Abstract

Steel corrosion in Reinforced Concrete (RC) bridge piers may occur due to particular environmental expositions or percolation of aggressive water from superstructures. In some cases, the causes of corrosion are non-uniformly distributed and produce non-homogeneous spatial deterioration patterns that can modify the capacity of the piers both in terms of strength and ductility with potential consequences on the overall bridge performances, especially for bridges located in seismic regions. The modeling of this type of situations represents specific challenges related to the description of the deterioration patterns and the calibration of material properties. A multi-level modeling approach for RC bridge piers subject to arbitrarily non-uniform corrosion patterns tailored to be used for the assessment of real bridges is proposed. A specific software implementation of the modeling has been developed in OpenSeesPy and is also described.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Ageing Reinforced Concrete (RC) structures can be subjected to several phenomena that may lead to degradation of their performances [1] and can be classified as follows:

-

direct deterioration of concrete due to various types of actions: mechanical (e.g. abrasion, erosion), physical (e.g. freeze-thaw) or chemical (e.g. reactivity of aggregates and cement past, acid dissolution);

-

combined deterioration of concrete, steel and their bond induced by corrosion of reinforcing bars.

RC bridge piers may be subjected to one or more of the above effects which, depending on intensity and extension, can eventually produce significant reduction of their capacity under horizontal actions. In this work, attention is focused on the deterioration induced by steel corrosion, although the proposed modeling procedure can be straightforwardly extended to cover additional sources of deterioration.

Electrochemical processes underlying corrosion of reinforcement steel are well known [1] but their effects on the response of RC still represents a challenge for modeling at the level of structural elements. After depassivation, parts of the outer layer of each corroded bar are transformed into mixtures of iron oxydes and hydroxydes, causing several concatenated consequences [1]. The superficial transformations of steel bars can occur in different ways depending on the specific processes that are activated. For example, carbonation-induced attacks tend to produce uniform corrosion whereas chloride-induced ones tend to produce localized pitting corrosion. As a result of actual processes, rebars can change shape in a complex way [2].

The experimental study of the influence of steel corrosion on the response of RC structural elements received a great deal of attention in the scientific literature of the past decades [3]. Most studies are devoted to the behavior of corroded beams in flexure or columns under lateral loads, with accelerated artificial uniform corrosion or, less frequently, natural corrosion [4]. In comparison, fewer studies are devoted to the investigation of the response of corroded bridge piers with hollow cross-section or the effect of non-uniform corrosion [5]. In the available studies non-uniformity of corrosion is typically taken into account only in elevation, namely by the consideration of a uniformly corroded section up to certain height [6].

On the other hand, in real bridges it often happens that causes of corrosion, like water percolation from superstructures or atmospheric agents exposition, occur in a distinctly non symmetric way causing strongly different corrosion effects on the sides of the pier.

This work deals with the modeling of fully non-uniform corrosion, namely both in elevation and within the cross-section, by means of a fiber-based Finite Element (FE) modeling approach.

1 Structural Modeling

A detailed modeling of the response of corroded reinforced concrete elements requires a coupled physically-based approach that takes into account all the effects of degradation phenomena occurring in the materials at different scales. To this end, numerical simulations can be based on two- or three-dimensional FE modeling [3]. The detailed approach is useful to investigate local stress distribution problems or to analyse the behaviour of structural components and members. However, the involved computational cost and the amount of data to be managed make this approach impractical for the analysis of entire structural systems. A structural modeling based on beam FE with fiber discretization of the cross-section represents an efficient alternative to obtain sufficiently accurate results at an affordable computational cost.

Most common fiber-based FE are framed within the Euler-Bernoulli beam theory. However, if shear or other types of deformations not included in the classical formulation becomes relevant they can be included either in an approximated way by empirically calibrated springs or, more accurately, by means of enhanced FE elements [7].

The proposed modeling procedure is based on Force-Based Euler-Bernouilli fiber beam-column elements where element response is evaluated by assuming an equilibrated interpolation of the cross-section internal forces along the element axis. The computation of the capacity of a real bridge pier under horizontal actions requires, moreover, careful consideration of the eventual relevance of additional aspects like: foundations stiffness, eventual influence of torsional stiffness of the superstructure, influence of shear deformations.

Within a fiber-based modeling approach, the effect of confinement is indirectly taken into account by means of phenomenological models that reproduce the effect of the lateral pressures through the modification of the axial material response. Transverse reinforcements are not explicitly modeled but their effect is accounted for by specifying suitably modified uniaxial constitutive laws for concrete fibers.

Through a conceptually similar approach, the influence of corrosion can be taken into account, without explicitly modeling deterioration phenomena, through suitable empirical degradation laws for the uniaxial stress-strain laws of the fibers. Generally speaking, a degradation law for a parameter \(X\) determining the uniaxial response of a fiber is an empirical relation between the value \({X}_{P}\) of the parameter for the Plain (P) material and the corresponding value \({X}_{D}\) of the same property for the Deteriorated (D) material, parameterized by one or more Damage Intensity Measure (DIM) \(\psi\):

A fiber-based beam-column element is characterized by an inherent hierarchy between components of the model: nodes, elements, integration points, fibers (Fig. 1). This feature can be profitably used to model non-uniformity of corrosion both in elevation and within the cross-section.

2 Deterioration Modeling Approach

To model spatially non-homogeneous degradation patterns within a fiber-based approach, a multi-level discretization approach is proposed. Each structural element is conceptually partitioned into: pieces, parts, zones, regions, fibers.

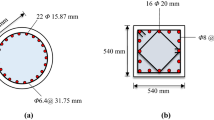

A part is a volume of the pier where concrete geometry, longitudinal and transverse reinforcement as well as the deterioration of the materials can be considered uniform (Fig. 2). Partitioning of a structural element into parts is determined by four aspects:

-

1.

concrete geometry;

-

2.

longitudinal rebars layout;

-

3.

transverse reinforcement arrangement;

-

4.

materials deterioration.

Subdivision of the pier into parts may lead to identify parts with different heights over different sides of the pier possibly staggered with respect to each other. This can induce several sectional patterns over the height. To develop the actual FE discretization, a further partition of the pier is required. A piece is a segment of the pier composed by a fixed arrangement of parts that determines a uniform cross-sectional pattern (Fig. 3). Each piece is then modeled by at least one FE, characterized by the same cross-section with a specific arrangement of reinforcement and deterioration.

The features of the cross-sections are described by further partitioning them into regions. A region is a portion of a cross-section to be discretized into fibers characterized by the same uniaxial constitutive law (Fig. 2). There are three types of regions: Unconfined Concrete (UC) and Confined Concrete (CC), to be located in the cover and core concrete, respectively, and Longitudinal Steel (LS), to be placed in coincidence with longitudinal rebars. The cross-sectional properties determined by the fibers generated in each region are then assigned to the various integration points of the beam elements (Fig. 1).

Since the constitutive laws of the fibers depend, not only on the mechanical properties of the materials, but also on the damage, a specific level of deterioration needs to be assigned to each region so that partition of the cross-section into regions is determined not only by the properties of the plain materials but also on the state of damage. Namely, to model non-uniform deterioration patterns it may be required to generate distinct regions of the same material with different levels of damage.

Example of multi-level deterioration modeling for a rectangular hollow pier. Different colors indicate parts with different properties in terms of materials, reinforcement or deterioration. Parts are subdivided into regions, regions into fibers (Fig. 2).

Material parameters of the constitutive laws of the fibers depend on both material properties of plain materials and degradation laws parameterized by DIMs. While in a laboratory test corrosion intensity and pattern are fully controlled, a basic problem of real structures assessment is the identification and the specification of the deterioration levels. A Local Deterioration Index (LDI) is an indicator of the damage level of a component of the structure. In general, a set of LDIs is needed to parameterize the level of deterioration of a region and can be defined in various ways, depending on both quantity and quality of the available information. Besides each specific choice, the modeling of the deterioration intensity must satisfy two general properties:

-

P1) each LDI has to be based on an underlying DIM to be used as an independent variable in a degradation law;

-

P2) the values of all LDIs have to be definable in terms of information obtainable by in-situ surveys.

In the proposed modeling procedure, three LDIs are considered:

-

Unconfined Concrete Deterioration (UCD), based on the average width of cracks \({\psi }_{C}\) in the concrete cover region. This quantity is amenable to a direct assessment from either visual or instrumental inspections of the concrete cover;

-

Longitudinal Steel Deterioration (LSD), based on the average mass loss \({\psi }_{L}\) of longitudinal rebars. This quantity can be deduced from direct or indirect evaluation of samples with a variety of diagnostic methodologies;

-

Transverse Steel Deterioration (TSD), based on the average mass loss \({\psi }_{T}\) of the transversal reinforcement.

LDIs can be evaluated both on the basis of a gross integer-valued scale or at a finer real-valued scale depending on the available information. In the first case, each value of a LDI corresponds to an interval of the underlying DIM and can be correlated with a qualitative gross characterization of damage intensity. On the other hand, a finer description can be obtained by enforcing coincidence between LDI and specific values of the corresponding DIM. Based on this scheme, various scales can be proposed according to specific situations (Table 1).

In principle, it is possible to assign a LDI independently to each region, however care is needed to assign consistent values among neighboring regions. For example, the deterioration of a concrete cover region must be consistent with the corrosion level of the neighboring steel regions. Similarly, the confinement reduction assigned to a confined concrete region must be consistent with the corrosion level assigned to the adjacent steel and concrete cover regions. To this end, in some cases, it is useful to group sets of regions into zones characterized by a Global Deterioration Index (GDI) which determines a consistent set of LDIs appropriate to the regions included in the zone. Typically, zones can be determined by identifying, a Gross Deterioration Depth (GDD) to be associated to the exposed surface of various parts the of the pier. This can be achieved either by targeted survey, involving visual inspections and in-situ measurements, or by indirect evaluation. In this way, for example, it is possible to assign different deterioration patterns to the external and internal surfaces of hollow piers.

3 Software Implementation

A specific software has been developed to implement the proposed multi-level deterioration approach for the computation of RC bridge piers capacity of under horizontal actions by means of Force-Based beam-column elements. The code is based on the open-source Python implementation of OpenSees [8] and offers a considerable flexibility in the modeling of both structural elements and materials deterioration.

Structural modeling options include: possibility to use nonlinear springs to approximatively model soil-structure interaction and torsional stiffness of the superstructure, discretization in a variable number of pieces which may reflect arbitrary reinforcement or deterioration patterns in elevation.

Sectional modeling options include: selection of several uniaxial materials for concrete and steel, implementation of various confinement models, possibility to include zero-length elements to model bar-slip at the base of the pier.

Deterioration modeling options include: customizable definition of LDI scales, implementation of several degradation laws for confined and unconfined concrete and steel as well as concrete-steel bond, definition of typical cross-sections with parametric discretization patterns in zones and regions, possibility to assign either LDI to regions or GDI to zones.

At the output level, the code stores and visualizes push-pullover or cyclic capacity curves of the pier for a given direction. During the analyses, at each time step, each region of each integration point is checked, over a given number of representative fibers, for the occurrence of a list of basic events that characterize the RC response (e.g. cracking and spalling of cover concrete, yielding of rebars in tension and compression, cracking and crushing of core concrete, failure of rebars in tension and compression).

Given the possibility to model arbitrary distribution of reinforcement and deterioration, it is useful to check not only the occurrence of the events but also their spatial location. To this end, the code can output the location where each event occurs (Fig. 4).

4 Conclusions

In this work a multi-level modeling approach based on the discretization of a pier into pieces, parts, zones, regions and fibers has been presented. This conceptual partition has been developed to model, by means of fiber-based finite elements, the response of RC bridge piers subjected to arbitrary distributions of corrosion-induced deterioration, both in elevation and within the cross-section. This type of modeling can be useful to investigate the response of piers undergoing strongly non-uniform distribution of corrosion which often take place on real bridges due to common patterns of water percolation from the superstructures or exposition to atmospheric agents.

A specific software implementation in OpenSeesPy of the proposed approach has been developed and a sample output shown. Due to space limitations, details about the implementation and the validation of the code are described in other publications.

References

Ayop SS, Cairns JJ (2013) Critical study of corrosion damaged structures. Int J Integ Eng 5(2):43–50

Wang XG, Zhang WP, Gu XL, Dai HC (2013) Determination of residual cross-sectional areas of corroded bars in reinforced concrete structures using easy-to-measure variables. Constr Build Mater 38:846–853

Kashani MM, Maddocks J, Dizaj EA (2019) Residual capacity of corroded reinforced concrete bridge components; state-of-the-art review. J Bridge Eng 24(7), 03119001_1–03119001_16

Meda A, Mostosi S, Rinaldi Z, Riva P (2014) Experimental evaluation of corrosion influence on the cyclic behavior of RC columns. Eng Struct 76:112–123

Cardone D, Perrone G, Sofia S (2013) Experimental and numerical studies on the cyclic behavior of R/C hollow bridge piers with corroded rebars. Earthq Struct 4(1):41–62

Li D, Wei R, Xing F, Sui L, Zhou Y, Wang W (2018) Influence of non-uniform corrosion of steel bars on the seismic behavior of reinforced concrete columns. Constr Build Mater 167:20–32

di Re P, Addessi D, Filippou FC (2018) Mixed 3D beam element with damage plasticity for the analysis of RC members under warping torsion. J Struct Eng 144(6), 04018064_1–04018064_13

Zhu M, McKenna F, Scott MH (2018) OpenSeesPy: python library for the OpenSees finite element framework. SoftwareX 7:6–11

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bernardini, D., Ruta, D., di Re, P., Paolone, A. (2022). Modeling Non-uniform Corrosion in Reinforced Concrete Bridge Piers. In: Pellegrino, C., Faleschini, F., Zanini, M.A., Matos, J.C., Casas, J.R., Strauss, A. (eds) Proceedings of the 1st Conference of the European Association on Quality Control of Bridges and Structures. EUROSTRUCT 2021. Lecture Notes in Civil Engineering, vol 200. Springer, Cham. https://doi.org/10.1007/978-3-030-91877-4_43

Download citation

DOI: https://doi.org/10.1007/978-3-030-91877-4_43

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-91876-7

Online ISBN: 978-3-030-91877-4

eBook Packages: EngineeringEngineering (R0)