Abstract

Mineral resource estimation has long been plagued with the inherent challenge of conditional bias. Estimation requires the specification of a number of parameters such as block model block size, minimum and maximum number of data used to estimate a block, and search ellipsoid radii. The choice of estimation parameters is not an objective procedure that can be followed from one deposit to the next. Several measures have been proposed to assist in the choice of kriging estimation parameters to lower the conditional bias. These include the slope of regression and kriging efficiency.

The objective of this paper is to demonstrate that both slope of regression and kriging efficiency should be viewed with caution. Lowering conditional bias may be an improper approach to estimating metal grades, especially in deposits for which high cutoff grades are required for mining. A review of slope of regression and kriging efficiency as tools for optimization of estimation parameters is presented and followed by a case study of these metrics applied to an epithermal gold deposit. The case study compares block estimated grades with uncertainty distributions of global tonnes and grade at specified cutoffs. The estimated grades are designed for different block sizes, different data sets, and different estimation parameters, i.e., those geared toward lowering the conditional bias and those designed for higher block grade variability with high conditional biases.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

When resource modeling by kriging, a number of estimation parameters must be established such as block model block size, minimum and maximum number of data used to estimate a block, or search ellipsoid radii. Arik (1990) studied the impact of search parameters in two case studies for gold and molybdenum and considered the drill density, skewness of the grade distribution, and availability of a suitable geology model. The studies involved estimating with drill hole data and comparing against blasthole data. As Arik demonstrated and many resource modelers know, the choice of the estimation parameters is by no means an objective procedure that provides a simple recipe for all types of deposits.

This long-standing topic is not new and has been addressed by many authors. At the center of the discussion is the issue of conditional bias, wherein the expected value of the true grade conditioned on the estimates is not equal to the estimated grade (Journel and Huijbregts 1978; Olea 1991):

The discussion among both theoreticians and practitioners revolves around how conditional bias affects the quality of the block grade estimates (McLennan and Deutsch 2002). The first school of thought insists that the conditional bias should be as small as possible and must be dealt with, and the second school of thought believes that the conditional bias should be ignored and the variability of block estimates should be as high as the variability of underlying true block grades.

Rivoirard (1987) suggested that the size of the kriging neighborhood should consider the weight given to the mean. If the mean is given a large weight, then the neighborhood should be expanded so as to increase the slope of regression and thereby reduce conditional bias. Conversely, if the weight of the mean is low, then a localized neighborhood is adequate. Krige introduced a metric called kriging efficiency (Krige 1997) that correlates to the slope of regression. He contends that one should never accept conditional bias in an effort to reduce the smoothing effect of kriging (Krige 1997; Krige et al. 2005). Deutsch et al. (2014) further expanded on potential sub-optimality of the estimates due to large conditional biases reflected in slope of regression and in kriging efficiency measures. Deutsch proposed a new expression of kriging efficiency to aid in the assessment of quality of estimated block grades.

From a procedural perspective, Vann et al. (2003) introduced quantitative kriging neighborhood analysis (QKNA) to optimize the estimation parameters for selection of the minimum/maximum of number of samples, quadrant search, search neighborhood, and block size. The proposed criteria for evaluating quality of block grade estimates include slope of regression of true block grades on estimated block grades, weight attached to the mean in simple kriging, distribution of kriging weights, and kriging variance.

All of the above contributors have focused on metrics and efforts to minimize conditional bias. On the other end of the spectrum of this discussion, Isaaks (2005) argued that estimates cannot be both conditionally unbiased and globally accurate at the same time. The estimates may be close to conditionally unbiased but the histogram of block estimates is smoothed, which results in inaccurate predictions of the recoverable tonnes and grade above cutoff grades. He advocates that a conditionally biased estimate is necessary to obtain a globally unbiased recoverable resource above cutoff grade. There is support that during the early stages of project feasibility assessments, it is more important to accurately predict the global recoverable reserves than to produce locally accurate estimates (Journel and Kyriakidis 2004).

Despite valid points on both ends of the spectrum, it appears that the first school of thought has been winning the discussion in recent years. The authors noticed a substantial increase in application of those measures for optimization of estimation parameters. Some of the proposed measures for optimization of kriging estimates, such as slope of regression and kriging efficiency, are currently readily available in most commercial software. In some organizations, this quantitative approach has become standard in the resource estimation process irrespective of the stage of exploration and/or development of the mineral deposit.

It appears that Isaaks’ sound argument for recoverable resources above an economic cutoff grade, particularly in early stage projects, appears to have been forgotten in the popularization of a quantitative approach because of software accessibility. In the wake of convenience, we seem to have lost the idea of a fit-for-purpose model, including consideration for the stage of the project.

The objective of this paper is to demonstrate that both slope of regression and kriging efficiency should be viewed with caution for optimizing estimation parameters. Lowering conditional bias may be an improper approach to estimating metal grades. In fact, it might be outright wrong especially in deposits for which high cutoff grades are required for mining.

This paper presents a summary of the two typical tools, suggested for optimization of estimation parameters, slope of regression and kriging efficiency, followed by application of these metrics applied to an epithermal gold deposit. The case study compares block estimated grades with uncertainty distributions of global tonnes and grade at specified cutoffs. The estimated grades are designed for different block sizes, different data sets, and different estimation parameters, i.e., those geared toward lowering the conditional bias and those designed for higher block grade variability with high conditional biases.

2 Two Proposed Measures for Optimization of Estimation Parameters

Block ordinary kriging is one of the most common estimation methods used for resource modeling in the mining industry (Journel and Huijbregts 1978; Sinclair and Blackwell 2002). Each block estimate can be written as:

where Z *(u) represents the estimated block grade at location vector u, and λ i is the kriging weight assigned to sample Z(u i ). The resource model, comprised of estimated block grade at all relevant locations, forms the distribution of estimated grades that is the basis for a mineral resource statement.

Among other considerations, such as geologic confidence, grade continuity, and database quality, a cutoff grade is used to differentiate between those blocks that are reported as a mineral resource (Sinclair and Blackwell 2002). This cutoff grade is applied throughout a project, depending on the method of mineral extraction. The smoothness of this estimated grade distribution, relative to the cutoff grade, is then paramount to this discussion of accurately predicting the global mineral resource for a project.

The smoothness of the estimated grade distribution depends not only on the quantity and location of conditioning data and the modeled variogram but also on the estimation parameters such as minimum/maximum number of samples, size of search neighborhood, and type of search. While there are a number of suggested measures for assistance in the choice of optimal kriging estimation parameters, such as slope of regression, kriging efficiency, or weight of the mean from simple kriging, this paper will only focus on the first two due to their prominent use in the mineral resources sector.

2.1 Slope of Regression

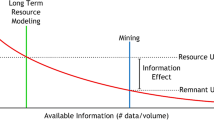

When kriged estimated Z* block grades are plotted on X axis and unknown true Z block grade are plotted on Y axis, then the regression of true values given the estimates is an indication of the conditional bias in the estimate (Journel and Huijbregts 1978) (Fig. 1). Conditional bias takes place when the expected value of true block grade Z conditional to estimated block grade Z* is not equal to the estimated grade. The slope of the regression b is often used to summarize the conditional bias of the kriging estimate:

Schematic illustration of conditional bias (McLennan and Deutsch 2002). The estimates Z* are on the X axis, and the true block grades Z are on the Y axis

Naturally, the block true values are unknown, but the slope b can be calculated once a variogram model is known by the following formula:

To calculate the slope from formula (2), it is enough to know kriging weights attached to samples used to estimate a block and to know covariances between samples and samples and the block. Note that actual sample grades are not taken into account in the calculation. The slope will be identical in both lower- and higher-grade areas, although potentially higher conditional bias, and by extension lower slope of regression, could be expected in the high-grade areas.

2.2 Kriging Efficiency

Kriging efficiency, introduced by Krige (1997), is considered a good measure of effectiveness of kriging estimates. The kriging efficiency can be calculated from two by-products of kriging procedure, block variance (σ 2Bl ) and kriging variance (σ 2kr ):

Kriging efficiency values can range from negative (poor estimates) to a maximum value of 1 (very good estimates). As with the slope of regression, actual assay data do not get used in the calculation. The results are purely dependent on a variogram model and on data locations used to estimate the blocks. Krige mentions that based on a number of case studies he conducted there is a correlation between the efficiency and the slope of regression (Krige 1997). For the increased slope value, there is also an increase in kriging efficiency.

3 Case Study

This case study is based on an epithermal gold deposit in British Columbia, localized along a major fault. Gold-bearing breccia, vein, and stockwork development occurs along the fault and in subsidiary dilational structures. Gold mineralization roughly parallels the fault. The deposit has been drilled out by more than 500 closely spaced holes drilled roughly on a 25 × 25 m grid. At one time, originally modeled from the full set of data, the lowest grade domain in the deposit had an average grade close to 0.7 g/t and the highest grade domain had an average gold grade more than 2 g/t with relatively low coefficient of variation at 1.3.

A portion of the deposit has been chosen for simulating gold grades on a dense 4 × 4 × 4 m grid. The chosen portion of the deposit does not differentiate between different geological units. This simplified approach, considering closely spaced large number of drill holes, is not considered detrimental to the results of the study. A typical realization with average grades very similar to declustered assay grades from the drill holes has been chosen for this study. Maximum range of gold continuity is at 160° azimuth and is much shorter in vertical direction and at 70° azimuth (Fig. 2). The relative nugget effect of 25 % and ranges of continuity spanning from 40 to 60 m are quite typical and encountered in many gold deposits. Note that although the following analysis is based on simulated grades, considering a large number of drill holes in a relatively small area from which the simulated grades are derived, the simulated grades do represent a distribution that closely resembles actual grades in this deposit.

The simulated deposit, with an average grade of 1.26 g/t, has been “drilled” with “exploration” holes. The location of the “exploration” holes was essentially random with some limitations on allowed distances between the holes and on generally higher density of drilling in higher-grade areas. Two data sets were created: The first set (large data set) represents 281 holes drilled at 30 m spacing outside of high-grade mineralization and at down to 16 m spacing within higher-grade regions. The second set (small data set) represents more typical case with 156 drill holes drilled at 40 m distance in lower-grade areas and down to 20 m in higher-grade areas (Fig. 3). Drill hole spacing in the second data set is similar to what would be typically expected in a gold deposit at the early stages of exploration.

The smaller data set was used for variogram modeling. As is common in practice, the best continuity was modeled for directions slightly different than those known from simulated grades. Moreover, the modeled variogram parameters were different from those applied for the simulated reference data. Each data subset was used to estimate gold grades by ordinary kriging for different block sizes and different number of data allowed to estimate the blocks. Vertical block size was kept constant at 8 m with increased sizes along easting and northing directions.

For strongly conditionally biased estimates, a small number of data was used with a minimum of 4 and a maximum of 12 composite assay grades (referred to as the “sub-optimal” design). In an attempt to lower the conditional bias, blocks were estimated with a large search ellipsoid with a minimum of 24 and maximum of 64 composite assays; this is referred to as the “optimal” design. For each estimated block grade, a slope of regression and kriging efficiency was calculated. In addition, the estimated block grades were compared to true block grades.

4 Results

Figure 4 shows how slope of regression and kriging efficiency change for different block sizes, different data sets, and estimation parameters used. As discussed, modification to the estimation parameters was limited to a number of data used starting from “poorly designed” not optimal estimation procedure with small number of data used for the estimation and ending with “well designed” optimal process with large number of data used for the estimation. As expected, the optimal estimation procedure results in higher slope of regression and increases kriging efficiency.

It is interesting that for the small data set used in the estimation, the actual block size did not have any effect on the slope of regression and kriging efficiency. On the other hand, when the large data set was used there was gradual increase in kriging efficiency with the increased block size. Note that kriging efficiency is quite low regardless of the estimation type. As expected, using the large number of data (optimal case) to estimate block grades resulted in a substantial increase in the slope of regression, i.e., it resulted in substantial decrease of conditional bias. Not surprisingly, the slope of regression is quite high for the large data set and large number of data used for the estimation. These graphs clearly indicate that using a lot of data during the estimation process lowers conditional bias and increases kriging efficiency.

Now that it has been established that applying more data to the block estimates increases slope of regression and by extension decreases conditional bias, the next step involved comparisons of actual true block grades with the estimated grades for different cutoffs. Figures 5 and 6 show relative tonnage and grade differences between true and estimated block grades at the 1.0 g/t cutoff for optimal and not optimal estimates from the small data and the large data sets, respectively. Both figures show that despite high conditional bias in the sub-optimal design, the estimated tonnes and grades are closer to reference tonnage and grade in the deposit. This is also true for the estimates from the large data set, although here the differences between the not optimal and optimal models are smaller. Note that, as presented in Fig. 6, at 20 m block size estimated tonnes and grade are very similar to reference tonnes and grade. At the same time, it would be misleading to conclude that this block size produced superior estimates.

In fact, the reported tonnage and grade from different block sizes is quite similar (Fig. 7). It just happens that the estimated tonnes and grade in this specific deposit are comparable to recoverable tonnes and grade at the selective mining unit (SMU) size higher than 20 m, roughly the size of half of drill hole spacing. This is an important observation that suggests it does not matter what block size is used for estimating resources. Reported resource at 8 m or 20 m block size will be similar, but the 20 m block appears to approach the size that, if successfully applied during mining operation, would result in actually recovered tonnes and grade very similar to those estimated. As long as there is no connection made between a block size used and actual SMU considered for mining, there is nothing particularly wrong with estimates based on a small block size.

An important result of the optimization of the estimation process is high smoothing of the estimated block grades. The smoothing effect may result in large differences between estimated and actual metal content at higher cutoff values. For block estimates from the typical (smaller) data set, the estimated metal content at higher cutoffs may be as much as 70–80 % lower than the actual metal content (Fig. 8) for the “optimized” parameters, while the “sub-optimal” model yields 50–60 % less metal content relative to the reference. Similar conclusions can be made for the larger data set, with percent differences ranging from 20 to 30 % for the sub-optimal model and 30–50 % for the optimal model. Therefore, it is obvious that the lower the conditional bias the higher the smoothing effect that can be expected when estimating from sparsely spaced data. The interesting trend, however, is that for both the sparsely and densely sampled data sets, the sub-optimal set of parameters yield the closest estimate of contained metal for cutoff grades above the 1.25 g/t mean grade.

The final task considered comparison of the estimation models with conditional simulation of the small data set. The purpose of this exercise was to compare the estimation model to a model constructed using a method that is considered to avoid conditional bias altogether (McLennan and Deutsch 2002; Journel and Kyriakidis 2004). The reference distribution was obtained via p-field simulation wherein the local distributions of uncertainty considered a local trend model. For this task, sequential Gaussian simulation was performed with no consideration for any trends, and variograms were calculated based on the small data set. As with the estimation models, the continuity directions vary slightly from those of the reference model. Multiple realizations were then generated at a 2 × 2 × 2 m resolution and subsequently block averaged to various block sizes: 8, 12, 16, and 20 m.

The uncertainty in grades and tonnage at a series of different cutoff grades were assessed, and the combined impact is summarized as contained metal at different cutoff grades (Fig. 9). The corresponding sensitivity curves for the sub-optimal and optimal estimation models, along with the reference model, are shown for comparison. Three interesting observations are made. Firstly, at a cutoff grade up to the mean grade of 1.25 g/t, there is no appreciable difference between the contained metal estimated using the optimal or sub-optimal parameters. Secondly, for the four block sizes considered, the sub-optimal parameters yield estimates closest to the reference model at higher cutoff grades. Thirdly, the simulation approach, which is considered to be a non-biased method, yields the distributions of uncertainty in contained metal that encompasses the reference data. This latter observation is important, particularly as a reference model is never available in practice for benchmarking purposes. This indicates that a conditional simulation approach can be used to validate the estimated tonnage, grades, and ultimately metal when determining an appropriate set of estimation parameters.

5 Discussion

Both slope of regression and kriging efficiency assume global stationarity within a specifically modeled domain. Mineral deposits are not stationary, even within a specific estimation domain. In an estimation domain, there are always small regions of high and small regions of very low grades. Slope of regression and kriging efficiency formulas do not take into account the fact that true variance of estimation errors depends on data values. In regions with higher grade or in regions with local data having more variance than in the whole domain, fluctuation of errors is larger. Disregarding these local changes in variability may lead to estimated resources that steer away from what would be expected of a typical resource estimate.

A resource block model should not be designed to produce an inventory of recoverable resource that is based on SMU size much larger than would generally be considered for mining, only because for this SMU size, when mined, the resource model will turn out to be correct. A deposit is never mined according to a resource block model. A decision on what will be mined will be based on grade control drilling, necessary both in open-pit and underground mining. A resource geologist should strive to produce a block model that predicts, reasonably well, the tonnage and grade that a mine can expect to achieve over the life of the mine, once it has sorted out its grade control procedures. In addition, the resource block models are often used for dilution calculations or blending issues. A block model designed from optimizing slope of regression, or block size, will not serve this purpose.

In short, optimizing kriged block estimates with slope of regression or kriging efficiency measures may lead to block models that do not adequately reflect true block grades. It is tempting and easy to use slope of regression and kriging efficiency for validation of block estimated grades. Those measures are commonly available in commercial software packages. Although theoretically high slope of regression, i.e., low conditional bias, is considered necessary for good quality estimates, in practice this approach may be outright harmful if the objective of the study is to predict global resource quantities above an economic cutoff grade. Both measures are a reflection of a modeled variogram and data locations and do not take into account actual assay values or their variability in the vicinity of an estimated block. Moreover, it is often quite difficult to construct a reliable variogram model, particularly in early exploration stages, and relying on its metrics to design “best” resource estimates cannot be considered best practice.

Based on the presented case study, there is strong indication that it is better to have conditionally biased block estimates for global resource quantities required for a potential investment decision, life-of-mine planning, and/or development decisions. Once a cutoff is applied to block estimated grades for reporting or further mining studies, it is better to have unsmoothed conditionally biased block estimates. In this context of achieving globally accurate predictions, it looks like the onus is back on a resource geologist to design estimation parameters that produce a realistic block model that reflects the underlying true block grades the best way possible.

Bibliography

Arik A (1990) Effects of search parameters on kriged reserve estimates. Int J Min Geol Eng 8(4):305–318

Deutsch J, Szymanski J, Deutsch C (2014) Checks and measures of performance for kriging estimates. J South Afr Inst Min Metall 114:223–230

Isaaks E (2005) The kriging oxymoron: a conditionally unbiased and accurate predictor, 2nd edn, Geostatistics Banff 2004. Springer, Dordrecht, pp 363–374

Journel A, Huijbregts C (1978) Mining geostatistics. Academic, London

Journel A, Kyriakidis P (2004) Evaluation of mineral reserves: a simulation approach. Oxford University Press, New York

Krige D (1997) A practical analysis of the effects of spatial structure and of data available and accessed, on conditional biases in ordinary kriging, Geostatistics Wollongong ’96, Fifth International Geostatistics Congress. Kluwer, Dordrecht, pp 799–810

Krige D, Assibey-Bonsu W, Tolmay L (2005) Post processing of SK estimators and simulations for assessment of recoverable resources and reserves for South African gold mines, Geostatistics Banff 2004. Springer, Dordrecht, pp 375–386

McLennan J, Deutsch C (2002) Conditional bias of geostatistical simulation for estimation of recoverable reserves, CIM Proceedings Vancouver 2002. CIM Proceedings Vancouver 2002, Vancouver

Olea R (1991) Geostatistical glossary and multilingual dictionary. Oxford University Press, New York

Rivoirard J (1987) Teacher’s aide: two key parameters when choosing the kriging neighborhood. Math Geol 19:851–856

Sinclair A, Blackwell G (2002) Applied mineral inventory estimation. Cambridge University Press, Cambridge

Vann J, Jackson S, Bertoli O (2003) Quantitative kriging neighbourhood analysis for the mining geologist – a description of the method with worked case examples. 5th International Mining Geology Conference, Bendigo, pp 1–9

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Nowak, M., Leuangthong, O. (2017). Conditional Bias in Kriging: Let’s Keep It. In: Gómez-Hernández, J., Rodrigo-Ilarri, J., Rodrigo-Clavero, M., Cassiraga, E., Vargas-Guzmán, J. (eds) Geostatistics Valencia 2016. Quantitative Geology and Geostatistics, vol 19. Springer, Cham. https://doi.org/10.1007/978-3-319-46819-8_20

Download citation

DOI: https://doi.org/10.1007/978-3-319-46819-8_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-46818-1

Online ISBN: 978-3-319-46819-8

eBook Packages: Mathematics and StatisticsMathematics and Statistics (R0)