Abstract

Posttranslational modifications (PTMs) serve as molecular switches for regulating protein folding, function, and interactome and have been implicated in the misfolding and amyloid formation by several proteins linked to neurodegenerative diseases, including Alzheimer’s and Parkinson’s disease. Understanding the role of individual PTMs in protein misfolding and aggregation requires the preparation of site-specifically modified proteins, as well as the identification of the enzymes involved in regulating these PTMs. Recently, our group has pioneered the development of enzymatic, synthetic, and semisynthetic strategies that allow site-specific introduction of PTMs at single or multiple sites and generation of modified proteins in milligram quantities. In this chapter, we provide detailed description of enzymatic and semisynthetic strategies for the generation of the phosphorylated α-Synuclein (α-Syn) at S129, (pS129), which has been identified as a pathological hallmark of Parkinson’s disease. The semisynthetic method described for generation of α-Syn-pS129 requires expertise with protein chemical ligation, but can be used to incorporate other PTMs (single or multiple) within the α-Syn C-terminus if desired. On the other hand, the in vitro kinase-mediated phosphorylation strategy does not require any special setup and is rather easy to apply, but its application is restricted to the generation of α-Syn_pS129. These methods have the potential to increase the availability of pure and homogenous modified α-Syn reagents, which may be used as standards in numerous applications, including the search for potential biomarkers of synucleinopathies.

Access provided by CONRICYT – Journals CONACYT. Download protocol PDF

Similar content being viewed by others

Key words

- Parkinson’s disease

- Posttranslation modification

- Alpha-synuclein

- Amyloid

- Phosphorylation

- Semisynthesis

- Native chemical ligation

- Desulfurization

1 Introduction

The misfolding and aggregation of the normally soluble neuronal protein α-Synuclein (α-Syn) play key roles in the pathogenesis of Parkinson’s disease (PD) and several associated neurodegenerative disorders colloquially known as synucleinopathies [1]. One of most widely recognized clinical hallmarks of PD consists of intracellular proteinaceous inclusions known as Lewy Bodies (LBs), composed mainly of insoluble α-Syn amyloid fibrils. This fibrillar form of α-Syn bears several covalent posttranslational modifications (PTMs) including phosphorylation, ubiquitination, nitrative oxidation, and proteolysis [2], suggesting that these modifications play a role in α-Syn aggregation, LB formation, and/or clearance [2, 3]. The most abundant PTM in α-Syn is serine 129 phosphorylation; its distinctive upregulation under pathological conditions [4–6] and in the brain of transgenic mice of synucleinopathies has triggered great interest in this PTM as a potential biomarker for early diagnosis of synucleinopathies [6–8] and a potential target for therapeutic intervention. In addition to its probable role in the pathogenesis of PD, several recent reports suggest that phosphorylation at S129 plays important roles in regulating the α-Syn degradation via autophagy or the proteasome, its subcellular localization [9, 10], and putative physiological function(s) [11]. Therefore, a better understanding of how PTMs may influence α-Syn’s behavior in health and disease is crucial for understanding the normal function(s) of α-Syn and developing novel diagnostic and therapeutic strategies for early intervention and treatment strategies of PD and related disorders.

Elucidating the effect of PTMs on the structure, aggregation, and toxicity of α-Syn requires homogenous preparations of chemically well-defined α-Syn PTMs. A limited number of α-Syn PTMs, such as serine 129 phosphorylation, are amenable to preparation with great site specificity using enzymatic methods [2, 9], while others (especially ubiquitinated variants) can only be obtained as heterogeneous mixtures of products. For example, our group recently reported the in vitro and in vivo identification of Y39 phosphorylation in α-Syn, with c-Abl as the principal kinase phosphorylating at this site [12]. Although c-Abl mainly phosphorylates α-Syn at Y39, it also targets Y125 [12], especially under preparative in vitro phosphorylation conditions. Thus c-Abl phosphorylation is not suitable for studying the effects of α-Syn Y39 phosphorylation in isolation. Likewise, Y125-phosphorylated α-Syn cannot be efficiently prepared enzymatically, due to the lack of either efficiency or specificity of kinases phosphorylating the C-terminal tyrosine residues of α-Syn [13, 14]. Similar problems were reported in studies of α-Syn nitration, since chemically induced nitration generally shows very little site specificity [15, 16]. This limitation has been addressed by the introduction of mutations to allow chemically induced nitration or enzyme-mediated phosphorylation at a single site. However, this approach results in the introduction of up to three mutations, which could dramatically alter the conformational and aggregation properties of the protein. In order to overcome these limitations, our group has developed semisynthetic approaches based on expressed protein ligation (EPL [17, 18]) that provide access to milligram-scale preparations of site-specifically modified α-Syn that has been used to introduce N-terminal acetylation [19], mono-ubiquitination at K6 [20] and K12 [21], poly-ubiquitination [21, 22], phosphorylation at Y125 and S129 [23], and FRET probe pairs [24]. In addition, we developed a total chemical synthesis approach [25] that allows greater flexibility in the introduction of single or multiple PTMs or unnatural amino acids (such as fluorescent probes) at single or multiple sites within any region of the protein sequence. In particular, these tools greatly facilitate the study of cross-talks between different PTMs, which have been demonstrated before between pY125 and pS129 [26], as well as between K12 poly-ubiquitination and pS129 [22].

In this chapter, we focus on the S129 phosphorylation (α-Syn_pS129) of α-Syn, one of the most actively studied α-Syn PTM, and present two methods for preparing and purifying site-specifically S129-phosphorylated α-Syn. The first method makes use of a native chemical ligation (NCL) between a recombinant fragment consisting of α-Syn residues 1–106 and a synthetic peptide containing the residues 107–140 C-terminal domain and bearing the phosphorylated residue. This method could easily be adapted to accommodate other α-Syn PTMs within the C-terminal domain.

We also present an alternative approach to prepare α-Syn_pS129 using in vitro phosphorylation, which is significantly faster to perform than the semisynthetic method and offers the possibility to perform homogeneous isotopic labeling of the whole protein for NMR studies, whereas the semisynthesis-based method is suitable to introduce isotopic labeling only within the first 106 residues (i.e., the recombinantly expressed fragment), due to the fact that isotope-labeled amino acid building blocks for peptide synthesis are prohibitively expensive. However, a significant limitation of the in vitro phosphorylation approach is that it is restricted to a single PTM (pS129), as no other enzymes have been identified that both efficiently and site specifically modify α-Syn at the C-terminus so far.

2 Materials

All chromatography buffer solutions should be filtered (0.65 μm pore size or smaller) and degassed before use.

2.1 Instrumentation

-

1.

Incubator (static, 37 °C).

-

2.

Agitator for 1.5 mL tubes with heating capability (such as Eppendorf Thermo-Mixers).

-

3.

pH microelectrode able to take measurements in 1.5 mL plastic tubes (e.g., Hanna Instruments HI2212 pH meter with model HI1083B microelectrode).

-

4.

Standard instrumentation for casting polyacrylamide gels, for electrophoresis, gel staining, and imaging.

-

5.

Chromatography system (FPLC) for protein purification under aqueous conditions, such as Äkta systems (GE Healthcare). The FPLC system should be placed in a cold room.

-

6.

Chromatography system for reversed-phase HPLC, for example Waters 2535 pump and Waters 2489 UV/VIS detector.

-

7.

Mass spectrometer or LC-ESI-MS system, for example Thermo Scientific LTQ ion trap. An appropriate deconvolution software such as ProMass (http://www.enovatia.com/products/promass/) should be installed in order to obtain the zero-charge mass spectra from the ESI charge envelopes.

2.2 Native Chemical Ligation (NCL)

-

1.

Purified recombinant α-Syn fragment comprising residues 1–106 with a C-terminal thioester functionality, α-Syn(1–106)SR. Expression and purification of α-Syn(1–106)SR has been described in detail previously, see ref. 27.

-

2.

Purified synthetic α-Syn fragment comprising residues 107–140 with the temporary point mutation A107C and bearing a phosphoserine residue at position 129. The synthesis and purification of α-Syn(A107C-140)_pS129 has been described by Hejjaoui and colleagues [27]. If the peptide is to be synthesized in-house, the following residues should be double-coupled: all residues following a proline residue, all glutamine (Fmoc-Gln(Trt)-OH) and asparagine (Fmoc-Asn(Trt)-OH), the phosphoserine residue, and the N-terminal cysteine residue (Fmoc-Cys(Trt)-OH). Alternatively, the synthetic α-Syn C-terminal peptides may be purchased from specialized vendors. In the latter case, the purity of purchased peptides should always be verified again using both mass spectrometry and analytical HPLC. Common impurities in such peptides (which are avoided if proper synthesis, peptide cleavage, and purification procedures are followed, as described in ref. 27) are incomplete deprotection of the t-butyl side chain protecting groups (+56 Da adduct) and methionine oxidation (as methionine sulfoxide, +16 Da).

-

3.

Guanidine hydrochloride solution: 6 M guanidine hydrochloride, 0.2 M sodium phosphate, pH 7.2 (see Note 1 ). To make 100 mL of this solution, dissolve 57.3 g guanidine hydrochloride and 2.4 g sodium phosphate monobasic into an initial volume of 40 mL of water. Slowly add water while vigorously stirring until complete dissolution; adjust the pH to 7.2 and finally bring up to 100 mL. Store at room temperature.

-

4.

NCL buffer: phosphate-buffered guanidine hydrochloride solution containing 20 mM tris(2-carboxyethyl)phosphine (TCEP). For 5 mL of NCL buffer, weigh 29 mg of TCEP.HCl and dissolve into guanidinium hydrochloride solution and mix thoroughly until complete dissolution. Addition of TCEP.HCl will significantly decrease the pH of the solution, which must be adjusted back to 7.2 using small aliquots of 1 M aqueous NaOH. After adjusting the pH, start degassing the buffer by bubbling inert gas (preferably argon) inside it. The buffer must be prepared freshly (see Note 2 ) and degassed (sparged with nitrogen or preferably argon) for 10 min before use in order to minimize oxidative side reactions (see Note 3 ).

-

5.

Sample dilution solution: water with 0.1 % v/v trifluoroacetic acid (TFA)

-

6.

Desalting column: PD-10 columns (manual, gravity-based flow) or HiPrep 26/10 Desalting (for automated operation using a FPLC system).

2.3 Desulfurization

-

1.

Guanidine hydrochloride solution: 6 M guanidine hydrochloride, 0.2 M sodium phosphate, pH 7.2 (same as in Subheading 2.2, item 3).

-

2.

Radical initiator stock solution: 100 mM 2,2′-Azobis[2-(2-imidazolin-2-yl)propane]dihydrochloride (VA-044, Wako Chemicals GmbH, Neuss, Germany). To prepare a 1 mL solution, weigh 32.3 mg VA-044 (MW: 323.3 g/mol) into a 1.5 mL plastic tube, add 1 mL guanidinium hydrochloride solution (see above) and vortex until the solution becomes clear. Keep on ice and use within 30 min.

-

3.

2-methylpropane-2-thiol (t-butyl mercaptan, Sigma).

2.4 In Vitro Phosphorylation

-

1.

Purified recombinant WT human α-Syn. We recommend a purification protocol that includes a reversed-phase HPLC purification step, in order to ensure complete removal of any enzymes (especially proteases) that may cause problems during the phosphorylation reactions. The expression and purification protocol is described in detail in [28].

-

2.

Purified recombinant PLK3 (Life Technologies, cat. # PV3812). Make 1 μL aliquots upon receiving the stock solution from the vendor and immediately flash-freeze them and store at −80 °C.

-

3.

0.5 M HEPES, pH 7.4. To prepare a 100 mL solution, dissolve 11.9 g HEPES (free acid) in 75 mL water, adjust the pH to 7.4 using sodium hydroxide, and then bring up to 100 mL. Store at room temperature.

-

4.

0.1 M dithiothreitol (DTT). Prepare this solution freshly each time since DTT is unstable in aqueous solutions (see Note 4 ). Dissolve 15.4 mg DTT in 1 mL of water; keep on ice.

-

5.

0.5 M EGTA solution. Obtained from Boston Bioproducts, cat. # BM-151

-

6.

0.2 M MgCl2. To prepare a 100 mL solution, weigh 4.07 g of magnesium chloride hexahydrate and dissolve to a final volume of 100 mL with water. Store at room temperature.

-

7.

0.1 M Mg-ATP. To prepare a 5 mL solution, weigh 254 mg of adenosine 5′ triphosphate, magnesium salt and dissolve in 5 mL of water. Adjust the pH to ~7.0; be extremely careful not to overshoot when adjusting the pH, in order to avoid causing significant hydrolysis of the ATP. Make 100 μL aliquots and store at −20 °C.

-

8.

Phosphorylation reaction buffer: 50 mM HEPES, 1 mM MgCl2, 1 mM EGTA, 1 mM DTT. This solution is to be freshly prepared each time. For 1 mL, mix 100 μL 0.5 M HEPES, 10 μL 0.1 M DTT, 2 μL 0.5 M EGTA, 5 μL 0.2 M MgCl2, and 883 μL water. Keep on ice.

2.5 LC-ESI-MS Mass Spectrometry

-

1.

LC-ESI-MS solvent A: nano-pure water containing 0.1 % v/v formic acid (FA).

-

2.

LC-ESI-MS solvent B: gradient-grade (HPLC) acetonitrile containing 0.1 % v/v FA.

-

3.

Sample dilution solvent: water containing 0.1 % v/v TFA.

-

4.

LC-MS column: Agilent Poroshell 300SB C3 column (1.0 mm ID, 75 mm length), cat. # 661750-909.

2.6 Protein Purification (Semisynthesis Protocol)

-

1.

Strong cation-exchange (SCX) column: HiTrap SP HP 5 mL (GE Healthcare, cat. # 17-1152-01).

-

2.

SCX buffer A1: 20 mM sodium citrate, pH 4.0. To prepare 500 mL of solution, dissolve 2.14 g of sodium citrate monobasic (MW: 214.1 g/mol) into 475 mL of water, adjust the pH to 4.0, bring up to 500 mL. Store at room temperature.

-

3.

SCX buffer B1: 20 mM sodium citrate, 500 mM NaCl, pH 4.0. To prepare 500 mL of solution, dissolve 2.14 g of sodium citrate monobasic (MW: 214.1 g/mol) and 14.6 g NaCl (MW: 58.4 g/mol) into 475 mL of water, adjust the pH to 4.0, bring up to 500 mL. Store at room temperature.

-

4.

SCX buffer A2: 20 mM sodium citrate, pH 5.0. To prepare a 500 mL solution, dissolve 2.14 g of sodium citrate monobasic into 475 mL of water, adjust the pH to 5.0, and bring up to 500 mL. Store at room temperature.

-

5.

SCX buffer B2: 20 mM sodium citrate, 250 mM NaCl, pH 5.0. To prepare a solution of 500 mL, dissolve 2.14 g of sodium citrate monobasic and 7.31 g NaCl into 475 mL of water, adjust the pH to 4.0, and bring up to 500 mL. Store at room temperature.

2.7 Protein Purification (In Vitro Phosphorylation Protocol)

-

1.

Inertsil WP300-C8 semiprep column, 7.6 mm ID × 250 mm, 5 μm particles with 300 Å pores (GL Sciences, cat. # 5020-05968). In order to extend column life, an appropriate guard column is recommended (GL Sciences, cat. # 5020-05969 (guard column cartridge) and 5020-06920 (guard column holder)).

-

2.

Reversed-phase HPLC solvent A: nano-pure water containing 0.1 % v/v TFA.

-

3.

Reversed-phase HPLC solvent B: HPLC-grade acetonitrile containing 0.1 % v/v TFA.

-

4.

HPLC loading buffer: 95:5 water:acetonitrile containing 0.1 % v/v TFA.

3 Methods

3.1 Semisynthesis of α-Syn Containing C-Terminal Modifications

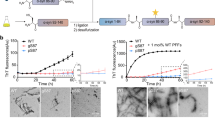

The following protocol describes the semisynthesis of the disease-relevant α-Syn phosphorylated on serine 129 (α-Syn_pS129), modified from the semisynthesis of pY125 α-Syn previously described by Hejjaoui and colleagues [27]. The reaction scheme is described in Fig. 1a.

Schematic depiction of the methods used to prepare α-Syn_pS129. (a) Protein semisynthesis method: the first step involves a native chemical ligation between the α-Syn(1–106)SR recombinant thioester (protein 1) and the synthetic α-Syn(A107C-140)_pS129 peptide (peptide 2) to obtain full-length α-Syn_pS129 with the temporary A107C mutation (protein 3). In the second step, a cysteine-specific desulfurization reaction restores the native alanine residue at position 107 to produce the final α-Syn_pS129 (protein 4). (b) α-Syn_pS129 preparation using in vitro phosphorylation with PLK3. In this scheme, purified recombinant WT (full-length) α-Syn (protein 1b) is incubated with ATP and active recombinant PLK3 which will site specifically phosphorylate α-Syn at S129, thereby producing protein 4

-

1.

Weigh 15 mg (1.4 μmol) of lyophilized α-Syn(1–106)SR (Fig. 1, protein 1) recombinant thioester protein into a 1.5 mL plastic tube at room temperature using a microbalance.

-

2.

Similarly, weigh two molar equivalents (2.8 μmol, 11 mg) of synthetic phosphorylated peptide α-Syn(A107C-140)_pS129 (Fig. 1, peptide 2) into a 1.5 mL plastic tube (Eppendorf).

-

3.

Dissolve α-Syn(A107C-140) first using 1 mL of degassed NCL buffer (see Note 5 ). Once the peptide is fully dissolved, add this solution to the lyophilized α-Syn(1–106)SR powder and vortex until complete dissolution.

-

4.

Immediately take 4 μL of solution at the initial time point and quench the reaction by diluting the aliquot with 36 μL of sample dilution solution (water + 0.1 % TFA) and keep on ice or store at −20 °C until use.

-

5.

Blanket the ligation solution with argon and incubate at 37 °C without agitation.

-

6.

Take and quench additional aliquots several times at later time points, for example 30 min, 1 h, and 2 h (as described in Subheading 3.1, step 5).

-

7.

Dilute 10 μL of the quenched reaction (see Subheading 3.1, step 5) into 90 μL of water + 0.1 % TFA; then briefly spin down to remove any aggregates or dust particles before injecting into the LC system. Inject 5 μL (approximately 750 ng) into the LC-ESI-MS system. In order to obtain a good signal with the Poroshell 300SB C3 column (1.0 mm ID, 75 mm length), run a gradient from 10 to 90 % LC-ESI-MS solvent B over 10 min at 0.3 mL/min, and acquire the MS data in positive ionization mode. The desired product (Fig. 1, protein 3) has an expected mass of 14,572 Da. The ligation can be considered as completed when the recombinant thioester protein α-Syn(1–106SR) (expected mass: 10,742 Da) is entirely consumed. The hydrolyzed form of the α-Syn(1–106) fragment is observed at 10,619 Da.

-

8.

SDS-PAGE: Mix 10 μL of the quenched reaction to 10 μL of 2× Laemmli (SDS-PAGE sample buffer), centrifuge at 20,000 × g for 5 min to remove precipitated guanidinium salts (which precipitate in the presence of SDS). Analyze the supernatant by electrophoresis on a 15 % polyacrylamide SDS gel (load 10 μL per lane).

-

9.

Note that analysis by reversed-phase HPLC is not recommended due to the co-elution of α-Syn(1–106) with the full-length protein, which happens using all of the commonly used stationary phases (C4, C8, and C18).

-

10.

Figure 2 shows a typical example of NCL reaction monitored by mass spectrometry and SDS-PAGE. Even small changes in the initial pH of the reaction may slow its kinetics; however if properly adjusted, SDS-PAGE analysis shows the ligation appears complete after 30–45 min (Fig. 2b). Once the ligation reaction is confirmed to be completed by both mass spectrometry and SDS-PAGE, the resulting full-length A107C/pS129 α-Syn must be desulfurized in order to restore the native alanine residue at position 107. Desulfurization is achieved by means of a radical-based reaction previously described by Wan and colleagues [29].

Fig. 2 Monitoring of the NCL between α-Syn(1–106)SR and the α-Syn(A107C-140)_pS129 peptide by mass spectrometry (a) and SDS-PAGE/Coomassie staining (b). Note that the 4 kDa α-Syn(A107C-140)_pS129 peptide is not detectable by SDS-PAGE. Calculated mass for α-Syn(1–106)SR: 10,742 Da (observed: 10,748 Da); calculated mass for the ligation product α-Syn(1–140)_pS129 A107C: 14,572 Da (observed: 14,572 Da)

-

11.

Add TCEP to a final concentration of 100 mM to the ligation reaction. This can be done by directly adding TCEP.HCl powder, or from a freshly prepared, pH-adjusted 1 M aqueous TCEP solution. Note that adding TCEP.HCl powder will require the pH to be adjusted again to 7.2.

-

12.

Add 64 μL of radical initiator stock solution to achieve a final VA-044 concentration of 6 mM.

-

13.

Add 50 μL of t-butyl mercaptan (final concentration: 400 mM). From this point onwards, all steps should be performed under a properly ventilated fume hood, due to the volatility and extremely unpleasant odor of t-butyl mercaptan (see Note 6 ). The reaction is then blanketed with inert gas and incubated at 37 °C with orbital shaking at 600–800 rpm.

-

14.

Monitor the progress of the reaction by mass spectrometry analysis. Withdraw aliquots and perform dilutions and mass spec analysis as described under Subheading 3.1, steps 4–7, with the exception that the tubes should not be opened outside of the fume hood, and the LC-ESI-MS sample vials should be appropriately sealed under the fume hood before being transferred to the mass spectrometer. The desulfurized product (Fig. 1, protein 4) is identified by a 32 Da mass loss compared to the starting material, corresponding to one sulfur atom, i.e., the expected mass of the desired product is 14,540 Da. Once the starting material is no longer detected by mass spectrometry (typically after 3–4 h), incubate the reaction for an additional 30 min before performing the next step in order to ensure completion of the reaction.

-

15.

Analysis by mass spectrometry of the desulfurization reaction is shown in Fig. 3. Care must be taken to analyze a narrow mass range around the desired product (calculated mass for α-Syn(1–140)_pS129: 14,540 Da) since the mass difference between the desulfurized product and the starting material is only 32 Da. The desulfurized protein is purified using a two-step cation-exchange chromatography method. Due to the co-elution of hydrolyzed α-Syn(1–106) fragment (and eventually remaining α-Syn(1–106)SR thioester) with the full-length protein (desulfurized and non-desulfurized) on reversed-phase HPLC columns, RP-HPLC purification cannot be performed. The next steps describe how to separate the desired full-length desulfurized pS129 α-Syn protein from the main contaminants, namely the excess of α-Syn(107–140)_pS129 synthetic peptide and the α-Syn(1–106) fragment.

-

16.

Wash the PD-10 desalting column with 25 mL of water, then equilibrate it with 25 mL of SCX buffer A1. Transfer the column under the fume hood and desalt the desulfurized protein as described in the manufacturer’s protocol [30].

-

17.

SCX Purification Step 1 (see Fig. 4a): Pool the desalted protein fractions and manually inject them into the HiTrap SP HP strong cation-exchange column at an approximate flow rate of 1 mL/min. During this step, all protein components from the desulfurization reaction will bind onto the column and the excess of α-Syn(107–140)_pS129 peptide should be found in the flow-through (Fig. 4a, b). Manual loading is preferred to minimize sample loss; however the desalted protein fractions can also be further diluted using SCX buffer A1 and loaded on the column using a chromatography system by the means of a sample loop or equivalent loading mechanism. In all cases, save the flow-through and analyze by mass spectrometry. The absence of protein in this fraction ensures complete binding of the protein onto the column.

Fig. 4 Purification of semisynthetic α-Syn(1–140)_pS129 by cation-exchange chromatography. (a) Scheme depicting the main steps of the purification protocol. Adapted from Hejjaoui et al. [23]. (b) SCX Step 1: Binding step at pH 4.0 where the full-length ligation product as well as the unreacted, hydrolyzed α-Syn(1–106) fragment bind onto the cation-exchange column and the excess of the (now desulfurized) synthetic α-Syn(107–140)_pS129 peptide is eliminated. (c) SCX Step 2: Elution step at pH 5.0 where the desired product α-Syn(1–140)_pS129 is separated from the α-Syn(1–106) fragment. The full-length phosphorylated protein (peak 1, blue bar) elutes before the α-Syn(1–106) fragment (peak 2, red bar). (d) SDS-PAGE/Coomassie analysis of fractions collected during SCX Step 2 (see panel c) showing the complete separation between the full-length α-Syn(1–140)_pS129 and the α-Syn(1–106) fragment

-

18.

While the full-length protein remains bound on the column, elute any bound α-Syn(107–140)_pS129 peptide by executing the following program on the FPLC system: set the flow rate to 2 mL/min and collect 5 mL fractions. Wash the column with 70 mL of SCX buffer A1, then perform a short linear gradient from 0 to 15 % of SCX buffer B1 over 20 mL to ensure complete removal of the α-Syn(107–140) peptide. Set the buffer composition back to 100 % of SCX buffer A1 and wash for an additional 30 mL.

-

19.

SCX Purification Step 2: This step is aimed at separating the full-length protein from the α-Syn(1–106) fragment based on their charge difference at pH 5.0 (Fig. 4a). Prime the FPLC system’s buffer lines with SCX buffers A2 and B2, respectively, then execute the following program on the FPLC system: set the flow rate to 1 mL/min and start collecting 2.5 mL fractions. After 5 mL with 100 % SCX buffer A2, perform a 150 mL-long linear gradient from 0 to 70 % SCX buffer B2 (Fig. 4a, c). Hold this composition for 5 mL, then switch to 100 % SCX buffer B2 and wash for 10 mL. Stop collecting fractions and re-equilibrate the column with either SCX buffer A1 if another purification is planned, or with water followed by 20 % ethanol if the column will be stored. During the gradient, the desired full-length α-Syn elutes first, followed by the α-Syn(1–106) fragment (see Fig. 4a, c). Analyze all the fractions corresponding to the observed peaks on the chromatogram by SDS-PAGE and pool them according to purity (Fig. 4d).

-

20.

Desalt or dialyze the protein against water, then quantify using UV absorbance to measure the yield. Concentration determination may be performed on a nanodrop UV spectrophotometer (or any cuvette-based UV spectrophotometer) using the same water solution as that used for dialysis or desalting for the blank reading. The concentration is calculated by measuring the absorbance of the dialyzed or desalted protein solution at 275 nm, where the extinction coefficient of α-Syn_pS129 is 5974 M−1 cm−1 (or equivalently, 0.4109 g−1 L cm−1).

-

21.

Perform final purity analyses using mass spectrometry, SDS-PAGE, and analytical HPLC (see Fig. 5); then lyophilize. Keep the lyophilized protein at −20 °C until use.

Fig. 5 Purity analyses of α-Syn(1–140)_pS129 after cation-exchange chromatography and dialysis by analytical RP-UHPLC (a); mass spectrometry (b, calculated mass: 14,540 Da; observed: 14,543 Da; the bottom panel shows an expanded view of the mass range shown in the dotted box from the top panel); and SDS-PAGE/Coomassie staining (c)

3.2 Enzyme-Based Preparation of S129-Phosphorylated α-Syn

Previous studies from our group and others have shown that the members of the polo like family of kinases PLK2 and PLK3 phosphorylate α-Syn efficiently and specifically at S129 [3, 10]. Because of the high specificity of α-Syn S129 phosphorylation by PLK2 and PLK3, pS129 α-Syn may also be obtained by co-incubation of recombinant full-length WT α-Syn with purified PLK3 (Fig. 1b). The following protocol describes how to perform preparative-scale in vitro α-Syn phosphorylation using commercially available recombinant PLK3.

-

1.

Weigh 500 μg of purified, lyophilized WT α-Syn (Fig. 1b, protein 1b) using an analytical microbalance.

-

2.

Freshly prepare the phosphorylation reaction buffer. During this time, thaw one aliquot of PLK3 stock solution and one aliquot of 100 mM Mg-ATP on ice.

-

3.

Dissolve the lyophilized WT α-Syn in 195 μL of phosphorylation buffer.

-

4.

Add 4 μL of 100 mM Mg-ATP (final concentration: 2 mM) and 0.42 μg (1 μL) of PLK3. Mix by pipetting up and down (do not vortex) and incubate for 12 h at 30 °C without agitation. Depending on the quantity of phosphorylated α-Syn material desired, several of these reactions may be performed in parallel. We have observed that scaling up of a single reaction produced reduced the phosphorylation efficiency; thus parallel, smaller-scale reactions are preferred.

-

5.

Verify the extent of the phosphorylation reaction by mass spectrometry: take a 1 μL aliquot from the reaction tube and add 49 μL of water containing 0.1 % v/v TFA to quench the reaction. Briefly spin down and inject 10 μL for analysis by LC-ESI-MS (positive ionization mode). α-Syn phosphorylated at S129 has an expected mass (M+H) of 14,541 Da, while unphosphorylated (WT) α-Syn is expected at 14,461 Da (M+H).

-

6.

It is expected that 500 μg of WT α-Syn should be completely phosphorylated after 12 h of incubation; however we observed this is not always the case, presumably due to factors such as PLK3 storage time and possible batch-to-batch variability in PLK3 activity. If incomplete phosphorylation is observed after 12 h of incubation, add again 0.45 μg of PLK3 and 2 mM of fresh Mg-ATP, then incubate for another 12 h, in order to ensure complete phosphorylation. This is particularly important since unphosphorylated α-Syn and α-Syn_pS129 are difficult to separate; co-eluting unphosphorylated α-Syn contaminates phosphorylated α-Syn fractions during purification, thus decreasing the yields.

-

7.

Once unphosphorylated α-Syn is confirmed to be undetectable by mass spectrometry, proceed to purify α-Syn_pS129 (Fig. 1b, protein 4) by reversed-phase HPLC, using a semipreparative (7.8 mm ID × 250 mm, 5 μm, 300 Å) C8 column. Before loading any sample, the column should be well equilibrated, by flowing 5 % solvent B at 3 mL/min for at least 20 min.

-

8.

Dilute the contents of up to two reaction tubes (400 μL, 1 μg of protein) into 2 mL of HPLC loading buffer. Filter (0.22 μm) or centrifuge before loading on the HPLC column. After loading the sample onto the loop, execute the following program on the HPLC system, with a constant flow rate of 3 mL/min: run isocratically at 5 % solvent B for 10 min, then increase to 20 % B over 3 min; then perform the separating linear gradient from 20 % B to 70 % B over 30 min. Then, wash the column by increasing the proportion of solvent B to 95 % over 3 min, leave at 95 % B for 5 min, then gradually switch back to 5 % B over 3 min, and finally re-equilibrate (5 % B) for 20 min.

-

9.

We recommend collecting fractions manually during the gradient elution in order to best discriminate between closely eluting peaks. Figure 6 shows a typical semipreparative chromatogram. Note that the actual retention time will vary depending on the specific configuration of the HPLC system (pre- and post-column volumes, presence and type of pre-column) and the specific column model (see Note 7 ). Fractions should be analyzed by mass spectrometry to assess purity. Typically, α-Syn_pS129 elutes immediately after a shoulder containing methionine-oxidized α-Syn_pS129 (expected mass: 14,556 Da) which can be minimized by using proper buffer degassing of the phosphorylation buffer (see Note 3 ).

Fig. 6 Semipreparative RP-HPLC purification of α-Syn(1–140)_pS129 prepared by in vitro phosphorylation of recombinant WT α-Syn by PLK3; using a 7.6 mm ID × 250 mm column. The chromatograms show the absorbance at 214 nm. The right panel shows an expanded view of the area shown in the dotted box on the left panel, highlighting the shoulder eluting just before the desired protein and containing one methionine sulfoxide residue (labeled “MetOx” on the chromatogram)

-

10.

Pool fractions according to purity (as assessed by mass spectrometry), then perform a final purity analysis using SDS-PAGE, analytical reversed-phase HPLC, and mass spectrometry (similarly as in Fig. 5); determine the yield by UV absorbance, and finally lyophilize. Keep the lyophilized protein at −20 °C until use.

4 Notes

-

1.

The NCL reaction is optimally performed at near-physiological pH. It is critically important that the pH of the reaction buffer is verified before each reaction. This requires a pH microelectrode (see Subheading 2.1, item 3) with a diameter small enough to fit into a 1.5 mL Eppendorf tube. Moreover, the pH meter should be re-calibrated immediately before the measurements. Significant deviations from the optimal pH reduce the yields of the reaction: a more basic pH will increase the rate of hydrolysis of the thioester-containing fragment, and high reaction pH also leads to nonspecific ligation events [31]. On the other hand, lowering the pH will result in drastically lower reaction rates due to decreased transthioesterification reaction rates under these conditions [31].

-

2.

It is recommended to add the TCEP to the NCL buffer shortly before performing the reaction, since TCEP is somewhat prone to oxidation in phosphate-containing buffers [32], although complete oxidation requires ~72 h in a pH 7.0 phosphate buffer [32].

-

3.

Degassing of the NCL buffer is useful to further minimize disulfide formation by the N-terminal cysteine and thus keeping it available for reacting with the thioester-containing fragment. Furthermore, removing dissolved oxygen helps keeping methionine residues in a reduced state. If the formation of methionine sulfoxides during NCL (as seen by a +16 Da shift by mass spectroscopy) is not minimized by simply degassing the NCL buffer, adding 5 mM to 20 mM l-methionine to the reaction has proven effective in our hands.

-

4.

DTT oxidizes relatively quickly when in solution, especially at room temperature (the half-life of DTT is only a few hours at 20 °C and pH 7.5 [33]). DTT solutions should thus be freshly made before each use and stored on ice during the working day.

-

5.

It is desirable to dissolve the fragment containing the N-terminal cysteine first, and then add the peptide thioester, in order to minimize the risks of hydrolyzing the thioester which might happen (albeit at a slow rate) if it is alone in solution at neutral pH.

-

6.

In order to minimize the spreading of t-butyl mercaptan vapors, bleach traps (200–300 mL of ~5 % aqueous sodium hypochlorite in plastic or glass containers) should be set up inside the hood near the reactions [34]. A bleach-containing waste container should also be used to discard any disposable plastics that have been in contact with solutions containing t-butyl mercaptan. Thiol-contaminated wastes should be left in a bleach solution for ~24 h before final disposal [34]. Moreover, we advise to dedicate a set of lab coats for work involving thiols. These lab coats should remain in the room where thiols are stored and used and should not be worn outside of that room.

-

7.

We have observed significant differences (up to ±5 min) between columns of the same dimensions, particle size, and phase but from different manufacturers. Thus it is generally preferable to monitor the entire run and collect fractions manually, especially during the first purification.

References

Lashuel HA, Overk CR, Oueslati A, Masliah E (2013) The many faces of alpha-synuclein: from structure and toxicity to therapeutic target. Nat Rev Neurosci 14:38–48

Oueslati A, Fournier M, Lashuel HA (2010) Role of post-translational modifications in modulating the structure, function and toxicity of alpha-synuclein implications for Parkinson’s disease pathogenesis and therapies. Prog Brain Res 183C:115–145

Oueslati A, Schneider BL, Aebischer P, Lashuel HA (2013) Polo-like kinase 2 regulates selective autophagic alpha-synuclein clearance and suppresses its toxicity in vivo. Proc Natl Acad Sci U S A 110(41):E3945–E3954

Anderson JP, Walker DE, Goldstein JM, de Laat R, Banducci K, Caccavello RJ, Barbour R, Huang J, Kling K, Lee M, Diep L, Keim PS, Shen X, Chataway T, Schlossmacher MG, Seubert P, Schenk D, Sinha S, Gai WP, Chilcote TJ (2006) Phosphorylation of Ser-129 is the dominant pathological modification of alpha-synuclein in familial and sporadic Lewy body disease. J Biol Chem 281:29739–29752

Fujiwara H, Hasegawa M, Dohmae N, Kawashima A, Masliah E, Goldberg MS, Shen J, Takio K, Iwatsubo T (2002) alpha-Synuclein is phosphorylated in synucleinopathy lesions. Nat Cell Biol 4:160–164

Wang Y, Shi M, Chung KA, Zabetian CP, Leverenz JB, Berg D, Srulijes K, Trojanowski JQ, Lee VM-Y, Siderowf AD, Hurtig H, Litvan I, Schiess MC, Peskind ER, Masuda M, Hasegawa M, Lin X, Pan C, Galasko D, Goldstein DS, Jensen PH, Yang H, Cain KC, Zhang J (2012) Phosphorylated α-Synuclein in Parkinson’s disease. Sci Transl Med 4:121ra120

Foulds PG, Mitchell JD, Parker A, Turner R, Green G, Diggle P, Hasegawa M, Taylor M, Mann D, Allsop D (2011) Phosphorylated alpha-synuclein can be detected in blood plasma and is potentially a useful biomarker for Parkinson’s disease. FASEB J 25:4127–4137

Schmid AW, Fauvet B, Moniatte M, Lashuel HA (2013) Alpha-synuclein post-translational modifications as potential biomarkers for Parkinson disease and other synucleinopathies. Mol Cell Proteomics 12:3543–3558

Paleologou KE, Schmid AW, Rospigliosi CC, Kim HY, Lamberto GR, Fredenburg RA, Lansbury PT Jr, Fernandez CO, Eliezer D, Zweckstetter M, Lashuel HA (2008) Phosphorylation at Ser-129 but not the phosphomimics S129E/D inhibits the fibrillation of alpha-synuclein. J Biol Chem 283:16895–16905

Mbefo MK, Paleologou KE, Boucharaba A, Oueslati A, Schell H, Fournier M, Olschewski D, Yin G, Zweckstetter M, Masliah E, Kahle PJ, Hirling H, Lashuel HA (2010) Phosphorylation of synucleins by members of the Polo-like kinase family. J Biol Chem 285:2807–2822

Burre J, Sharma M, Tsetsenis T, Buchman V, Etherton MR, Sudhof TC (2010) Alpha-synuclein promotes SNARE-complex assembly in vivo and in vitro. Science 329:1663–1667

Mahul-Mellier AL, Fauvet B, Gysbers A, Dikiy I, Oueslati A, Georgeon S, Lamontanara AJ, Bisquertt A, Eliezer D, Masliah E, Halliday G, Hantschel O, Lashuel HA (2014) c-Abl phosphorylates alpha-synuclein and regulates its degradation: implication for alpha-synuclein clearance and contribution to the pathogenesis of Parkinson’s disease. Hum Mol Genet 23(11):2858–2879

Negro A, Brunati AM, Donella-Deana A, Massimino ML, Pinna LA (2002) Multiple phosphorylation of alpha-synuclein by protein tyrosine kinase Syk prevents eosin-induced aggregation. FASEB J 16:210–212

Ellis CE, Schwartzberg PL, Grider TL, Fink DW, Nussbaum RL (2001) alpha-synuclein is phosphorylated by members of the Src family of protein-tyrosine kinases. J Biol Chem 276:3879–3884

Hodara R, Norris EH, Giasson BI, Mishizen-Eberz AJ, Lynch DR, Lee VM, Ischiropoulos H (2004) Functional consequences of alpha-synuclein tyrosine nitration: diminished binding to lipid vesicles and increased fibril formation. J Biol Chem 279:47746–47753

Uversky VN, Yamin G, Munishkina LA, Karymov MA, Millett IS, Doniach S, Lyubchenko YL, Fink AL (2005) Effects of nitration on the structure and aggregation of alpha-synuclein. Brain Res Mol Brain Res 134:84–102

Muir TW, Sondhi D, Cole PA (1998) Expressed protein ligation: a general method for protein engineering. Proc Natl Acad Sci U S A 95:6705–6710

Evans TC Jr, Benner J, Xu MQ (1998) Semisynthesis of cytotoxic proteins using a modified protein splicing element. Protein Sci 7:2256–2264

Fauvet B, Fares MB, Samuel F, Dikiy I, Tandon A, Eliezer D, Lashuel HA (2012) Characterization of semisynthetic and naturally Nalpha-acetylated alpha-synuclein in vitro and in intact cells: implications for aggregation and cellular properties of alpha-synuclein. J Biol Chem 287:28243–28262

Hejjaoui M, Haj-Yahya M, Kumar KS, Brik A, Lashuel HA (2011) Towards elucidation of the role of ubiquitination in the pathogenesis of Parkinson’s disease with semisynthetic ubiquitinated alpha-synuclein. Angew Chem Int Ed Engl 50:405–409

Shabek N, Herman-Bachinsky Y, Buchsbaum S, Lewinson O, Haj-Yahya M, Hejjaoui M, Lashuel HA, Sommer T, Brik A, Ciechanover A (2012) The size of the proteasomal substrate determines whether its degradation will be mediated by mono- or polyubiquitylation. Mol Cell 48:87–97

Haj-Yahya M, Fauvet B, Herman-Bachinsky Y, Hejjaoui M, Bavikar SN, Karthikeyan SV, Ciechanover A, Lashuel HA, Brik A (2013) Synthetic polyubiquitinated alpha-Synuclein reveals important insights into the roles of the ubiquitin chain in regulating its pathophysiology. Proc Natl Acad Sci U S A 110:17726–17731

Hejjaoui M, Butterfield SM, Fauvet B, Vercruysse F, Cui J, Dikiy I, Prudent M, Olschewski D, Zhang Y, Eliezer D, Lashuel HA (2012) Elucidating the role of C-terminal post-translational modifications using protein semisynthesis strategies: alpha-synuclein phosphorylation at tyrosine 125. J Am Chem Soc 134(11):5196–5210

Wissner RF, Wagner AM, Warner JB, Petersson EJ (2013) Efficient, traceless semi-synthesis of alpha-synuclein labeled with a fluorophore/thioamide FRET pair. Synlett 24:2454–2458

Fauvet B, Butterfield SM, Fuks J, Brik A, Lashuel HA (2013) One-pot total chemical synthesis of human alpha-synuclein. Chem Commun (Camb) 49:9254–9256

Chen L, Periquet M, Wang X, Negro A, McLean PJ, Hyman BT, Feany MB (2009) Tyrosine and serine phosphorylation of alpha-synuclein have opposing effects on neurotoxicity and soluble oligomer formation. J Clin Invest 119:3257–3265

Hejjaoui M (2012) Elucidating the role of post-translational modifications of alpha-synuclein using semisynthesis - phosphorylation at Tyrosine 125 and monoubiquitination at Lysine 6, EPFL

Khalaf O, Fauvet B, Oueslati A, Dikiy I, Mahul-Mellier AL, Ruggeri FS, Mbefo MK, Vercruysse F, Dietler G, Lee SJ, Eliezer D, Lashuel HA (2014) The H50Q mutation enhances alpha-synuclein aggregation, secretion, and toxicity. J Biol Chem 289:21856–21876

Wan Q, Danishefsky SJ (2007) Free-radical-based, specific desulfurization of cysteine: a powerful advance in the synthesis of polypeptides and glycopolypeptides. Angew Chem Int Ed Engl 46:9248–9252

PD-10 gravity-flow column user manual: https://www.gelifesciences.com/gehcls_images/GELS/Related%20Content/Files/1314723116657/litdoc52130800BB_20110830191706.pdf

Hackenberger CP, Schwarzer D (2008) Chemoselective ligation and modification strategies for peptides and proteins. Angew Chem Int Ed Engl 47:10030–10074

Han JC, Han GY (1994) A procedure for quantitative determination of tris(2-carboxyethyl)phosphine, an odorless reducing agent more stable and effective than dithiothreitol. Anal Biochem 220:5–10

Stevens R, Stevens L, Price NC (1983) The stabilities of various thiol compounds used in protein purifications. Biochem Educ 11:70

Singletary AM (1997) Hazardous laboratory chemicals disposal guide margaret-Ann Armour, CRC Press, Inc., Boca Raton, FL, (1996), 546 Pages, [ISBN No.: 1–56670–108–2] U.S. List Price: 7$79.95. Environ Prog 16:S5

Acknowledgements

This work has been possible thanks to the tremendous efforts of all the members of the Lashuel group that have contributed to developing and optimizing the protocols described here. We wish to specially thank Mr. John Perrin for the enzymatic preparation of α-Syn_pS129; as well as Mr. Anass Chiki, Dr. Sean Deguire, and Dr. John Warner for helpful comments on the manuscript. This work was supported by grants from the European Research Council (ERC grant n° 243182), the Michael J. Fox Foundation for Parkinson’s Research (grant n° 531107), and Ecole Polytechnique Fédérale de Lausanne Swiss National Science Foundation (grant n (31003A_120653).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media New York

About this protocol

Cite this protocol

Fauvet, B., Lashuel, H.A. (2016). Semisynthesis and Enzymatic Preparation of Post-translationally Modified α-Synuclein. In: Eliezer, D. (eds) Protein Amyloid Aggregation. Methods in Molecular Biology, vol 1345. Humana Press, New York, NY. https://doi.org/10.1007/978-1-4939-2978-8_1

Download citation

DOI: https://doi.org/10.1007/978-1-4939-2978-8_1

Publisher Name: Humana Press, New York, NY

Print ISBN: 978-1-4939-2977-1

Online ISBN: 978-1-4939-2978-8

eBook Packages: Springer Protocols