SJ, Turkenburg JP, Parkin A, Davies GJ, Walton PH (2013) The copper active site of CBM33 polysaccharide oxygenases. J Am Chem Soc 135(16):6069–6077

Hemsworth GR, Henrissat B, Davies GJ, Walton PH (2014) Discovery and characterization of a new family of lytic polysaccharide monooxygenases. Nat Chem Biol 10(2):122–126

Henrissat B, Davies GJ (2000) Glycoside hydrolases and glycosyltransferases. Families, modules, and implications for genomics. Plant Physiol 124:1515–1519

Highley TL (1975) Inhibition of cellulases of wood decay fungi. US Forest Service Research Paper FPL 247, 1–8, 1975. http://accellerase.dupont.com/fileadmin/user_upload/live/accellerase/documents/DUP-00413_ProdSheet_1500_web.pdf

Hu J, Arantes V, Pribowo A, Saddler JN (2013) The synergistic action of accessory enzymes enhances the hydrolytic potential of a “cellulase mixture” but is highly substrate specific. Biotechnol Biofuels 6(1):112

Ishizawa CI, Jeoh T, Adney WS, Himmel ME, Johnson DK, Davis MF (2009) Can delignification decrease cellulose digestibility in acid pretreated corn stover? Cellulose 16:677–686

Jing X, Xhang X, Bao J (2009) Inhibition performance of lignocellulose degradation products on industrial cellulase enzymes during cellulose hydrolysis. Appl Biochem Biotechnol 159:696–707

Kallioinen A (2014) Development of pretreatment technology and enzymatic hydrolysis for biorefineries. VTT Technical Research Centre of Finland

Kim Y, Ximenes E, Mosier NS, Ladisch MR (2011) Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzyme Microb Technol 48:408–415

Kim Y, Kreke T, Hendrickson R, Parenti J, Ladisch MR (2013) Fractionation of cellulase and fermentation inhibitors from steam pretreated mixed hardwood. Bioresour Technol 135:30–38

Kjaergaard CH, Qayyum MF, Wong SD, Xu F, Hemsworth GR, Walton DJ, Young NA, Davies GJ, Walton PH, Johansen KS, Hodgson KO, Hedman B, Solomon EI (2014) Spectroscopic and computational insight into the activation of O2 by the mononuclear Cu center in polysaccharide monooxygenases. Proc Natl Acad Sci U S A 111(24):8797–8802

Kumar R, Wyman CE (2009) Effect of xylanase supplementation of cellulase on digestion of corn stover solids prepared by leading pretreatment technologies. Bioresour Technol 100:4203–4213

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48(8):3713–3729

Kurakabe M, Shinjii O, Komaki T (1997) Transxylosilation of β-xylosidase from Aspergillus awamori K4. Biosci Biotechnol Biochem 6112:2010–2014

Larsson S, Reimann A, Nilvebrant NO, Jönsson LJ (1999) Comparison of different methods for the detoxification of lignocellulose hydrolyzates of spruce. Appl Biochem Biotechnol 77:91–103

Lee K-M, Kalyani D, Tiwari MK, Kim T-S, Dhiman SS, Lee J-K, Kim I-W (2012) Enhanced enzymatic hydrolysis of rice straw by removal of phenolic compounds using a novel laccase from yeast Yarrowia lipolytica. Bioresour Technol 123:636–645

Li X, Chomvong K, Yu VY, Liang JM, Lin Y, Cate JH (2015) Cellobionic acid utilization: from Neurospora crassa to Saccharomyces cerevisiae. Biotechnol Biofuels 8:120

Lo Leggio L, Simmons TJ, Poulsen JC, Frandsen KE, Hemsworth GR, Stringer MA, von Freiesleben P, Tovborg M, Johansen KS, De Maria L, Harris PV, Soong CL, Dupree P, Tryfona T, Lenfant N, Henrissat B, Davies GJ, Walton PH (2015) Structure and boosting activity of a starch-degrading lytic polysaccharide monooxygenase. Nat Commun 6:5961

Lynd LR, Laser MS, Brandsby D, Dale BE, Davison B, Hamilton R, Himmel M, Keller M, McMillan JD, Sheehan J, Wyman CE (2008) How biotech can transform biofuels. Nat Biotechnol 26:169–172

McClure WR, Chow Y (1980) The kinetics and processivity of nucleic acid polymerases. Methods Enzymol 64:277–297

McMillan JD, Jennings EW, Mohagheghi A, Zuccarello M (2011) Comparative performance of precommercial cellulases hydrolyzing pretreated corn stover. Biotechnol Biofuels 4:29

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Comb Sci 38:522–550

Michelin M, Polizeli MLTM, Ruzene DS, Silva DP, Teixeira JA (2014) Application of lignocellulosic residues in the production of cellulases and hemicellulases from fungi. In: Polizeli MLTM, Rai M (eds) Fungal enzymes. CRC Press, Boca Raton, pp 31–64

Michelin M, Ximenes E, Polizeli MLTM, Ladisch MR (2016) Effect of phenolic compounds from pretreated sugarcane bagasse on cellulolytic and hemicellulolytic activities. Bioresour Technol 199:275–278

Miranda, E.E. (2010) Questões Ambientais (Impactos Locais e Globais) e energéticas: A expansão da Cana de Açúcar e a ocupação das terras no estado de São Paulo.In: Cortez LAB (ed) Bioetanol de Cana-de-açúcar—P&D para produtividade e sustentabilidade. Editora Blucher (Chapter 6)

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10

Nacke H, Engelhaupt M, Brady S, Fischer C, Tautzt J, Daniel R (2012) Identification and characterization of novel cellulolytic and hemicellulolytic genes and enzymes derived from German grassland soil metagenomes. Biotechnol Lett 34(4):663–675

Nakagame S, Chandra RP, Saddler JN (2010) The effect of isolated lignins, obtained from a range of pretreated lignocellulosic substrates, on enzymatic hydrolysis. Biotechnol Bioeng 105(5):871–879

Novozymes (2012) Cellulosic ethanol: novozymes cellic Ctec3. http://www.bioenergy.novozymes.com/en/cellulosic-ethanol/Cellic-HTec3/Documents/CE_APP_Cellic_Ctec3.pdf

Pakarinen A, Haven MO, Djajadi DT, Várnai A, Puranen T, Viikari L (2014) Cellulases without carbohydrate-binding modules in high consistency ethanol production process. Biotechnol Biofuels 7(1):27

Parawira W, Tekere M (2011) Biotechnological strategies to overcome inhibitors in lignocellulose hydrolysates for ethanol production: review. Crit Rev Biotechnol 31:20–31

Payne CM, Knott BC, Mayes HB, Hansson H, Himmel ME, Sandgren M, Ståhlberg J, Beckham GT (2015) Fungal cellulases. Chem Rev 115(3):1308–1448

Polizeli MLTM, Rizzatti ACS, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Pollet A, Delcour JA, Courtin CM (2010) Structural determinants of the substrate specificities of xylanases from different glycoside hydrolase families. Crit Rev Biotechnol 30(3):176–191

Purich DL (2010) Enzyme kinetics: catalysis & control. Academic Press, London

Qing Q, Wyman CE (2011) Supplementation with xylanase and β-xylosidase to reduce xylo-oligomer and xylan inhibition of enzymatic hydrolysis of cellulose and pretreated corn stover. Biotechnol Biofuels 4:18

Qing Q, Yang B, Wyman CE (2010) Xylooligomers are strong inhibitors of cellulose hydrolysis by enzymes. Bioresour Technol 101:9624–9630

Rahikainen J, Mikander S, Marjamaa K, Tamminen T, Lappas A, Viikari L, Kruus K (2011) Inhibition of enzymatic hydrolysis by residual lignins from softwood—study of enzyme binding and inactivation on lignin-rich surface. Biotechnol Bioeng 108(12):2823–2834

Rani V, Mohanram S, Tiwari R, Nain L, Arora A (2014) Beta-glucosidase: key enzyme in determining efficiency of cellulase and biomass hydrolysis. J Bioproces Biotech 5(1):8

Ribeiro LFC, Lucas RC, Vitcosque GL, Ribeiro LF, Ward RJ, Rubio MV, Damasio ARL, Gregory RC, Walton PH, Jorge JA, Prade RA, Buckeridge MS, Polizeli MLTM (2014) A novel thermostable xylanase GH10 from Malbranchea pulchella expressed in Aspergillus nidulans with potential applications in biotechnology. Biotechnol Biofuels 7:115–126

Rocha GJM, Gonçalves AR, Oliveira BR, Olivares EG, Rossella CEV (2011) Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Ind Crop Prod 35:274–279

Rollin JA, Zhu Z, Sathitsuksanoh N, Zhang YHP (2011) Increasing cellulose accessibility is more important than removing lignin: a comparison of cellulose solvent-based lignocellulose fractionation and soaking in aqueous ammonia. Biotechnol Bioeng 108:22–30

Romaní A, Ruiz HA, Pereira FB, Teixeira JA, Domingues L (2014) Integrated approach for effective bioethanol production using whole slurry from autohydrolyzed Eucalyptus globulus wood at high-solid loadings. Fuel 135:482–491

Santos FA, Queiróz JH, Colodette JL, Fernandes SA, Guimarães VM, Rezende ST (2012) Potencial da palha de cana-de-açúcar para produção de etanol. Quim Nova 35:1004–1010

Segato F, Damasio AR, Gonçalves TA, Murakami MT, Squina FM, Polizeli MLTM, Mort AJ, Prade RA (2012) Two structurally discrete GH7-cellobiohydrolases compete for the same cellulosic substrate fiber. Biotechnol Biofuels 5:21

Segato F, Damasio ARL, de Lucas RC, Squina FM, Prade RA (2014) Genomics review of holocellulose deconstruction by Aspergilli. Microbiol Mol Biol Rev 78:588–613

Segel IH (1993) Enzyme kinetics: behavior and analysis of rapid equilibrium and steady-state enzyme systems. Wiley, New York

Soccol RC, Vandenberghe LPS, Medeiros ABP, Karp SG, Buckeridge M, Ramos LP, Pitarelo AP, Ferreira-Leitão V, Gottschalk LMF, Ferrara MA, Bon EPS, Moraes LMP, Araújo JA, Torres FAG (2010) Bioethanol from lignocelluloses: status and perspectives in Brazil. Bioresour Technol 101:4820–4825

Souza, G. M., Victoria, R. L., Joly, C. A., Verdade, L. M. (eds) (2015) Bioenergy & sustainability: bridging the gaps. Scientific Committee on Problems of the Environment (SCOPE)

Tavares EQP, Buckeridge MS (2015) Do cell walls have a code? Plant Sci 241:286–294

Tejirian A, Xu F (2011) Inhibition of enzymatic cellulolysis by phenolic compounds. Enzyme Microb Technol 48:239–247

Tenkanen M, Siika-Aho M (2000) An alpha-glucuronidase of Schizophyllum commune acting on polymeric xylan. J Biotechnol 78(2):149–161

Thomas CA Jr (1956) The enzymatic degradation of desoxyribose nucleic acid. J Am Chem Soc 78:1861–1868

UNICA (2015) from Brazil’s National Institute for Space Research. http://www.unica.com.br/unicadata. Accessed 4 June 2016

Vitcosque GL, Ribeiro LF, de Lucas RC, da Silva TM, Ribeiro LF, Damasio ARL, Farinas CS, Gonçalves AZ, Segato F, Buckeridge MS, Jorge JA, Polizeli MLTM (2016) The functional properties of a xyloglucanase (GH12) of Aspergillus terreus expressed in Aspergillus nidulans may increase performance of biomass degradation. Appl Microbiol Technol 100(21):9133–9144. doi:10.1007/s00253-016-7589-2

Vuong TV, Wilson DB (2010) Glycoside hydrolases: catalytic base/nucleophile diversity. Biotechnol Bioeng 107(2):195–205

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2010) Inhibition of cellulases by phenols. Enzyme Microb Technol 46:170–176

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2011) Deactivation of cellulases by phenols. Enzyme Microb Technol 48:54–60

Yang B, Willies DM, Wyman CE (2006) Changes in the enzymatic hydrolysis rate of avicel cellulose with conversion. Biotechnol Bioeng 94:1122–1128

Yang B, Dai Z, Ding S, Wyman CE (2011) Enzymatic hydrolysis of cellulosic biomass. Biofuels 2(4):421–450

Zhang YP, Lynd LR (2004) Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88:797–824

Zhang PYH, Himmel ME, Mielenz JR (2006) Outlook for cellulase improvement: screening and selection strategies. Biotechnol Adv 24(5):452–481

Acknowledgements

We thank Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP, process 2010/52322-3) and Conselho de Desenvolvimento Científico e Tecnológico (CNPq, process 563260-6). This project is also part of National Institute of Science and Technology of the Bioethanol (FAPESP, process 2008/57908-6). Dr. M. L. T. M. Polizeli has a Fellowship of Research Productivity of CNPq. We thank Abilio Borghi for the technical assistance with the English language.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

de Lourdes T.M. Polizeli, M., Somera, A.F., de Lucas, R.C., Nozawa, M.S.F., Michelin, M. (2017). Enzymes Involved in the Biodegradation of Sugarcane Biomass: Challenges and Perspectives. In: Buckeridge, M., De Souza, A. (eds) Advances of Basic Science for Second Generation Bioethanol from Sugarcane. Springer, Cham. https://doi.org/10.1007/978-3-319-49826-3_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-49826-3_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-49824-9

Online ISBN: 978-3-319-49826-3

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)