Abstract

The COVID-19 pandemic has resulted in major disruptions to businesses, supply chains and economies alike. The negative effects of the pandemic are yet to be fully realised. In this study, we aimed to reflect on and explore strategies for supply chain sustainability in the face of business downturn caused by the COVID-19 pandemic. The focus of this study is the heavy engineering industry in South Africa as it relies on a global supply chain network. The paper begins with a brief introduction of negative effects of COVID-19 on supply chains followed by the research questions that drives this study. We used a literature review to select the critical success factors which were further refined using experts’ opinion. These factors subsequently, were used as input to an interpretive structural modeling (ISM) technique. The ISM model yielded some interesting findings that can aid organizations in building resilient supply chains that are sustainable in nature. We conclude that organizations need to develop a culture of collaboration; since greater collaboration among value chain members is required to create a more resilient supply chain.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Supply chains are dynamic processes with multifaceted operations and associated disruption risks [1]. Disruption risks can evolve naturally or artificially with or without forewarning [2]. Pandemic outbursts are extraordinary disruptive circumstances, which significantly contribute towards supply chain management risk with endured presence, prolonged proliferation and elevated ambiguity [3]. The outbreak of COVID-19 is one of the biggest examples in the history of pandemics that has extensively contributed towards supply chain management disruptions globally [4, 5]. It is pertinent to understand that the existing management processes are mostly not equipped to sustain COVID-19 pandemic disruptions [1, 6]; instead hold worrying weaknesses. Organizations are facing various challenges such as failing to optimise supply and demand gaps and developing resilient supply chains that can recover fast after disruptions. Lastly, organizations are facing challenges to develop sustainable supply chains [7]. COVID-19 has not only caused health care crises [8]; but caused severe economic downturn that shifted attention of organizations towards business continuity and sustainability [9]. The health and safety aspects of employees and community are at stake. Organizations are assisting employees to adapt to new systems [7]. The whole world is experiencing effects of COVID-19 for the first time and many new strategies and practices have evolved since March 2020 to cope up with this situation. To extend the knowledge base we aim to answer the below research question.

RQ1: What are the critical success factors for enhancing supply chain sustainability amid COVID-19 pandemic?

The relation between each set of critical success factors and outcomes of the interaction can provide rich insights which can be useful in redesigning the supply chain to cope up in this pandemic. Since COVID-19 is a completely new phenomenon facing supply chain managers; understanding the interrelationships between critical success factors of supply chain sustainability can add great value [10]. However, literature on COVID-19 is mainly limited to medical studies and thus highlights the need for investigation in the supply chain sustainability context. We therefore, aim to address the second research question namely;

RQ2: What is the interrelationship between the critical success factors that can empower supply chain resilience amid the COVID-19 pandemic?

The rest of the sections are organized as follows. Section 2 presents literature review followed by Sect. 3 that presents the ISM methodology and data analysis. The discussion is presented in Sect. 4 and conclusions are drawn in Section 4.

2 Literature Review

Critical success factors for supply chain sustainability amid COVID-19 pandemic were identified from literature review and presented below.

a) Technology readiness of organizations

- Technology readiness is essential to cope with supply chain disruptions such as the COVID-19 pandemic [7]. Advanced information and communication technologies do more than assisting in making timely decisions but also aid in factory automation; and thus, connecting the factory shop floor to the top floor (i.e., top management level) [11]. The COVID-19 pandemic and the resultant national lockdowns and social distancing have impacted the normal factory operations; which can be overcome by factory automation and use of digital systems to run production, quality checking and packing [12]. Technologies such as big data powered artificial intelligence can enhance sustainable manufacturing [13].

b) Historical disruption data analysis

- It has clearly been demonstrated that healthcare supply chains have not learned any lessons from previous epidemics such as Middle East Respiratory Syndrome (MERS) and Severe Acute Respiratory Syndrome (SARS) [14]. However, Ivanov and Dolgui [15] have argued that the analysis of historical disruption data can help in managing disruption risks.

c) Availability of real-time disruption data

- It is not possible for any supply chain to become fully immune from global shocks created by COVID-19; however, availability of real-time data can reduce the risks. Supply chain executives can collect real-time data, infer insights and take immediate actions. This will reduce the response times significantly and lower incidents of customer complaints. It is a necessity during a pandemic to access real-time disruption data and keep updated on the latest trends. China is considered a powerhouse of the global economy as they have shown ability to manufacture and supply products at low costs. However, with the onset of the novel coronavirus, thousands of factories had to shut their production units [16]. Consequently, supply chain managers need real time disruption data to assess the supply chain status and change strategies accordingly. Real-time disruption data thus proves to be an important agility mechanism for supply chain managers [15].

d) Ensure end-to-end visibility

- Supply chain managers must have end-to-end visibility to identify problems in the supply chain and take immediate actions. This has been recently confirmed by Ivanov and Dolgui [15] where they opined that end-to-end visibility is important for companies operating in international markets. Visibility in supply chains has reduced significantly during this COVID-19 pandemic [7]. Ivanov and Dolgui [15] emphasized on supply chain visibility to enhance end-to-end supply chain visibility and avert risks. Advanced supply chain visualizations can uncover the relationships behind big data sets. Other benefits include: data validation, chain-of-custody reporting, supplier benchmarking, supply chain planning and optimization, risk heat maps and alerts, emergency response and control tower-like visibility [21].

e) Derive values from technology deployment

- In this Industry 4.0 era harnessing the power of technology such as big data and artificial intelligence, automation, IoT, blockchain, edge computing, deep learning, advanced computing power, application programming interfaces and high-power satellites can help an organization become cautious about supply chain challenges and an organization can change strategies and practices to mitigate the same [7].

f) Prevent exploitation of workers

- It has been found that COVID-19 has triggered modern slavery. The pandemic has resulted in severe job losses in the last six months and existing employees fear job losses and thereby ready to overwork even after getting pay cuts/suffering from other mal-treatments. Trautrims et al. [17] cautioned that organizations need to prevent exploitation of workers in COVID-19 pandemic. Sharma et al. [7] opined that organizations need to take care of the health and wellbeing of their own employees and also need to consider the health and wellbeing of tier one and tier two suppliers’ employees to gain sustainability.

g) Consider the value of flexibility

- Remko [18] suggested organizations to consider the value of flexibility. For example, Sub-Saharan African countries need to put in place flexible but effective policies and legislation approaches that harness and formalise the informal trade and remove supply chain barriers. This could include strengthening cross-border trade facilities such as adequate pro-poor, gender-sensitive, and streamlined cross-border customs, tax regimes, and information flow [19]. Additive manufacturing has proven to enhance flexibility in COVID-19 pandemic and organizations need to adopt flexibility to gain sustainability [20].

h) Short response times

- It is essential that organizations devise strategies to ensure short response times to changes in their business environment [18]. The more agile an organization is, the better its chances for survival during the COVID-19 pandemic [1].

i) Adoption of multiple supply sources

- Adoption of multiple supply strategy has become more important for managing supply risks [18]. In the current pandemic, some suppliers may be located in red zones (high spread of infection) resulting in restricted business operations and supply shortages Therefore, dependency on a few of suppliers is no longer a viable option for organizations; instead, organisations are increasingly adopting multiple supplier sourcing strategies to ensure continuity of timely supplies for production [18].

j) Near shore and local sourcing

- Near shore and local sourcing is suggested by Remko [18] as another strategy to ensure supply chain sustainability in the face of a global pandemic. The closure of international borders resulting from national lockdowns amid the COVID-19 pandemic, necessitates near shore and local sourcing of raw material in order to sustain business operations. Most importantly, the sustainability standards need to be checked [17].

k) Greater utilization of information technology

- It was suggested by Remko [18] that supply chain managers need to undertake greater utilization of information technology to drive more complete and immediate information availability for quality decision making and that too in a timely manner.

l) Collaboration with external stakeholders

- Collaboration with external stakeholders results in supply chain sustainability and enhances competences to sustain business operations particularly during a pandemic such as the COVID-19 pandemic [7]. Literature indicates that more intensive information exchange and collaboration with unions, NGOs, and other expert stakeholders increases supply chain transparency and allows for a proactive detection of early warning signals on deteriorating conditions even when physical audits are disrupted [17].

m) Develop a collaborative culture

- A collaborative organizational culture is a very important factor in ensuring collaboration with suppliers and customers to make timely production and dispatches. Literature indicates that greater collaboration among value chain members is required to create a more resilient supply chain [7].

n) Synchronize strategic processes

- is essential that organizations focus on synchronization of strategic processes [7]. If an organization mechanizes processes by converting into intelligent workflows—starting from managing demands to dispatch strategies, organizations will provide a platform to processes, people and technology to interact. This will bridge the current gap in a firm’s ability to feel the changes in the environment, respond to that with the help of intelligent workflows, and generate required businesses [7].

o) Supply chain resilience

- Supply chain disruptions can result in significant economic downturn. Resilience is the ability to deal with sudden changes in business environment while retaining the organization’s basic functions [22]. Supply chain resilience has turned out to be one of the key factors amid COVID-19 pandemic for managing risks and enhancing supply chain sustainability [23].

3 Research Method

3.1 Interpretive Structural Modelling (ISM)

The ISM methodology is used in this study to develop the structural model. This technique was popularized by Sushil [24, 25]. The critical success factors (CSFs’) for enhancing supply chain sustainability amid COVID-19 pandemic are identified from the literature review and further refined using two experts’ opinion. Therefore, the CSFs’ are validated in context to South Africa. The final list of Critical success factors (CSFs’) is presented in Table 1.

The second step in ISM involves examining the contextual relationship between pairs of critical success factors/elements. A questionnaire was used to collect the responses from five referees, who are working in the heavy engineering sector for more than 20 years. We applied the statistical function “mode” to develop the aggregate structural self-interaction matrix (SSIM).

The aggregate structural self-interaction matrix (SSIM) in Table 2, is based on the notations below which denote the direction of relationships between variables (i and j):

V: i lead to j but j does not lead to i

A: i do not lead to j but j lead to i

X: i lead to j and j lead to i

O: i and j are unrelated to each other

The SSIM has been converted into a binary matrix, i.e., the reachability matrix (Table 3) by substituting V, A X and O by 1 and 0. The substitution rule is explained below:

-

If the (i, j) entry in the SSIM is V, then the (i, j) entry in the reachability matrix becomes ‘1’ and (j, i) entry becomes ‘0’

-

If the (i, j) entry in the SSIM is A, then the (i, j) entry in the reachability matrix becomes ‘0’ and (j, i) entry becomes ‘1’

-

If the (i, j) entry in the SSIM is X, then the (i, j) entry in the reachability matrix becomes ‘1’ and (j, i) entry also becomes ‘1’

-

If the (i, j) entry in the SSIM is O, then the (i, j) entry in the reachability matrix becomes ‘0’ and (j, i) entry also becomes ‘0’

The transitivity principle is checked in this step. If element i leads to element j and element j leads to element k, then element i should lead to element k. By transitivity embedding, the final reachability matrix is obtained as shown in Table 4.

The level partitioning is done in this stage. After the first iteration, the variable classified to level 1 are discarded and the partitioning process is repeated on the remaining variable to determine the level 2. These iterations are continued until the level of each variable is completed. The results for iterations 1 to 9 are summarised in Table 5.

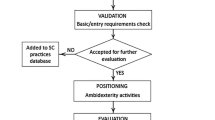

The structural model is developed using nodes and lines of edges. The digraph is presented in Fig. 1.

From ISM digraph we developed the ISM model (refer Fig. 2).

4 Conclusion

Byron and Thatcher [26] indicated that one of the more intimidating challenges researchers face is in understanding theory and theory-building. The following questions circle on the mind of researchers such as (a) What is (and isn’t) theory? (b) Should we care about theory? (c) Where do new theories come from? (d) How do you build a good theory? and lastly (d) How do you get your theory published?

Referring back to the building blocks of theory suggested by Whetten [27] which articulates theory as consisting of following fundamental things: What and How (description), Why (explanation), and Who, Where, When (boundary conditions) we further explain our research findings to extend the knowledge base.

In the current study which is exploratory in nature; we have used ISM technique to build theory and answer two key questions- What, and How. We have answered as to what are the critical success factors for supply chain sustainability amid COVID-19 pandemic. Second, we have also answered-how these critical success factors been interrelated. The bottom level CSF i.e., development of collaborative culture is very important and more attention is required on this element as it influences the final outcome i.e., supply chain resilience. Figure 2 provides a clear understanding about how to use this model as it demonstrates the interrelationships between all variables.

References

Ivanov, D.: Predicting the impacts of epidemic outbreaks on global supply chains: a simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E: Logistics Transp. Rev. 136, 101922 (2020a)

Basole, R.C., Bellamy, M.A.: Supply network structure, visibility, and risk diffusion: a computational approach. Decis. Sci. 45(4), 753–789 (2014)

Ivanov, D., Dolgui, A.: New disruption risk management perspectives in supply chains: digital twins, the ripple effect, and resileanness. IFAC-PapersOnLine 52(13), 337–342 (2019)

Kırılmaz, O., Erol, S.: A proactive approach to supply chain risk management: shifting orders among suppliers to mitigate the supply side risks. J. Purch. Supply Manag. 23(1), 54–65 (2017)

Lai, Y., Sun, H., Ren, J.: Understanding the determinants of big data analytics (BDA) adoption in logistics and supply chain management. The International Journal of Logistics Management (2018). https://doi.org/10.1108/IJLM-06-2017-0153

Giannakis, M., Papadopoulos, T.: Supply chain sustainability: a risk management approach. Int. J. Prod. Econ. 171, 455–470 (2016)

Sharma, A., Adhikary, A., Borah, S.B.: Covid-19’s impact on supply chain decisions: strategic insights for NASDAQ 100 firms using Twitter data. J. Bus. Res. 117, 443–449 (2020)

Liu, Y., Lee, J.M., Lee, C.: The challenges and opportunities of a global health crisis: the management and business implications of COVID-19 from an Asian perspective. Asian Bus. Manag. 19, 277–297 (2020)

Queiroz, M.M., Ivanov, D., Dolgui, A., Wamba, S.F.: Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Annals of Operations Research, pp. 1–38 (2020)

Sarkis, J.: Supply chain sustainability: learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 41(1), 63–73 (2021)

Telukdarie, A., Buhulaiga, E., Bag, S., Gupta, S., Luo, Z.: Industry 4.0 implementation for multinationals. Process Safety Environ. Prot. 118, 316–329 (2018)

Malik, A.A., Masood, T., Kousar, R.: Repurposing factories with robotics in the face of COVID-19. Science Robotics, vol. 5, no. 43 (2020). https://doi.org/10.1126/scirobotics.abc2782

Bag, S., Pretorius, J.H.C.: Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. International Journal of Organizational Analysis (2020). https://doi.org/10.1108/IJOA-04-2020-2120

Peeri, N.C., et al.: The SARS, MERS and novel coronavirus (COVID-19) epidemics, the newest and biggest global health threats: what lessons have we learned?. Int. J. Epidemiol. 49(3), 717–726 (2020). https://doi.org/10.1093/ije/dyaa033

Ivanov, D., Dolgui, A.: A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control, pp. 1–14 (2020)

Wang, J., Wang, Z.: Strengths, weaknesses, opportunities and threats (Swot) analysis of china’s prevention and control strategy for the covid-19 epidemic. Int. J. Environ. Res. Public Health 17(7), 2235 (2020)

Trautrims, A., Schleper, M.C., Cakir, M.S., Gold, S.: Survival at the expense of the weakest? managing modern slavery risks in supply chains during COVID-19. J. Risk Res. 23(7-8), 1–6 (2020)

Remko, V.H.: Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 40(4), 341–355 (2020)

Renzaho, A.: The need for the right socio-economic and cultural fit in the COVID-19 response in sub-saharan Africa: examining demographic, economic political, health, and socio-cultural differentials in COVID-19 morbidity and mortality. Int. J. Environ. Res. Public Health 17(10), 3445 (2020)

Ivanov, D.: Viable supply chain model: integrating agility, resilience and sustainability perspectives—lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research, pp. 1–21 (2020b)

Sourcemap white paper: End-to-End supply chain visualization. https://static1.squarespace.com/static/56ad86dffd5d088a88b8a425/t/5d2cdef8dd52da000123cca1/1563221752511/End-toEnd%2BSupply%2BChain%2BVisualization%2Bby%2BSourcemap.pdf

Holling, C.S.: Resilience and stability of ecological systems. Annu. Rev. Ecol. Syst. 4(1), 1–23 (1973)

Ivanov, D., Das, A.: Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: a research note. Int. J. Integr. Supply Manag. 13(1), 90–102 (2020)

Sushil. Interpretive ranking process’. Glob. J. Flexible Syst. Manag. 10(4), 1–10 (2009)

Sushil. Interpreting the interpretive structural model. Glob. J. Flexible Syst. Manag. 13(2), 87–106 (2012)

Byron, K., Thatcher, S.M. (Eds) Comments: “What I know now that I wish I knew then”—teaching theory and theory building. Academy of Management Review, vol. 41, no. 1 (2016). https://doi.org/10.5465/amr.2015.0094

Whetten, D.: What constitutes a theoretical contribution? Acad. Manag. Rev. 4, 490–495 (1989)

Golan, M.S., Jernegan, L.H., Linkov, I.: Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Decis. 40(2), 222–243 (2020). https://doi.org/10.1007/s10669-020-09777-w

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 IFIP International Federation for Information Processing

About this paper

Cite this paper

Bag, S., Kilbourn, P., Pisa, N., Giannakis, M. (2021). Key Success Factors for Supply Chain Sustainability in COVID-19 Pandemic: An ISM Approach. In: Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D. (eds) Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, vol 633. Springer, Cham. https://doi.org/10.1007/978-3-030-85910-7_76

Download citation

DOI: https://doi.org/10.1007/978-3-030-85910-7_76

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85909-1

Online ISBN: 978-3-030-85910-7

eBook Packages: Computer ScienceComputer Science (R0)