Abstract

Biochemical selectivity profiling is an integral part of early drug development. Typically compounds from optimization phase are regularly tested for off-target activities within or across target families. This article presents workflow and critical aspects of biochemical protein kinase profiling based on microfluidic mobility shift assays.

Access provided by CONRICYT – Journals CONACYT. Download protocol PDF

Similar content being viewed by others

Key words

1 Introduction

Protein kinases belong to the most important families of pharmaceutical targets. However, it took several scientific break-through, from the discovery of protein phosphorylation as regulatory mechanism [1, 2], to become a highly investigated class of drug targets. Despite initial doubts about the general “druggability” of this target class [3], several inhibitors had been described [4] and helped to better understand the roles and functions of kinases. Finally, the clinical success and subsequent approval of Gleevec (imatinib) in 2001 demonstrated protein kinases as valid drug targets. By now, 28 small-molecule protein kinase inhibitors have been approved by the FDA and many more have entered clinical studies [3, 5].

One hallmark of protein kinases as target family is that they share a highly conserved binding site for ATP. While this provides a well-defined pocket that can be targeted and explored by medicinal chemistry, the high degree of structural similarity between different family members also raises concerns about the selectivity of inhibitors and thus, the safety of drug candidates. This question is addressed throughout the development of kinase inhibitors and starts early in the drug development process, typically by testing candidate compounds in panels of biochemical kinase assays. The size, composition, and assay technology of this selectivity testing can vary largely depending on the purpose, resources available, and stage in drug discovery. Many of these assays are also available as service by CROs, offering additional options and flexibility for groups with limited internal resources [6].

Biochemical kinase profiling became a quasi-standard within the pharmaceutical industry. Still, it needs to be clear that, as it is only one part of integrated drug discovery efforts, the value of profiling data has to be seen in the context of other information, such as data from cellular assays and pharmacokinetics.

Hand in hand with the growing interest in protein kinases, the number and variety of available tools and assay technologies to study kinases have increased. To provide a comprehensive overview of the available methods is out of scope for this article. However, several excellent reviews have been published on the topic [7, 8].

While, most available assay technologies can be used for profiling, some technologies are better suited for profiling, depending on assay conditions and reagent or reader requirements. Profiling usually involves parallel testing the same compounds in several assays, typically using different kinases. The objective for running those assays is to provide data that are able to guide the medicinal chemistry efforts by predicting cellular potency and selectivity. While it is not possible to simulate the full complexity of a cellular environment in single biochemical readouts, relevant cellular assays can be used as guidance during assay development and optimization.

Features expected from any assay technology and particularly required for profiling are robustness and flexibility with regard to assay conditions. Profiling assays can run for extended periods and are expected to deliver comparable results over time. For monitoring purpose, it is recommended to run reference compounds for each assay to control plate-to-plate variability and trends over time. Setting up kinase panels for compound profiling requires sufficient flexibility with regard to the assay conditions to allow biologically relevant assays and at the same time keep overall similar and defined conditions that allow comparison and interpretation of the results from different assays. Therefore, the number of specific reagents needed for individual assays (e.g., antibodies) should be minimized. A much discussed topic is the choice of the ATP concentration. A widely applied approach is to adjust the ATP concentration in each assay to the individual apparent K M of the enzyme under the chosen conditions. This leads to standardized assay sensitivity toward inhibitors across all assays. Alternatively, the preference maybe to run all assays at rather high ATP concentrations in order to simulate competition closer to the estimated ATP concentration in cells. However, some assay technologies have limitations with regard to the tolerated ATP concentration.

Different preferences and different prerequisites lead to different compromises and setups, and the chosen conditions must be taken into account when interpreting the results.

Aspects of kinase profiling not covered in the article are for example potency and selectivity assessment with regard to different kinase conformations, as well as “kinetic profiling” also looking at on- and off-rates of inhibitors [3, 9, 10].

We have chosen to use a microfluidic mobility shift technology, originally developed by Caliper technologies [11] (now part of PerkinElmer). Two types of readers are available in our profiling laboratory: the LC3000, a stand-alone reader with plate stackers and environmental controls, and the EZ-reader II, a smaller desktop instrument for single plates integrated in small lab automation systems.

The basic assay principle of this technology is based on the separation of phosphorylated and unphosphorylated peptides in an electric field due to their charge difference (more precisely charge over mass z/m difference) introduced by the kinase. Typically, kinase reactions are performed in regular 384 well microplates. This can be done with multiple plates on any automated liquid handling system. Kinase reactions are stopped and transferred to the reader (endpoint determination), or run continuously with the plate in the reader and repeated sampling (kinetic mode). The separation and detection are done in a microfluidic chip with 4 or 12 sippers (Fig. 1). For sampling, the plate is placed underneath the chip and lifted up until the sippers are submerged in the assay solution in the plate wells. A small volume (in the nanoliter range) is taken up by the sippers and transported into the flow cell of the chip. The transport and separation of molecules of different z/m ratios is achieved by a combination of continuous flow and electric field. The peptides used for kinase assays typically carry a fluorescent tag and their migration is monitored by laser excitation . For each well, the intensities of product peak (phospho peptide) and substrate peak (unphosphorylated peptide) are determined. The turnover of the enzymatic kinase reaction is expressed as product-sum ratio (p/(p + s)) (Fig. 2a, b) [12].

(a) Illustration of flow, separation, and detection of fluorescently labeled peptides in a microfluidic channel. Peptide substrates (blue) carrying a fluorescent label (yellow) are transported through the microfluidic system by constant flow. An electric field is applied to one part of the capillaries separating molecules with different charge/mass ratios, e.g., phosphorylated vs. unphosphorylated peptides. Each peptide is detected by laser- or LED-induced fluorescence . (b) Image of the detection output of repeated sampling from a kinase reaction (kinetic mode) showing the increase of the product peak (left peak) and decrease of the substrate peak (right peak)

We found the microfluidic mobility shift technology well suited for large-scale profiling of kinase inhibitors. The main advantages of the used method are the robustness of this assay, achieved by the separation and ratiometric quantitation of product and substrate , the fact that no further reagents are needed and the possibility of running continuous kinetic measurements. On the other hand, one drawback of the method is the limitation to peptide substrates that may not be available or feasible for each kinase.

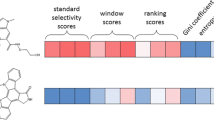

Larger data sets as generated from testing many compounds across broad kinase panels can be visualized as so called “heat maps.” Assay data are organized in tables assay ID vs. compound ID with color coded potency data. This visualization supports, e.g., the identification of specific (A) vs. promiscuous inhibitors (B) (Fig. 3).

Continued running of compounds across enzymatic panels under defined assay conditions quickly generates consistent, large data sets that can serve as valuable source for data mining. Several groups have published in-silico approaches trying to identify general principles for the explanation and better prediction of kinase inhibitor selectivity [13–15].

2 Materials

-

1.

Kinases: Many kinases can be obtained from commercial sources. They can carry tags for affinity purification, however, it is preferred to use proteins with cleaved tags in order to avoid potential interference with, e.g., activity or activation. Some kinases with special features, e.g., a defined phosphorylation state were prepared in-house.

-

2.

Substrates: Substrate peptides were usually ordered as custom synthesis from external vendors with either Fluorescein isothiocyanate (FITC) or 5-Carboxyfluorescein (5FAM) dye, joined via an aminohexanoic (Ahx) linker to the N- or C-terminus of the peptide. Some substrates may require additional modifications, such as phospho-amino acids for “pre-phosphorylation.” Peptides containing cysteine or methionine are sensitive to oxidation and therefore impurities. Those amino acids may be substituted on a case by case basis, if no impact on biological activity is apparent (see Notes 1 – 3 ).

-

3.

Compounds: Compounds were usually received as 10 mM stock solutions in DMSO . Test solutions were prepared by serial dilutions of the stocks in 90 % DMSO to cover the desired concentration range (see Note 4 ). Compounds were typically tested as 8-point dilutions with 10 μM as highest tested concentration. 50 nl of the prediluted compound solutions were transferred to the corresponding wells of the empty assay plate prior to addition of assay solutions using an Echo 555 (Labcyte).

-

4.

Assay buffer: 50 mM HEPES, pH 7.5, 1 mM DTT, 0.02 % Tween 20, 0.02 % BSA, 10 mM beta-glycerophosphate, 10 μM sodium orthovanadate. The concentrations for the kinase, ATP, and peptide substrate , as well as for MgCl2 and MnCl2 were adjusted to conditions optimal for the individual kinase. ATP concentrations were adjusted to the apparent K M for ATP for the respective kinase. Assay concentrations for the peptide substrate were adjusted to the apparent K M for the substrate peptide for the respective kinase if lower than 2 μM or set to 2 μM as the maximal arbitrary concentrations.

-

5.

2× enzyme mix: 2× assay concentration of kinase in 50 mM HEPES, pH 7.5, 1 mM DTT, 0.02 % Tween 20, 0.02 % BSA, 10 mM beta-glycerophosphate, 10 μM sodium orthovanadate.

-

6.

2× substrate mix: 2× assay concentration of peptide, ATP, and MgCl2/MnCl2 in 50 mM HEPES, pH 7.5, 1 mM DTT, 0.02 % Tween 20, 0.02 % BSA, 10 mM beta-glycerophosphate, 10 μM sodium orthovanadate.

-

7.

Stop buffer: 100 mM HEPES pH 7.5, 5 % DMSO , 10 mM EDTA, and 0.015 % Brij 35.

-

8.

Run Buffer: 100 mM HEPES pH 7.5, 5 % DMSO, 10 mM EDTA, and 0.015 % Brij 35, 0.1 % PerkinElmer coating reagent CR-3, 50 μM PerkinElmer coating reagent CR-8. Typically, 200 ml of running buffer was prepared and supplied in the appropriate reservoir of the reader for circulation in the chip and system.

-

9.

Wash Buffer: 0.001 % Pluronic F68 and 10 % Isopropanol in Milli-Q water.

-

10.

Plates: Assays are performed in black low volume 384 well plates. Compound dilutions were done in V-bottom 96-well polypropylene plates. 384-well polypropylene plates were used for compound master plates.

-

11.

Reader and chips: Plates with terminated kinase reactions were read in either a Labchip 3000 system or in an EZ-reader II. Both instruments were loaded with a Labchip 12-sipper chip allowing the analysis of 12 samples in parallel. Individual separation protocols were developed for each substrate peptide and optimized for the best combination of peak resolution and reading time (see Notes 1 – 3 ).

-

12.

Automation : All assays and protocols can be done also manually; however, the majority of profiling assays are done on automated liquid handling systems. A typical setup consists of a 16-channel Nanodrop express (Innovadyne) for contact-free reagent dispensing, an incubator STX40ICBT (Liconic Instruments), and a Twister II robotic arm (Perkin Elmer).

3 Methods

-

1.

Compound Preparation: All containers used for handling compounds including matrix tubes and plates were barcoded and registered in internal databases to allow status tracking at any time. Compounds were typically received as 10 mM stock solutions in 100 % DMSO in 1.4 ml Matrix tubes. Tubes were stored at 2 °C or at −20 °C for longer storage.

-

(a)

Pre-dilution plates: Four 96-well polypropylene plates were used to prepare serial dilutions of the test compounds. Each plate contained ten test compounds on the plate positions A1-A10, one standard compound at A11, and one DMSO control at A12. Rows B to H were used to prepare serial dilutions of the test compounds in 90 % (v/v) DMSO, by applying either a semi-log or 1:5 dilution depending on the desired concentration range.

-

(b)

Master plates: 100 μl of all individual compound solutions including standard compound and controls of the 4 “pre-dilution plates” were transferred into one 384 “master plate.” The final layout of the plate contains 8-point serial dilutions for 40 test compounds in the columns 1–20, four 8-point serial dilutions reference compounds in the columns 21 and 22, and DMSO controls in the columns 23 and 24. The DMSO controls in the last two columns are used for high and low controls of the assay.

-

(c)

Assay plates: Identical “assay plates” were prepared by dispensing 50 nl of compound solutions from the “master plates” into empty 384-well “assay plates” with an Echo 555 workstation. Other volumes may be dispensed for different concentration ranges. Typically, one assay plate is prepared for each enzyme/assay in the panel and one kinase is run per plate. Assay plates with pre-dispensed compound solutions are considered “ready-to-use,” however, can be stored over night at 4 °C if sealed or lidded. Each plate is used for one kinase assay.

-

(a)

-

2.

Manual Assays: The manual procedure is used for assay development and small campaigns with a limited number of targets. Pipetting steps are performed manually with electronic hand pipettes. Incubations for endpoint determinations were performed in an incubator at 30 °C and plates subsequently transferred to a PerkinElmer LC3000 for reading. For kinetic measurements, plates were incubated in the PerkinElmer LC3000 workstation. Kinase reactions were prepared in 384 standard volume plates by the following sequence:

-

(a)

0.1 μl Compound.

-

(b)

9 μl 2× peptide/ATP solution.

-

(c)

9 μl 2× enzyme solution.

-

(d)

Incubate for 60 min at 30 °C.

-

(e)

70 μl stop/run buffer.

-

(a)

-

3.

Automated Assays: The automated procedure is used for in-vitro kinase panel profiling with higher throughput. Compared to the manual procedure, the pipetting volumes were reduced by 50 % or modified according to automation requirements. Incubation time and temperature were kept identical. Liquid handling and incubation steps were done on a PerkinElmer Staccato workstation equipped with an Innovadyne Nanodrop Express. Between pipetting steps, tips were cleaned in wash cycles using wash buffer. Plates with terminated kinase reactions were transferred to the PerkinElmer LC3000 workstations for reading. Kinase reactions were prepared in 384 low volume plates by the following sequence:

-

(a)

0.05 μl Compound.

-

(b)

+4.5 μl 2× peptide/ATP solution.

-

(c)

+4.5 μl 2× enzyme solution.

-

(d)

Incubate for 60 min at 30 °C.

-

(e)

+16 μl stop/run buffer.

-

(a)

-

4.

Assay Development : A typical assay development consists of several steps and helps to define and optimize assay parameters such as enzyme concentration, substrate concentrations for ATP and peptide, and buffer composition. For automated testing of compound solutions, it is also advisable to test for DMSO tolerance and protein stability over time. Some assay parameters are kept constant, if possible, for reasons of automation and comparability. In our setup, those are for example, reaction time and temperature, buffer pH, detergent . It should, however, always be kept in mind that compromising on important biological parameters should be avoided in order to maintain biological relevance.

Except for the titration of Mg/Mn, all assays during assay development are typically done manually in kinetic mode. This ensures the linearity of the reaction and is particularly relevant with regard to stability and Michaelis-Menten kinetics.

-

(a)

Enzyme Titration : To determine the necessary enzyme concentration for further experiments, a serial dilution of the kinase is done in a standard buffer containing 0.5 mM ATP and 10 mM MgCl2. This is usually done as manual assay in kinetic mode. The aim is to use the lowest possible enzyme concentration as it determines the theoretical sensitivity of the assay. A reasonable starting point for further experiments is the enzyme concentration achieving 10–20 % turnover in 60 min.

-

(b)

Mg/Mn Titration : Protein kinases depend on the presence on bivalent cations for the coordination of ATP. Therefore, kinase assays usually contain either Mg2+ or Mn2+ or a mixture of both. The best concentration for a given kinase is determined by running assays with a 2-dimensional dilution of MgCl2 vs. MnCl2 at 0–10 mM (Fig. 4). Whenever possible, the preference should be given to MgCl2 alone for physiological reasons.

Fig. 4 Two-dimensional Titration of MgCl2 vs. MnCl2. Increasing concentrations of MgCl2 and MnCl2 and pipetted into the columns and rows of a 384-well micro plate generating mixtures of different Mg/Mn ratios. Buffer, ATP, peptide substrate , and kinase are added to start the kinase reaction. After 60 min incubation at 30 °C, the reactions are stopped and the plate analyzed in the reader. Enzymatic activity at the respective conditions is shown as percent turnover

-

(c)

K M Determinations: Once the final buffer conditions have been defined, the apparent Michaelis-Menten constants for the substrates are determined under those conditions. First, a twofold serial dilution of ATP is tested at 2 μM constant peptide concentration and the ATP concentration is determined leading to half-maximal activity. Second, a twofold serial dilution of the peptide is tested at the previously determined K M for ATP. Both titrations are done in kinetic mode to ensure the linearity of kinase reaction over time under the chosen conditions (Fig. 5). It should be noted that the analysis of the peptide titration is more difficult, since using variable concentrations of the labeled peptide leads also to variable peak sizes for substrate and product in the detection.

Fig. 5 -

(d)

DMSO Sensitivity: Once the assay conditions have been defined, the kinase reaction is tested under increasing concentration of DMSO (Fig. 6). This test is again performed in kinetic mode, to ensure that the enzyme reaction is stable over time at the desired DMSO concentration. A high sensitivity of an assay to DMSO can limit the maximal compound concentration that can be tested.

-

(a)

-

5.

Data Analysis .

-

(a)

Kinetic Data: Product -sum-ratios from different time points were exported from the reader software and imported to GraphPad Prism (Version 6.04; GraphPad software). Kinetics for, e.g., different enzyme or substrate concentrations were analyzed by linear regression. Obtained slopes are used as read-out for enzyme activity. Apparent K M values for substrates were determined by plotting slopes vs. substrate concentration and analyzed in GraphPad Prism by nonlinear regression using the equation (Eq. 1):

$$ V={V}_{\max}\cdotp \left[S\right]/\left(\left[S\right]+{K}_{\mathrm{M}}\right) $$(1) -

(b)

IC50 determination of kinase inhibitors: Product-sum-ratios from endpoint determinations were exported from the reader software and converted to percent inhibition using the high and low controls as reference (Eq. 2).

$$ \%\mathrm{i}\mathrm{n}\mathrm{h}=-100\times \left({\mathrm{PSR}}_{\mathrm{sample}}-{\mathrm{PSR}}_{\mathrm{LC}}\right)/\left({\mathrm{PSR}}_{\mathrm{HC}}-{\mathrm{PSR}}_{\mathrm{LC}}\right) $$(2)PSR: product-sum ratio p/(p + s).

LC: low control.

HC: high control.

IC50 values were calculated, using the standard Novartis in-house assay data analysis software (Helios software application, Novartis Institutes for BioMedical Research, unpublished) using the methods described by Normolle, Formenko et al., Sebaugh, Kelly et al., and Kahm et al. [16–20] (see Notes 5 and 6 ).

-

c.

Assay quality and consistency was monitored by calculating Z′ as plate-based quality parameter [21] and reference inhibitors on each plate (Fig. 7a, b) (see Note 7 ). Z′ values were calculated according to Eq. 3:

Fig. 7 $$ Z^{\prime }=1-\left(3\times \left({\mathrm{SD}}_{\mathrm{HC}}+{\mathrm{SD}}_{\mathrm{LC}}\right)/\left({\mathrm{MEAN}}_{\mathrm{HC}}-{\mathrm{MEAN}}_{\mathrm{LC}}\right)\right) $$(3)SD: standard deviation.

MEAN: arithmetic mean.

LC: low control.

HC: high control.

-

(a)

4 Notes

-

1.

It is advisable to order the labeled substrate peptides HPLC purified at the highest possible purity, e.g., ≥90 %. Problems can arise, if even small contaminants of 10 % or less that also carry the fluorescent label co-migrate with the product peak. If it is not possible to separate those two peaks by adapting the separation conditions, this will have a negative impact on the minimal turnover, necessary for robust determination of the product peak.

-

2.

Since the separation of substrate and product (unphosphorylated vs. phosphorylated peptide) is controlled by the z/m ratio, size and net charge of the substrate peptides should be considered during substrate design. Smaller peptides are preferable over large ones and good net-charges for the substrate are close to plus one or zero.

-

3.

Multiple phosphorylation sites should be avoided, since this could lead to more than one substrate peak and interfere with the analysis.

-

4.

Compound preparation has a big impact on assay quality. It is recommended to perform all compound dilutions in 90–100 % DMSO in order to avoid precipitations in intermediate DMSO/water mixtures. Dispensing of compounds directly from DMSO solutions might require low-volume dispensing technologies, such as the Labcyte Echo or the Hamilton Hummingbird, to keep the final DMSO concentration within the determined DMSO tolerance of the assay. 100 % DMSO solutions are prone to water uptake and require additional measures such as environmental controls or lidded containers. Use of 90 % DMSO limits further uptake of water and provides a stable condition for compound dilutions.

-

5.

The specific details of all assays are captured in an in-house assay registration database , linking the reported results to the applied assay conditions and allowing a better interpretation and understanding of the data.

-

6.

Single point vs. IC50: Since potencies of individual inhibitors often vary between different kinases, compounds are usually tested as dose-responses (yielding IC50 values for each compound) to allow better comparison than percent inhibition at a single concentration (Fig. 8). For large sets of compounds, it can be more economically to pretest at a single concentration (e.g., 10 μM) and retest only active compounds as dose response.

Fig. 8 Fitted dose–response curves for staurosporine tested with three different kinases, with IC50 values of 0.2, 3, and 235 nM. The respective %-inhibition values for single point testing at, e.g., 3 nM were −96, −53, and −4 %. Single point testing at 100 nM or higher would not have distinguished between kinase A and B

-

7.

High and low controls: High controls (maximal enzymatic activity) contain typically all assay reagents as in the other wells, but only DMSO instead of a compound solution. Negative controls (no enzymatic activity) can be achieved by omitting the kinase. However, we prefer to use all reagents including kinase with pre-dispensed EDTA stop solution.

References

Fischer EH, Krebs EG (1955) Conversion of phosphorylase b to phosphorylase a in muscle extracts. J Biol Chem 216:121–132

Krebs EG, Kent AB, Fischer EH (1958) The muscle phosphorylase b kinase reaction. J Biol Chem 231:73–83

Klebl B, Müller G, Hamacher M (2011) Protein kinases as drug targets. Methods and principles in medicinal chemistry, vol 49. Wiley, New York, NY

Cohen P (2002) Protein kinases - the major drug targets of the twenty-first century? Nat Rev Drug Discov 1:309–315

Wu P, Nielsen ET, Clausen MH (2015) FDA-approved small-molecule kinase inhibitors. Trends Pharmacol Sci 36(7):422–439

Comley J (2013) Outsourced kinase profiling services - adding value to in-house kinase programmes. Drug Discov World Fall 2013:26–45

Ma H, Deacon S, Horiuchi K (2008) The challenge of selecting protein kinase assays for lead discovery optimization. Exp Opin Drug Discov 3(6):607–621

Li H (2009) Review of biochemical assays for protein kinase drug discovery. Trends Bio/Pharmaceutical Ind 5(1):24–32

Chène P (2008) Challenges in design of biochemical assays for the identification of small molecules to target multiple conformations of protein kinases. Drug Discov Today 13(11/12):522–529

Heedmann B, Klumpp M (2015) Screening for inhibitors of kinase autophosphorylation. In: Janzen WP (ed) High throughput screening: methods and protocols, 3rd edn. Springer, New York, NY

Cohen CB, Chin-Dixon E, Jeong S, Nikiforov TT (1999) A microchip-based enzyme assay for protein kinase A. Anal Biochem 273:89–97

Perrin D, Frémaux C, Shutes A (2010) Capillary microfluidic electrophoretic mobility shift assays: application to enzymatic assays in drug discovery. Exp Opin Drug Discov 5(1):51–61

Miletti F, Hermann JC (2012) Targeted kinase selectivity from kinase profiling data. Med Chem Lett 3:383–386

Niijima S, Shiraishi A, Okuno Y (2012) Dissecting kinase profiling data to predict activity and understand cross-reactivity of kinase inhibitors. J Chem Inf Model 52:901–912

Jacoby E, Tresadern G, Bembenek S, Wroblowski B, Buyck C, Neef J-M, Rassokhin D, Poncelet A, Hunt J, van Vlijmen H (2015) Extending kinome coverage by analysis of kinase inhibitor broad profiling data. Drug Discov Today 20(6):652–658

Normolle DP (1993) An algorithm for robust non-linear analysis of radioimmunoassay and other bioassays. Stat Med 12:2025–2042

Formenko I, Durst M, Balaban D (2006) Robust Regression for high-throughput screening. Comput Methods Programs Biomed 82:31–37

Sebaugh JL (2011) Guidelines for accurate EC50/IC50 estimation. Pharm Stat 10:128–134. doi:10.1002/pst.426, http://onlinelibrary.wiley.com/doi/10.1002/pst.426/pdf

Kelly C, Rice J (1990) Monotone smoothing with application to dose-response curves and the assessment of synergism. Biometrics 46(4):1071–1085

Kahm M, Hasenbrink G, Lichtenberg-Frate H, Ludwig J, Kschischo M (2010) grofit: fitting biological growth curves with R. J Stat Softw 33(7):1–21

Zhang JH, Chung TDY, Oldenburg KR (1999) A simple statistical parameter for use in evaluation and validation of high throughput screening assays. J Biomol Screen 4:67–73

Acknowledgment

I would like to thank Shin Numao and Patrik Roethlisberger for their helpful input to the manuscript. I would like to thank Joerg Trappe for suggesting and encouraging the drafting of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media New York

About this protocol

Cite this protocol

Drueckes, P. (2016). Protein Kinase Selectivity Profiling Using Microfluid Mobility Shift Assays. In: Janzen, W. (eds) High Throughput Screening. Methods in Molecular Biology, vol 1439. Humana Press, New York, NY. https://doi.org/10.1007/978-1-4939-3673-1_9

Download citation

DOI: https://doi.org/10.1007/978-1-4939-3673-1_9

Published:

Publisher Name: Humana Press, New York, NY

Print ISBN: 978-1-4939-3671-7

Online ISBN: 978-1-4939-3673-1

eBook Packages: Springer Protocols