Abstract

Fiber reinforced self-compacting concrete (SCC) has several advantages compared to normal concrete. It has higher tensile strength and better flowability to fill the gaps and voids in mold. Fiber distribution and orientation are the most important factors for the mechanical performance of the fiber reinforced SCC. In this paper a numerical framework consisting computational fluid dynamics (CFD) and discrete element method (DEM) is suggested to model the casting process of the fiber reinforced SCC. First the casting procedure for fresh concrete is modeled as non-Newtonian fluid by computational fluid dynamics (CFD), and the CFD simulations are validated against the slump and LCPC test. Then the fiber movement and rotation are simulated with discrete element method (DEM). The results showed that the proposed framework could be utilized to model casting process of the fiber reinforced SCC and the simulation results have a good agreement with the test data from literature.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Casting simulation

- Computational fluid dynamics

- Discrete element method

- Fiber reinforced concrete

- Self-compacting concrete

- Three-dimensional modeling

1 Introduction

Concrete has been used in the construction industry from 19th Century. Concrete has high compressive strength, and it is a cost-effective material. However, due to its low tensile strength concrete requires reinforcement to withstand the tensile forces. Traditionally, steel rebar has been used inside concrete to improve the tensile characteristic of the concrete. During casting process, normal concrete needs to be vibrated to fill voids and gaps in molds. Also, the rebar in concrete has the potential to be corroded which reduces the effectiveness of the reinforcement.

Fiber reinforced SCC can solve some of these issues. SCC can flow by its own weight and fill the molds, which requires no vibration and results in less labor, time and cost. Also, the presence of fiber in SCC improves tensile strength, durability and ductility. So, fiber reinforced SCC has great potential to be used instead of normal concrete. However, the presence of random fibers does not necessarily result in improved strength. Therefore, the alignment of fiber in the tensile stress plane is an important factor that needs to be considered when designing structural elements made of fiber reinforced concrete.

Fiber orientation and location depend on several factors, including casting procedure, concrete rheology properties, fibers geometry, the geometry of rebar reinforcement and formwork surface. The orientation and location of fibers can be quantified through experimental tests such as image analysis, manual counting, inductive test and numerical simulation. Only few parameters could be studied by the experimental tests due to the high cost and long time. On the other hand, numerical simulation can be used to study the effect of the different parameters during the casting procedure and it also can be used to simulate the different structural elements, such as beam, slab, wall etc.

Kulasegaram and Karihaloo [1] used smoothed-particle hydrodynamics (SPH) to model the casting procedure of fiber reinforced concrete. The concrete flow was simulated as particles based on the non-Newtonian Bingham model. The fibers were modeled as rigidly connected pairs of particles. The distance between each fiber particle remained constant. 2D simulation was performed for the casting process of a concrete block with dimension of 200x200mm with a 2.5% fiber volume fraction. They also investigated the influence of different parameters on the fiber distribution, including the height of the inlet, the opening of the inlet, and obstruction in the flow path of concrete.

Svec et al. [2] used the Lattice Boltzmann Method (LBM) and Immersed Boundary Method (IBM) to model the effect of the formwork surface on fiber orientation in fiber reinforced SCC. Several slabs were cast, and samples were extracted from each slab, and CT scan was used to evaluate the fiber orientation. In their work, experimental and numerical results showed good agreement. They also showed that the formwork surface has an effect on fiber orientation.

In another research, Zirgulis et al. [3] performed a study on the effect of presence of rebar reinforcement on fiber orientation. The same numerical framework developed by Svec et al. [4,5,6] was used to simulate the casting procedure for slabs with combination of rebar and fiber reinforcement. Also, they compared their numerical results with experimental tests. They concluded that numerical simulation could predict the experimental evaluation of fiber orientation. The differences between simulation and experiments was not significant.

Zhao et al. [7] developed a numerical framework to evaluate steel fiber orientation during the casting process. This method combined the CFD with discrete particle method was previously used by Bi et al. [8]. Fibers were modeled as several rigid spheres that are connected and have rigid body translation and rotation. Concrete was modeled as Bingham fluid in Ansys CFX and MATLAB code was developed to calculate the rotation and translation of the fibers. For verification of the model, they cast several beams. Comparison between the simulation and experimental test showed a good agreement, and they suggested that this model can be used for casting procedure simulation.

Lee et al. [9] studied the effect of the nozzle with a blade on the fiber orientation and tried to improve the casting procedure. COMSOL software was used to perform a simulation to investigate the effect of the different blade lengths and locations on fiber orientation. They also fabricated a nozzle with optimum blade geometry and used that to verify the simulation. The results showed that the nozzle with a blade affects the fiber orientation during the casting procedure, and this solution can be used for the construction of concrete elements.

In previous researches [1, 7, 8], steel fibers were modeled mostly as several connected spheres. It has some disadvantages, such as the inability to efficiently model large-scale simulation containing fibers with high aspect ratio.

In addition, some research neglected the interaction between fibers in the simulation which could lead to unrealistic results. Therefore, further studies are required to achieve efficient modelling of fibers with high aspect ratio and take into account the fiber interactions during casting process.

In this paper, the casting procedure of steel fiber reinforced SCC was simulated by the proposed framework. At first, SCC is modeled as non-Newtonian fluid by CFD, and the CFD simulations are validated against the slump and LCPC test. Then the numerical simulation is performed for the casting process of a beam and compared with test data from literature. The concrete flow in the beam was simulated by Ansys Fluent. The results of fluid simulation, such as velocity and acceleration, are used in Rocky DEM to calculate the interaction between concrete and fiber. The simulation could be performed in one-way or two way coupling between fluid and fibers. In present study, the simulation is performed with one-way coupling, i.e. the fibers do not affect the concrete flow. Finally, the simulation results are compared with experimental test results from the literature.

2 Methodology

2.1 CFD Simulation for Fresh Concrete

There are mainly two types of fluids: Newtonian fluid and non-Newtonian fluid. In Newtonian fluid shear stress has a linear relationship with shear strain rate. Water, oil and air are examples of the Newtonian fluid. In a non-Newtonian fluid, the shear stress has non-linear relation with the shear strain rate. Some examples of non-Newtonian fluids are toothpaste, ketchup, and cornstarch. Non-Newtonian fluid can be categorized into three different subgroups which are the Bingham plastic, dilatant (shear-thickening) and pseudoplastic (shear-thinning). Shear stress vs. shear strain rate is shown for different types of fluids in Fig. 1. Several studies [1, 7, 8, 10,11,12,13] suggested that concrete can be modeled as Bingham fluid. The formulation of Newtonian and Bingham fluid are shown in Table 1.

Shear stress vs. rate of deformation for different fluids [14]

The concrete flow is simulated by CFD. The solution to the mass and momentum conservation equations gives the velocity field and pressure of the fluid in the modelled domain. Mass and momentum conservation equations are as follows [15]:

\(\frac{\partial \rho }{{\partial t}} + \vec{\nabla } \cdot \left( {\rho \vec{V}} \right) = 0\) | ρ is the fluid density [kg.m−3] t is the time [s] V is the fluid velocity [m.s−1] g is the gravity acceleration [m.s−2] μ is the dynamic viscosity [Pa.s] |

\(\rho \frac{{D\vec{V}}}{Dt} = - \vec{\nabla }P + \rho \vec{g} + \mu \nabla^{2} \vec{V}\) |

2.2 DEM-CFD Simulation for Fiber Reinforced SCC Concrete

In order to evaluate the effectiveness of fibers in the mechanical behavior of fiber reinforced concrete, the fiber orientation and distribution across the structural elements need to be identified. Discrete Element Modeling (DEM) is a numerical technique to simulate interactions between particles-particles and particles and boundaries. It can account for many types of forces acting on individual particles and predict particle flow dynamics and bulk solids behavior. This approach is extremely powerful in solving many industrial problem [16]. DEM could be utilized to investigate fiber movement and rotation during the casting procedure with the combination of CFD simulation. Rocky DEM has the capability to model real 3D particles shapes and fibers and shells, both rigid and flexible [17]. The movement of fibers is due to interaction between fiber and concrete flow. There are two dominant forces that affect fiber orientation and distribution: drag and buoyancy. The drag force is caused by the difference between the velocity of the fiber and the fluid, while the buoyance force results from the density difference between the fiber and the fluid. The formulation for drag force is shown in Table 2.

3 CFD Simulation of Slump and LCPC Box Test for Fresh SCC

Slump and LCPC box test are two most common methods to measure the flow properties of SCC. In order to validate CFD simulation for the casting of SCC, numerical simulations are performed for those two tests and the simulation results are compared with test results.

3.1 Slump Test

2D simulations of slump tests for two groups of SCCs are performed in Ansys Fluent. The concrete rheology is formulated as Bingham fluid with the yield stress and plastic viscosity shown in Table 3. The volume of fluid (VOF) has been used for modeling concrete and air phase. The method is capable of evaluating the free surface of concrete [20].

The simulation results were compared with the work of Li et al. [21] for the slump test. The simulation results for the slump test are showed in Fig. 2 and Table 4, and they have good agreement with test results.

3.2 LCPC Box Test

Roussel [22] suggested a simple method (LCPC box) to measure the concrete yield stress, and LCPC box test could be easily performed on the site. The box has a dimension of 150 mm height, 200 mm width and 1200 mm length. The geometry of the LCPC box is shown in Fig. 3. The volume of concrete was set to be 6 L. Concrete was poured slowly within the 30 s inside the box. After two minutes when the concrete flow stops, the spread length and height of the concrete inside the box are measured. Roussel [22] presented the following equation to calculate yield stress.

\(\begin{gathered} A = \frac{{2\tau_{0} }}{{\rho gl_{0} }} \hfill \\ L = \frac{{h_{0} }}{A} + \frac{{l_{0} }}{2A}\ln \left( {\frac{{l_{0} }}{{l_{0} + 2h_{0} }}} \right) \hfill \\ \end{gathered}\) | τ0 is the fluid yield stress [Pa] g is gravitational acceleration [m.s−2] l0 is the width of the LCPC box [m] h0 is the maximum thickness of the sample [m] ρ is the concrete density [kg.m−3] L is the spread length at stoppage [m] |

LCPC box [22]

3D simulation is performed for the LCPC box test in Ansys Fluent, and the results were compared with the work of Roussel et al. [23]. Concrete properties used in simulation are shown in Table 5. Simulation results are shown in Fig. 4 and Table 6.

4 CFD-DEM Simulation for Fiber Reinforced SCC

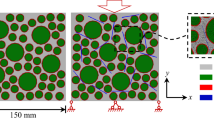

The casting process for a beam of dimension 100x100x400 mm is simulated by coupled CFD-DEM method. The beam has the same geometry as the one studied by Zhao et al. [20] with the dimension of 40x40 mm. For casting simulation, different dimension is used for the inlet to prevent fiber blocking.

The straight steel fibers with a length of 35 mm and a diameter of 0.75 mm are used in the fiber reinforced SCC. The fiber density is set to 7850 kg/m3. Two cross-sections, as shown in Fig. 6, are selected in the beam to evaluate the fiber density, i.e. number of fiber per cm2, and the fiber orientation. The calculation of the fiber density and the fiber orientation at cross section is given as:

\(d_{n} = \frac{{N_{fiber} }}{{A_{c} }}\) | dn is fiber density at the cross-section [m−2] Nfiber is the number of fibers Ac is the cross-section area [m−2] |

\(\eta_{\theta } = \frac{1}{{N_{fiber} }}\sum\limits_{i = 0}^{{N_{fiber} }} {\cos \theta_{i} }\) | θ is the angle between the fiber and the beam axis |

4.1 Fluid Simulation

The simulation domain in Ansys Fluent is same as the geometry of beam, i.e. 100x100x400 mm and the mesh size is 0.005 m which creates a total number of 32000 elements. The concrete flow is modelled as non-Newtonian fluid by Bingham model by setting \(n=1\) for the Herschel-Bulkley model in Ansys Fluent. The viscosity and yield stress are set to 19.2 Pas and 22.3 Pa and the flow is assumed to be laminar. The density of the concrete is set 2304 kg/m3. The casting procedure is modeled as two Eulerian phases (air and concrete), and the VOF method was used to evaluate the interface between concrete and air.

The velocity of fluid entering the domain is set to 0.3 m/s, and the total time for filling the mold was 3.7 s. Also, the timestep is set to 0.01 s, and the total step of the simulation is 370. The simulation result at time 1.97 s is shown in Fig. 7.

4.2 Discrete Particle Simulation

Discrete particle simulation is performed to evaluate fiber orientation and location during the casting procedure by using Rocky DEM. There are two approaches to handle the interaction between fibers and concrete fluid: one-way and two-way coupling. In one-way coupling, the fibers do not affect the fluid flow, which means that flow of concrete can be modeled by CFD simulation separately, and then the random distributed fibers are added to the concrete flow at each time step, and the velocity and acceleration of the concrete flow at cells can be used to calculate the forces acted on the fibers which induce the translation and rotation movement of the fibers. In two-way coupling, the fiber and the fluid interact with each other, and CFD and DEM simulation is performed consecutively in each time step. In other word, the concrete flow affects the movement of fiber and vice versa the movement of fiber also affects the flow of concrete.

In the present study, the interaction between fibers and the concrete fluid is modeled as one-way coupling. The velocity of fibers entering the domain is set to be the same as concrete. The simulation duration is the same as that of concrete flow simulation which is 3.7 s. A total number of 747 fibers were added in SCC at the end of the simulation. The drag force is calculated by Marheineke & Wegener drag model which was developed for long slender fibers immersed in turbulent dilute flows [18]. This model decomposes the force into normal and tangential components and is uniformly valid for all Reynolds number regimes. By taking into account the fiber orientation and alignment with the incident flow, the drag coefficient estimate is more accurate [24].

4.3 Simulation Results and Discussion

In fiber reinforced SCC, fiber distribution and orientation are the two most important parameters that define the mechanical behavior of the structural element. When more fibers are oriented in the same direction of tensile stress both the tensile strength and the tensile residual strength will be significantly improved. In this section, the fiber orientations at two selected cross sections are evaluated and compared with experimental results, which were published by Zhao et al. [20] is shown in Table 7. The fiber distribution and orientation alongside the beam during the casting process at time step of 2 s and at the end of simulation are shown in Fig. 8.

As can be seen from Table 7, the simulation results show similar fiber orientation and distribution to the experimental test performed by Zhao et al. [20]. It can be concluded that the proposed method in this paper can be used to simulate the casting process of fiber reinforced SCC to predict the fiber distribution and the fiber orientation. It should be noted that in the current simulation, the width and length of the inlet are modified, and further investigation is needed to verify the proposed method with more experimental data. Furthermore, the one-way coupling method is used in the simulation to model the interaction between fibers and concrete fluid, and the two-way coupling simulation will be performed in future to further study the interaction between the steel fiber and concrete during casting.

5 Conclusion

The results presented and discussed in the manuscript lead to the following remarks:

-

The CFD simulations of concrete flow are validated against slump test and LCPC test.

-

The Rocky DE has the capability to model the realistic fiber geometry for the fiber reinforced SCC.

-

The simulation results based on one-way coupling between CFD and DEM show reasonable agreement with the experimental results from literature. It can be concluded the proposed numerical framework has good potential to be applied in the simulation of the casting process of the fiber reinforced SCC.

-

Further studies should be conducted with different fiber geometry and fluid characteristics with one-way and two-coupling to gain better understanding of fiber orientation and distribution.

References

Kulasegaram S, Karihaloo BL (2013) Fibre-reinforced, self-compacting concrete flow modelled by smooth particle hydrodynamics. Proc Inst. Civ Eng Eng Comput Mech 166(1):22–31

Švec O, Žirgulis G, Bolander JE, Stang H (2014) Influence of formwork surface on the orientation of steel fibres within self-compacting concrete and on the mechanical properties of cast structural elements. Cem Concr Compos 50:60–72

Žirgulis G, Švec O, Geiker MR, Cwirzen A, Kanstad T (2016) Influence of reinforcing bar layout on fibre orientation and distribution in slabs cast from fibre-reinforced self-compacting concrete (FRSCC). Struct Concr 17(2):245–256

Švec O, Skoček J, Stang H, Geiker MR, Roussel N (2012) Free surface flow of a suspension of rigid particles in a non-Newtonian fluid: a lattice Boltzmann approach. J Nonnewton Fluid Mech 179:32–42

Svec O, Skocek J, Stang H, Olesen JF, Poulsen PN (2011) Flow simulation of fiber reinforced self compacting concrete using Lattice Boltzmann method. In: 8th International Congress on the Chemistry of Cement

Švec O, Skoček J (2013) Simple Navier’s slip boundary condition for the non-Newtonian Lattice Boltzmann fluid dynamics solver. J Nonnewton Fluid Mech 199:61–69

Zhao Y, Bi JH, Huo LY, Wang ZY, Guan J, Zhao YR (2021) Development of a coupled numerical framework of steel fiber reinforced self-compacting concrete. Constr Build Mater 303:124582

Bi J, Zhao Y, Guan J, Huo L, Qiao H, Yuan L (2019) Three-dimensional modeling of the distribution and orientation of steel fibers during the flow of self-compacting concrete. Struct Concr 20(5):1722–1733

Lee J-H, Hu JW, Kang J-W (2019) Effects of blades inside a nozzle on the fiber orientation and distribution in fiber-reinforced cement-based materials. Compos Struct 221:110885

Bao C, Bi JH, Xu D, Guan J, Cheng WX (2020) Numerical simulation of the distribution and orientation of steel fibres in SCC. Mag Concr Res 72(21):1102–1111

Deeb R, Karihaloo BL, Kulasegaram S (2014) Reorientation of short steel fibres during the flow of self-compacting concrete mix and determination of the fibre orientation factor. Cem Concr Res 56:112–120

Dufour F, Pijaudier-Cabot G (2005) Numerical modelling of concrete flow: homogeneous approach. Int J Numer Anal Meth Geomech 29(4):395–416

Gram A, Silfwerbrand J (2011) Numerical simulation of fresh SCC flow: applications. Mater Struct 44(4):805–813

Nguyen Q-H, Nguyen N-D (2012) Incompressible non-Newtonian fluid flows. Continuum Mechanics-Progress in fundamentals and Engineering applications, pp 47–72

ANSYS Inc (2020) ANSYS FLUENT 12.0/12.1 Documentation

Rocky ESSS (2023) An introduction to Discrete Element Modeling (DEM). https://rocky.esss.co/blog/introduction-discrete-element-modeling-dem-interview/

Rocky ESSS (2019) Clustered x polyhedral shape: why is it important to consider particle shape. https://rocky.esss.co/blog/clustered-x-polyhedral-shape-why-is-its-important-to-consider-particle-shape/

Marheineke N, Wegener R (2011) Modeling and application of a stochastic drag for fibers in turbulent flows. Int J Multiph Flow 37(2):136–148

Rocky E (2022) CFD Coupling Technical Manual, ESSS Rocky DEM, S.R.L.,

Zhao Y et al (2021) Numerical simulation of the casting process of steel fiber reinforced self-compacting concrete: Influence of material and casting parameters on fiber orientation and distribution. Constr Build Mater 312:125337

Li Y, Mu J, Wang Z, Liu Y, Du H (2021) Numerical simulation on slump test of fresh concrete based on lattice Boltzmann method. Cement Concr Compos 122:104136

Roussel N (2007) The LCPC BOX: a cheap and simple technique for yield stress measurements of SCC. Mater Struct 40(9):889–896

Roussel N et al (2016) Numerical simulations of concrete flow: A benchmark comparison. Cem Concr Res 79:265–271

Rocky E Modeling real fibers: everything you need to know about the Rocky DEM flexible fiber model

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Abedi, M., Lin, C., Ji, G. (2023). Numerical Simulation of Casting Process of Fiber Reinforced Self-compacting Concrete (SCC). In: Ilki, A., Çavunt, D., Çavunt, Y.S. (eds) Building for the Future: Durable, Sustainable, Resilient. fib Symposium 2023. Lecture Notes in Civil Engineering, vol 349. Springer, Cham. https://doi.org/10.1007/978-3-031-32519-9_161

Download citation

DOI: https://doi.org/10.1007/978-3-031-32519-9_161

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-32518-2

Online ISBN: 978-3-031-32519-9

eBook Packages: EngineeringEngineering (R0)