Abstract

Polymeric cryogels, the gels formed in moderately frozen gelling systems, have been empirically known for many decades, but systematic scientific research on various cryogels and the peculiarities of cryotropic gel formation only commenced at the beginning of the 1980s. This historical review briefly describes the principal stages of the studies on these very interesting gel materials. It also discusses some mechanisms of their formation, as well as summarizes published data on the main representatives of chemically crosslinked (covalent), ionically linked, and noncovalent (physical) cryogels.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introductory Remarks

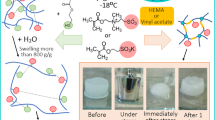

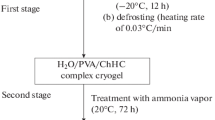

Polymeric cryogels are the gel systems formed via the cryogenic treatment (moderate freezing—frozen storage—thawing) of solutions or colloidal dispersions of the appropriate precursors [1]. On a microscopic level, moderately frozen molecular or colloid solutions are heterophase systems containing both solids (i.e., the polycrystals of frozen solvent) and some unfrozen fraction called “unfrozen liquid microphase” [2], where the solutes are concentrated. Thus, gelation can only occur within the latter unfrozen regions of the system while the crystals of frozen solvent act as porogens. Such specific conditions of gel formation are the key factors in determining the rather unusual heterophase macroporous morphology of the resulting polymer materials, the whole set of their physicochemical characteristics and, as a consequence, their operational capabilities. The present volume deals with the diverse aspects of preparation, properties, structure, and practical implementation of various cryogels based on synthetic organic or inorganic polymers, as well as on natural biopolymers. Taking into account the fact that the number of the works published in this field has grown almost exponentially during recent years (Fig. 1a), it is reasonable to first give a brief historical overview of these gel systems, which are very interesting both from the fundamental and applied viewpoints. Moreover, the authors of some recent publications devoted mainly to the applied aspects often seem to be unaware of the pioneering studies and main scientific sources. It is hoped that this chapter will also contribute to a better understanding of the developments achieved in cryotropic gel formation over the past three decades.

The number of publications (a) and citations (b) with keywords “cryogel” or “cryogels” from 1980 to 1 November 2013 according to the ISI Web of Knowledge portal [3]

In many cases, it is difficult to indicate which exactly was the very first communication on some experimentally observed phenomenon, especially if it was discovered many years ago in the pre-electronic era, and the report appeared in an issue hardly available now, or if it was patented locally in a language not commonly used. The present brief historical information certainly has no claim to be an exhaustive review of all the early pioneering publications on cryogenically produced gel matrices. Nevertheless, we can assert that the term “cryogel” was most probably applied for the first time in a paper published in 1984 to designate polymeric materials prepared via chemical crosslinking of macromolecular precursors in moderately frozen organic media [4]. The term was created by combining “cryo” (from the Greek kryos, meaning frost or ice) and “gel,” thus highlighting the specific formation conditions for the gels of this family. Besides the mentioned article, different terms were used for gels formed in frozen systems (mainly, aqueous ones): cryocoacervates [5], cryocoagulates [6], cryo-concentrated gels [7, 8], anomalous gels [9], freeze–thaw gels [10], etc. However, since the end of the 1980s the term “cryogel” has become more and more popular (Fig. 1b).

It should also be noted that several other materials are currently called “cryogels.” Specific examples are as follows:

-

1.

Commercially available jelly-like medical liniments causing a cooling-down effect when spread on the skin surface [11]. It is evident that this has no relation at all to gel formation under frozen conditions.

-

2.

The proteinaceous water-swollen coagulates that are formed upon low-positive-temperature chilling of blood plasma taken from the patients with rheumatoid arthritis or some complex immune diseases [12, 13]. Since no freeze–thaw treatment is applied to the precursor liquid in order to induce the formation of such coagulates, the use of the term “cryogel” for this protein matter appears unjustified.

-

3.

The so-called “carbon cryogels” prepared by swelling of certain crosslinked organic polymers, e.g., swelling of phenol–formaldehyde resins in crystallizable organic solvents such as benzene, followed by freezing of the swollen matter and finally freeze-drying to obtain a macroporous polymeric texturate, which is then subjected to high-temperature carbonization with the formation of activated carbon (charcoal) possessing specific macroporosity [14–16]. It is also obvious that such final materials (i.e., “carbon cryogels”) are not gels at all, because gels are 3D networks constructed from organic or inorganic polymers and necessarily contain immobilized low molecular weight solvate liquid (i.e., water in the case of hydrogels).

-

4.

Some authors have named the polymeric matrices fabricated via conventional freeze-drying by the term “cryogels.” Certainly, freezing of polymeric solutions or colloidal dispersions causes solid–liquid phase separation, and the subsequent sublimation of the solidified solvent crystals “fixes” the system thus structured [17, 18], but no gelation occurs during these consecutive steps. Therefore, it is more correct to call such freeze-dried polymeric matrices “cryostructurates” or “cryotexturates” rather than “cryogels.”

Taking into account the above considerations, one can conclude that the polymeric and biopolymeric materials mentioned above are not related directly to proper cryogels and that they are probably named by such a term rather accidentally.

2 Types of Initial Systems Capable of Being Precursors for the Preparation of Cryogels

Numerous studies on various aspects of cryotropic gelation phenomena have demonstrated that cryogels can be prepared, similarly to the traditional gels formed at positive temperatures, from precursor systems that fall into the following categories (see review articles [1, 18–29]):

-

Colloidal dispersions: Freezing of colloid sols and the resulting cryo-concentration effects cause reinforcement of the interparticle interactions, leading to the formation of tight particle-to-particle contacts. These contacts are stabilized either by the cohesion forces or, if some reactive auxiliary substances are present, by the formation of chemical links between the grains of particulate matter. It seems likely that the freeze–thaw structuring and gelling of colloid systems is the oldest example of cryotropic gelation and has been known for many decades, especially by people who deal with the frozen storage of foodstuffs (some particular instances are given below).

-

Solutions of monomeric precursors: Chemically or radiation-induced crosslinking polymerization or polycondensation in moderately frozen aqueous or organic media (depending on the chemical nature of the monomers) results in covalently crosslinked gel materials that generally possess a wide-pore spongy morphology.

-

Solutions of high molecular weight precursors: Covalent crosslinking, i.e., curing of macromolecules either with chemical agents or by irradiation (gamma-rays, electron beams, UV irradiation, photolysis in the presence of a suitable photoinitiator) in non-deeply frozen systems, results in chemically crosslinked highly porous matrices. The characteristics of the porosity of such gel materials (i.e., their macroporous or supermacroporous sponge-like texture) are governed by the freezing conditions, by the amount of freezable solvent, and by the size of porogen particles, namely, solvent polycrystals.

-

Solutions of so-called self-gelling polymers: Such precursor systems are capable of forming physical (noncovalent) gels upon “worsening” of the thermodynamic quality of the solvent [1, 30] or by the addition of a solute that induces a change in the conformation of the macromolecular chains, e.g., a protein denaturant [31, 32].

-

Solutions of polyelectrolytes containing low molecular weight or polymeric crosslinking counterions: These precursor systems are able to form sufficiently stable ionic bridges between the polyelectolyte chains. Such kind of gel formation is a relatively rare variant of the cryotropic gelation case, since the ion-exchange reactions are fast processes and, thus, it is technically difficult to freeze the precursor solution prior to its gelation. Therefore, some special methods must be implemented to overcome the mentioned impediments, that is, to shift the onset of gelation beyond the freezing of the reaction solution. For instance, an ionic crosslinker can be introduced in the feed solution in the form of a solid powdered salt having a negative temperature coefficient of solubility, i.e., its solubility rises with lowering of the temperature. In this way, the feed can first be frost-bound, and ionotropic gelling will then occur within the moderately frozen bulk system [33, 34].

The above classification of the precursor systems is also convenient for an overview of the “cryogel story,” since different types of polymeric cryogels at the early stages of their history have been discovered virtually independently. This situation continued at least until the beginning of 1980s, when general approaches for the preparation of covalently crosslinked cryogels based on both monomeric and polymeric precursors were elaborated and patented [35]. The listed variants are considered here in the same sequence.

However, one important remark should be made first regarding the definitions of “positive” and “negative” temperatures. In the subsequent discussion, the freezing/melting point of the feed system is taken as “zero” in the temperature scale; therefore, the processes under the thermal conditions above this point occur at positive temperatures, while gel formation below this point occurs at negative temperatures. Further, in this context, we also use the terms “non-deeply frozen” or “moderately frozen” to designate frozen systems that are not completely solid at the corresponding negative temperature, and in which some fraction of unfrozen liquid microphase still exists. As a rule, such temperatures lie not lower than several tens of centigrade under the freezing/melting point of the corresponding feed solution [1, 2].

2.1 Polymeric/Biopolymeric Cryogels Formed by Freeze–Thaw Aging of Colloid Sols

Perhaps the earliest example of a technologically realized process in which freeze–thaw-induced gel formation was employed is the manufacture of the food product named “kori-tofu,” which has been known for centuries and is still very popular in Japan [36]. The starting material for the fabrication of this soybean-protein foodstuff is the soya curd “tofu,” a colloid-type dispersion of the salting-out coagulate of 11S globulins. Tofu is subjected to freezing, during which the SH groups of cysteine residues of the neighboring macromolecules are coupled into intermolecular disulfide bridges, thus resulting in the formation of a 3D supramolecular network of protein particles [37–40]. Another example of cryotropic gel formation of colloidal dispersions is the freeze–thaw-caused structuration of minced meat and pastes of myofibrillar protein isolates, e.g., those extracted from various kinds of fish, shrimp or Antarctic krill [41–48]. Since the major myofibrillar proteins, actin and myosin, are rich in cysteine, chemical crosslinking of proteinaceous colloid particles in non-deeply frozen systems is accompanied by the formation of interparticle covalent SS-bonds with the participation of air oxygen dissolved in the unfrozen liquid microphase. This gelation mechanism was elucidated using studies on the cryogel formation of model thiol-bearing polymers [49–52].

Cryotropic crosslinking of discrete particles of colloidal dispersions in the presence of a crosslinking agent to produce 3D macroporous polymeric materials has also been reported. The preparation of cryostructured collagen sponges [53–55] or the process of fabrication of leather-like materials from milled tanned leather wastes [56–58] are examples of such type of cryogel formation. In these cases, the respective dispersion was mixed with a crosslinking agent (e.g., glutaraldehyde) and then this heterophase reaction mass was frozen and kept in the frozen state for a necessary period of time and finally defrosted, resulting in spongy matter built of a supramolecular framework of chemically bound polymer particles. The same approach was also employed in subsequent years for the creation of macroporous materials based on covalently linked particulate matters like latexes [59, 60], microbial cells [27, 61], or small gel particles [27, 62, 63].

As well as covalent freeze–thaw gels derived from colloid dispersions, noncovalent cryogels with aligned macroporous morphology have also been prepared from particulate precursors. These include protein-containing systems [64–69], cryogels fabricated from the colloid solutions of gelatinized starch [5, 70–78], and cryostructured polymer matrices formed as a result of the freeze–thaw treatment of frost-sensitive latexes [79–84]. The nature of the interparticle links in the first case is a combination of hydrogen bonding, ionic interactions, and hydrophobic interactions. Multiple H-bonds are responsible for gelation of the starch-based systems, while the hydrophobic associations are the basis of particles “glueing” in the latex examples. The macroporous morphology of the resulting polymer materials and their physicochemical properties are determined by the initial concentration of the dispersed particles; their size, shape, and chemical structure; and by the conditions of the freeze–thaw process. All these parameters must be taken into account in order either to prepare certain cryogels/cryostructurates or to prevent their formation when it is undesirable, as in the case of staving off the cryocoagulation phenomena in latex dispersions at negative temperatures [85].

2.2 Cryogels Prepared from Monomeric Precursors

The following three points are of principle significance for the preparation of cryogels from solutions of monomeric precursors:

-

1.

The chosen solvent must crystallize rather than vitrify under the cryostructuring conditions; otherwise, if the solvent undergoes a glass transition, the unfrozen liquid microphase will not form and, hence, no cryo-concentrating effects will take place. This requirement is also valid for any other precursor system to be gelled cryogenically.

-

2.

The solubility of the monomers should be high enough not only at positive temperatures, but also in the unfrozen liquid microphase. If the solubility of the monomer decreases drastically with decreasing temperature, the monomer concentration in the reaction medium becomes insufficient for the formation of a spatial network; that is, the critical concentration of gelation will not be reached. Various cryogels have been synthesized by using low molecular weight monomeric precursors, as in the majority of the reported cases, or macromonomers (macromers) such as the methacrylated derivatives of gelatine and chondroitin sulfate [86, 87], or poly(vinyl alcohol) [88, 89]. In the latter cases, the properties of the resulting gel matrices depend, along with common factors such as the monomer concentration or the freezing conditions, on the molecular weight of the macromonomer and on the amount of unsaturated groups in its molecule.

-

3.

The crucial problem in the case of cryotropic gelation via free radical polymerization is the performance of the initiator system at negative temperatures. Chemical initiators such as peroxides that generate primary radicals owing to thermal decomposition are not suitable for cryopolymerization. Therefore, redox initiating systems capable of generating radicals at reduced temperatures are commonly employed [1, 26, 35, 90, 91]. Nonetheless, some rare cases are also known, where the “high-temperature” radical cryopolymerization of vinyl monomers has been carried out using thermally decomposed initiators. One such example is the 2,2′-azoisobutyronitrile-initiated copolymerization of styrene and divinylbenzene at 50 °C in the medium of crystallized naphthalene having a crystallization temperature of about 80 °C [35, 91, 92]. In the case of radiation-induced cryopolymerization, the above-discussed problem of the temperature-dependent activity of chemical initiators is virtually absent. The efficiency of radiation-induced processes is mainly a function of the applied radiation dose but not of the temperature, as demonstrated in the pioneering studies conducted in Japan (see, e.g., [19, 93–100]). Yet another possibility for the preparation of cryogels of the polymerization type is the use of electron beams [101] or photoinitiation [102–104]. An essential point in this case is that the penetration capability of both these kinds of radiation is not very high, which limits the thickness of the samples. Therefore, the simplest approach, applicable in most laboratories, for the synthesis of polymerization-type cryogels is the use of a suitable chemical initiator system, where no specific radiation source is required and the amount of the added initiating substances can easily be controlled.

In the context of historical aspects of the development of polymerization-type cryogels, Table 1 summarizes the reaction components, e.g., the monomers, crosslinkers, initiator systems, solvents, and the temperature for cryogelation reactions starting from monomeric precursors. The data were taken from the pioneering reports on such gelation systems as well as from the most significant studies revealing the basic mechanisms of the key processes or ascertaining specific properties of the corresponding cryogels. Naturally, this selection is subjective, from the viewpoint of the author, and some works of good quality might have been missed.

Cryogels synthesized via polycondensation reactions are also known. These are mainly inorganic cryogels prepared by the sol–gel transformation in non-deeply frozen precursor systems, where the condensation of certain hydroxides accompanied by water liberation leads to the formation of polyoxides, as detailed in [173]. Polycondensation-type organic cryogels have also been reported in a few publications. Obviously, the first examples of such cryogels are those synthesized in frozen aqueous medium at −15 °C from the mixture of lysine (a trifunctional amino acid bearing two NH2 groups and one COOH group) with water-soluble carbodiimide or from the mixture of lysyl-lysine (a dipeptide having three NH2 groups) with glutaraldehyde [35]. In any case, the basic principle is that one of the precursors must be at least trifunctional or higher in order to ensure the branched 3D character of the forming polymer and its crosslinking. One recent example realizing this principle is the polycondensation-type cryogel prepared via the reaction of three-arm amino-terminated oligo(ethylene glycol) star polymers with dithio-bis(maleimido)ethane in the medium of non-deeply frozen dioxane at −8 °C [174]. Here, a 3D polymeric network forms as a result of the Michael addition of the primary amino groups to the double bonds of maleimide residues.

2.3 Preparation of Cryogels by Covalent Crosslinking of High Molecular Weight Precursors

As for the systems discussed in Sect. 2.2, the requirement of a good solubility of the high molecular weight precursors in the medium of the unfrozen liquid microphase is also important. If a decrease in the temperature and resulting freezing of the initial solution causes a loss of solubility and therefore precipitation/coagulation of the polymer, no crosslinked product can be obtained after thawing of the system, especially when the concentration of the crosslinking agent is relatively low. In addition, a rather important parameter is the molecular weight of the polymeric precursor, which determines both the initial viscosity of the feed solution prior to freezing and the viscosity in the reaction zone, i.e., within the volume of the unfrozen liquid microphase. Due to the generally high molecular weight of the polymeric precursors, very high viscosity of the reaction zone significantly reduces the segmental and translational mobilities of the polymer chains, thus preventing the occurrence of gelation reactions. Therefore, some preliminary experiments are often required to select the optimum molecular-weight characteristics of the corresponding polymeric precursor [1, 175, 176].

Cryogels prepared by chemical crosslinking of proteins were the first cases that exploited a scheme for producing immobilized biocatalysts. These were microbial or plant cells entrapped in a spongy carrier composed of serum albumin or gelatine cured with glutaraldehyde or formaldehyde, respectively [177–181]. In these early works, the factors influencing the gelation process and the properties of the final cryogels were not studied. Specific features inherent in this kind of cryotropic gelation and its mechanisms were basically established later using polymers chemically simpler than proteins, namely homopolymers or plain AB-copolymers, where the process of interest is not sophisticated by the numerous secondary interactions. Such a “modeling” approach found a series of significant effects that turned out to be characteristic for the formation of various cryogels. For instance, it was shown that cryogels in both aqueous [50, 182] and organic [4] media can be prepared at considerably lower initial concentration of precursors as compared to their gelation at positive temperatures. Thus, the effect of an apparent decrease in the critical concentration of gelation is inherent in the gel formation processes occurring in the non-deeply frozen reaction systems [1, 91]. The reason for such an effect is the cryo-concentrating phenomenon, which makes the concentration of the gelling agents considerably higher than that in the initial liquid feed. The same phenomenon generally causes the acceleration of cryochemical reactions in moderately frozen solutions over a certain range of negative temperatures [2, 183, 184] and is also observed during cryotropic gelation through covalent crosslinking of macromolecular precursors with suitable crosslinking agents, (see, e.g., [1, 91]). For instance, the oxidation of SH groups in thiol-containing poly(acrylamide) induced by water-dissolved air oxygen and leading to the formation of disulfide-crosslinked 3D polymeric network was at least five times faster in a frozen system at −15 °C than in a solution at +15 °C. Moreover, the gel-point was reached about 1 h after freezing of the feed solution in the former case, whereas in the latter case the time was about 1 day [52].

Examples of the majority of the reported covalent cryogels prepared from macromolecular precursors are given in Table 2. These data show that such cryogels based on natural and synthetic polymers can be synthesized by chemical crosslinking or by irradiation techniques in frozen aqueous, organic, or mixed water–organic media. Thus, the chemical structure, physico-chemical properties, and porous morphology of cryogels discussed in this section can be varied over a very wide range, so that their potential applications are many. Judging from the published information, biomedical and biotechnological applications are the primary uses for the cryogels prepared from polymeric precursors. In addition, some other promising implementation fields also exist for such cryogels, including the employment of rubber-based “cryosponges” developed in Turkey as a reusable sorbent for the removal of oil spill from water surfaces [211, 212, 214, 223], crosslinked chitosan cryogels for the absorption of radionuclides from waste water [224, 225], crosslinked and partially saponificated poly(vinyl alcohol) cryogel composites containing activated carbon particles for the absorption of dyes [29, 199, 200], and so forth.

2.4 Physical (Noncovalent) Polymeric Cryogels

The publications on this group of cryogels are the most numerous and include several well-known and very informative reviews. The majority of these studies are related to poly(vinyl alcohol) (PVA) cryogels, which have been known since the 1970s [226–231]. The formation mechanisms of PVA cryogels [1, 29, 232–237] and their applications in various fields have been investigated extensively. These gel materials are used in medicine [1, 232, 235, 238–251], in biochemistry and biotechnology [1, 234, 252–262], in environmental protection [1, 263], in construction in the permafrost regions [1, 264, 265], etc. Such popularity of PVA cryogels is due to the combination of a set of remarkable features they possess, such as excellent physico-mechanical properties, a high thermal endurance compared with other physical hydrogels, a high resistance to abrasive erosion, a macroporosity that ensures good diffusion characteristics, the availability and relatively low cost of PVA itself, and a comparatively simple procedure for the preparation of such cryogels. In addition, PVA cryogels have a high biocompatibility and are nontoxic for biological objects.

Noncovalent cryogels based on other “self-gelling” synthetic and natural macromolecules have also been described for more than 40 years. In 1971, it was demonstrated that freezing of a 17 % solution of poly(acrylonitrile) in dimethylformamide/water (95–97:5–3, v/v) mixtures at −78 °C leads to the formation of physical gels that are stable at room temperature [266]. Later, the freeze–thaw-induced formation of noncovalent cryogels was also reported for other polymeric systems. For instance, freezing of an aqueous solution of syndiotactic poly(methacrylic acid) and poly(ethylene oxide) mixture at −78 °C, followed by its defrosting at room temperature, results in noncovalent cryogels [267]. Similarly, freezing of semidilute aqueous solutions of agar-agar or A-type gelatine at −10 °C for 24 h followed by thawing at 25 °C leads to the formation of biopolymer cryogels [30]. The cryogels thus obtained possess macroporous morphology, whose characteristics mainly depend on the type of polymeric precursor and its initial concentration in the feed. The cryogels formed from gelatinized starch [5, 70–78] (mentioned in Sect. 2.1) as well as those based on starch-polysaccharides [268, 269] are also noncovalent cryogels that are stable at room temperature, but can be fused upon heating to 70–90 °C.

There is also a special case of the formation of physical cryogels where the self-gelation processes occur at a high rate even at positive temperatures. The aqueous solutions of >1 wt% agarose or >5–10 wt% gelatine belong to this category of gel-forming systems. When such solutions are being frozen at a moderate negative temperature, the ice is formed inside the already formed polymeric gel rather than in the liquid feed solution. As a consequence, the cryo-concentrating processes will not be realized to a significant extent, and the growing solvent polycrystals can even destroy the primary gel structure. The preparation of cryogels based on such quickly self-gelling precursors requires that freezing of the initial polymer solution should occur before the onset of the gelation. Principally, there are two possible ways to achieve this goal (1) freezing the initial hot solution very rapidly, e.g., in a liquid nitrogen bath, or (2) decreasing the self-gelation rate of the precursors by using specific additives capable of partially inhibiting the sol-to-gel transition. These two options were examined in detail in gelation systems containing agarose as a polymeric precursor [270, 271]. It was shown that the first option results in rather brittle gel materials with micrometer-sized pores. For the second approach, that is, to reduce the self-gelation rate of the precursor system, some solutes capable of partially interfering with H-bond formation between agarose chains were introduced into the initial feed solutions. This resulted in agarose cryogels with porosity and operational properties suitable for various applications, e.g., as wide-pore scaffolds for culturing of animal or human cells, including stem cells [271–277], and as supermacroporous continuous chromatographic beds for manipulation of particulate sorbates like viruses, cell organelles, and whole cells [272, 278]. It was found that the most convenient method of decelerating self-gelation in agarose solutions is to shift the pH so that some of the agarose hydroxyl groups are ionized, thus creating charges of the same sign along the chains, which causes certain repulsion between the chains [271].

Examples of various physical cryogels are summarized in Table 3, where the data are categorized according to the nature of the polymeric precursors, namely, polysaccharides, proteins, and synthetic polymers. The data for PVA cryogels are given separately due to the large number of papers published on these cryogels.

The history of PVA cryogels is also interesting because such gel systems have been discovered twice, as it were. First, there were mainly empiric recordings on the formation of these cryogels [230, 231] and the first patents were issued on the “virtual” applied possibilities of such materials [226–229]. Almost 10 years later, two approaches for increasing the strength of PVA cryogels were reported, namely, multiple freeze–thaw processing [299, 365–370] and the partial dehydration of frozen specimens in vacuo [9, 300, 301, 371]. These findings initiated numerous fundamental studies due to the amazing combination of cryogel properties and their macroporous structure. The investigations of frozen PVA solutions by nuclear magnetic resonance (NMR) and electron spin resonance (ESR) allowed better understanding of the fine details of the gelation processes inside frost-bound heterophase PVA–solvent systems [308, 332–337]. Features of the microstructure of PVA cryogels were ascertained using various microscopy techniques [330, 331, 333, 338–346] and other physicochemical analysis methods [237, 326, 347–351].

In these studies, the following five principal facts were established:

-

1.

The nodes in the 3D supramolecular network of PVA cryogels have a noncovalent nature. Therefore, such cryogels can be fused upon heating above the gel melting temperature with the formation of a polymer solution without any change in the characteristics of PVA molecular weight compared to that before freezing [30, 302–304]. This feature is observed provided that the used polymer is pure, i.e., it contains no reactive admixtures, frequently present in industrial PVA specimens.

-

2.

Intermolecular H-bonding via the interactions of OH groups of the neighboring PVA chains plays a key role in the formation of PVA cryogels [305–309].

-

3.

The junction knots in these cryogels were experimentally proven to be PVA microcrystallites [312–317]. A series of works conducted by a team of Italian researchers on this topic [318–325] is very impressive; the same can be said about the precision study by a Japanese team who found that each junction knot in PVA cryogels includes, depending on the gel formation conditions, about 2–3 chains with around 24–120 segments [314].

-

4.

The defrosting rate of frozen PVA solutions plays a significant role in the formation and properties of PVA cryogels [234, 311, 326–331].

-

5.

The molecular weight of PVA, chain tacticity, amount of residual O-acyl groups, and PVA concentration, as well as the conditions of freezing, frozen storage, and thawing have a significant effect on the properties and macroporosity of PVA cryogels [1, 9, 10, 23, 29, 30, 232–236, 254, 258, 299–301, 310–316, 326–331, 333, 338, 346, 352–364, 366–372].

Because the number of publications dealing with the relationships between the preparation conditions of PVA cryogels and their properties is large, Table 3 summarizes only the most important of them, from the viewpoint of the author of this review. Apart from PVA cryogels formed from simple two-component feeds (e.g., from systems composed of PVA dissolved in a neat solvent), a large amount of data is also available in the literature on PVA cryogels that contain soluble foreign additives, both of low and high molecular weights. In the former case, the corresponding cryogels can be classified as those prepared from PVA dissolved in a mixed solvent, whereas in the latter case a more suitable term is “complex PVA cryogels.” It should also be noted that there are also extensive studies on “composite PVA cryogels” that contain various discrete fillers. Different soluble and insoluble additives have been introduced in the initial PVA solutions to obtain complex and filled PVA cryogels, respectively. It was shown that the type of additives can affect, more or less, the properties and the microstructure of the resulting cryogels. Since the character of such an influence is very diverse and the observed effects can be multidirectional, such examples are not cited in Table 3. However, readers interested in the principal studies in these fields can find the corresponding references in the following reviews and recent experimental articles: PVA formed in mixed solvents [1, 20, 23, 234, 264, 373], complex PVA cryogels [1, 234, 239, 374], and composite PVA cryogels [1, 20, 23, 29, 234, 236, 237, 252, 254, 265, 375–377].

2.5 Ionic (Ionotropic) Cryogels

As pointed out above, the accomplishment of gel formation through crosslinking of polyelectrolyte chains with suitable counterions within the space of the unfrozen liquid microphase is a difficult task because of the high rate of the ionic processes. As a rule, conventional ionotropic gelation occurs before freezing of the gelling system. This is the reason why there is only a limited number of successful examples of preparation of ionically crosslinked cryogels by this “direct” route (e.g., [33, 34]). However, the cryogenically structured macroporous gel-like matrices can be fabricated by using roundabout pathways.

One way is the freezing of the partially (incompletely) formed gel, followed by its frozen storage in order to complete the ionic crosslinking, and then sublimation of the frozen solvent crystals. Such a sequence of operations results in macroporous dry cryostructurates that are transformed upon swelling in macroporous gels. This approach was used, for instance, for the preparation of Ca-alginate-based wound/burn dressings [34], or wide-pore scaffolds for tissue engineering [378–380].

Another method includes freezing the polyelectrolyte solution, followed by the removal of frozen solvent crystals without their thawing. The latter can be done either via freeze-drying, or via cryoextraction, i.e., by rinsing the frozen sample at a negative temperature with a liquid that acts as a solvent for the crystalline phase but a nonsolvent for the polyelectrolyte. The resulting macroporous cryostructurate is then treated with an agent capable of either ionically crosslinking the polymeric chains, or recharging their ionogenic groups. This stage is also carried out in a nonsolvent for the macromolecular material. A macroporous gel is obtained upon subsequent swelling of the resulting material in the respective solvating liquids. This approach was employed for the fabrication of wide-pore cryostructured matrices based on both polyacids and polybases [1]. For example, in order to prepare Ca-alginate sponges, the initial aqueous sodium alginate solution was frozen, and ice polycrystals were then removed via vacuum sublimation or via cryoextraction with cold ethanol. The resultant cryogenically structured polymer was then immersed in an ethanolic solution of calcium salt for ionic crosslinking leading to water-insoluble sponge-like Ca-alginate cryogel [381]. Such sponges possessing a system of interconnected gross pores of capillary size are of interest as cell culture scaffolds in biotechnological systems [382–384]. The preparation of cryostuctured polyelectolytes through recharging of their ionic groups can be exemplified by chitosan-based sponges. Here, after removal of ice crystals from the frozen chitosan–aqueous acetic acid system, the resulting cryostructurate was treated with alkaline acetone, thus causing formation of water-insoluble unprotonated chitosan base [385]. Wide-pore sponges of this material were also used as scaffolds for the 3D culturing of animal cells [386].

Thus, there are wide opportunities for the creation of diverse polyelectrolyte-based cryostructured gel-like matrices, whose properties and porous morphology can be varied in desired directions by an appropriate choice of the polymeric precursor and the respective counterions, their concentrations, by the freezing conditions, and by the procedure for the removal of frozen solvent.

3 Concluding Remarks

Fundamental studies and applied research on cryotropic gelation and various polymeric cryogels have been in progress for more than 40 years. As a result, numerous interesting observations have been made, mechanisms of the processes contributing to the formation of cryogels have been established, a series of cryogels possessing remarkable properties have been developed, and diverse practical applications have been realized (see reviews [1, 18–29, 184, 232–265, 387–404]).

It is evident that this part of polymer science did not start from a “clean slate.” First of all, there were different empiric observations on the freeze–thaw-caused gelation in systems like the above mentioned kori-tofu case. Second, it is necessary to emphasize the key role of the knowledge accumulated on the specific features of various chemical reactions in non-deeply frozen multicomponent solutions. In this respect, the pioneering studies that revealed the occurrence per se of such reactions in the moderately frozen systems were of great significance (see, e.g., [405–408]). These studies identified the existence of an unfrozen liquid microphase, and gave quantitative descriptions of the kinetic peculiarities of the relevant cryochemical reactions [2, 409–412]. Third, another important basis for the development of research on cryotropic gel formation was information on routes for the preparation of conventional covalent and noncovalent gels, their properties, and the factors that influence them. Moreover, a series of studies on frozen polymer–solvent systems should also be noted (e.g., [413–417]). The results of these studies allow a deeper understanding of the important fact that, in moderately frozen macromolecular solutions and even in frozen gels, the chain segments do not lose a certain degree of mobility and, hence, interaction of such segments can cause further transformations within the system up to the formation of a spatial polymeric network. Therefore, all the listed sources can be considered as the roots that supplied the “tree of polymeric cryogels” with the necessary primary “nutrients” available at the time when intense studies on cryotropic gel formation began. The subsequent growth and branching of this tree produced fine fruits, these being both new fundamental knowledge and the development of such wonderful gel materials as polymeric cryogels with their multitudinous practical applications, which are discussed in some of the subsequent chapters of this volume.

References

Lozinsky VI (2002) Russ Chem Rev 71:489

Sergeev GB, Batyuk VA (1976) Russ Chem Rev 45:391

Thomson Reuters (2013) Web of science http://apps.webofknowledge.com/summary.do?SID=S2oiGehEbAGc9ng8Jb1&product=WOS&qid=1&search_mode=GeneralSearch

Lozinsky VI, Vainerman ES, Korotaeva GF, Rogozhin SV (1984) Colloid Polym Sci 262:617

Schulze WE, Yu DT, MacMasters MM (1964) Stärke 16:41

Vol’khin VV, Ponomarev EI, Zolotavin VL (1973) Kolloidn zhurn 35:144 (in Russian)

Tolstoguzov VB, Braudo EE (1983) J Texture Stud 14:183

Lawrence R, Consolacion F, Jelen P (1986) Food Technol 40:77

Watase M, Nishinari K, Nambu M (1983) Polym Commun 24:52

Nagura N, Nagura M, Ishikawa H (1984) Polym Commun 25:313

Cryogel (2007) Ice ball thermal storage. http://www.cryogel.com

Katsume C, Abe Y, Horiuchi T, Matsubara S, Ueno M, Matsugane T, Blasutig E, Smith JW, Malchesky PS, Nose Y (1983) Trans Am Soc Artif Inter Organs 29:463

Miyamoto K, Tokita K, Miyashita K, Sakashita E (2001) Int J Biol Macromol 28:183

Tamon H, Ishizaka H, Yamamoto T, Suzuki T (1999) Carbon 37:2049

Tamon H, Ishizaka H, Yamamoto T, Suzuki T (2001) Dry Technol 19:313

Job N, Thery A, Pirard R, Marien J, Kocon L, Rouzaud JN, Beguin F, Pirard JP (2005) Carbon 43:2481

Zhang H, Cooper AI (2007) Adv Mater 19:1529

Gutiérrez MC, Ferrer ML, del Monte F (2008) Chem Mater 20:634

Kaetsu I (1993) Adv Polym Sci 105:81

Lozinsky VI, Plieva FM, Galaev IY, Mattiasson B (2001) Bioseparation 10:163

Lozinsky VI, Galaev IY, Plieva FM, Savina IN, Jungvid H, Mattiasson B (2003) Trends Biotechnol 21:445

Dainiak MB, Galaev IY, Kumar A, Plieva FM, Mattiasson B (2007) Adv Biochem Eng Biotechnol 106:101

Lozinsky VI (2008) Russ Chem Bull 57:1015

Plieva FM, Galaev IY, Noppe W, Mattiasson B (2008) Trends Microbiol 16:543

Kumar A, Mishra R, Reinwald Y, Bhat S (2010) Mater Today 13:42

Plieva FM, Galaev IY, Mattiasson B (2010) Production and properties of cryogels by radical polymerization. In: Mattiasson B, Kumar A, Galaev I (eds) Macroporous polymers: production, properties and biological/biomedical applications. CRC, Boca Raton, p 23

Kirsebom H, Mattiasson B (2011) Polym Chem 2:1059

Plieva FM, Kirsebom H, Mattiasson B (2011) J Sep Sci 34:2164

Gun’ko VM, Savina IN, Mikhalovsky SV (2013) Adv Colloid Interface Sci 186–187:1

Rogozhin SV, Lozinsky VI, Vainerman ES, Domotenko LV, Mamtsis AM, Ivanova SA, Shtil'man MI, Korshak VV (1984) Doklady Akademii nauk SSSR 278:129–133 (in Russian)

Lozinsky VI, Konstantinova NR, Solov’eva NI (1994) Russian Patent 2,058,083

Konstantinova NR, Lozinsky VI (1997) Food Hydrocolloids 11:113

Vainerman ES, Lozinsky VI, Rogozhin SV, Raskina LP, Shapiro LA, Yakubovich VS, Bronshtein VY (1983) SU Patent 1,171,474

Vainerman ES, Lozinsky VI, Rogozhin SV, Raskina LP, Shapiro LA, Yakubovich VS, Shenker MB, Komissarova AL, Potapov VD, Gudochkova VM, Atyasova NM, Ivanova GA (1983) SU Patent 1,171,476

Lozinsky VI, Vainerman ES, Rogozhin SV (1982) SU Patent 1,008,214

Fukushima D (1981) J Am Oil Chem Soc 58:346

Watanabe T, Nakayama O, Iwasaki N (1963) Nippon Shokuhin Kogyo Gakkaishi 10:163 (in Japanese)

Hashizume K, Kakiuchi K, Koyama K, Watanabe T (1971) Agric Biol Chem 35:449

Watanabe T (1974) J Am Oil Chem Soc 51:111A

Shimoyama M, Tomadsu K, Oku S, Watanabe K (2000) J Agric Food Chem 48:2775

Buttkus H (1971) Can J Biochem 49:97

Buttkus H (1974) J Food Sci 39:484

Rogožin SV, Slonimskij GL, Rogovina LZ, Vajerman ES, Pivovarov PP (1981) Die Nahrung 25:391

Rogozhin SV, Belavtseva EM, Vainerman ES, Radchenko LG, Pivovarov PP, Golvina TO, Pertsevoy FV (1984) Die Nahrung 28:165

Jiang ST, Hwang BS, Tsao CY (1987) J Agric Food Chem 35:22

Jiang ST, Hwang BS, Tsao CY (1987) J Food Sci 52:117

Bhattacharya M, Hanna MA, Mandigo RW (1988) J Food Sci 53:696

Stoyachenko IA, Vainerman ES, Rogozhin SV (1988) Appl Biochem Microbiol 24:712

Vainerman ES, Lozinsky VI, Rogozhin SV (1981) Colloid Polym Sci 259:1198–1201

Rogozhin SV, Vainerman ES, Lozinsky VI (1982) Doklady Akademii nauk SSSR 263:115 (in Russian)

Lozinsky VI, Golovina TO, Vainerman ES, Rogozhin SV (1989) Polym Sci USSR 31A:367

Lozinsky VI, Golovina TO, Gusev DG (2000) Polymer 41:35

Rogozhin SV, Vainerman ES, Pichugin NM, Kirilenko YK, Lozinsky VI, Kosolapov AM, Gnezdilova TV, Chumakov SD, Aboyants RK, Istranov LP (1988) SU Patent 1,603,723

Lozinsky VI, Gnezdilova TV (1992) Russian Patent 2,053,796

Podorozhko EA, Kulakova EA, Kurskaya EA, Lozinsky VI (1995) Russian Patent 2,116,801

Rogozhin SV, Pichugin NM, Vainerman ES, Gnezdilova TV, Kirilenko YK, Chumakov SD, Lozinsky VI (1988) SU Patent 1,653,318

Mikhalev OI, Petrov AN, Genzdilova TV, Lozinsky VI, Alfimov MV (1992) Russian Patent 2,008,362

Kalinina EV, Semenova NN, Rogozhin SV, Lozinsky VI (1995) Russian Patent 2,116,350

Vainerman ES, Portnaya IB (1992) Russian Patent 2,108,350

Vainerman ES, Portnaya IB (1996) US Patent 5,494,939

Kirsebom H, Mattiasson B, Galaev IY (2009) Langmuir 25:8462

Kirsebom H, Mattiasson B, Galaev IY (2010) Macromol Rapid Commun 31:1095

Hajizadeh S, Xu C, Kirsebom H, Ye L, Mattiasson B (2013) J Chromatogr 1274A:6

Connell JJ (1959) Nature 183:664

Connell JJ, Howgate PF (1964) J Food Sci 29:717

Arai S, Watanabe M (1986) Agric Biol Chem 50:169

Podorozhko EA, Portnaya IB, Kulakova VK, Kurskaya EA (1995) Russian Patent 2,115,668

Podorozhko EA, Andreeva LM, Kurskaya EA, Lozinsky VI (1997) Russian Patent 2,118,495

Podorozhko EA, Kurskaya EA, Kulakova VK, Lozinsky VI (2000) Food Hydrocolloids 14:111

Schierbaum F, Richter M (1964) Die Nahrung 8:487

Chan WS, Toledo TR (1976) J Food Sci 4:301

Von Eberstein K, Hopcke R, Konieczny-Janda G, Stute R (1980) Stärke 32:397

Ferrero C, Martino MN, Zaritzky NE (1993) Int J Food Sci Technol 17:191

Lozinsky VI, Damshkaln LG, Brown R, Norton IT (2000) J Appl Polym Sci 78:371

Guraya HS, James C, Champague ET (2001) Starch/Stärke 53:64

Chung HJ, Jeong HY, Lim ST (2003) Carbohydr Polym 54:449

Wasserman LA, Vasil’ev VG, Motyakin MV, Blaszchak W, Fornal J, Damshkaln LG, Lozinsky VI, Yuryev VP (2009) Starch/Stärke 61:377

Qian D, Chang PR, Ma X (2011) Carbohydr Polym 86:1181

Blažek L, Dvoržak E, Myšik S (1964) Koll Zhurn 26:657 (in Russian)

Myšik S, Blažek L, Dvoržak E (1965) Koll Zhurn 27:563 (in Russian)

Kiseleva OG, Tikhonova TS, Khryukina NM, Neiman RE (1975) Koll Zhurn 37:783 (in Russian)

Nakamura A, Osada R (1977) Colloid Polym Sci 255:362

Vainerman ES, Podorozhko EA, Portnaya IB (1992) Russian Patent 2,062,227

Collard CAL, Cave RA, Grossiord N, Covington JA, Bon SAF (2009) Adv Mater 21:2894

Neiman RE (1967) Coagulation of synthetic latexes. Voronezh State University, Voronezh, pp 148–159 (in Russian)

Van Vlierberghe S, Dubruel P, Lippens E, Masschaele B, Van Hoorebeke L, Cornelisson M, Unger R, Kirkpatrick CJ, Schacht E (2008) J Mater Sci Mater Med 19:1459

Van Vlierberghe S, Dubruel P, Schacht E (2010) J Bioact Compat Polym 25:498

Artyukov AA, Shtilman MI, Kuskov AN, Pashkova LI, Tsatsakis AM, Rizos AK (2011) J Non-Cryst Solids 357:700

Artyukov AA, Shtilman MI, Kuskov AN, Fomina AP, Lisovyy DE, Golunova AS, Tsatsakis AM (2011) J Polym Res 18:667

Lozinsky VI, Korneeva MN, Vainerman ES, Rogozhin SV (1983) Doklady Akademii nauk SSSR 270:101 (in Russian)

Lozinsky VI (1994) Doctoral Science Thesis. Institute of Organoelement Compounds, Russian Academy of Sciences, Moscow (in Russian)

Rogozhin SV, Lozinsky VI, Vainerman ES, Korshak VV (1983) Doklady Akademii nauk SSSR 273:1140 (in Russian)

Yoshida M, Kumakura M, Kaetsu I (1979) Polymer 20:3

Yoshida M, Kumakura M, Kaetsu I (1979) Polymer 20:9

Kumakura M, Kaetsu I (1983) Makromol Chem 184:1831

Kaetsu I, Kumakura M, Yoshida M (1979) Biotechnol Bioeng 21:847

Kumakura M, Kaetsu I (1983) J Polym Sci Polym Lett 21:609

Kumakura M, Kaetsu I (1984) Polymer J 16:113

Kumakura M, Kaetsu I (1984) Colloid Polym Sci 262:450

Kumakura M (2001) Polym Adv Technol 12:415

Reichelt S, Abe C, Hainich S, Knolle W, Decker U, Prager A, Konieczny R (2013) Soft Matter 9:2484

Petrov P, Petrova E, Tsvetanov CB (2009) Polymer 50:1118

Petrov P, Pavlova S, Tsvetanov CB, Topalova Y, Dimkov R (2011) J Appl Polym Sci 122:1742

Kostova B, Momekova D, Petrov P, Momekov G, Toncheva-Moncheva N, Tsvetanov CB, Lambov N (2011) Polymer 52:1217

Lozinsky VI, Vainerman ES, Titova EF, Belavtseva EM, Rogozhin SV (1984) Colloid Polym Sci 262:769

Belavtseva EM, Titova EF, Lozinsky VI, Vainerman ES, Rogozhin SV (1984) Colloid Polym Sci 262:775–779

Lozinsky VI, Vainerman ES, Ivanova SA, Titova EF, Shtil'man MI, Belavtseva EM, Rogozhin SV (1986) Acta Polym 37:142

Lozinsky VI, Morozova SA, Vainerman ES, Titova EF, Shtil'man MI, Belavtseva EM, Rogozhin SV (1989) Acta Polym 40:8

Plieva FM, Savina IN, Deraz S, Andersson J, Galaev IY, Mattiasson B (2004) J Chromatogr 807B:129

Persson P, Baybak O, Plieva F, Galaev I, Mattiasson B, Nilsson B, Axelsson A (2004) Biotechnol Bioeng 88:224

Plieva FM, Andersson J, Galaev IY, Mattiasson B (2004) J Sep Sci 27:828

Plieva FM, Karlsson M, Aguilar MR, Gomez D, Mikhalovsky, Galaev IY (2005) Soft Matter 1:303

Plieva F, Huiting X, Galaev I, Bergenstähl B, Mattiasson B (2006) J Mater Chem 16:4065

Dinu MV, Ozmen MM, Dragan E, Okay O (2007) Polymer 48:195

Gusev DG, Lozinsky VI, Bakhmutov VI (1993) Eur Polym J 29:49

Kirsebom H, Rata G, Topgaard D, Mattiasson B, Galaev IY (2009) Macromolecules 42:5208

Ozmen MM, Okay O (2008) React Funct Polym 68:1467

Ozmen MM, Dinu MV, Okay O (2008) Polym Bull 60:169

Shtil’man MI, Denisova LA, Ostaeva GY, Donetsky IA, Kondaryuk VV, Pchelintseva OA, Lozinsky VI, Vainerman ES, Rogozhin SV (1987) SU Patent 1,531,440

Mattiasson B, Galaev I, Lozinsky V, Plieva F (2003) WO 2003/041830

Arvidsson P, Plieva FM, Savina IN, Lozinsky VI, Fexby S, Bulow L, Galaev IY, Mattiasson B (2002) J Chromatogr 977A:27

Arvidsson P, Plieva FM, Lozinsky VI, Galaev IY, Mattiasson B (2003) J Chromatogr 986A:275

Yao K, Shen S, Yun J, Wang L, He X, Yu X (2006) Chem Eng Sci 61:6701

Demiryas N, Tüzmen N, Galaev IY, Pişkin E, Denizli A (2007) J Appl Polym Sci 105:1808

He X, Yao K, Shen S, Yun J (2007) Chem Eng Sci 62:1334

Topus F, Okay O (2009) React Funct Polym 69:273

Ceylan D, Ozmen MM, Okay O (2006) J Appl Polym Sci 99:319

Zhang XZ, Zhuo RX (1999) Macromol Rap Commun 20:229

Zhang XZ, Zhuo RX (1999) Macromol Chem Phys 200:2602

Srivastava A, Jain E, Kumar A (2007) Mater Sci Eng 464:93

Chalal M, Ehrburger-Dolle F, Morfin I, Vial JC, de Armas MRA, Roman JS, Bülgen N, Pişkin E, Ziane O, Caslegno R (2009) Macromolecules 42:2749

Liu H, Liu M, Bai L, Sun S, Liu Y, Yang G (2011) Talanta 85:1193

Zhang XZ, Chu CC (2003) Chem Commun 2003(12):1446

Zhang XZ, Chu CC (2003) J Mater Chem 13:2457

Zhao Q, Sun J, Zhou Q (2007) J Appl Polym Sci 104:4080

Zhao Q, Sun J, Ling Q, Zhou Q (2008) J Polym Sci Polym Chem 19:6594

Xue W, Hampley IW, Huglin MB (2002) Polymer 43:5181

Xue W, Champ S, Huglin MB, Jones TGJ (2004) Eur Polym J 40:468

Akkaya B, Akkaya R (2012) J Macromol Sci Pure Appl Chem 49:736

Vakifli A, Demirel G, Caykara T (2010) J Appl Polym Sci 117:817

Komarova GA, Starodubtsev SG, Lozinsky VI, Kalinina EV, Landfester K, Khokhlov AR (2008) Langmuir 24:4467

Komarova GA, Starodubtsev SG, Lozinsky VI, Nasimova IR, Khokhlov AR (2013) J Appl Polym Sci 127:2703

Burova TV, Grinberg NV, Kalinina EV, Ivanov RV, Lozinsky VI, Alvarez-Lorenzo C, Grinberg VY (2011) Macromol Chem Phys 212:72

Lozinsky VI, Kalinina EV, Grinberg VY, Grinberg NV, Chupov VA, Platé NA (1997) Polym Sci 39А:1300

Ozmen MM, Okay O (2005) Polymer 46:8119

Ozmen MM, Okay O (2006) J Macromol Sci Pure Appl Chem 43:1215

Kirsebom H, Rata G, Topgaard D, Mattiasson B, Galaev IY (2008) Polymer 49:3855

Kirsebom H, Rata G, Topgaard D, Mattiasson B, Galaev IY (2009) Macromolecules 42:2009

Lozinsky VI, Zaborina OE (2011) Russian Patent 2,467,017

Caykara T, Küçüktepe S, Turan E (2006) Macromol Mater Eng 291:1278

Chen Z, Xu L, Liang Y, Wang J, Zhao M, Li Y (2008) J Chromatogr 1182A:128

Pavlova LA, Kostel’yanos-Dominges OM (1996) Zhurn Prikl Khim 69:829 (in Russian)

Pavlova LA, Kostel’yanos-Dominges OM (1996) Zhurn Prikl Khim 69:1558 (in Russian)

Savina IN, Cnudde V, D’Hollander S, Van Hoorebeke L, Mattiasson B, Galaev IY, Du Prez F (2007) Soft Matter 3:1176

Andac M, Plieva FM, Denizli A, Galaev IY, Mattiasson B (2008) Macromol Chem Phys 209:577

Tekin K, Uzun L, Sahin CA, Bektas S, Denizli A (2011) React Funct Polym 71:985

Bereli N, Erturk G, Denizli A (2012) Sep Sci Technol 47:1813

Srivastava A, Shakya AK, Kumar A (2012) Enzyme Microb Technol 51:373

Srivastava A, Kumar A (2010) J Mater Sci Mater Med 21:2937

Tamada M, Kasai N, Kaetsu I (1988) Biotechnol Bioeng 32:386

Higa OZ, Kumakura M (1977) Biomaterials 18:697

Kumakura M, Kaetsu I (1984) React Polym 2:243

Kumakura M, Kaetsu I (1984) J Chem Technol Biotechnol 34B:39

Di Nino G, Turrachio M, D’Archivio AA, Lora S, Corain B, Antonini G (2004) React Funct Polym 61:411

Kumakura M, Kaetsu I (1984) J Mol Catal 23:1

Yoshi F, Kaetsu I (1983) Appl Biochem Biotechnol 8:115

Fujimura N, Kaetsu I (1987) Biotechnol Bioeng 29:171

Piskin K, Arca E, Piskin E (1984) Appl Biochem Biotechnol 10:73

Kahveci MU, Beyazkilic Z, Yaggi Y (2010) J Polym Sci Polym Chem 48:4989

Christova N, Petrov P, Kabainova L (2013) Z Naturforsch 68c:47

Petrov PD, Geoigiev GL (2012) Eur Polym J 48:1366

Okaji R, Taki K, Nagamine S, Ohshima M (2012) J Appl Polym Sci 125:2874

Shlyakhtin O (2014) Inorganic cryogels. In: Okay O (ed) Polymeric cryogels: macroporous gels with remarkable properties, vol 263, Advances in polymer science. Springer, Heidelberg

Dispinar T, Van Camp W, De Cock LJ, De Geest BG, Du Prez PE (2012) Macromol Biosci 12:383

Nikonorov VV, Ivanov RV, Kil’deeva NR, Lozinsky VI (2011) Polym Sci 53A:1150

Ivanov RV, Lozinsky VI, Noh SK, Lee YR, Han SS, Lyoo WS (2008) J Appl Polym Sci 107:382

Cocquemcot MF, Thomas D, Champigny ML, Moyse A (1979) Eur J Appl Microbiol Biotechnol 8:37

Dhulster P, Parascandola P, Scardi V (1983) Enzyme Microb Technol 5:65

Estival F, Burstein C (1985) Enzyme Microb Technol 7:29

Papageorgiou GC, Lagoyanni T (1986) Appl Microbiol Biotechnol 23:417

Carpenter R, Lemieux S (1987) Appl Biochem Biotechnol 15:107

Lozinsky VI, Vainerman ES, Rogozhin SV (1982) Colloid Polym Sci 260:776

Pincock RE (1969) Acc Chem Res 2:97

Hansler M, Jakubke HD (1996) J Pept Sci 2:279

Elowsson L, Kirsebom H, Carmignac V, Durbeej M, Mattiasson B (2012) J Mater Sci Mater Med 23:2489

Jain E, Srivastava A, Kumar A (2009) J Mater Sci Mater Med 20:S173

Dainiak MB, Allan IU, Savina IN, Cornelio L, James ES, James SL, Mikhalovsky SV, Jungvid H, Galaev IY (2010) Biomaterials 31:67

Jurga M, Dainiak MB, Sarnowska A, Jablonska A, Tripathi A, Plieva FM, Savina IN, Strojek L, Jungvid H, Kumar A, Lukomska B, Domanska-Janik K, Fooraz N, McGuckin CP (2011) Biomaterials 32:3423

Mu C, Liu F, Cheng Q, Li H, Wu B, Zhang G (2010) Macromol Chem Eng 295:100

Rodrigues SC, Salgado CL, Sahu A, Garcia MP, Fernandes MH, Monteiro FJ (2013) J Biomed Mater Res 101A:1080

Chien KB, Shah RN (2012) Acta Biomater 8:694

Ak F, Oztoprak Z, Karakutuk I, Okay O (2013) Biomacromolecules 14:719

Kirsebom H, Aguilar MR, San Roman J, Fernandez M, Prieto MA, Bondar B (2007) J Bioact Compat Polym 22:2007

Nikonorov VV, Ivanov RV, Kil’deeva NR, Bulatnikova LN, Lozinsky VI (2010) Polym Sci 52A:828

Hoffmann B, Seitz D, Mencke A, Kokott A, Ziegler G (2009) J Mater Sci Mater Med 20:1497

Berillo D, Elowsson L, Kirsebom H (2012) Macromol Biosci 12:1090

Chang C, Zhang L, Zhou J, Zhang L, Kennedy JF (2010) Carbohydr Polym 82:122

Plieva FM, Karlsson M, Aguilar MR, Gomez D, Mikhalovsky S, Galaev IY, Mattiasson B (2006) J Appl Polym Sci 100:1057

Ivanov AE, Kozynchenko OP, Mikhalovska LI, Tennison SR, Jungvid H, Gun’ko VM, Mikhalovsky SV (2012) Phys Chem Chem Phys 14:16267

Zheng Y, Gun’ko VM, Howell CA, Sandeman SR, Phillips GJ, Kozynchenko OP, Tennison SR, Ivanov AE, Mikhalovsky SV (2012) ACS Appl Mater Interface 4:5936

Ivanov RV, Lozinsky VI, Noh SK, Han SS, Lyoo WS (2007) J Appl Polym Sci 106:1470

Hedström M, Plieva F, Galaev I, Mattiasson B (2008) Anal Bioanal Chem 390:907

Kathuria N, Triparthi A, Kar KK, Kumar A (2009) Acta Biomater 5:406

Peter M, Ganesh N, Selvamurugan N, Nair SV, Furuike T, Tamura H, Jayakumar R (2010) Carbohydr Polym 80:687

Sun S, Tang Y, Fu Q, Liu X, Guo L, Zhao Y, Chang C (2012) Int J Biol Macromol 50:1002

Vishnoi T, Kumar A (2013) J Mater Sci Mater Med 24:447

Orakdogen N, Karacan P, Okay O (2011) React Funct Polym 71:782

Okay O (2011) J Polym Sci Polym Phys 49:551

Karacan P, Okay O (2013) React Funct Polym 73:442

Welzel PB, Grimmer M, Renneberg C, Naujox L, Zschoche S, Freudenberg U, Werner C (2012) Biomacromolecules 13:2349

Tuncaboylu DC, Okay O (2009) Eur Polym J 45:2033

Karakutuk I, Okay O (2010) React Funct Polym 70:585

Liu X, Hu Y, Zou J, Chai, Li B (2013) Appl Mech Mater 295–298:1368

Tuncaboylu DC, Okay O (2010) Langmuir 26:7574

Park KR, Nho YC (2003) J Appl Polym Sci 90:1477

Doycheva M, Petrova E, Stamenova R, Tsvetanov C, Reiss G (2004) Macromol Mater Eng 289:676

Petrov P, Petrova E, Stamenova R, Tsvetanov C, Reiss G (2006) Polymer 47:6481

Petrov P, Petrova E, Tchorbanov B, Tsvetanov CB, Reiss G (2007) Polymer 48:4943

Velickova E, Winkelbausen E, Kuzmanova S, Cvetkovska M, Tsvetanov C (2009) React Funct Polym 69:688

Velickova E, Petrov P, Tsvetanov C, Kuzmanova S, Cvetkovska M, Winkelhausen E (2010) React Funct Polym 70:908

Jovanovic-Malinovska R, Cvetkovska M, Kuzmanova S, Tsvetanov C, Winkelhausen E (2010) Macedon J Chem Chem Eng 29:169

Petrov P, Utrata-Wesolek A, Trzebicka B, Tsvetanov CB, Dworak A, Aniol J, Sieron A (2011) Eur Polym J 47:981

Ceylan D, Dogu S, Karacik B, Yakan SD, Okay OS, Okay O (2009) Environ Sci Technol 43:3846

Veleshko IE, Nikonorov VV, Veleshko AN, Rumyantseva EV, Mikhailov SN, Lozinsky VI, Ivanov RV, Gal’braikh LS, Kil’deeva NR (2011) Fibre Chem 42:364

Kil’deeva NR, Veleshko IE, Vladimirov LV, Nikonorov VV, Lozinsky VI, Ivanov RV, Perminov PA, Mikhailov SN (2012) Fibre Chem 43:426

Inoue T (1972) Japanese Patent 47-012854

Inoue T (1973) Japanese Patent 48-030462

Inoue T (1972) Japanese Patent 48-030463

Inoue T (1972) US Patent 3,875,302

Kukharchik MM, Baramboim NK (1972) Vysokomolekul soed 14B:843 (in Russian)

Peppas NA (1975) Makromol Chem 176:3433

Nambu M (1990) Kobunshi Ronbunshu 47:695 (in Japanese)

Peppas NA, Stauffer SR (1991) J Control Release 16:305

Lozinsky VI (1998) Russ Chem Rev 67:573

Hassan CM, Peppas NA (2000) Adv Polym Sci 153:37

Gutiérrez MC, Aranaz I, Ferrer ML, del Monto F (2010) Production and properties of poly(vinyl alcohol) cryogels: recent developments. In: Mattiasson B, Kumar A, Galaev I (eds) Macroporous polymers: production, properties and biological/biomedical applications. CRC, Boca Raton, p 83

Shapiro YE (2011) Progr Polym Sci 36:1184

Suzuki M, Hirasa O (1993) Adv Polym Sci 10:241

Lazzeri L (1996) Trends Polym Sci 4:249

Chu KC, Rutt BK (1997) Magn Reson Med 37:314

Langer R, Peppas NA (2003) AIChE J 49:2990

Surry KJM, Austin HJB, Fenster A, Peters TM (2004) Phys Med Biol 49:5529

Fromageau J, Genninsson JL, Schmitt C, Maurice RL, Mongrain R, Cloutier G (2007) IEEE Trans Ultrason Ferroelectr Freq Control 54:498

Hoskins PR (2008) Ultrasound Med Biol 34:693

Ghanbari H, Viatge H, Kidane AG, Buriesci G, Tavakoli M, Seifalian AM (2009) Trends Biotech 27:359

Wang BH, Campbell G (2009) Spine 34:2745

Alves MH, Jensen BEB, Smith AAA, Zelikin AN (2011) Macromol Biosci 11:1293

Gajra B, Pandya SS, Vidyasagar G, Rabari H, Dedania RR, Rao S (2012) Int J Pharm Res 4:20

Baker MI, Walsh SP, Schwartz Z, Boyan BD (2012) J Biomed Mater Res 100B:1451

Lamouche G, Kennedy BF, Kennedy KM, Bisaillon CE, Curatolo A, Campbell G, Pazos V, Sampson DD (2012) Biomed Optics Expr 3:1381

Iatridis JC, Nicoll SB, Michalek AJ, Walter BA, Gupta MS (2013) Spine J 13:243

Lozinsky VI, Vakula AV, Zubov AL (1992) Soviet Biotechnol #4:1

Varfolomeev SD, Rainina EI, Lozinsky VI (1992) Pure Appl Chem 64:1193

Lozinsky VI, Plieva FM (1998) Enzyme Microb Technol 23:227

Varfolomeev SD, Rainina EI, Lozinsky VI, Kalyuzhnyi SB, Sinitsyn AP, Makhlis TA, Bachurina GP, Bokova IG, Sklyankina OA, Agafonov EV (1990) In: de Bont JAM, Visser J, Mattiasson B, Tramper J. (eds) Physiology of immobilized cells: proceedings of an international symposium, Wageningen, The Netherlands, 10–13 Dec 1989. Elsevier, Amsterdam, p 325

Filippova IY, Bacheva AV, Baibak OV, Plieva FM, Lysogorskaya EN, Oksenoit ES, Lozinsky VI (2001) Russ Chem Bull 50:1896

Lozinsky VI, Galaev IY, Plieva FM, Savina IN, Jungvid H, Mattiasson B (2003) Trends Biotechnol 21:445

Lozinsky VI (2004) Chem Ind (Belgrade) 58:111

Sheldon RA (2007) Adv Synth Catal 349:1289

Kumar A, Srivastava A, Galaev IY, Mattiasson B (2007) Progr Polym Sci 32:1205

Plieva FM, Galaev IY, Noppe W, Mattiasson B (2008) Trends Microbiol 16:543

Stolarzewicz I, Bialecka-Florjańczyk E, Majewska E, Krzyczkowska J (2011) Chem Biochem Eng 25Q:135

Cunningham CJ, Ivshina IB, Lozinsky VI, Kuyukina MS, Philp JC (2004) Int Biodeterior Biodegr 54:167

Altunina LK, Kuvshinov VA, Dolgikh SN (2006) NATO Sci Ser IV Earth Environ Sci 65:103

Vasiliev NK, Ivanov AA, Sokurov VV, Shatalina IN, Vasilyev KN (2012) Cold Reg Sci Techn 70:94

Labudzińska A, Ziabicki A (1971) Koll Z u Z Polym 243:21

Kim HJ, Sakamoto M, Tanami H (1983) Kobunshi Ronbunshu 40:579 (in Japanese)

Lozinsky VI, Damshkaln LG, Brown CRT, Norton IT (2000) J Appl Polym Sci 75:1740

Lozinsky VI, Damshkaln LG, Brown CRT, Norton IT (2002) J Appl Polym Sci 83:1658

Lozinsky VI, Damshkaln LG, Plieva FM, Galaev IY, Mattiasson B (2001) Russian Patent 2,220,987

Lozinsky VI, Damshkaln LG, Bloch KO, Vardi P, Grinberg NV, Burova TV, Grinberg VY (2008) J Appl Polym Sci 108:3046

Plieva FM, Galaev IY, Mattiasson B (2010) Macroporous polysaccharide gels. In: Mattiasson B, Kumar A, Galaev I (eds) Macroporous polymers: production, properties and biological/biomedical applications. CRC, Boca Raton, p 131

Bloch K, Lozinsky VI, Galaev IY, Yavriyanz K, Vorobeychik M, Azarov D, Damshkaln LG, Mattiasson D, Vardi P (2005) J Biomed Mater Res 75A:802

Petrenko YA, Petrenko AY, Lozinsky VI, Gurin IV, Gorokhova NA, Volkova NA, Sandomirskii BP (2007) Transplantologiya (Kyev) 9:221 (in Russian)

Petrenko YA, Petrenko AY, Damshkaln LG, Volkova NA, Lozinsky VI (2008) Bull Exp Biol Med 146:129

Petrenko YA, Volkova NA, Zhulikova EP, Damshkaln LG, Lozinsky VI, Petrenko AY (2008) Biopolym Cell 24:399

Bloch K, Vanichkin A, Damshkaln LG, Lozinsky VI (2010) Acta Biomater 6:1200

Mattiasson B, Galaev I, Lozinsky V, Plieva F (2003) WO 2003/031014

Wu J, Zhang H (2010) In: Williams OA, Phillips GO (eds) Gums and stabilizers for the food industry, vol 15. Royal Society of Chemistry, Cambridge, p 420

Najii S, Razavi SMA, Karazhiyan H (2013) Food Bioprocess Techn 6:1302

Lazaridou A, Biliaderis CG (2004) Food Hydrocolloids 18:933

Vaikousi H, Biliarderis CG (2005) Food Chem 91:505

Lazaridou A, Vaikousi H, Biliaderis CG (2008) Food Hydrocolloids 22:263

Dea ICM, Morris ER, Rees DA, Welsh J, Barnes HA, Price J (1977) Carbohydr Res 57:249

Bringham JE, Gidley MJ, Hoffmann RA, Smith CG (1994) Food Hydrocolloids 8:331

Tanaka R, Hatakeyama T, Hatakeyama H (1998) Polym Int 45:118

Hatakeyama T, Naoi S, Iljima M, Hatakeyama H (2005) Macromol Symp 224:253

Lozinsky VI, Damshkaln IG, Brown R, Norton IT (2000) Polym Int 49:1434

Zeira A, Nussinovich A (2004) J Texture Stud 34:561

Doyle JP, Giannouli P, Martin EJ, Brooks M, Morris ER (2006) Carbohydr Polym 64:391

Himeda Y, Yanagi S, Kakema T, Fujita F, Umeda T, Miyoshi T (2003) J Int Med Res 31:509

Himeda Y, Umeda T, Miyata Y, Miyoshi T (2004) J Genecol Surg 20:39

Himeda Y, Kaneko H, Umeda T, Miyata Y, Miyoshi T (2005) J Genecol Surg 21:55

Giannouli P, Morris ER (2003) Food Hydrocolloids 17:495

Najii S, Razavi SMA, Karazhiyan H (2013) Food Bioprocess Technol 6:1302

Mu C, Li X, Zhao Y, Zhang H, Wang L, Li D (2013) J Appl Polym Sci 128:3141

Berillo D, Mattiasson B, Galaev IY, Kirsebom H (2012) J Colloid Interface Sci 368:226

Zuo Z, Guo Y, Li Y, Lv J, Liu H, Li Y (2009) Macromol Rap Commun 30:1940

Watase M, Nishinari K, Nambu M (1983) Cryo-Lett 4:197

Watase M, Nishinari K (1983) Polym Commun 24:270

Watase M, Nishinari K, Ogino K, Nambu M (1983) Polym Commun 24:345

Lozinsky VI, Domotenko LV, Vainerman ES, Mamtsis AM, Rogozhin SV (1986) Polym Bull 15:333

Liu M, Cheng R, Wu C, Qian R (1997) J Polym Sci Polym Phys 35:2421

Liu M, Cheng R, Wu C (1999) Eur Polym J 35:1907

Kobayashi M, Ando I, Ishii T, Amiya S (1995) Macromolecules 28:6677

Kobayashi M, Ando I, Ishii T, Amiya S (1998) J Mol Struct 440:155

Kanekiyo M, Kobayashi M, Ando I, Kurosu H, Ishii T, Amiya S (1998) J Mol Struct 447:49

Masuda K, Horii F (1998) Macromolecules 31:5810

Lai S, Casu M, Saba G, Lai A, Husu I, Masci G, Crescenzi V (2002) Solid State Nucl Magn Reson 21:187

Peppas NA, Mongia NK (1997) Eur J Pharm Biopharm 43:51

Damshkaln LG, Simenel IA, Lozinsky VI (1999) J Appl Polym Sci 74:1978

Yakoyama F, Masada I, Shimamura K, Ikawa T, Monobe K (1986) Colloid Polym Sci 264:595

Hatakeyama T, Yamauchi A, Hatakeyama H (1987) Eur Polym J 23:361

Nishinari K, Watase M, Tanaka F (1996) J Chim Phys 93:880

Hassan CM, Peppas NA (2000) Macromolecules 33:2472

Holloway JL, Lowman AM, Palmese GR (2013) Soft Matter 9:826

Tretinnikov ON, Sushko NI, Zagorodskaya SA (2013) Polym Sci 55A:91

Ricciardi R, Gaillet C, Ducouret G, Lafuma F, Lauprêtre F (2003) Polymer 44:3375

Ricciardi R, Auriemma F, De Rosa C, Lauprêtre F (2004) Macromolecules 37:1921

Ricciardi R, Auriemma F, Gaillet C, De Rosa C, Lauprêtre F (2004) Macromolecules 37:9510

Ricciardi R, D’Errico G, Auriemma F, Ducouret G, Tedeschi AM, Gaillet C, De Rosa C, Lauprêtre F, Lafuma F (2005) Macromolecules 38:6629

Ricciardi R, Mangiapia G, Celso FL, Paduano L, Triolo R, Auriemma F, De Rosa C, Lauprêtre F (2005) Chem Mater 17:1183

Ricciardi R, Auriemma F, De Rosa C (2005) Macromol Symp 222:49

Auriemma F, De Rosa C, Triolo R (2006) Macromolecules 39:9429

Auriemma F, De Rosa C, Ricciardi R, Celso FL, Triolo R, Pipich V (2008) J Phys Chem 112B:816

Domotenko LV, Lozinsky VI, Vainerman ES, Rogozhin SV (1988) Polym Sci USSR 30A:1758

Lozinsky VI, Domotenko LV, Vainerman ES, Rogozhin SV (1989) Polym Sci USSR 31A:1983

Lozinsky VI, Damshkaln LG (2000) J Appl Polym Sci 77:2017

Lozinsky VI, Zubov AL, Savina IN, Plieva FM (2000) J Appl Polym Sci 77:1822

Lozinsky VI, Damshkaln LG, Shaskol’skii BL, Babushkina TA, Kurochkin IN, Kurochkin II (2007) Colloid J 69:747

Lozinsky VI, Damshkaln LG, Kurochkin IN, Kurochkin II (2012) Colloid J 74:319

Mikhalev OI, Yakovleva IV, Trofimov VI, Shapiro AB (1985) Cryo-Lett 6:245

Lozinsky VI, Vainerman ES, Domotenko LV, Blumenfel'd AL, Rogov VV, Barkovskaya EN, Fedin EI, Rogozhin SV (1989) Colloid J USSR 51:592

Mikhalev OI, Serpinski M, Lozinsky VI, Kapanin PV, Chkeidze II, Alfimov MV (1991) Cryo-Lett 12:197

Gusev DG, Lozinsky VI, Vainerman ES, Bakhmutov VI (1990) Magn Res Chem 28:651

Horii F, Masuda K, Kaji H (1997) Macromolecules 30:2519

Nakano T, Nakaoki T (2011) Polym J 43:875

Lozinsky VI, Vainerman ES, Domotenko LV, Mamtsis AM, Titova EF, Belavtseva EM, Rogozhin SV (1986) Colloid Polym Sci 264:19

Hyon SH, Cha WI, Ikada Y (1989) Kobunshi Ronbunshu 46:673 (in Japanese)

Trieu HH, Qutubuddin S (1994) Colloid Polym Sci 272:301

Trieu HH, Qutubuddin S (1995) Polymer 36:2531

Lozinsky VI, Zubov AL, Titova EF (1996) Enzyme Microb Technol 18:561

Willcox PJ, Howie DW, Schmidt-Rohr K, Hoagland DA, Gido S, Pudjijanto S, Kleiner LW, Venkatraman S (1999) J Polym Sci Polym Phys 37:3438

Lozinsky VI, Damshkaln LG (2001) J Appl Polym Sci 82:1609

Szczesna M, Galas E, Bielecki S (2001) J Mol Catal 11B:761

Lozinsky VI, Damshkaln LG, Kurochkin IN, Kurochkin II (2008) Colloid J 70:189

Nakaoki T, Yamashita H (2008) J Mol Struct 875:282

Millon LE, Mohammadi H, Wan WK (2006) J Biomed Mater Res 79B:305

Millon LE, Nieh MP, Hutter JL, Wan W (2007) Macromolecules 40:3655

Hudson SD, Hutter JL, Nieh MP, Pencer J, Millon LE, Wan W (2009) J Chem Phys 130:#034903

Valentin JL, López D, Hernández R, Mijangos C, Saalwächter K (2009) Macromolecules 42:263

Watase M, Nishinari K (1988) Makromol Chem 189:871

Hirai T, Asada Y, Suzuki T, Hayashi S, Nambu M (1989) J Appl Polym Sci 38:491

Urushizaki F, Yamaguchi H, Nakamura K, Namajiri S, Sugibayashi K, Morimoto Y (1990) Int J Pharm 58:135

Stauffer SR, Peppas NA (1992) Polymer 33:3932

Hickey AS, Peppas NA (1995) J Membr Sci 107:229

Hatakeyama T, Uno J, Yamada C, Kishi A, Hatakeyama H (2005) Thermochim Acta 431:144

Mori Y, Tokura H, Yoshikawa M (1997) J Mater Sci 32:491

Pazos V, Mongrain R, Tardif JC (2009) J Mech Behav Biomed Mater 2:542

Gonzalez JG, Alvarez VA (2011) Thermochim Acta 521:184

Fukae R, Yoshimura M, Yamamoto T, Nishinari K (2011) J Appl Polym Sci 120:573

Londoňo ME, Jaramillo JM (2011) DYNa-Colombia 78:132 (in Spanish)

Huang M, Cai D, Liu Y, Sun J, Wang J, Qin C, Dai L, Yamaura K (2012) Fiber Polym 13:955

Stasco J, Berzina-Cimdina L, Kalnins M (2012) Proc Eston Acad Sci 61:228

Numbu M, Motomachi H, Tatsuo K, Watase M (1982) Japanese Patent 57-164,870

Watase M (1983) Nippon Kagaku Kaisi #7:973 (in Japanese)

Watase M (1983) Nippon Kagaku Kaisi #9:1254 (in Japanese)

Nagura M, Nagura M, Ishikawa H (1984) Polym Commun 25:313

Watase M, Nishinari K (1985) Makromol Chem 186:1081

Watase M, Nishinari K (1985) J Polym Sci Polym Phys 23:1803

Numbu M (1981) Japanese Patent 56-045,439

Bercea M, Morariu S, Rusu D (2013) Soft Matter 9:1244

Lozinsky VI, Sakhno NG, Damshkaln LG, Bakeeva IV, Zubov VP, Kurochkin IN, Kurochkin II (2011) Colloid J 73:234

Lozinsky VI, Damshkaln LG, Ezernitskaya MG, Glotova YK, Antonov YA (2012) Soft Matter 8:8493

Podorozhko EA, Korlyukov AA, Lozinsky VI (2010) J Appl Polym Sci 117:1332

Podorozhko EA, Vorontsova TV, Lozinsky VI (2012) Colloid J 74:110

Podorozhko EA, D’yakonova EA, Kolosova OY, Klabukova LF, Lozinsky VI (2012) Colloid J 74:711

Shapiro L, Cohen S (1997) Biomaterials 18:583

Glicklis R, Shapiro L, Agbaria R, Merchuk JC, Cohen S (2000) Biotechnol Bioeng 67:344

Zmora S, Glicklis R, Cohen S (2002) Biomaterials 23:4087

Lozinsky VI, Simenel IA, Chebyshev AV (1994) Russian Patent 2,035,476

Shmarov MM, Tutykhina IL, Logunov DY, Tokarskaya EA, Naroditsky BS, Damshkaln LG, Ivanov RV, Lozinsky VI (2008) Russian Patent 2,381,272

Petrenko YA, Ivanov RV, Lozinsky VI, Petrenko AY (2011) Bull Exp Biol Med 150:543

Petrenko YA, Ivanov RV, Petrenko AY, Lozinsky VI (2011) J Mater Sci Mater Med 22:1529

Lozinsky VI, Zubov AL (1994) Russian Patent 2,078,099

Ho MH, Kuo PY, Hsieh HJ, Hsien TY, Hou LT, Lai JY, Wang DM (2004) Biomaterials 25:129

Mallik R, Hage DS (2006) J Sep Sci 29:1686

Plieva FM, Galaev IY, Mattiasson B (2007) J Sep Sci 30:1657

Jungbauer A, Hahn R (2008) J Chromatogr 1184A:62

Kumar A, Bhardwaj A (2008) Biomed Mater 3:#034008

Nordborg A, Hilder EF (2009) Anal Bioanal Chem 394:71

Bolto B, Tran T, Hoang M, Xie Z (2009) Progr Polym Sci 34:969

Svec F (2010) J Chromatogr 1217A:902

Tetala KKR, van Beek TA (2010) J Sep Sci 33:422

Kumar A, Srivastava A (2010) Nat Protocols 5:1737

Kirsebom H, Galaev IY, Mattiasson B (2011) J Polym Sci Polym Phys 49:173

Spross J, Sinz A (2011) J Sep Sci 34:1958

Arrua RD, Igarzabal CIA (2011) J Sep Sci 34:1974

Van Vlierberghe S, Dubruel P, Schacht E (2011) Biomacromolecules 12:1387

Gunasena DN, Rassi ZE (2012) Electrophoresis 33:251

Podgornik A, Krajnc NL (2012) J Sep Sci 35:3059

Pfaunmiller EL, Paulemond ML, Dupper C, Hage DS (2013) Anal Bioanal Chem 405:2133

Henderson TMA, Ladewig K, Haylock DN, McLean KM, O’Connor AJ (2013) J Mater Chem 21B:2682

Zhang H, Zhang F, Wu J (2013) React Funct Polym 73:923

Grant NC, Clark DE, Alburn HE (1961) J Am Chem Soc 83:4476

Batler AR, Bruice TC (1964) J Am Chem Soc 86:313

Pincock RE, Kiovsky TE (1965) J Am Chem Soc 87:2072

Pincock RE (1969) Acc Chem Res 2:97

Grinberg OY, Nikitaev AT, Zamaraev KI, Lebedev YS (1969) Zhurn Strukt Khim 10:230 (in Russian)

Sergeev GB, Batyuk VA, Stepanov MB, Sergeev BM (1973) Doklady Akademii nauk SSSR 213:891 (in Russian)

Kvlividze VI, Pylova MB (1977) Koll Zhurn 39:1167 (in Russian)

Sergeev GB, Sergeev BM, Kalnina IA (1984) Zhurn Fiz Khim 58:2431 (in Russian)

Kawai T (1958) J Polym Sci 32:425

Solms DJ, Rijke AM (1971) J Phys Chem 75:2623

Meryman HT (1971) Cryobiology 8:173

Smith P, Pennings AJ (1974) Polymer 15:413

Bhat S, Tripathi A, Kumar A (2011) J R Soc Interface 8:540

Acknowledgement

The author expresses his great appreciation to Oguz Okay for very productive discussions on polymeric cryogels and for help in preparation of the present review. The work was supported in parts by a grant from the Russian Foundation for Basic Research (RFBR Project # 12-03-00216-a), as well as by a joint Russian–Turkish grant from RFBR and the Scientific and Technical Research Council of Turkey (Project # 12-03-91371-CT-a).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Lozinsky, V.I. (2014). A Brief History of Polymeric Cryogels. In: Okay, O. (eds) Polymeric Cryogels. Advances in Polymer Science, vol 263. Springer, Cham. https://doi.org/10.1007/978-3-319-05846-7_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-05846-7_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-05845-0

Online ISBN: 978-3-319-05846-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)