Abstract

The phase change material (PCM) using in buildings, a significant technology for the global warming solution, has received considerable attention over the last decade. PCM depending on the phase state change can passively store the solar energy or excess heats as latent heat and release the heats to the indoor environment within a specific temperature range, leading to building energy consumption reducing, and indoor thermal comfort enhancing by smoothing indoor temperature fluctuations. They can also be coupled using with active building energy supply systems to increase the system efficiency and shift peak loads. This study has reviewed the state-of-the-art PCM applications in buildings found on the researches and markets. First, PCM classification, PCM thermal properties, PCM study, and selection methods have been introduced. Second, PCM passively used in building envelops, inclusive of PCM wall, PCM roof, PCM floor, PCM concrete, PCM gypsum board, PCM window, and so on, have been detailedly analyzed. Thirdly, PCM coupled with active system, such as PCM and solar energy hot water/air systems, PCM and floor heating system, PCM and GSHP system, and PCM and air condition and ventilation system, etc., have been extendedly reviewed. Lastly, the potential further researched area for PCM used in buildings has also been presented in conclusion.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- PCM

- Building

- Energy storage

- Global warming solution

- Latent heat

- Building energy consumption

- Thermal comfort

- Passive

- Active

1 Introduction

1.1 Building Energy Efficiency and the Global Warming

The most serious problem humankind has ever to face might be global warming which causes disastrous consequences and adverse effects. Global warming results from the what we call “greenhouse effect” and mainly caused by greenhouse gases (GHGs), especially the CO2 [1]. In the last 150 years, the rapid development of industrialization and human activities have accumulated huge amount of CO2 to the Earth’s atmosphere [2]. Burning of fossil fuels, form which CO2 products thus results in climate changes in a long time for affecting the atmosphere chemically [3]. By the 1990s the fossil fuels, such as coal, oil, and natural gas supplied more than 80 % of the energy and emitted about 95 % of the total CO2 emission [4–6].

Unfortunately, nowadays, fossil fuels are still the world’s main energy source. Buildings, both residential and commercial, consume 40 % of the world’s energy and generate 30 % of the CO2 emissions around the world [7]. To make matters worse, different from industrialization and transportation, whose energy consumption can be restricted even interrupted by controlling operation status, the energy consumption of buildings is ceaseless and pushed up gradually by the increasing desire for comfortable levels. The energy consumed for heating and cooling systems accounts for a major portion of the total building energy consumption [8]. To mitigate the global warming effect of fossil fuel using for buildings, a lot of new methods and technologies have been pursued. The energy storage (ES) technology is one of the most impressive directions.

1.2 Energy Storage Technology

ES technology contains five major branches, as shown in Fig. 1, and they are generally implemented to balance the energy demand with supply. The development of energy storage technology is the prime task under the current energy situation, along with the global warming issues. Energy storage system’s potentiality is so attractive for their ability to store some kind of energy that can be utilized further [9]. An energy storage process contains three fundamental steps: charging, storing, and discharging [10]. Moreover, for residential and commercial buildings, where the thermal energy plays a vital role, one of the thriving techniques is phase change material (PCM) implementation, for the truth that the latent heat usually large than the sensible heat. PCM using in buildings can help to enhance energy efficiency and reduce energy consumption especially in building heating and cooling. Therefore, PCM can play a vital role for slowing down global warming by mitigating emissions of CO2, as well as SO2, NOx, and CFCs [11].

PCM can be applied to make renewable energy (especially solar energy) a continuous and stable energy resource for saving primary energy. Thus, PCM has been selected and developed as the beat medium of ES technologies during the last 30 years. The PCM’s ability to store a large number of thermal energy in the melting process and release energy when below the freezing point make it an excellent method to improve the performance of building heating and cooling. Besides, the PCM can also be used in buildings as a part of structures systems for three advantages: first, PCM could smooth the temperature fluctuation and reduce the energy loss for temperature around phase transition temperature stay constant or near constant during the process PCM of melting or freezing; second, the latent heat energy storage of PCM required a much smaller volume of material than any conventional sensible heat energy storage material; third, various kinds of PCM with different phase transition temperatures and latent heat storage abilities provided a lot of choices for using in buildings, according to the use functions and requires [12].

1.3 Developmental Stages of PCM Using in Buildings

The study of PCM pioneered by Telkes and Raymond [13] in 1949, but did not receive much attention. In early 1970s, the PCM thermal protection system began to use for the Lunar Roving Vehicle and Skylab [14]. And in decade, PCM technologies were developed very fast from applied for space crafts on a small scale to on a larger scale for buildings in order to help ease the global energy crisis [15–18]. The studies of the PCM applied in buildings boomed from 1982, when a research of high strength microencapsulated PCM (MEPCM) used in buildings was funded by the US Department of Energy. At the same year, the US Argonne National Laboratory started a research of the PCM applying in solar energy collection and storage in building systems. And in 1988, these researches were further promoted by the US Department of Energy [19, 20]. After years of development, PCM using in buildings could be summarized into three stages: the first stage, before 1990, during which the focus is to analyze the feasibility of PCM using in buildings and to select PCM that can be used in buildings; the second stage covers 1990s, during which the researchers put focus on the compatibility, stability and useful life of PCM used in buildings; the third stage begins in late 1990s and continues to the present days, the focus of this stage has shifted to applying PCM in all kinds of building systems such as wall system, roof system, floor system, building materials and HVAC systems, and evaluating the performance [21–23].

1.4 The Applications of PCM Used in Buildings and Building Systems

The latest applications of PCM used in buildings mainly include PCM wall system, PCM-roof system, PCM floor system, PCM panel, PCM in building materials and PCM windows and sunshade. PCM wall system where PCM, encapsulated in microcapsule or containers, such as panels, bottles, and boxes, are embedded in wall structure, can substantially reduce and delay the thermal load through latent heat storage process to achieve the goal decreasing the temperature difference and energy consumption [24–27]. PCM roof systems include PCM roof structure and PCM ceiling, where PCM is usually embedded or filled a layer in the roof and ceiling structure; moreover ventilation systems are also added as auxiliary in some case to improve its thermal performance [28–32]. PCM floor systems are often designed working with floor heating system to store thermal energy and smooth indoor temperature fluctuation; the PCMs are embedded in the middle of floor or somewhere in floor near heat resource [33–35]. PCM panel is one of common type of application for that the PCMs do not need to be embedded in structure during construction; the PCM is encapsulated by panels and then affixed firmly to any structure surfaces conveniently and rapidly [36–42]. PCM in building material is generally encapsulated by the microcapsule, and the applications include PCM-modified mortar, PCM concrete, and PCM gypsum board; when added PCMs, the thermal properties of building materials can be enhanced and promoted [43–58]. PCM windows and sunshades are an emerging application where PCM is filled into glass, frame, cavity, layer, and other parts; the PCM window and sunshade have the ability to change light and thermal transmittance to control solar radiation, infrared radiation, and thermal conduction and reduce heat gains and losses [59–66].

The latest PCM building energy systems mainly include solar energy storage system, indoor temperature conditioning system and ground source heat pump system. Besides, some applications on electricity peak load shifting and electrical energy storage heating emerged in recent years. In the field of solar energy storage system, hot water and hot air are the usually energy carrier. The PCM can be installed in the collector, tank, pipes, air flues, and even carrier itself [67–82]. In indoor thermal environment conditioning systems, the PCM is often placed in terminals and special storage tanks of heating, cooling and ventilation systems to store excess heat for smoothing indoor temperature fluctuation and saving thermal energy. In addition, in some case the PCM is installed in building structures, such as floors which are designed as the terminal of floor heating systems [83–88]. Ground source heat pump system is in some sense the integration of solar energy storage system and indoor thermal environment conditioning system for it collects renewable energy to adjust indoor thermal environment. Thus, the PCM can be installed in both energy collection part and terminals [89–91]. Applications on electricity peak load shifting and electrical energy storage heating have the same mechanism. The electrical energy is converted into thermal energy which stored in PCM in melting process and released in discharging process for avoiding peak load or heating [34, 73, 92–94].

2 PCM

2.1 Classification and Characteristic of PCM

There are three types of PCMs suitable for different building applications: organic, inorganic, and eutectic mixture of PCMs. Figure 2 shows the types of PCMs. The usual PCMs used in buildings include salt hydrates, paraffin waxes, fatty acids, and eutectics of organic or nonorganic compounds [9, 95–97]. They need to equip some properties as follows: large latent heat, high thermal conductivity, moderate phase change temperature, well chemically stability, low cost, nontoxic, and noncorrosive [23].

Types of PCMs [109]

Organic PCMs have many advantages such as chemically stable, free from super cooling, nonphase segregation material, noncorrosive, nontoxic, and high latent heat of fusion capacitance for thermal energy storage [9]. However, they are considered as inflammable and low thermal conductive. Organic PCMs can be divided into two types: paraffin and non-paraffin. Non-paraffin organics are fatty acids, esters, alcohols, and glycols [95]. Generally, organic PCMs using in buildings have a melting point range 20–32 °C [96].

Inorganic PCMs are considered as high latent heat, preferable thermal conductivity, fire resistance, and inexpensive [9]. But, corrosive, super cooling, and segregation are the disadvantages of inorganic PCMs [95]. The inorganic PCMs are commonly applied in solar energy storages [97].

Eutectic mixtures contain three types: organic–organic, inorganic–inorganic, and inorganic–organic mixtures [9]. These mixtures have different thermal properties with the components. Generally, eutectic PCMs are mostly used in building applications [96].

2.2 Thermal Properties of Some Potential PCMs

Thermal properties mainly include latent heat and phase change temperature of a kind of PCM. Melting/freezing point and heat of fusion can be one of the most important principles to choose the PCM for certain usage. Table 1 shows the thermal properties of some potential PCMs for building applications in the literatures.

2.3 PCM Selection and Study Methods

PCMs should equip some desired thermal properties for building application. Although many kinds of PCMs have been tested in the literatures, the amount of PCMs is too large and different types of applications need PCMs with different thermal properties. Besides, some actual factors, such as purity, impurity, and operating error can also change the thermal properties. There are some common techniques, including differential scanning calorimeter (DSC), Fourier transform infrared spectroscopy (FTIR), thermal gravimetric analyzer (TGA), and scanning electron microscopy (SEM), which are used to measure thermal properties of PCMs [9].

DSC is one of the most widely used analytical instruments. DSC can provide a serious of thermodynamic data of PCMs. A single DSC test usually consists in regularly cooling and heating process of a PCM sample. Thermal properties of PCMs, such as transition temperature, enthalpy, heat capacity, specific heat, and latent heat, can be determined from the obtained qualitative and quantitative information during the phase change process [98].

FTIR is a kind of molecular absorption spectrometry which can be recorded for identifying compounds and molecular structure. The complex process when a eutectic mixture PCM is producing needs to be identified a chemical reaction or a physically mixing by comparing the before-and-after FTIRs to ensure its stability and consistency [99].

TGA can express the mass loss of PCM during a heating process. The inner pressure of PCM always changes with volume during phase transition process and poses a threat to microcapsule structure. TGA is used to evaluate volatilization of PCM in different temperature range, mass loss, durability, and stability [99].

SEM can observe and record microstructure, such as micro-shape, porosity, grain boundary, and agglomeration, which may affect the operation performance of PCM, especially microcapsule. The images SEM captured are real, clear, and three-dimensional [100].

3 PCM Used in Building Envelope

3.1 PCM Wall

Researches about the PCM application on the wall system have been done a lot. Some new form PCM wall forms and new methodology to improve the study on the wall system have been proposed. And also those new thoughts have been validated positive influence on reducing the temperature difference and energy consumption.

Alexander confirmed that adding a certain amount of microencapsulated PCMs to concrete walls and increasing the latent heat both substantially reduced and delayed the thermal load. To achieve the maximum time delay, the phase change temperature should be increased with increasing average outdoor temperature.

Romen has investigated three different form walls shown in Fig. 3. And the experiment results revealed that the high thermal amplitude reduction of the specimens M2 and M3 are about 50 % and 80 %, respectively compared with M1. The time delay of maximum and minimum temperatures peak is about 1 h while the values increase to 3 h for specimens M2 and M3 form.

Wall system geometry and composition (Romeu [26])

3.2 PCM Roof

Quite a number of researchers have investigated the thermal performance on the difference forms of roof, as shown in Fig. 4. Those studies have also proposed some similar conclusions or found some reasons about the differences between experiment and simulation results.

Experimental model of concrete roof with a empty holes and b holes filled with PCM (Alqallaf [28])

Heat gain can be reduced with larger PCM holes diameter when the volume of the holes is constant and heat gain of the house is influenced by the phase change temperature to a much greater extent.

Li has found that the effects of the phase change temperature and the latent heat to the peak temperature and the staring time are slight, the roof slope, and the absorption rate of the exterior roof surface weak, while the thickness of the PCM layer violent, as shown in Fig. 5.

Construction of roof [31]

Maciej has developed a PCM roof system to improve the night ventilation system in Fig. 6 and found that not all the PCM melted and solidified fully, which should be optimized through changing some parameter in this experiment.

The scheme of repetitive element of a ceiling panel, dimensions of experimental setup (Maciej [32])

3.3 PCM Floor

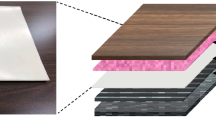

In the view of latest achievements, the effects of PCM floor system can reduce the energy consumption and shift the peak loads. Enhancing the thermal conductivity of a PCM to be no more than 1.0 W/m K could apparently improve energy efficiency and reduce the thickness of thermal insulating materials. And the PCM system shown in Fig. 7 has the most comfortable feelings and the economic efficiency compared with other systems.

Structure of the underfloor heating system with HCE-SSPCM [33]

Reza has found that the PCM floor-wallboard system did shift the peak load to the morning so that the energy and the electricity can be saved 18.8 % and 28.7 %, respectively because of the electricity charge policy.

To solve the problem of the thermal comfort for persons in summer, Laurent has proposed a solution of using a specific PCM into floors as is shown in Fig. 8 to reduce the temperature difference day and night and to enhance the thermal storage of the envelop.

Schematic representation of the experimental setup (Royona [110])

3.4 PCM Panel

A certain amount of investigations on the PCM panels have been proceeding by researchers around the world. Most researches pay much more attention on the optimal location of the panel in the wall and different panel forms. And the results have also been validated that those kinds of applications can save much energy.

Kong has found that compared with the reference room, the inside wall surface peak temperatures of PCM installed in Outer surface of Wall (PCMOW) and PCM installed in Inner surface of Wall (PCMIW) shown in Fig. 9 are 0.6 K, 2.4 K lower, respectively. Also the author has found that PCMIW performed better than PCMOW, especially with the condition of nature ventilation at night.

Demonstration of PCM panels installed for the PCMOW and PCMIW (Kong [36])

Lee has proposed a novel way for testing various kinds of wall constructions, known as plug-and-play walls (PPW) shown in Fig. 10, and found that there exist the optimal location for the PCM panel [38–41]. Other research about the wall board proved that the total thickness of the light wall integrated into PCM panels can be reduced from 45 cm of the traditional heavy wall to 26–27 cm.

Schematic of a wall section showing the locations of the PCMTS (Lee and Mario [37])

Alvaro has validated the new type ventilated façade with PCM shown in Fig. 11 that those systems can save 2.49 MJ/day and 1.67 MJ/day, respectively. Also the authors have verified that this new type design has three potential benefits in free cooling, cold storage and decrease of solar radiation.

Lai has studied the different combination forms of a new prototype PCM panel, the diagram of which has showed in Fig. 12. And the author has achieved a conclusion that the new prototype has a better performance because of the high thermal conductivity [101].

a Investigated target (mPCM honeycomb wallboard). b Physical model (Lai [101])

3.5 PCM in Building Materials

3.5.1 PCM-Modified Mortar

As we all know there are three methods of incorporating PCMs in conventional construction materials, namely the direct incorporation, the immersion, and the encapsulation [43], among which the encapsulation is the most common method. Systematic experiments were carried out to study the incorporation of PCMs with the mortars. The addition of PCM not only affects the mechanical properties of mortar, but also plays a role in the thermal properties of mortars.

This paragraph only concerns the physical and mechanical properties of PCM-modified mortar. Generally, PCM has a much smaller specific gravity than the sand, if we use PCM to replace a certain percentage of sands in the geopolymer mortar mixture, the unit weight of the geopolymer mortar decreases when more PCM is included [100]. No matter cooling or heating the mortar, the compressive strengths decreased with the increasing of PCM incorporated. This conclusion of strength is reasonably consistent with the study of Li et al. [44], who got the results of the compressive strength and the bending strength of the mortar decrease with an increase of the content of composite PCM. The reason is that the composite PCM does not react with water; however, cement can react with water and maintain strength. The compressive strength and bending strength of mortar should not be less than 5.0 MPa and 2.0 MPa, respectively, according to standard JC 890-2001. Therefore, it is not true that the more PCM in mortar, the better.

One of the most important characteristics of PCMs is its thermal properties. It can change phase at phase change temperature, thus it has very high heat storage potential, preventing too high temperature of the surfaces of constructions once applied to building materials [45–47]. Lots of researches about PCM-modified mortar have been done. Authors mainly concerned thermal conductivity, the specific heat capacity, the phase change temperature and latent heat of the mortar with or without PCM. The heat capacity and the thermal conductivity are the thermophysical properties of the composite material determined in the shape and dimensions in which it is implemented in buildings [48]. The phase change temperature and latent heat of the mortar can be tested by DSC. The incorporation of PCM leads to a reduction of peak temperatures and an increase in minimum temperatures and the PCM keeps its characteristics when integrated into hardened cement-based mortars [49]. The PCM-modified mortar not only can smooth temperature fluctuations, but also prone to hysteresis phenomenon. Ling et al. [50] designed three cubicles during thermal test, proving that the bottom surface temperature of the 10 % PCM slab and the 20 % PCM slab is about 3.3 and 6.2 °C lower than that of the slab containing no PCM respectively and the time delay of temperature rising in the case of 20 % PCM is longer than that at 10 % PCM (Fig. 13).

Measured temperature at bottom of slabs (Ling et al. [50])

3.5.2 PCM-Concrete

The properties of PCM-concrete also included two categories: mechanical properties and thermal properties. First, investigations on using the immersion technique have found that there is no significant difference in the strength between the control and immersion PCM-concrete [50]. However, in the case of direct mixing, inclusion of PCM microcapsules significantly reduces the compressive strength. Lecomptea et al. [51] studied the properties of PCM microcapsules, proving that the presence of PCM drastically lowered the mechanical strength and bending strength, and the reason can be found in Ref. [51]. The addition of a stiff quartz inclusion results in an increase in the strength with increasing volume fraction, while the addition of PCMs reduces the strength of composite [52]. So we can add stiff quartz to offset strength decrease of PCM. Silica fume can also replace cement in the binder fraction of the concrete to improve compressive strengths.

Several workers [53–55] have studied the thermal performance and noted that there is potential value in using encapsulated or impregnated PCM in different types of concrete slab and blocks. Pomianowski et al. [53] concluded that the difference between the volumetric heat capacity of the 4 and 6 wt% PCM concrete is quite insignificant though the heat capacity increased with the increasing of PCM [50]. At the same time, the thermal inertia of PCM-concrete is significantly higher than the thermal inertia of the reference concrete without PCM but only within the melting range where the specific heat capacity is high. Pomianowski et al. [49] concluded that thermal conductivity of building materials drastically drops due to addition of low thermally conductive microencapsulated PCM and PCM can increase heat storage of the mortar material/concrete within PCM melting and solidification temperature range, which is similar to the theoretical results of [50]. With the special thermal properties, concrete materials incorporating PCMs can provide a more stable temperature which ensures temperatures conducive to human thermal comfort in the buildings’ internal space.

3.5.3 PCM-Gypsum Board

Gypsum is usually found in partition walls and it is always located in the interior side of a wall as a cladding element. The physical and mechanical properties of gypsum board with PCM have been studied by many authors. When microcapsules are added, the mixture workability decreases and it solidifies in a shorter time [56], leading the number of the bubbles which remain trapped in the gypsum increases, thus influencing the density of PCM gypsum board. Zhang et al. [57] proved that the bending strength and compressive strength of the thermal-regulated gypsum board decreased with an increase of the volume of the composite PCM, which is similar to the theory of Oliver [58]. Borregueroa et al. [102] also concluded that the addition of microcapsules produces a decrease of the bulk density and modifies the gypsum porosity.

Several researchers [58, 102, 103] have tried to introduce PCMs into gypsum board to enhance the heat storage capacity of constructions. The higher the microcapsules content, the lower the slope of the temperature profiles when the temperature reaches the region in which the PCM starts to melt which indicated the microcapsules addition reduce the composite thermal conductivity [102]. Oliver [58] studied the thermal behavior of gypsum board containing 45 % by weight of PCMs reinforced with additives. He proved that a 1.5 cm thick gypsum board with PCMs stored 5 times the thermal energy of a laminated gypsum board, and the same energy as a 12 cm thick brick wall within the comfort temperature range (20–30 °C). Jaworski and Shady [103] presented the results of thermal conductivity measurement of gypsum-based composites incorporating microencapsulated PCMs. They also used the hot plate apparatus to measure thermal conductivity under steady state conditions.

3.6 PCM Window and Sunshade

3.6.1 PCM Window

A PCM filled window is thermally more effective than an air-filled window as it filters out thermal radiation which in term reduces heat gains or losses [59]. A comparison on the dynamic heat transfer characteristics of PCM-filled glass window and hollow glass window was performed by Li et al. [60], who concluded that the annual energy consumption of the air conditioning system and the heating system because of the heat transferred though the PCMW (the PCM-filled glass window) decreased 40.6 % comparing with the HW (the hollow glass window) applied in the representative sunny summer day. PCM glazing systems not only have great benefit on cold climates, also show a positive effect in warmer climates [61].

The PCM glazing has a good ability to store solar energy and to smooth and delay peak values of the total heat flux [62]. The energy storage process (the “charge phase” of the PCM) is mainly driven by incident solar radiation, while the energy release process (the “discharge phase” of the PCM) is influenced by the indoor and outdoor temperature difference. Gowreesunker et al. [63] analyses the optical and thermal aspects of a PCM glazed unit, and compares its performance with a standard double-glazed unit, making a conclusion that the transmittance spectra at different PCM phases are different and the use of PCM within a double-glazed unit improves the thermal mass during phase change, relative to a standard double-glazed unit. Goia et al. studied thermal comfort conditions of PCM glazing systems in different climates (summer season, winter season and mid-season), compared with a conventional reference double-glazed unit [64]. For each season, they observed between DGU PCM (Double Glass Unite PCM) and DGU CG (Double Glass Unite Clear Glass) for days with three kinds of solar irradiation, namely low solar irradiation (low H), moderate solar irradiation (moderate H), and high solar irradiation (high H). In general, the higher the outdoor solar irradiance, the greater the benefits offered by DGU PCM [64]. However, the surface temperature of the internal glass panes reaches quite high values that can affect thermal comfort in a negative way if the PCM melts completely before the sunset, especially during summer.

3.6.2 PCM Sunshade

It seems that application of PCM on the sunshade has not been received enough attention. Only several literatures about sunshade and sandwich form shutter can be found. And the results show some positive influence on the heat gain reduction and peak load shift.

The peak temperature reduction, appearance delay, and the time increase in comfort conditions have been found in the building mixing microencapsulated PCM shown in Fig. 14 [65].

Outer view of the concrete cubicles with awnings (left) and a bird’s eye view of the roof with an awning (right) (Pablo [65])

Researches on the sandwich form sunshade shown in Fig. 15 revealed that the air gap and the PCM layer thickness have negative influence on the heat gain while the phase change temperature have essential influence on the reduction of the heat gain through window [66, 104].

Schematic representation of the windows PCM system and the boundary conditions (Wang [66])

Tiago has confirmed that a new type shutter shown in Fig. 16 revealed a better thermal performance compared with the one without PCM, which can be proved by the experiment results that the maximum indoor temperature were 37.2 and 53.8 °C in the test room and reference room respectively and the heat flux were 6.5 and 16 Wm−2 accordingly [105, 106].

Structure of a new type shutter [105]

4 PCM Used in Building Energy System

4.1 PCM Used in Solar Energy Storage System

4.1.1 Hot Water by PCM and Solar Energy

In order to harvest solar energy, thermal energy storage system with PCM has been receiving greater attention because of its large energy storage capacity and isothermal behavior during charging and discharging processes. Hence, more researchers have studied the system combining PCM with solar energy to heat water and then save the thermal energy in it. The current research intriguing interests are still the selection of PCM, the optimization design of phase change heat storage unit structure, the thermodynamic properties, and economic performance researches of the coupled system, and so on. In this study, different technologies about PCM inserted in the solar water collectors were studied as follows.

Huang et al. [67] researched a new PCM floor which included capillary plaits and macro-packaged PCM layer. The results showed that the utilization of macroencapsulated PCM in solar water floor heating system greatly enhanced thermal energy storage capacity of the floor. Besides, the latent heat storage by capric acid in the PCM room was much more suitable and available than sensible heat storage by concrete within the floor in the ordinary room.

Al-Kayiem and Lin [68] conducted outdoor experimental measurements of a flat plate solar collector integrated with built-in thermal energy storage (TES). The study investigated three cases, respectively without PCM, with PCM, and with the Cu-PCM nanocomposite. The integrated solar-TES experimental setup is shown in Fig. 17. The measurement results of the tank water temperature after 24 h of operation, were 35.1 °C, 40.1 °C, and 40.7 °C, respectively. The results indicated that the enhancement of the system using TES with paraffin wax is considerable, while further enhancement is not significant in the case of nanocomposite.

The experimental setup of the integrated solar collector-TES water heater (Al-Kayiem [68])

Chaichan and Kazem [69] took use of Paraffin wax as PCM. The experimental results showed that the system working time increased to 3 h when PCM added without sun tracker; further the time was increased to about 5 h with sun tracker by concentrating dish and adding PCM to the system. Alemrajabi also conducted a similar experimental study, as a result of using PCM, the time the solar heater could supply hot water, extended up to 25 % in 80 °C charging mode [70]. Moreover, Bouadila et al. have achieved the conclusion: the solar collector could remain a uniform useful heat around 400 W during 5 h after sunset [71]. Mahfuz et al. [72] also utilized paraffin wax as PCM, and they calculated the total life cycle cost for different flow rates of the heat transfer fluid. They found that the total life cycle cost decreased when increased the flow rate. Khalifa et al. [73] integrated a storage solar collector which consisted of six 80 mm diameter copper pipes connected in series with a back container of a PCM (paraffin wax) thermal storage media. Schematic diagram of the construction was showed in Fig. 18. Several tests were conducted during selected clear and semi-cloudy days in January–March. It was observed that in contrast to the increasing trend previously obtained for a similar system without the PCM back layer, the plate temperature increases up to a distance of 2.5 m from entrance, after which a nearly steady temperature is noticed for the remaining 7.6 m of the total length. Moreover, it was found that nearly steady variation in the system’s useful efficiency for all months.

Schematic diagram of the storage system showing the location of the temperature measurements inside the wax back layer and on the absorber plate (Khalifa [73])

Chaabane et al. [74] developed two numerical models in three-dimensional modeling, taking use of two different kinds of PCMs (myristic acid and RT42-graphite) of the PCMs layer. Numerical results showed the advantage of PCMs for night thermal losses reduction. Moreover, the use of myristic acid is more beneficial for this solar application comparing with RT42-graphite. Haillot et al. [75] evaluated of the performance of the solar domestic hot water systems including a PCM storage volume in the heat transfer loop. The new system configuration is shown in Fig. 19. They developed and used a numerical model with an inverse method to determine the best configuration to maximize the solar fraction or minimize the electrical consumption. It was shown that the parametric study highlighted a significant increase of the system efficiency due to the PCM. However the optimum was not unique and depended upon the meteorological data. Padovan and Manzan [76] also performed two optimizations for a solar domestic hot water system with a tank which contained PCM modules to determine the more influence factor (PCM modules or insulation width). The results showed that the PCM modules had no improvements of the saved energy while the insulation width had some. This was mainly because temperatures inside the tank changed largely, which may weaken the benefits of the latent heat of PCM with a reduced sensible heat absorbed.

Layout of the solar domestic hot water system with PCM (Haillot et al. [75])

4.1.2 Hot Airs by PCM and Solar Energy

One of the potential applications of solar energy is the supply of hot air for heating buildings during winter. PCM-based thermal storage could be employed in some of these systems as a peak shaving measure. Drying of various products is another area in which solar air.

Some new air-based solar thermal systems with PCM were investigated [77] using laboratory experiments and numerical simulations. Bouadila et al. [78] proposed a new solar air heater with a packed-bed latent storage energy system using PCM spherical capsules. A schematic arrangement of the solar air heater with phase change energy storage using spherical capsules and the experimental setup are given in Figs. 20 and 21, respectively.

Schematic view [78]

Experimental setup [78]

Esakkimuthu et al. [79] investigated the feasibility of using a latent heat storage unit with HS 58, an inorganic salt-based PCM, to store the excess solar energy. The design and modeling of the heat transfer of a solar air heating system were studied by Arkar et al. [80], which consists of a vacuum tube air solar collector (SC) and latent heat thermal energy storage (LHTES), and a parametric analysis of the performance of this system. A novel indirect solar dryer (ISD) design using PCM was experimentally investigated by Shalaby et al. [81]. The ISD was tested under no load with and without PCM. The experiment setup is shown in Fig. 22.

A schematic diagram of the experiment setup [81]. 1 Solar air heater; 2 Pyranometer; 3 The room wall; 4 The room roof; 5 Flowing air; 6 PVC tube; 7 Inverter; 8 Three phase induction motor coupled with fan; 9 Pitot tube; 10 U tube manometer; 11 Drying compartment; 12 PCM; 13 Trays; 14 Thermocouple positions

Cakmak et al. [82] applied a new dryer for evaluating the drying kinetics of seeded grapes needing lower moisture value and less drying time. There are an expanded-surface solar air collector, a solar air collector with PCM and drying room with swirl element as Fig. 23. A state-of-the-art solar dryer was developed by Jain and Tewari [107] with thermal energy storage drying plenum with crop trays and natural ventilation system.

Schematic view of manufactured experimental setup [82]

4.2 PCM Used in Conditioning System of Indoor Thermal Environment

4.2.1 Floor Heating System

The present work is focused on the use of PCM in a radiant floor system. Radiant floor systems have the main advantage of working with lower temperature gradients compared to other conventional heating elements.

Jeon et al. [83] discusses PCM application methods for residential building using radiant floor heating systems with the goal of reducing energy consumption. Figure 24 shows that the Ministry of Land has specified the standard floor formation. It reveals that hot water pipes are built in the floor as the heating medium of radiant floor heating systems.

Standard floor formation for Korean ministry of land [83]

4.2.2 Air Condition and Ventilation System

Many different approaches have been studied to use PCM materials for night cooling and ventilation application, depending on the building material and its location in the building.

Moreno [84] presents the evaluation of an experimental setup consisting of a heat pump system coupled to TES tanks, as shown in Fig. 25. The experimentation was carried out under simulated summer conditions to refrigerate a small like-house (2.4 × 2.4 × 2.4 m). The results have demonstrated that the PCM storage tank gives some advantages over the water one.

PCM thermal energy storage tanks. a A sketch with the main dimensions, b real TES tanks [84]

Solutions proposed by Álvarez et al. in the MECLIDE project are a combination of three old types [85], so that they can have been incorporated in the structure of the building. The solutions of MECLIDE project use PCM in containers. This air flow is controlled by a control system that can change the air-flow rate, the origin, and the destination of air flow. They even can stop the system totally.

A new type of ventilated façade including a PCM in its external layer has been designed by Diarce et al. [86]. This type of façade could be used in new buildings and in retrofitting processes. It combines the beneficial effects of a ventilated façade with the suitable thermal properties of a PCM. The prototype façade was designed to be suitable for use in building restoration. The façade is composed of five different layers, as shown in Fig. 26.

Ventilated façade with filled with PCM [86]

Models for various designs have been developed to study the performance of PCM integration in building walls. Romero-Sanchez et al. [87] evaluated the incorporation of PCMs in natural stone. Experimental and computational studies were conducted to improve the thermal properties of natural stone by exploiting the associated latent heat storage phenomenon. A study based on the ventilated facade with PCM in its air chamber was present [88]. Two cubicles were built in an experimental setup one with this ventilated facade system and the other without. The results of the LCA show that considering a lifetime of 50 years, the use of this particular ventilated facade reduces by 7.7 % the overall environmental impact of the whole building.

4.3 Coupled Application of PCM and Ground Source Heat Pump System

In recent years, there are more and more studies that have concentrated on the combination of GSHP and thermal energy storage (TES) system, improving the accuracy of the models and design method.

Wang et al. [89] carried numerical and experimental study on a solar GSHP system integrated with PCM as latent heat storage tank (LHST) in Harbin, China. In order to verify the performance of the system and the model,2 days were chosen to compare the numerical results with experimental data. Inlet and outlet temperatures of the water in the LHST, temperature of PCM and storage and emission heat of LHST were measured. The trends of the variation of numerical results and experimental data were in close agreement. Bottarelli et al. [90] studied yearly by taking into account the estimated energy requirement for an assumed residential building located in Northern Italy. In comparison with the case without PCMs, the surface temperatures of the ground heat exchangers coupled with PCMs could be higher in winter and lower in summer by several degrees. This indicates the potential increase in the coefficient of performance of the heat pump. The optimal control method of GSHP system integrated with PCM cooling storage tank in an office building was studied by Zhu et al. [91] in an office building in Wuhan, China. The annual operation cost of the combined system under cooling storage ratio of 40 % was reduced by 63.8 % compared with that without cooling storage. The annual cost of the GSHP combined PCM cooling storage system under cooling storage ratio of 40 % was reduced by 34.2 % compared with common GSHP hybrid cooling tower system without cooling storage.

4.4 PCMs Applied to Electrical Energy Storage

PCMs applied to electrical energy storage for two mainly purposes: shifting electricity peak load and supplying heat. With the development of economic and improvement of people’s living standards, the degree of tension in peak period power supply situation is more serious, while the contradictions between peak power supply shortage and low surplus become increasingly prominent. The phase change energy storage technology as an emerging technology can play a good role in peak power shifting. Thus, PCMs with large thermal energy storage capability have been widely used for shifting electricity peak load in buildings in recent years. Many studies have been focused on the load shifting utilizing PCMs. Through analyzing several publications, most of the researches applied the PCMs to these systems, such as hot water tank, the underfloor heating system, an inverter chiller cooling system or domestic heat pumps. These coupling systems can play an effective role for the electricity peak load shifting; however, these systems also have their drawbacks. Therefore, the further efforts needed for developing more applicable PCMs or new coupling systems used for electricity load shifting.

Nkwetta et al. [92] investigates the potential of using PCMs to shift the electricity peak load demand. For this purpose, the study was carried out taking use of a model that applied PCMs to a validated hot water tank. The results showed that the combinative application of PCMs in a hot water tank increased the amount of the stored thermal energy contrasted to the hot water tank without PCMs (only sensible heat). Moreover, this stored energy and potential in shifting electricity peak load are directly proportional to the amount of PCM added into the hot water tank.

Sun et al. [93], presents a comprehensive review of the peak load shifting control strategies using PCMs in commercial buildings. The paper summarized the existing studies and found that significant benefits can be obtained in peak load reductions (from 10 to 57 %), overall cost savings (from 11 to 96.6 %) and improved thermal comfort taking use of no or simple load shifting control strategies.

Phase change thermal storage electric heating is a novel way of heating, it is still under investigation. It uses a PCM and stores cheap electricity consumed by the electric film or cable during the night in the form of heat energy for daytime heating. So you can not only save heating operating costs, but also achieve the peak power load shifting. Currently, the wider application of this heating method is coupled PCM into the radiant floor heating systems as floors can offer large heat transfer areas within the building. The heat stored in PCMs, is a clean, energy-saving, convenient, and comfortable choice. Currently, there have been some studies embarked on research in this area.

Barzin et al. [34] conducted a series of experiments in two identical test huts, as previously described. Experimental results showed that PCM wallboard coupled in the underfloor floor heating system resulted in getting benefits from both of the systems and consequently reducing electricity usage while maintaining the room temperature within the desired range. Application of this method resulted in sizable saving of 18.8 % over a five-day period, with a maximum saving of 35 %. What’s more, the amount of saving mainly depends upon the solar radiation of the day and the outdoor temperature, as is similar to the conclusion in [94]. Khalifa et al. [73] adopted a new PCM floor in solar water heating system, and the schematic of the floor was seen in Fig. 27. By experimental and simulation method, it was indicated that the use of macroencapsulated PCM as a composite energy storage layer in solar water floor heating system highly enhance heat storage capacity of the floor. In addition, there were hardly any degradation for capric acid used as PCM in the composite PCM layer after 200 accelerated thermal cycles and it is qualified for latent heat storage.

Configuration of the novel PCM floor (Huang et al. [73])

5 Conclusions

The building efficiency is one of effective solutions to the global warming. As a significance technology for building efficiency, PCM using in buildings can decrease the fossil fuel usage by reducing the building energy consumption and then reduce the emission of GHGs.

For the passive application by incorporating PCM into buildings, such as PCM wall, PCM floor, and PCM gypsum, excess heat/direct solar radiation can be stored during the interval with room temperature higher than the melting point, and the heat can be released in the interval with room temperature lower than the freezing point during the winter season. In summer, the cold energy can be passively stored or released, and the better performance will be achieved if the passive process can work together with the natural ventilation because of higher heat convection in room. PCM can also be actively used in building energy systems, which can be exampled as the PCM and solar energy hot water/air systems, PCM and floor heating system, PCM and GSHP system, and so on. The renewable energy, inclusive of solar energy, shallow geothermal energy, natural cold energy, etc., can be stored or released by PCM for the building energy supply in the PCM active application processes, so as to decrease the conventional energy consumption. It may also work the other way around, extending the cooling/heating effect by PCM storage tanks to reduce the active energy consumption, for instance, PCM and air condition and ventilation system.

The benefits of using PCM in buildings mainly revolve building energy consumption reduce and thermal comfort enhancement by adjusting the indoor temperature fluctuation. Besides, because of the enormous energy storage ability of the PCM, another advantage use, electricity peak load shifting, has been emerged. It refers to that the heat or cold from electrical heating or electrical refrigeration are stored by PCM in the valley interval, and then released in the peak interval. The electricity network loads in the peak period can be alleviated, so as to reduce the power generation loss, and save the user electric cost in the zones with peak and valley electric charges.

The PCM technology is a promising and significance method for the global warming solution, but some difficulties which need to be overcome still existed for a large-scale promotion of this technology. The series standards, which can regulate the performance tests of PCM and PCM applications and identify the proper PCM matching the different climate zone need, are lack. The cost will be increased for the PCM used in buildings. Hence, the technical economic investigations for the payback periods for PCM installations are also needed to further conduct. For the property of PCM, the rise of thermal conductivity usually results in latent heat storage reducing. Security and environmental protection is still an obstacle for organic PCM application in buildings.

References

Alexiadis A (2007) Global warming and human activity: a model for studying the potential instability of the carbon dioxide/temperature feedback mechanism. Ecol Model 203(3–4):243–256

VijayaVenkataRaman S, Iniyan S, Goic R (2012) A review of climate change, mitigation and adaptation. Renew Sustain Energy Rev 16(1):878–897

Karakurt I, Aydin G, Aydiner K (2012) Sources and mitigation of methane emissions by sectors: a critical review. Renew Energy 39(1):40–48

British Petroleum (B.P), statistical review of world energy (2010)

Guo KW (2012) Green nanotechnology of trends in future energy: a review. Int J Energy Res 36(1):1–17

Radhi H (2009) Evaluating the potential impact of global warming on the UAE residential buildings-a contribution to reduce the CO2 emissions. Build Environ 44(12):2451–2462

United nations environment programme, building and climate change: status, challenges and opportunities, UNEP sustainable building and climate initiative (UNEP), Paris (2007)

Perez L, Ortiz J, Coronel J, Maestre I (2011) A review of HVAC systems requirements in building energy regulations. Energy Build 43:255–268

Anisur MR, Mahfuz MH, Kibria MA, Saidur R, Metselaar IHSC, Mahlia TMI (2013) Curbing global warming with phase change materials for energy storage. Renew Sustain Energy Rev 18:23–30

Fernandes D, Pitie F, Caceres G, Baeyens J (2012) Thermal energy storage: how previous findings determine current research priorities. Energy 39(1):246–257

Dincer I, Rosen MA (2007) Energetic, exergetic, environmental and sustainability aspects of thermal energy storage for sustainable energy consumption. Therm Energ Storage Sustain Energ Consumption, NATO Sci Ser 234:23–46

Kong X, Shilei L, Huang J, Cai Z, Wei S (2013) Experimental research on the use of phase change materials inperforated brick rooms for cooling storage. Energy Build 62:597–604

Telkes M, Raymond E (1949) Storing solar heat in chemicals—a report on the dover house. Heat Vent 46(11):80–86

Hale DV, Hoover MJ, O’Neill MJ (1971) Phase change materials handbook, NASA CR-61363. Marshall space flight center, AL. <http://hdl.handle.net/2060/19720012306>

Sarier N, Onder E (2012) Organic phase change materials and their textile applications: an overview. Thermochim Acta 540:7–60

Pauken M, Emis N, Watkins B (2007) Thermal energy storage technology developments. AIP Conf Proc 880(1):412–420

Lacroix M (1993) Study of the heat transfer behavior of a latent heat thermal energy storage unit with a finned tube. Int J Heat Mass Transf 36(8):2083–2092

Buddhi D, Sawhney RL, Seghal PN, Bansal NK (1987) A simplification of the differential thermal analysis method to determine the latent heat of fusion of phase change materials. J Phys D Appl Phys 20:1601–1605

Zhang XX, Wang X, Wu WJ (2009) Production and application of phase change materials capsule. Chemical Industry Press, Beijing (in Chinese)

Zhang RY (2009) PCMs and energy storage technologies. Science Press, Beijing (in Chinese)

Fu H, Ouyang D, Ning B, Yin FL (2012) Latest research progress of phase change energy storage building materials. Concrete 1:55–57 (in Chinese)

Wang YJ (2009) Application of phase change energy storage materials to building energy efficiency. Chem Build Mater 25(5):25–27 (in Chinese)

Kong XF (2013) Study on the performance of PCM combined with building envelop for cold storage. Tianjin university (in Chinese)

Alexander M (2015) Diurnal thermal analysis of microencapsulated PCM-concrete composite walls. Energy Convers Manag 93:215–227

Biswas K, Jue L (2014) Combined experimental and numerical evaluation of a prototype nano-PCM enhanced wallboard. Appl Energy 131:517–529

Vicente R (2014) Brick masonry walls with PCM macrocapsules: an experimental approach. Appl Therm Eng 67:24–34

Soares N, Gaspar AR (2014) Multi-dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build 70:411–421

Alqallaf HJ (2013) Concrete roof with cylindrical holes containing PCM to reduce the heat gain. Energy Build 61:73–80

Alawadhi EM (2011) Building roof with conical holes containing PCM to reduce the cooling load: numerical study. Energy Convers Manag 52:2958–2964

Chou H-M (2013) A new design of metal-sheet cool roof using PCM. Energy Build 57:42–50

Dong L, Yumeng Z (2015) Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers Manag 100:147–156

Jaworski M (2014) Thermal performance of building element containing phase change material (PCM) integrated with ventilation system—an experimental Study. Appl Therm Eng 70:665–674

Cheng W (2015) Effect of thermal conductivities of shape stabilized PCM on under-floor heating system. Appl Energy 144:10–18

Barzin R (2015) Application of PCM underfloor heating in combination with PCM wallboards for space heating using price based control system. Appl Energy 148:39–48

Royona L (2013) Thermal energy storage and release of a new component with PCM for integration in floors for thermal management of buildings. Energy Build 63:29–35

Kong X (2014) Numerical study on the thermal performance of building wall and roof incorporating phase change material panel for passive cooling application. Energy Build 81:404–415

Lee KO, Medina MA (2015) On the use of plug-and-play walls (PPW) for evaluating thermal enhancement technologies for building enclosures: evaluation of a thin phase change material (PCM) layer. Energy Build 86:86–92

Lee KO, Medina MA (2015) Assessing the integration of a thin phase change material (PCM) layer in a residential building wall for heat transfer reduction and management. Appl Energy 137:699–706

Jin X, Medina MA (2013) On the importance of the location of PCMs in building walls for enhanced thermal performance. Appl Energy 106:72–78

Jin X, Medina MA (2014) On the placement of a phase change material thermal shield within the cavity of buildings walls for heat transfer rate reduction. Energy 73:780–786

Guarinoa F, Dermardiros V (2015) PCM thermal energy storage in buildings: experimental study and applications. Energy Procedia 70:219–228

Chwieduk DA (2013) Dynamics of external wall structures with a PCM (phase change materials) in high latitude countries. Energy 59:301–313

Soaresa N, Costa JJ, Gaspar AR, Santos P (2013) Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build 59:82–103

Li M, Zhishen W, Tan J (2013) Heat storage properties of the cement mortar incorporated with composite phase change material. Appl Energy 103:393–399

Biwan X, Li Z (2013) Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl Energy 105:229–237

Pomianowskia M, Heiselberg P, Zhang Y (2013) Review of thermal energy storage technologies based on PCM application in buildings. Energy Build 67:56–69

Joulin A, Zalewski L, Lassue S, Naji H (2014) Experimental investigation of thermal characteristics of a mortar with or without a micro-encapsulated phase change material. Appl Therm Eng 66:171–180

Franquet E, Gibout S, Tittelein P, Zalewski L, Dumas J-P (2014) Experimental and theoretical analysis of a cement mortar containing microencapsulated PCM. Appl Therm Eng 73:32–40

Vaz Sá A, Azenha M, de Sousa H, Samagaio A (2012) Thermal enhancement of plastering mortars with phase change materials: experimental and numerical approach. Energy Build 49:16–27

Ling T-C, Poon C-S (2013) Use of phase change materials for thermal energy storage in concrete: an overview. Constr Build Mater 46:55–62

Lecomptea T, Le Bideau P, Glouanneca P, Nortershauser D, Le Masson S (2015) Mechanical and thermo-physical behaviour of concretes and mortars containing phase change material. Energy Build 94:52–60

Fernandes F, Manari S, Aguayo M, Santos K, Oey T, Wei Z, Falzone G, Neithalath N, Sant G (2014) On the feasibility of using phase change materials (PCMs) to mitigate thermal cracking in cementitious materials. Cement Concrete Compos 51:14–26

Pomianowski M, Heiselberg P, Jensen RL (2012) Dynamic heat storage and cooling capacity of a concrete deck with PCM and thermally activated building system. Energy Build 53:96–107

Pomianowski M, Heiselberg P, Jensen RL (2013) Full-scale investigation of the dynamic heat storage of concrete decks with PCM and enhanced heat transfer surface area. Energy Build 59:287–300

Memon SA, Cui H, Lo TL, Li Q (2015) Development of structural–functional integrated concrete with macro-encapsulated PCM for thermal energy storage. Appl Energy 150:245–257

Toppi T, Mazzarella L (2013) Gypsum based composite materials with micro-encapsulated PCM: experimental. Energy Build 57:227–236

Zhang J, Guan X, Song X, Hou H, Yang Z, Zhu J (2015) Preparation and properties of gypsum based energy storage materials with capric acid–palmitic acid/expanded perlite composite PCM. Energy Build 92:155–160

Oliver A (2012) Thermal characterization of gypsum boards with PCM included: thermal energy storage in buildings through latent heat. Energy Build 48:1–7

Grynning S, Goia F, Rognvik E, Time B (2013) Possibilities for characterization of a PCM window system using large scale measurements. Int J Sustain Built Environ 2:56–64

Li S, Zhong K, Zhou Y, Zhang X (2014) Comparative study on the dynamic heat transfer characteristics of PCM-filled glass window and hollow glass window. Energy Build 85:483–492

Goia F, Perino M, Haase M (2012) A numerical model to evaluate the thermal behaviour of PCM glazing system configurations. Energy Build 54:141–153

Goia F, Perino M, Serra V (2014) Experimental analysis of the energy performance of a full-scale PCM glazing prototype. Sol Energy 100:217–233

Gowreesunker BL, Stankovic SB, Tassou SA, Kyriacou PA (2013) Experimental and numerical investigations of the optical and thermal aspects of a PCM-glazed unit. Energy Build 61:239–249

Goia F, Perino M, Serra V (2013) Improving thermal comfort conditions by means of PCM glazing systems. Energy Build 60:442–452

Arce P, Castellón C (2012) Use of microencapsulated PCM in buildings and the effect of adding awnings. Energy Build 44:88–93

Wang Q, Zhao CY (2015) Parametric investigations of using a PCM curtain for energy efficient buildings. Energy Build 94:33–42

Huang K, Feng G, Zhang J (2014) Experimental and numerical study on phase change material floor in solar water heating system with a new design. Sol Energy 105:126–138

Al-Kayiem HH, Lin SC (2014) Performance evaluation of a solar water heater integrated with a PCM nanocomposite TES at various inclinations. Sol Energy 109:82–92

Chaichan MT, Kazem HA (2015) Water solar distiller productivity enhancement using concentrating solar water heater and phase change material (PCM). Case Stud Therm Eng 5:151–159

Fazilati MA, Alemrajabi AA (2013) Phase change material for enhancing solar water heater, an experimental approach. Energy Convers Manag 71:138–145

Bouadila S, Fteïti M, Oueslati MM, Guizani A, Farhat A (2014) Enhancement of latent heat storage in a rectangular cavity: solar water heater case study. Energy Convers Manag 78:904–912

Mahfuz MH, Anisur MR, Kibria MA, Saidur R, Metselaar IHSC (2014) Performance investigation of thermal energy storage system with phase change material (PCM) for solar water heating application. Int Commun Heat Mass Transf 57:132–139

Khalifa AJN, Suffer KH, Mahmoud MS (2013) A storage domestic solar hot water system with a back layer of phase change material. Exp Therm Fluid Sci 44:174–181

Chaabane M, Mhiri H, Bournot P (2014) Thermal performance of an integrated collector storage solar water heater (ICSSWH) with phase change materials (PCM). Energy Convers Manag 78:897–903

Haillot D, Franquet E, Gibout S, Bédécarrats J-P (2013) Optimization of solar DHW system including PCM media. Appl Energy 109:470–475

Padovan R, Manzan M (2014) Genetic optimization of a PCM enhanced storage tank for solar domestic hot water systems. Sol Energy 103:563–573

Klimes L, Charvát P, Ostry M (2014) Numerical and experimental investigation of a PCM-based thermal storage unit for solar air systems. Energy Build 68:488–497

Bouadila S, Lazaar M, Skouri S, Kooli S, Farhat A (2014) Energy and exergy analysis of a new solar air heater with latent storage energy. Int J Hydrogen Energy 39:15266–15274

Esakkimuthu S, Hassabou AH, Palaniappan C, Spinnler M, Blumenberg J, Velraj R (2013) Experimental investigation on phase change material based thermal storage system for solar air heating applications. Sol Energy 88:144–153

Arkar C, Medved S (2015) Optimization of latent heat storage in solar air heating system with vacuum tube air solar collector. Sol Energy 111:10–20

Shalaby SM, Bek MA (2014) Experiment investigation of a novel indirect solar dryer implement PCM as energy storage medium. Energy Convers Manag 83:1–8

Cakmak G, Yıldız C (2011) The drying kinetics of seeded grape in solar dryer with PCM-based solar integrated collector. Food Bioprod Process 89:103–108

Jeon J, Lee J-H, Seo J, Jeong S-G, Kim S (2013) Application of PCM thermal energy storage system to reduce building energy consumption. Therm Anal Calorim 111:279–288

Moreno P, Castell A, Solé C, Zsembinszki G, Cabeza LF (2014) PCM thermal energy storage tanks in heat pump system for space cooling. Energy Build 82:399–405

Álvarez S, Cabeza LF, Ruiz-Pardo A, Castell A, Tenorio JA (2013) Building integration of PCM for natural cooling of buildings. Appl Energy 109:514–522

Diarce G, Urresti A, García-Romero A, Delgado A, Erkoreka A, Escudero C, Campos-Celador Á (2013) Ventilated active façades with PCM. Appl Energy 109:530–537

Romero-Sanchez MD, Guillem-Lopez C, Lopez-Buendia AM et al (2012) Treatment of natural stones with phase change materials: experiments and computational approaches. Appl Therm Eng 48:136–143

de Gracia A, Navarro L, Castell A, Boer D, Cabeza LF (2014) Life cycle assessment of a ventilated facade with PCM in its air chamber. Solar Energy 104:115–123

Wang F, Liu ZL, Li ZG (2010) Numerical simulation of solar ground-source heat pump with latent heat storage. In: International conference on material and manufacturing technology, Chongqing, China, 17–19 September 2010

Bottarellia M, Bortoloni M, Su Y, Yousif C, Aydın AA, Georgiev A (2014) Numerical analysis of a novel ground heat exchanger coupled with phase change materials. Appl Therm Eng 88:1–7

Zhu N, Hu P, Lei Y, Jiang Z, Lei F (2015) Numerical study on ground source heat pump integrated with phase change material cooling storage system in office building. Therm Eng 87:615–623

Nkwetta DN, Vouillamoz P-E, Haghighat F (2014) Phase change materials in hot water tank for shifting peak power demand. Sol Energy 107:628–635

Sun Y, Wang S, Xiao F, Gao D (2013) Peak load shifting control using different cold thermal energy storage facilities in commercial buildings. Energy Convers Manag 71:101–114

Qureshi WA, Nair NKC, Farid MM (2011) Impact of energy storage in buildings on electricity demand side management. Energy Convers Manage 52(5):2110–2120

Baetens R, Jelle BP, Gustavsen A (2010) PCMs for building applications: a state-of-the-art review. Energy Build 42(9):1361–1368

Tyagi VV, Buddhi D (2007) PCM thermal storage in buildings: a state of art. Renew Sustain Energy Rev 11(6):1146–1166

Zalba B, Marin JM, Cabeza LF, Mehling H (2003) Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl Therm Eng 23(3):251–283

Kousksou T, El Rhafiki T, Jamil A, Bruel P, Zeraouli Y (2013) PCMs inside emulsions: some specific aspects related to DSC (differential scanning calorimeter)-like configurations. Energy 56:175–183

Wang JC (2012) The preparation and energy-saving assessment of a phase change building material. South China university of technology (in Chinese)

Shadnia R, Zhang L, Li P (2015) Experimental study of geopolymer mortar with incorporated PCM. Constr Build Mater 84:95–102

Lai C-M, Hokoi S (2014) Thermal performance of an aluminum honeycomb wallboard incorporating microencapsulated PCM. Energy Build 73:37–47

Borreguero AM, Garrido I, Valverde JL, Rodríguez JF, Carmona M (2014) Development of smart gypsum composites by incorporating thermo regulating microcapsules. Energy Build 76:631–639

Jaworski M, Shady A (2011) Thermal conductivity of gypsum containing phase change material (PCM) for building applications. J Power Technol 91:49–53

Alawadhi EM (2012) Using phase change materials in window shutter to reduce the solar heat gain. Energy Build 47:421–429

Silva T, Vicente R (2015) Development of a window shutter with phase change materials: full scale outdoor experimental approach. Energy Build 88:110–121

Silva T, Vicente R (2015) Performance of a window shutter with phase change material under summer mediterranean climate conditions. Appl Therm Eng 84:246–256

Jain D, Tewari P (2015) Performance of indirect through pass natural convective solar crop dryer with phase change thermal energy storage. Renew Energy 80:244–250

Dincer I, Rosen MA (2010) Energy storage systems thermal energy storage. Wiley, New York, pp 51–82

Sharma A, Tyagi VV, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 13(2):318–345

Royona L (2014) Optimization of PCM embedded in a floor panel developed forthermal management of the lightweight envelope of buildings. Energy Build 82:385–390

de Gracia A, Navarro L (2013) Numerical study on the thermal performance of a ventilated façade with PCM. Appl Therm Eng 61:372–380

de Gracia A, Navarro L (2015) Energy performance of a ventilated double skin facade with PCM under different climates alvaro. Energy Build 91:37–42

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Lu, S. et al. (2017). A Review of PCM Energy Storage Technology Used in Buildings for the Global Warming Solution. In: Zhang, X., Dincer, I. (eds) Energy Solutions to Combat Global Warming. Lecture Notes in Energy, vol 33. Springer, Cham. https://doi.org/10.1007/978-3-319-26950-4_31

Download citation

DOI: https://doi.org/10.1007/978-3-319-26950-4_31

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-26948-1

Online ISBN: 978-3-319-26950-4

eBook Packages: EnergyEnergy (R0)