Abstract

The article’s objective was to develop a method for analyzing the operational reliability of means of transport, emphasizing destructive factors affecting the disruptions in the continuity of supply. The introduction contains a diagram of the occurrence of adverse events in the transport system. The concept of reliability analysis of rolling stock based on two conditions (its fitness and unfitness) was presented. We describe the proposed method in three stages. The first one is related to activities aimed at extending the fitness condition of the rolling stock. As part of this stage, destructive factors were classified, depending on the rolling stock life cycle phase, with degradation parameters identified and characterized. The second stage concerns diagnostic activities. An approach to assessing damage based on the diagnostic indicator, which resulted in the so-called diagnostic matrix’s suggestion, was developed. The last stage of the presented method includes repair activities, based on which the concept of applying risk measures, including the risk measure of rolling stock unavailability, was introduced. The results acquired based on the presented method are designed to provide data enriching the decision-making process in transport activities, aimed at reducing the risk of failure to perform the transport task. The method of analyzing the reliability of means of transport presented in our work forms part of the author’s work on developing a comprehensive analysis of the operational reliability of transport systems.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Road transport plays a dominant role in cargo transport in many different countries. It is largely implemented by lorries in the form of road sets consisting of a tractor unit and a semi-trailer. It should be noted that the road rolling stock is one of the elements of the transport system, the reliability of which is of crucial importance for the correct functioning of national economies. There exist many different approaches to reliability concerning transport systems. One of them assumes that the reliability of the system equals the probability of performing the transport task. Transport disruptions may occur in all parts of the transport system, i.e., road infrastructure, rolling stock, technical facilities, organizational division, etc. However, issues related to infrastructure and road rolling stock play a crucial role here. In connection in addition to that, the reliability models were identified, which include:

-

infrastructure failure models,

-

rolling stock failure models,

-

rolling stock reliability models,

-

models taking into account the time and operating cycles of the rolling stock,

-

load-endurance models of vehicle structures and infrastructure.

All these models can be either analytical, stochastic, or combined. If the system fails to operate as intended, there has been a loss of reliability. It can adopt different forms, including the partial loss of reliability, e.g., due to a failure of a subsystem of a vehicle, which allows, although with some limitations, to continue the transport, or the total loss of reliability that renders further transport impossible, e.g., due to destruction of means of transportation in consequence of an adverse event. Figure 1 presents the diagram of the occurrence of adverse events in the transport system.

The presented diagram shows the cyclicality of adverse events occurring during the operation of the transport system. Most of them are left without consequences. Nevertheless, some of them lead to a loss of system reliability of a long-term nature. In these situations, the inability to continue the transport task may lead to its complete non-performance and the loss of the transported load. To prevent this, on the one hand, research is carried out to prevent the occurrence of adverse events and, on the other hand, to alleviate negative effects, e.g., by quickly restoring the system’s reliability they occur. In the case of heavy goods vehicles, it is important to research both to increase their operational reliability and restore this condition as quickly as possible in the event of its loss, both of which are the present article’s objective.

2 Literature Review

Transport systems in the context of their reliability are a frequent topic of scientific research. In some cases, the transport system is considered [1,2,3,4,5], and on other occasions, it is divided. This division includes such elements as infrastructure, means of transport, traffic control systems, organizational, legal, and institutional divisions. The important issue from the viewpoint of the present publication, at least as far as road infrastructure reliability is considered, is the occurrence of disturbances discussed, among other things, in [6,7,8,9]. Furthermore, the concept of road infrastructure reliability inevitably links us with the concepts of the durability of technical structures, such as bridges [10, 11]. Due to the proposed analysis of the reliability of the transport system narrowed down to one of its elements, i.e., means of transport, our review of subject literature focused primarily on issues related to diagnostic and repair activities and the risk of failure to perform the transport task related to rolling stock’s loss of reliability. The diagnostics issues as an activity impacting the reliability of technical structures [12, 13] may include both individual elements and entire systems present in means of transport [14,15,16]. Particularly noteworthy are the onboard and remote diagnostics mentioned below in the present article, which were the research subjects [17,18,19,20] in the last few years. Carrying out diagnostics and repair activities forms the starting point for determining the risk of non-performance of the transport task [21, 22], which was the final part of the author’s research. Based on the conducted analysis of the subject literature on the methods of determining risk measures [23,24,25], we elaborated a concept of measuring the risk of failure to perform the transport task.

3 Research Methodology

Maintaining the operational reliability of means of transport plays a crucial role in maintaining the continuity of supplies. In reality, we observe certain operating cycles, and we can simulate their course. These cycles typically include several conditions, i.e.:

-

fitness condition and connected reliability of the means of transport,

-

condition of partial unfitness in which it is possible to perform transport tasks, albeit after taking certain limitations into account,

-

condition of unfitness, preventing the implementation of tasks.

Different tasks are performed, depending on the current cycle of the means of transport. In the first of them - the condition of fitness - measures are taken to extend it. These activities include, among others use of the means of transport according to their purpose, ensuring structural strength and efficiency of systems at the production stage, servicing.

The second condition, partial failure, has the most complex characteristics and is also the most common practice condition. What can be related to the complexity of a technical structure in the form of means of transport? Partial unfitness adopts many different forms, from a mild scenario to an extremely destructive one. Damage to parts increasing the comfort of the driver, such as the radio, is of marginal importance in the context of the possibility of performing the transport task, otherwise, when there is damage, for example, to a refrigeration unit when transporting perishable cargo, the vehicle can, at least physically, continue to perform the transport, but there is a serious risk of loss cargo properties, which may lead to failure to perform the transport task. Therefore this particular condition has a non-uniform structure, requiring us to introduce a classification for different failures.

The ultimate condition - the condition of total unfitness - adopts two different forms. The first one concerns the condition in which the means of transport cannot be restored to fitness, or at least such actions are not economically justified, and the vehicle is permanently excluded from further operation. The second form assumes the possibility (and economic justification) for restoring the condition of fitness. For this purpose, diagnostic activities are carried out.

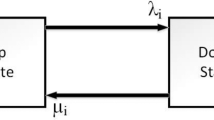

Figure 2 presents a general outline of the transitions of means of transport between the conditions of fitness and unfitness, along with an attempt to restore the desired condition. Based on the presented diagram, we elaborated a method for analyzing the rolling stock’s operational reliability, consisting of three stages, with particular emphasis on destructive factors affecting the disruptions in the continuity of supplies and diagnostic and corrective actions aimed at eliminating the disruptions as mentioned above.

Stage I: Activities Aimed at Extending the Roadworthiness of the Rolling Stock

Analysis and classification of factors that impact the possible transition to the condition of unfitness:

-

factors of a violent nature, e.g., road collisions, causing a sudden transition to the condition of unfitness in the result of one or more features of the means of transport transferring beyond acceptable standards,

-

factors of a reversible nature, e.g., tire wear, predictable and characterized by the ease with which they can be counteracted,

-

factors of a slow nature, i.e., aging processes, wear processes, etc., in which case, despite the awareness of their occurrence, it is difficult to determine the moment of transition to the condition of unfitness.

At this stage, the classification of possible degradation factors was also proposed within the adopted classification parameters and types of damage. This classification was based on seven parameters:

-

1.

occurrence of failure, types: rapid, gradual, cascade;

-

2.

connection with other damages, types: dependent, independent;

-

3.

repairability, types: full, partial, impossible;

-

4.

necessity to perform repair, types: immediate, recommended, optional;

-

5.

detectability, types: high, low;

-

6.

causes of occurrence, types: natural, artificial;

-

7.

time-consuming repair, types: high, low.

The analysis and classification aimed to provide tools supporting the decision-making process aimed at extending the fitness of the means of transport.

Stage II: Diagnostic Activities

Diagnostics are used to examine the current condition and identify possible faults. Defects occurring in means of transport can be very diverse, and therefore there exists a wide variety of diagnostic tools. Based on the literature review, we identified the diagnostic methods. These methods can be divided into traditional ones, i.e., functional control, condition control, fault location, and mathematical methods, i.e., deterministic, stochastic, and simulation models. The comparative analysis of the measured parameters and their comparison to theoretical values is also a frequently applied method.

Diagnostics also supports the decision-making process related to servicing the operated rolling stock and allows us to assess whether the rolling stock’s condition was restored.

Diagnostic systems should be considered according to two categories. Internal, concerning onboard equipment and decision support systems, and external, i.e., stationary (workshop-installed) and mobile (which can be performed in road conditions) diagnostics. An important part of diagnostics is the tests of accident-damaged means of transport. On their basis, parameters such as the roadworthiness/unfitness of the vehicle, the damage and the mechanisms of its occurrence, the possibility of repair, etc., are all determined.

Stage III: Repair Activities

Repair activities are directly related to diagnostics. Their implementation is possible only after the identification of damaged parts. As was the case in stage II, repair activities can be divided into those performed in road conditions (mobile) and those performed in workshop conditions (stationary). In the case of cargo transport, especially in the context of perishable cargo, ad hoc repairs play an important role, enabling the continuation of transport, taking into account the limitations resulting from less repair possibilities under road conditions. Nevertheless, there are economic reasons for this, because the disruption of the continuity of transport is often associated with failure to meet delivery terms, which results in contractual penalties. The recent development of services in the just-in-time system further strengthens the requirement to create a network of mobile diagnostic and repair centers.

The methodology of analysis of operational reliability of means of transport and its restoration methods presented in our work forms one of the elements of the author’s work on the creation of a comprehensive assessment of operational reliability of transport systems.

4 Results

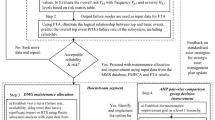

The results will be discussed in stages proposed in the methodology. Stage I: What is important is that not every defect leads to permanent damage to the vehicle. Therefore, cyclical reliability assessments should be carried out by analyzing changes occurring in the used vehicle. In addition, it is recommended to prepare forecasts of the impact of individual factors, depending on environmental conditions. The impact assessment of individual factors on the fitness of the rolling stock was classified according to the phases of the life cycle of the means of transport and presented in Table 1.

Stage II: Damage assessment can be performed using a comparative analysis of functional parameters f(x). According to the theory, each of the parameters can take values within the defined min-max range. Moreover, the so-called diagnostic indicator λ, which determines whether the parameter has exceeded the permissible values, may adopt the value 0 or 1. In the case of fault diagnosis, it is assumed that the diagnostic indicator λ = 1, when:

In the case of no failure, when the diagnostic indicator λ = 0, the following relationship is satisfied:

The application of the above method enables the creation of a matrix of diagnostic results, as presented in Table 2.

Stage III: We developed risk measures to obtain indicators enabling the assessment of the risk of failure to perform the transport task. These measures were divided into several issues. One of them is the calculation of the risk measure of the rolling stock unavailability RMRSU, calculated as the ratio of the average rolling stock availability time to the sum total of this time and the duration of diagnostic and repair activities, i.e.:

where: \(T\left(z\right)\)- the average service life of the rolling stock, \({T}_{DN}\)- average time of diagnostic and repair activities.

The comprehensive analysis of the risk of failure to perform the transport task will be further enriched with the risk measure of an undesirable event, as developed by the author.

5 Conclusions

Developing an effective strategy to extend the roadworthiness of road rolling stock requires in-depth knowledge of the phases of the life cycle of vehicles and the factors contributing to the formation of degradation processes in technical systems.

The conducted research on car diagnostics allowed us for their division into stationary and mobile diagnostic activities. The latter is particularly important in terms of maintaining continuity of supplies. One of the most common reasons necessitating diagnostic operations is the occurrence of damage, e.g., due to a collision. It is connected with the intensive exploitation of these vehicles. The proposed diagnostic indicator enables the assessment of the tested object’s suitability based on a comparative analysis of its functional parameters. In the event of a condition of unfitness, it is necessary to carry out corrective actions. Whenever possible, it is recommended to perform the repair in road conditions, but if this proves impossible, there is a need to send a replacement unit, which contributes to delays and, consequently, to failure to perform the transport task. Considering the issues mentioned earlier, a measure of the risk of failure to perform the transport task was elaborated, based on the average time the means of transport remain in a fit condition and the average duration of diagnostic and repair activities.

Based on the method for assessing the reliability of means of transport presented in the paper, we can conclude that it is justified to develop a comprehensive methodology for evaluating the reliability of transport systems with a holistic approach, applying system analysis.

References

Soltani-Sobh, A., Heaslip, K., Stevanovic, A., El Khoury, J., Song, Z.: Evaluation of transportation network reliability during unexpected events with multiple uncertainties. Int. J. Disaster Risk Reduct. 17, 128–136 (2016)

Walther, C., Niemeier, E.: Reliability in transport systems: what do we really know? In: 26th World Road Congress World Road Association (PIARC) (2019)

Gidebo, F.A., Szpytko, J.: Reliability assessment of the transport system, Addis Ababa case study. J KONBiN 49(4), 27–36 (2019)

Shramenko, N., Muzylyov, D.: Forecasting of overloading volumes in transport systems based on the fuzzy-neural model. In: Ivanov, V., et al. (eds.) DSMIE 2019. LNME, pp. 311–320. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-22365-6_31

Semenov, I.N., Filina-Dawidowicz, L.: Topology-based approach to the modernization of transport and logistics systems with hybrid architecture. Part 1. Proof-of-concept study. Arch. Transp. 43, 105–124 (2017)

Jacyna, M., Żak, J.: Simulation models in testing reliability of transport process. J. KONBiN 37(1), 203–230 (2016)

Islam, M.R., Kalevela, S.A., Rivera, J.A., Rashid, T.B.: Dynamic modulus and field performance of cold-in-place recycled asphalt pavement. J. Eng. Sci. 6(2), B1–B7 (2019). https://doi.org/10.21272/jes.2019.6(2).b1

Kawa, A., Anholcer, M.: Exclusionary constraints in transport-results of quantitative research. LogForum 16(4), 573–592 (2020)

Kim, H., Kim, C., Chun, Y.: Network reliability and resilience of rapid transit systems. Prof. Geogr. 68(1), 53–65 (2016)

Teichgraeber, M., Hawryszków, P.: The SHM system as a data source for durability assessment. Case study of Rędziński Bridge stay cable system. MATEC Web Conf. EDP Sci. 219, 03012 (2018)

Soltani-Sobh, A., Heaslip, K., Scarlatos, P., Kaisar, E.: Reliability based pre-positioning of recovery centers for resilient transportation infrastructure. Int. J. Disaster Risk Reducti. 19, 324–333 (2016)

Pavlenko, I., Ivanov, V., Kuric, I., Gusak, O., Liaposhchenko, O.: Ensuring vibration reliability of turbopump units using artificial neural networks. In: Trojanowska, J., Ciszak, O., Machado, J.M., Pavlenko, I. (eds.) MANUFACTURING 2019. LNME, pp. 165–175. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-18715-6_14

Pavlenko, I., Trojanowska, J., Ivanov, V., Liaposhchenko, O.: Parameter identification of hydro-mechanical processes using artificial intelligence systems. Int. J. Mechatron. Appl. Mech. 2019(5), 19–26 (2019)

Goncharov, A.E., Bondarenko, E.V., Krasnoshtanov, S.Y.: Theoretical aspects of diagnostics of car as mechatronic system. MS&E 327(4), 042037 (2018)

Fedotov, A.I., Kuznetsov, N.Y., Lysenko, A.V., Vlasov, V.G.: Car suspension system monitoring under road conditions. In: AIP Conference Proceedings, vol. 1915, no. 1, p. 040014. AIP Publishing LLC. (2017)

Komorska, I., Wółczyński, Z.: Fault diagnostics of air intake system of the internal combustion engine. In: Timofiejczuk, A., Łazarz, B.E., Chaari, F., Burdzik, R. (edS.) ICDT 2016. ACM, vol. 10, pp. 91–100. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-62042-8_8

Dragojević, M., Stević, S., Stupar, G., Živkov, D.: Utilizing IoT technologies for remote diagnostics of next generation vehicles. In: 2018 IEEE 8th International Conference on Consumer Electronics-Berlin (ICCE-Berlin), pp. 1–4. IEEE (2018)

Kalmeshwar, M., Prasad, K.N.: Development of on-board diagnostics for car and it’s integration with Android mobile. In: 2017 2nd International Conference on Computational Systems and Information Technology for Sustainable Solution (CSITSS), pp. 1–6. IEEE (2017)

Naik, P., Kumbi, A., Telkar, N., Kotin, K., Katti, K.C.: An automotive diagnostics, fuel efficiency and emission monitoring system using CAN. In: 2017 International Conference on Big Data, IoT and Data Science (BID), pp. 14–17. IEEE (2017)

Kirthika, V., Vecraraghavatr, A.K.: Design and development of flexible onboard diagnostics and mobile communication for internet of vehicles. In: 2018 International Conference on Computer, Communication, and Signal Processing (ICCCSP), pp. 1–6. IEEE (2018)

Vilko, J., Ritala, P., Hallikas, J.: Risk management abilities in multimodal maritime supply chains: visibility and control perspectives. Accid. Anal. Prev. 123, 469–481 (2019)

Goloshchapova, L., Plaskova, N., Prodanova, N., Yusupova, S., Pozdeeva, S.: Analytical review of risks of loss of profits in cargo transportation. Int. J. Mech. Eng. Technol. 9(11), 1897–1902 (2018)

Filina-Dawidowicz, L., Iwańkowicz, R., Rosochacki, W.: Risk measures of load loss during service of refrigerated containers in seaports. Archiv. Transp. 34, 19–27 (2015)

Antosz, K., Stadnicka, D.: Evaluation measures of machine operation effectiveness in large enterprises: study results. Maint. Reliab. 17, 107–117 (2015)

Świderski, A., Jóźwiak, A., Jachimowski, R.: Operational quality measures of vehicles applied for the transport services evaluation using artificial neural networks. Maint. Reliab. 20, 292–299 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Trojanowski, P., Trojanowska, J. (2021). Reliability of Road Transport Means as a Factor Affecting the Risk of Failure – The Transport Problem Case Study. In: Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D. (eds) Advances in Design, Simulation and Manufacturing IV. DSMIE 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-77719-7_26

Download citation

DOI: https://doi.org/10.1007/978-3-030-77719-7_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77718-0

Online ISBN: 978-3-030-77719-7

eBook Packages: EngineeringEngineering (R0)