Abstract

In this chapter, I first propose to distinguish, on an experimental basis, five different technical ‘modes’ or ‘mechanical steps’ that the pressure technique used on flint or flint-like materials may have followed, from the production of microblades detached ‘in the hand’ to that of very large blades detached with the use of a lever. The particularity of obsidian and heat-treated flint is then discussed on the matter of these technical modes. A presentation on the different types of platform preparation adapted to the pressure technique, using an antler point and a copper point follows. Some comments are then given about methods of core shaping and possible systematic sequencing of blade core reduction. Finally, I propose some postulates on the matter of development and transmission of the pressure techniques.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

We owe to D. Crabtree, through his successful replication of obsidian pressure blades – even if it was not the genuine ‘Mexica technique’ reconstructed by J. Clark (1982, and Chap. 3 of this volume) – a first explanation of the stigmata of the pressure technique. These early experiments of mesoamerican blade production by pressure from D. Crabtree (1968) allowed J. Tixier to first recognize this particular technique applied to flint in the Old World, specifically in the Upper Capsian from Algeria in the late 1960s (Tixier 1984). Since then, this technique has been widely recognized in the Old World. The main steps of this recognition took place in Europe as part of research on the ‘Chasséen méridional’ (a large middle Neolithic culture primarily defined in the South of France; Binder 1984), the Neolithic of Greece (Perlès 1984, 2001, 2004), and the Maglemosian and Kongemosian Mesolithic in Denmark (Callahan 1985; Chap. 9 by Sørensen, this volume). Meanwhile, M.-L. Inizan detected this technique in several cultures from the Near and Middle East (Inizan 1991, and Chap. 2 of this volume).

Considering different allusions to this technique, or recent confirmations of it within other contexts, there is still much to discover and study in order to complete the picture. Beyond the economical significance of the pressure technique in each of the techno-complexes where it was put into use, such a picture should form the basis for a historical reconstruction of its origin(s) and development, its significance, and above all, its diffusion. With this aim in mind, experimental replication reference collections remain a key for the identification of archaeological production techniques.

2 Background to This Research

I started my experimental investigations of the pressure technique in 1981, after Jean-Paul Thevenot showed me in 1980 a few very regular bladelets from his ongoing excavations at Chassey-le-Camp and asked me ‘How could these have been made?’ During 1980, I put a lot of effort into reproducing them by indirect percussion, but the friendly critique of D. Binder led me to admit ‘that was not exactly it’. That is the reason I turned to testing pressure techniques, all the while ignoring Tixier’s early experiment with a flint core, bearing in mind Bordes’ opinion that flint was much harder than obsidian when it came to detaching products larger than microblades (1969).

I also felt that it was time to solve the practical aspects of Crabtree’s technique (the copper point, the core fixation device with a strong steel screw, the core prepared by modern sawing). That led me to test different holding devices, one of them quite simple, using a somewhat different and more ergonomic standing position and a flexible crutch, and to test different ways of preparing pressure cores by percussion. These adaptations, which allowed me to produce a series of small flint blades up to 14 cm long and 18 mm wide with an antler point, were demonstrated during the 3rd meeting of lithic technology held at Meudon in October 1982 (Pelegrin 1984a, b, c).

Aware that there existed much ‘smaller’ versions of pressure, for instance the small bullet cores from the Near East, and that the standing technique I used could not be invented from scratch, I tried, from 1984 to 1987, various different ways to reproduce microblades and bladelets (Pelegrin 1988).Footnote 1 I also started an early and successful test of lever pressure in 1983 at the Archéodrome for the detachment of large pressure blades, which proved to be easy but for an unstable holding device. I was, however, conscious that one could not recognize lever pressure without a practical exploration of its ‘competing’ technique, that being indirect percussion.

This second program, started in 1986 and 1987 at the Lejre Centre (Denmark) together with Bo Madsen, had the purpose of being a preliminary exploration of the many parameters of indirect percussion (length, curvature and stiffness of the punch, holding position of the core, length and curvature of the blade-products, etc.). This ‘blade’ experiment was continued over a period from 1988 to 1991 with the indirect percussion technique (carefully exploring and demonstrating the interest of an elastic support for the core, testing of copper-tipped punches, etc.), until it appeared that two of my archaeological reference cases could not be successfully reproduced using a punch (not so much regarding morphology and dimensions of the blades, but for discrete technical stigmata such as ripples on the bulb, cracks on the blade platform, terminations, etc.). That led me to explore once again the lever pressure technique, mainly in 1992 and 1993, with further tests in relation to specific archaeological cases (1997). In 1993, thanks to an invitation to the Western United States by friends and colleagues (J. Flenniken, P. Geib, G. Titmus, M. Warburton and J. Woods, to whom I am very grateful), I was given access to obsidian from California and Oregon, and could mail 70 kg of prepared cores to France for further knapping tests. However, throughout these years, the main driving force of this research has been the progressive discovery of the diversity of the archaeological record.

3 Several ‘Modes’ of Pressure

The main principle of this step-by-step progression comes from a simple fact that is acknowledged by knappers (since Crabtree) with pressure experience, ‘the wider the blade, the greater the amount of pressure that is required’ (Crabtree 1968, p. 468, see also Titmus and Clark 2003, p. 84). Since the pressure force depends on the physico-mechanical conditions of its application, the maximal width of the products constitutes a good indicator of the pressure mode employed.

From a methodological point of view, after the collection has been classified according to eventual types of products and sequences, the distribution of the product width, or more specifically, of the width and thickness (cloud of points diagram), should reveal a rather concentrated cluster indicative of a technical mode. For example, a scatter of width values between 10 and 18 mm and a few points up to, but not more than, 20–22 mm for a series of flint blades and fragments identified as pressure detached according to their morphological features (regularity, almost straight profile, often with a thin section, small platform) would be indicative of a standing pressure technique (mode 4 infra). If some blades are wider, one should reconsider the pressure diagnosis and consider a percussion technique.

In many contexts, indirect percussion is known to exist alongside pressure for the production of larger blades. This can be from specific cores, or from the same cores before they are further reduced by pressure. Indirect percussion can also be limited to the refined pre-shaping of pressure core preforms, including a series of axial punch blades, so as to create regular ridges on the flaking surface that will help start the pressure production. Indirect percussion blades can also help in repairing or rejuvenating the flaking surface, or even be used instead of pressure for a simple blade detachment that happens to be too difficult to produce by pressure (possibly after a mis-preparation of the platform). Some of these punch blades can therefore be as regular as pressure blades, yet somewhat wider. If a consistent fraction of the blades appear wider than the envisioned limit (for a given pressure mode), one should reconsider the hypothesis of a very careful indirect percussion technique. A difficult case, as I have seen in a Cardial collection from Portugal, is that of the reduction of cores by indirect percussion for the first step, followed by a pressure technique for the second step, with heat treatment of the core in between.

In this study, I postulate that, if anything, the main trend of innovation regarding pressure blade production techniques was to make them wider (which is a necessary condition to eventually make them longer), which assumes an improvement in the force applied and/or the stability of the core. We start with flint and follow with obsidian.

3.1 Mode 1

By mode 1, we define the simplest way of applying pressure on a small core: using a hand-held pressure tool such as a ‘baguette’ or selected tine of antler (for a discussion about the quality of other materials such as bone, ivory, etc.; see Crabtree 1967). The core is directly held in the left hand (in this chapter, the right versus left indications apply to a right-handed worker), without any specific holding device except for a piece of leather to protect the palm and the fingers (Fig. 18.1). This seems to be the case for the detachment of tiny microblades from the evolved Aurignacian ‘burins busqués’, (Fig. 18.1 b) an archaeological ‘burin busqué’ from Laussel, Musée du Grand-Pressigny) which J.-G. Bordes has identified as microblade cores for ‘lamelles Caminade’ (Bordes and Lenoble 2002), and that I recognize, at least for some of them, as produced by pressure (Pelegrin and Bordes, in prep.; documentation in Michel 2010). These ‘burins busqués’ seem to be ordinarily rejected when reduced to 4.5 cm in length, which corresponds exactly to the minimum size for holding them (see Pataud level 7 in Bricker, 1995). The width of the microblades I could detach using mode 1 is about 5 mm, which is the same width attained by Callahan (1985) in similar conditions (with a maximum of up to 7–8 mm and 4 cm long).

In the Far East, some Horoka and Yubetsu cores (about 15,000 B.P., if not earlier) seem to provide the earliest evidence of microblades produced using this mode of pressure (Chap. 14 by Gomez-Coutouly, this volume).

3.2 Mode 1b

Still using a simple hand pressure tool, a first complementary tool can help to hold a flint core in the left hand. Indeed, if the core is not long enough – such as the so-called handle or keeled cores from Denmark – to be grasped transversally with several fingers, it seems impossible to squeeze the core with enough strength so as to stabilize it. For such slender cores that cannot be grasped firmly in the left hand, another device must therefore be used to help immobilize the core. As I have proposed elsewhere (Pelegrin 1988; see also Wilke, 1996), it can be a small, grooved piece of wood, bone or antler on which the core can be placed face down towards the palm and thus held more firmly (Fig. 18.2). The groove keeps the flaking surface free of contact and thus prevents the microblade from terminating in a hinge or step against the palm. A little piece of fur placed in the groove also reduces breakage of the microblades.

Using such a simple tool, microblades up to 8 mm wide can be produced from flint (Fig. 18.3). This device was effective for the reproduction of the tiny ‘Rocher-de-la-Caille’ microblade pressure cores from the middle Magdalenian in central France (Alix et al. 1995). E. Callahan (1985) proposed that having a composite clamp acting as a handle to hold elongated cores, and by using a short antler tine as a pressure flaker, he could detach flint microblades up to 3 cm long in a series with the longest reaching 4.5 cm long and 7–8 mm wide. The ‘pocket’ holding device from Tabarev (1997) reproduces the same principle as that from Callahan and does not seem to provide a better solution to the holding of slender cores.

A flint microcore (planar orthogonal platform created by a thick flake removal on a small nodule, shaped by axial removals + a dorsal crest) and its microblades pressure flaked using a hand-held baguette and core held in a grooved piece (mode 1b). The microblades are about 4 cm long and 5–8 mm wide. The detailed view of the core shows the curling distal end of the last microblade scar, an obvious stigmata of distal contact: the distal end of the core was pressed against the firm material of the grooved piece (hard wood, could be bone or antler as well) so that the fracture front started to plunge towards the too pointed distal tip of the core, but, feeling the compression, it ‘curls up’ 1 or 2 mm before the tip of the core. The distal fragment of the last microblade, broken during its detachment due to this distal contact, shows a complementary aspect of this ‘curling’ (described also by Titmus and Clark 2003, p. 97)

3.3 Mode 2

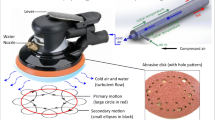

A second mode can be proposed as an improvement of mode 1, replacing the hand pressure flaker with a shoulder crutch to produce a greater force (Fig. 18.4), as the strong muscles of the torso and shoulder will act to produce the pressure force instead of those of the right wrist (see Crabtree 1967, p 68). With such a tool, the width of flint microblades can reach 10 mm (Fig. 18.5). As Crabtree (1967) described it, such a shoulder crutch should be 30–40 cm long, adapted to the knapper’s size and working position (sitting low or cross-legged on the ground).

A flint microcore (flat or planar orthogonal platform created by removing a thick flake on a small nodule, shaped by axial removals) and its microblades pressure flaked using a shoulder crutch and core held in a grooved piece (mode 2). The microblades can be up to 10 mm wide. The pointed tip of the nearly exhausted conical core (not far from a bullet shape) is discretely splintered (crushed), which is also a stigmata of distal contact. Most of the microblades reached the distal end of the core and therefore the material of the holding device, which explains the high rate of breakage. This could be improved

When using such a tool with full force, a holding device for the core is certainly necessary for holding a flint core in the left hand. A larger, grooved piece was used here, but a hand-held clamp such as in Callahan’s model is possible for large enough cores, or alternatively some other device may be developed.

3.4 Mode 3

I postulate that the next step in microblade production consists of switching to the ground from the previous shoulder mode 2 (Fig. 18.6). It should be noted that the tools involved require little adaptation from those used in mode 2, and the low sitting position of the knapper can be maintained. The new key element lies in the fact that the core is placed on the ground so that the knapper can use a part of his or her own weight to build up the pressure force, with three positive consequences.

The first positive consequence is that the force is delivered in a straight axis that can be better controlled by the eye and exerted exactly in line with the blade to be removed, which is visualized while setting the core. This explains a ‘jump’ in the regularity of blades produced due to excellent control of the flaking direction, whereas many of the microblades detached by modes 1–2 are somewhat twisted or skewed. The second positive consequence is the stability of the core, which, while using an adequate hold, does not move or tip at all. The third improvement is the significant ease of executing mode 3 compared to the more laborious modes 1 and 2. Once the position is properly adjusted, the knapper just needs to bend forward to push the short crutch placed at his belt straight to the front of the core platform and then initiate the fracture by an extra outward push with the hand(s) that hold the crutch. Indeed, some practice and coordination will permit the knapper to use the free left hand for maintaining the core in place during the setting of the pressure tool and the bladelet detachment.

Once again, a simple grooved device with a forked base kept in place by the heels offers good stability and practicality for different core shapes and sizes, and it can be adjusted by adding a small piece of wood or thick leather at the distal end of the core as it gets shorter. This device simply needs to be resting with the correct obliquity against a stone that is just high enough. In addition, one can easily imagine an improvement for sedentary knappers. One can select a superficial root, or stick a notched piece of wood in the ground in front of a small hole in which the core can be placed and adjusted with a set of small pieces of wood to secure its distal contact.

The regularity, ease and comfort of mode 3 accounts for the detachment of flint bladelets up to 12 mm wide and about 8 cm long (Fig. 18.7; in this case up to 11.5 mm wide and 7 cm long due to constraints imposed by the core). For extra force, if necessary, the knapper can lean forward on his heels to use more of his body weight. This can be considered as mode 3’ and leads to the next mode.

A flint core (flat or planar orthogonal platform created by removing a thick flake on a small nodule, shaped by axial removals and two dorsal crests) and its bladelets pressure flaked using a short (abdominal) crutch in a sitting position, core held in a grooved device against the ground (mode 3). In this case, the distal contact of the removals was carefully avoided, explaining the low rate of breakage. The morphometric study of this experimental collection has been published by M. Gallet (1998)

Callahan’s clamp might be adapted to mode 3 (in sitting position, the clamp being pressed on the ground with the left hand and/or a foot) but not to mode 4 (standing), as the left hand will not be able to stabilize the clamp. By any mode, the clamp – or any other device in which the core is squeezed vertically between its platform and distal end – is not well adapted to cores that finish with a bullet core shape, that is with a very small platform offering little grip to the clamp. Moreover, it becomes necessary to reposition the core quite often as its width or thickness is decreasing, which is impractical. Avoiding distal contact of the bladelet that is detached is possible if a notch has been carved in the lower jaw of the clamp, but the core will have to be repositioned in the clamp for each bladelet detachment that can be expected to reach the distal end of the core.

Conversely, it can be suggested that keeled core types which are always abandoned seemingly early (i.e. with a thickness greater than several cm) were held by their thickness and/or length, for example in a clamp (up to mode 3), in the hand (mode 1a or 2), in some hollow handle (for instance, I saw in Japan a few carinated ‘burins’ on long blades with the opposite end regularly shaped into a long ovate that can be suspected to have been forced into a hollow piece of bone or antler) or possibly pressed by the left hand and/or foot on the ground in a concavity or on some socket. To my knowledge however, there are no cores of such a shape that produced flint bladelets wider than 10–12 mm, if not 8 mm, which means that they were not reduced using modes greater than 3, and possibly just modes 1 and 2.

Consequently, I presume, but for new experiments that might prove otherwise, the flint microblade or bladelet cores that are exhausted and have a slender shape (‘bullet core’ conical or sub-conical, and those with an acute platform edge) were necessarily held in some kind of grooved or forked device, and not held in the hand or in some clamp device.

According to F. Brunet (Chap. 12, this volume), bullet cores appeared in Central Asia (Kazakhstan, Uzbekistan) possibly during the tenth or ninth millennium, and certainly during the eighth millennium cal B.C. In the Near East, they are common in the Pre-Pottery Neolithic and Early Neolithic from Anatolia (Cayönü circa 8500–8250 B.C.; Binder 2007) to Pakistan, from about the mid-ninth to mid-seventh millennium (most present in Iran; Wilke 1996; Chap. 2 by Inizan, this volume).

3.5 Mode 4

In the next step, mode 4 defines the potential use of the entire body weight as the knapper uses a longer crutch from a standing position (Fig. 18.8). The high force delivered requires an effective holding device for the core. After many attempts and adaptations with different clamps or ‘squeezing vices’ (Pelegrin 1984b), I am convinced that they constitute at best a mediocre, and possibly wrong, solution because any kind of binding used will still allow the core to move a little, judging in part from the grating sound that is produced (unless there is a metal screw somewhere that can be screwed very strongly). At any rate the holding device should certainly be rigid.

While trying to press off very long blades in flint using a forked device that bends somewhat during the push, it seemed very difficult to drive the blades all the way to the distal end of the core, and most of them came out rippled and broken. Switching to a rigid grooved device, with all other elements remaining the same, culminated in better results with complete blades running the full length of the core. It seems that a non-rigid device absorbs, and thus reduces, the bending force of the crutch as the core appears to shake or vibrate. Curiously, this phenomenon occurs with long flint blades but not so much with shorter blades, nor obsidian blades, and it is possible that its manifestation depends on the duration of the detachment (if we assume that a 20 cm long blade takes twice the time to detach as a 10 cm long blade).

‘Stuck’ devices, like sticking a core into a hollow trunk or log, can be effective for some types of cores but they imply an adaptation of the core morphology (although the core decreases in size during knapping). They also need to be heavy, rendering them barely transportable and therefore inadequate for non-sedentary people.

Using the full weight of the body, flint blades up to 20–21 mm wide (for an antler tip, add 1 or 2 mm with a copper tip) can be detached with a well-adapted long crutch. The main shaft is made of boxwood or another strong wood, with a slight curve to produce a discrete but clear bending elastic effect, while the Mexican crutch used with obsidian should be more rigid (Titmus and Clark 2003). In my experience, more curved crutches are better adapted to the detachment of curved blades, but producing curved blades was apparently never intentional. The length of pressure blades – up to 20 cm – depends mainly on the stability of the core holding device and on the quality of the pressure tool (the rigidity of the holding device allows for a full expression of the ‘spring’ of the bending crutch), assuming that the core allows for it in length, shape regularity and material homogeneity (Fig. 18.9).

A flint core (facetted platform, shaped by three axial crests) and 30 of its first 65 blades (the core was further reduced to a bullet shape 16 cm long and 17× 22 mm wide, after producing 94 blades), using a long crutch in a standing position (mode 4). The widest blade (No. 10 from top left on this view) reaches 22 mm (a copper point was used for this test, reproducing the classic Harappan blade pressure production)

3.6 Mode 5

Developing extra force by pressure – much more than the body force – implies the use of a lever that can multiply human strength by 10 or 15 times. Possibly used during the Paleolithic period to move mammoth carcasses or remove large stones out of a rock shelter, the lever principle was undoubtedly well understood by early Neolithic people who erected standing megaliths weighing several hundred kilograms in the Near East and who also constructed very large houses with strong poles in Europe. Although I could not measure it precisely, I estimate that about 300 kg of pressure is needed to detach Neolithic or Chalcolithic pressure blades in flint that reach 3–4 cm in width and more than 30 cm long (the longest flint blade known comes from grave n°1 of the Varna Chalcolithic cemetery in Bulgaria; it is 43.4 cm long and 3.2 cm wide: Manolakakis 1996, 2005, 2006; Pelegrin 2006).

A strict immobilization of the core is required to adequately perform this technique, and preliminary attempts involved setting the core in the ground (with intermediary pieces allowing space for the blade to detach) and using a lever fixed through a socket in a tree or against a stone. This gave irregular results because the core tended to sink in the ground. I concluded that the whole device should be made from one single piece of wood, which could be a tree trunk about 20 cm wide, in which both the socket of the lever and the core would be fixed. Again, the groove principle can work here (with a double frontal support and a bottom rest), carved through the wood so that the detached blade ‘flies’ through it (Fig. 18.10).

In theory there is no dimensional limit for blades detached by lever pressure. While I was able to detach blades up to almost 6 cm wide and 40 cm long in flint, it is really the size and homogeneity of the raw material that determines the limit (Fig. 18.11). In the diagram presented in Fig. 18.12, we summarize the width of blades produced using these different pressure modes.

4 Obsidian and Heat-Treated Flint

With regards to obsidian, which is more fragile and brittle than flint, experimental attempts provide some results that are different to those obtained for the production of flint microblades or bladelets. Indeed, different types of obsidian cores of a small to medium size can be reduced by pressure without the need for any holding device. For instance, Jeff Flenniken demonstrated that regular microblades up to 10 mm wide could be detached from a narrow obsidian core that was simply squeezed between the fingers and the palm of the left hand (protected by a piece of soft skin), with the flaking surface of the core being turned face up and free of contact (Flenniken, 2003). This would be considered as a mode 1 pressure technique.

Ohnuma (1993) presented two different pressure techniques to detach obsidian microblades (and also some in siliceous shale from Yamagata in northern Honshu). The first is done using a short, hand-held tine and a vice made from a forked branch to hold a small core in the left palm. Ohnuma writes that the vice prevents the core from moving due to the flexibility of the palm, but we consider the real advantage to be the prevention of direct compression of the flaking surface of the core into the palm, which regularly results in a fracture of the microblade, or at worst a step or hinge termination of the detachment.

The second manner is performed using a 40 cm long antler tine controlled by the right hand and pressed vertically by the chest/shoulder (standing on his feet but bending forward) with the platform of a necessarily elongated core being pressed by the left hand on and against an organized set of rock blocks. As a result, Ohnuma demonstrated the production of microblades in obsidian and siliceous shale which are up to 6.5 mm wide and 4.5 cm long, but without mentioning which technique produced which results. Ohnuma’s first technique can be considered consistent with mode 1b (his forked vice being equivalent to our grooved vice Pelegrin 1988). However his second technique, the archaeological plausibility of which requires more discussion (are such rocks available everywhere, at every site where such microblades were produced?), is difficult to classify.

The morphology of elongated cores allows them to be stabilized, with the knapper sitting in a low position (10–15 cm above the level of the core) while squeezing and pressing the core down onto the ground with the feet (with the help of the left hand if necessary), while the right hand controls the pressure stick pushed by the abdominal muscles (Fig. 18.13a). This is how I was able to reduce a large Yubetsu obsidian core into about 100 microblades up to 7 cm long and 15 mm wide (Fig. 18.13b, c), using a 35 cm long, slightly curved antler tine (Hokkaïdo red-deer) as a pressure tool placed at the belt. In this case, the technique resembles our flint mode 3, with the critical difference being that no complementary holding tool is needed. However, there should be a minimal size limit for the core to be immobilized in this way, a limit that remains to be further investigated. Fortunately, I was able to detect the stigmata of this ‘between the feet’ technique: the contact of one of the heels on the side of the detachment surface provokes a slackening of the fracture front so that the edge of the microblade, as well as the remaining ridge on the core, have overlapping lancets (Fig. 18.13d).

Experimental model proposed for the detachment of pressure bladelets from an obsidian ‘Yubetsu’ core. (a) Holding the core between the feet with the help of the left hand and using an antler tine. (b) The experimental core with (top) ‘crested blade’ removed to create the platform and showing the volume reduced. (c) View of the bladelets detached. (d) Two views of overlapping ‘lancets’ produced by a contact between the bladelet detached and one of the ridges

Using mode 3 as described for flint (short crutch pressed with the abdomen in a sitting position, core set in a grooved piece facing the knapper), it is possible to detach obsidian bladelets up to 18 mm wide and 12–15 cm long. It is worth noting that in Kaletepe in Central Anatolia, the excavations by D. Binder and N. Balkan-Atli (2001) provided ‘unipolar bladelet cores’ with technical stigmata clearly indicative of the use of a similar device for holding the core to the one we developed for mode 3, that is evidence of distal contact and bilateral upper frontal contact for the core, with an 18 mm straight distance in between, which is exactly the maximum width that we experienced with obsidian in mode 3.

Mode 4 (a long crutch placed under the belt in a standing position using most of the body weight, with a core set in the ground) can produce obsidian blades up to 26–28 mm wide and 20, to even 30, cm long. That also seems to be the limit of both the technique proposed by Crabtree (1968) and the ‘Mexica technique’ rediscovered by J. Clark and put into practice by G. Titmus (Titmus and Clark 2003). These latter experiments with obsidian show that using the same pressure mode, obsidian allows for the detachment of blade(let)s about 30–40% wider than flint (not far from the P. Kelterborn experience of >50% with glass as compared to flint under controlled conditions, Kelterborn 2003).

In recent attempts, an antler tipped pressure stick was used in the application of lever pressure on obsidian, and as expected it proved its feasibility (Fig. 18.14). A mode 5 for the production of large obsidian pressure blades is presently recognized in Anatolia starting during the PPNB (Chap. 5 by Altinbilek et al., this volume), in the Neolithic and Chalcolithic of Armenia (Chap. 6 by Chabot and Pelegrin, this volume) and, I suspect, in the Early Classic Maya period (e.g. at the Kaminaljuyu site in Guatemala, Hirth 2003). A doctoral student from Japan (Oba Kobayashi) recently showed me some photos of a huge obsidian blade core collected in Northeast China that was obviously reduced in the form of very large blades (about 40 cm long and 4 cm wide) by lever pressure.

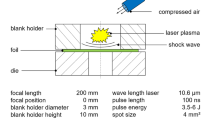

The heat treatment of flint ‘pre-cores’ prior to their bladelet production by pressure is presently demonstrated in different places around the Mediterranean Sea as early as the Middle, if not the Early, Neolithic period, and even earlier in some places in the Near and Middle East (Binder 1984; Pelegrin 1994; Inizan et al. 1975–76; Inizan and Tixier 2001; Chap. 7 by Binder et al., this volume). Some recent success in the heat-treatment of medium-sized flint cores (ongoing research with D. Binder and V. Léa) allowed me to test the increase in bladelet width using the pressure technique outlined for mode 3. Blades up to 16 mm wide were produced, as compared to the production of bladelets up to 12 mm wide using the same flint that was heat-treated. As measured by P. Kelterborn (2003) in laboratory conditions, heat-treatment seems to provide an increase of 20–30% to the width of flake products given the use of the same pressure mode.

5 Different Types of Platform Morphology and Preparation

Keeping different archaeological cases in mind, there are different types of core platform preparation used for pressure blade(let) production, which in turn lead to different types of blade platform (the portion of the platform that is detached with the blade and is still visible at the proximal end of it). They can be considered as more or less complex and thus can be presented with some order.

We start with those adapted to an organic pressure tool point, the most basic and widely used being the orthogonal, and thin blade platform. With this method, the pressure tool is placed just behind the edge of the core platform (a planar surface which forms an angle of about 90° with the detachment surface) after this edge was trimmed towards the flaking surface (reduction of the overhang, eventual lateral isolation +/− smoothing). The organic pressure tool point is offered a reasonable contact on a flat surface, spreading across the platform according to the force necessary for fracture initiation: from less than 1 mm in thickness for microblades, to 1–2 mm for mode 3 (Fig. 18.15) and 2–3 mm for mode 4 (Fig. 18.16) and even 5–7 mm for mode 5 (the respective thickness can be somewhat reduced on obsidian).

View of the flat platform of a flint core and refitted blades detached by the standing pressure technique with a long crutch (mode 4, antler tip). Note that the gap between the blade platforms, due to overhang removal and platform isolation, looks slightly exaggerated because of photographic distortion

Depending on the minute preparation of the platform edge, the blade platform appears more or less elliptic, with a width larger than its thickness, but it is not really punctiform or linear. There is usually no visible crack on the blade platform because the organic point is too soft to create a circular crack, and because the pressure spreads on the whole of the blade platform. A discrete and regular lip can be seen and felt behind the platform because the fracture initiates from the tearing out of the outward component once the full compression of the inward component is produced (a pressure detachment movement involves a vertical equal inward component and a tear out equal outward component, according to Crabtree 1968).

This orthogonal thin modality seems to have existed everywhere that pressure blade(let) production occurred, both flint and obsidian. One should expect the blade platform size to remain relatively small, as the larger (wider and thicker) the blade platform, the more force necessary to initiate the fracture. As the pressure force is limited given the mode (except for mode 5), the knapper will avoid tearing out excessive blade platforms through unnecessary effort. An exception to this rule is given by the pressure detachment in Mesoamerica (Post-Classic, central Mexico, Titmus and Clark 2003, p. 91), of bladelets with a wide and thick platform (with unreduced overhang) from cores with a platform which has been pecked and ground, which clearly facilitates the fracture initiation using an organic point (hard wood, see Chap. 3 by Clark, this volume).

Another modality of platform preparation is that of faceting, where the platform of the core is not created as a flat surface but is corrected more or less frequently (for each blade or after a series of blades) so as to offer a small, flat surface or a little bump on the pressure tip. The platform of the blades can thus be somewhat thicker and quite variable, from a flat facet to a flat/convex/dihedral (non acute) facetted platform (Fig. 18.17). Such is the case, for example in the Upper Capsian (Tixier 1976, 1984) and in the Castelnovian (Chap. 7 by Binder et al., this volume).

A more specific platform morphology is that forming an acute edge angle with the flaking surface, as it has been already identified in the Recent Chassean (Binder 1984, 1991; Léa 2004a, b) and in Anatolia (Binder 2007 and Chap. 7 of this volume), seemingly adapted to a mode 3 (or 2?) pressure technique and using an antler point (practically, an antler point withstands the moderate force delivered without damage). In this case, the platform preparation for the next blade to be removed is very easy. From an acute edge, it can be done very precisely using a handheld pressure tool like in the Recent Chassean (Binder 1984, p. 83). Within this group can be mentioned the very recent diagnosis of the pressure production of small- and medium-sized pressure blades in Northern Finland (Rankama and Kankaanpää 2008).

A peculiar platform preparation observed in Poland and Ukraine for the detachment of lever pressure blades (mode 5) leads to thick convex facetted or dihedral blade platforms (Pelegrin in press). At first glance this could be evocative of the use of a copper pressure point, but the typical cracks created by a copper point are absent on the archaeological blades, and experiments demonstrate that a well-prepared deer antler pressure stick (tine or trimmed base) can withstand the pressure on such facetted or dihedral platforms. As another diagnostic feature, there is a tear out lip just behind the impact point or zone.

The use of a copper tip on the pressure tool certainly facilitates the initiation of a blade (let) fracture compared to an antler tip. That is because (1) copper is somewhat harder than antler which eases the fracture initiation and (2) copper can be shaped and used as a tiny end tip offering a very small impact point on the core platform or platform edge, while a similar antler or ivory point will split or crush under similar pressure (Inizan and Pelegrin 2002). A copper point also allows the detachment by pressure of minute faceting flakes on the core platform that procure additional facilitation of fracture initiation. The common consequence of these different elements explains how while using the same mode of pressure on flint, the use of a copper point instead of an antler point allows roughly for an extra 10% in blade(let) width (in Fig. 18.12, an extra point for the maximal width of mode 4 flint blades was recently added considering the experimental results of José Heredia, using a copper point on facetted platforms). Associated with the use of a metallic pressure tool point (more or less pure copper from native nuggets or some deliberate or non-deliberate alloy), one can describe different core platform preparation and related blade platform morphologies.

A pointed tip of copper (or bronze) is incisive enough to create a deep cone and thus facilitating fracture initiation. It is possible to detach a series of flint pressure blade(let)s using modes 1b–4 without any preparation from a flat orthogonal platform (Fig. 18.18) as seen in Pakistan near the Rohri (Pelegrin 1994, p. 592) dating possibly to the Indus period (Briois et al. 2005). The thick platforms of these blades, along with preserved overhangs, shows a clear circular crack of 1–2 mm in diameter which renders the diagnosis clear (indirect percussion using a copper-tipped punch can give a similar aspect with a larger diameter circular crack, but our experimental tests of the technique did not match the regularity of the blades produced by a pressure technique). Using mode 5 (lever pressure), the contact diameter reaches 2–3 mm (Fig. 18.19). A very early mention of the probable use of a copper pressure tool point is given by D. Binder (2007, p. 237) in the Early PPNB from Cayönü in Anatolia.

View of the flat platform of a flint core and refitted blades detached by standing pressure technique (mode 4, copper tip). Most of the blade platforms show a clear circular crack indicative of a small contact 1.5–2 mm in diameter. Light brown semi-translucent flint. The dark traces on this and following pictures are those of copper

View of the proximal end of five flint blades detached by lever pressure using a copper-tipped tool. The orthogonal core platform was prepared with reduced overhang removal creating rather thick blade platforms. Each of them presents a partial or complete circular crack indicative of a small contact, 2–3 mm wide. Grey, semi-translucent flint

The orthogonal rather thin abraded platform modality can also be used with a copper point, the pointed tip of which is placed just behind the edge of the platform after it has been abraded (overhang reduction) and smoothed to prevent edge crushing while the pressure is built up. The use of copper can be distinguished from that of antler because on most of the blade(lets) a punctiform initiation of the fracture will be visible at the back of the blade platform, the back line of which sometimes shows a half circle with a small diameter (about 2 mm). A similar observation has been made with obsidian (Pelegrin in Astruc et al. 2007).

Elliptical and small blade platforms detached from an acute edge core platform can be observed in different large blade productions (mode 5, possibly mode 4 for smaller blades) around the western Mediterranean (southeast of France with identified traces of copper, cf. Renault 1998, 2006; Renault et al. in prep.; Sardinia cf. Costa and Pelegrin 2004; Italy cf. Guilbeau 2010; Algeria cf. Pelegrin in press.). The platform of the core can be flat and generally inclined or it can be facetted, with each blade detachment being prepared by the removal of a small flake, the bulbar scar of which forms a localized acute edge angle. After lateral isolation and some smoothing by gentle grinding, the copper tip of the pressure tool is directly set on the acute edge with the resulting blade having round or ogival shoulders.

The fracture initiation usually starts right at the contact with the copper point, giving a very tiny blade platform (a few mm wide and about 1–2 mm thick for mode 4, 2–3 mm for mode 5). Using a somewhat translucent flint, a frontal light reveals diverse aspects of cracks that are a good indication of the use of a metallic material (Fig. 18.20). However, these cracks remain much less frequent (or invisible?) with opaque flint (Fig. 18.21). Note that the fracture initiation may start behind the actual contact, thus giving a somewhat larger blade platform with an obvious lip (Fig. 18.21: 5; an antler point would give a similar aspect), and that a few blade platforms can be discreetly split or splintered (Figs. 18.20: 3 and 18.21: 3). This is a crafty way of preparing the blade detachment, because such a tiny blade platform facilitates the fracture initiation and the bulb remains small or moderately prominent, which eases the preparation and detachment of further blades.

View of the proximal end of five flint blades detached by lever pressure using a copper-tipped tool. The somewhat acute edge platform (75–85°) was prepared with repeated overhang reduction and lateral isolation. Each blade platform, except that of blade No. 3 which splintered during the detachment, presents a crack indicative of the reduced contact from a rather hard material. Blade No. 1: three posterior cracks. Blade No. 2 and 4: lateral cracks. Blade No. 5: a complete front crack. Brown, semi-translucent flint

View of the proximal end of five flint blades detached by lever pressure using a copper-tipped tool. The acute edge platform was prepared with overhang removal, isolation and smoothing. The first and last blades, with a large lip, show that the fracture initiation occurred well behind the contact area. Blade No. 2 bears a transversal crack on its platform. The platform from blade No. 3 is splintered. Blade No. 4 has a very small platform (2 mm thick and 4 mm wide) with an irregular back-line, indicative of a hard tip. It is possible that a crack exists at the limit of the dark spot (copper trace of the contact) on blade platform of No. 1, but it is not visible on this rather opaque and dry flint

A very specific platform preparation seemingly adapted to a copper-tipped pressure tool is dihedral acute, as seen in South Iberia for flint cores of very different sizes corresponding to modes 1b–5 (Pelegrin 2006; Morgado et al. 2008). Two small flakes are detached (best done with a copper-tipped pressure or punch tool) on the platform so that their scars form an acute arris precisely in the axis of the blade to be detached. The pressure point is placed on this arris, a few millimeters back from the edge. The arris forms an angle of about 90° with the detachment surface. Experimentally, the copper point is hard enough to initiate the fracture most of the time at the very contact on the arris so that there is no lip just under the arris (an organic point would create a clear lip).

The same preparation, more or less systematic, can be observed in different ‘Canaanean’ productions (mode 5) in the Levant or Near East (Chabot 2002; Chap. 6 by Chabot and Pelegrin, this volume), and in Pakistan (Pelegrin 1994) where copper traces were identified on such a blade detached by mode 4 (Méry et al. 2007). A similar preparation, from convex faceting to dihedral, appears on obsidian (mode 3), with the recent Neolithic in Greece (Perlès 2004) probably associated with the use of a copper point. A series of experimental blades detached using mode 4 shows that about half of the blades present a crack on the platform (Figs. 18.22, 18.23).

View of the facetted platform of a flint core and refitted blades detached by standing pressure technique (mode 4) using a copper-tipped tool, following a convex facetted or dihedral preparation. In this barely translucent flint, about half of the blade platforms bear a crack, as can be seen on the photo: (a) back crack (located just behind the pressure point), (b) front crack (located in front of the pressure point), (c) lateral crack (occurred at one side of the pressure point, (d) ‘^’ shape indicates bilateral crack, regarding their position to the pressure point

Another specific preparation adapted to the use of a copper point on obsidian is done by isolating, using careful bilateral abrasion, a tiny beak (protruding 1 mm over 2 mm wide) at the edge of the core platform, and then smoothing it completely round by gentle grinding with a fine-grained sandstone. The copper point is then set precisely on this round ‘nipple’ and detaches a blade/bladelet with a minute, smooth blade platform (seen on pressure blades detached with mode 3 and 4 within different Anatolian archaeological contexts). A careful examination under light shows that most of the blade platforms bear stigmata of a very punctiform contact indicative of a hard material (an antler point would spread and produce a larger contact, and therefore a larger blade platform with a clear lip).

Table 18.1 summarizes some of the main archaeological cases that are referenced in the text above and in different chapters of this volume. It is obviously not exhaustive, but gives a general appraisal of the state of knowledge on the matter.

6 Shaping of Pressure Cores: A Brief Overview

There are different methods of core shaping for pressure blade/bladelet production, the use of which is more or less dependant on the available raw material. Regarding the larger modes 4 and 5, there are only two ways to shape a core. In the first case, the raw material offers a large lenticular, or tabular, shape about 5–10 cm thick, with a rather thin cortex on both regular faces. Ideally, the shaping of the core can be limited to the creation of a platform and to the regularization of the flaking surface by ‘opening’ axial removals or by transversal, unifacial or bifacial flakes (cresting). In the second case, the raw material is nodular or irregular and a total, or nearly complete, core shaping must be completed. After an initial roughing out by hard hammer stone percussion, an elongated volume is built up using three or even four axial crests, giving the volume a triangular or quadrangular cross section. The blade production can thus start from one or two of these crests, by the detachment of crested blade(s).

Shaping out medium-sized cores (from 10 to15cm high) from nodules can be efficiently done by first creating the platform by removing a well-placed thick cortical flake, then using this platform for the detachment of axial shaping blades by indirect percussion, combined, if necessary, with transversal flakes (e.g. one partial temporary frontal crest and one or two back-crests). For smaller cores, a similar method can be applied to a short or long, but thick, flake or chunk, using the ventral face as a platform and shaped by axial flakes into a more or less elongated volume, for example the ‘carinated scraper’ type, similar to the Danish ‘keeled-core’ (Chap. 9 by Sørensen, this volume) or to the Japanese ‘Horoka’ method (Chap. 11 by Takakura, this volume). Another family of cores for small bladelets or microblades is the ‘burin-like core’. In this case a platform is created by abrupt retouch and/or a burin spall at the corner of a flake or at the end of a blade and the bladelets/microblades will be detached on the side of the blank, the thickness of which is represented by the width of the flaking surface possibly further corrected by a notch or repeated abrupt retouch.

The well-known Yubetsu method (Inizan et al. 1999; Chap. 11 by Takakura, this volume) starts with the shaping of an asymmetrical biface from which a crested blade is detached, the negative scar of it serving as a platform for the detachment of microblades/bladelets. One can consider as simplified variants of this method the partial bifacial shaping of a large flake or thin slab, but treating the platform by transversal truncation should be considered as a significant variant (Chap. 14 by Gómez-Coutouly, this volume). Indeed, one has to consider the different factors of the raw material (dimensions, shape and quality) that can determine or influence the shaping method options observed within an archaeological assemblage prior to making any ‘cultural’ interpretation.

7 Different Sequences of Blade Production

After a careful examination of the ‘diacritical schema’ (order of the previous blade scars) on the cores and blades, D. Binder (1984; Binder and Gassin 1988) was the first to notice a clear difference between the Early and Recent Chassean. In the latter, the 2-1-2′ code (on the dorsal side of bladelets with three facets, the two lateral scars are chronologically later than the central scar) is clearly dominant, indicating that the reduction sequence was organized in a systematic order either by unidirectional (Binder and Gassin 1988) or by convergent, divergent or ‘inserted’ series (Pelegrin in Astruc et al. 2007). These observations, the code 2/1/2′ versus 1/2/3 or 3/2/1 from the blade(let)s and the eventual systematic order of the reduction sequence visible on the core(s), are indeed relevant to the characterization of a pressure production.

8 Development and Transmission of the Pressure Techniques

In the last part of this chapter, I discuss the archaeological development of pressure techniques (from the smallest to the largest), and examine the practical conditions of their diffusion or transmission. Let us first recall, as M.L. Inizan has already done (1991, 2002, Chap. 2 of this volume), the importance of pressure techniques in understanding cultural questions. It employs specific categories of knowledge. The first refers to its practicability: someone who would have never seen or heard that stone can be detached by pressure (but for edge regularization or steep retouch) has very little chance to discover it by himself. Another specific knowledge category relates to the specific tool(s) involved in pressure technique. Barring the detachment of tiny microblades from an elongated core simply grasped in the left hand (mode 1), a flint core has to be held with a specific tool, the minimal form of which being a grooved piece such as the one that I proposed in 1988, or a hollow shaft for the ‘burin on blade’ or ‘carinated scraper’ microblade core types.

From that base (mode 1b in flint) the particularity of the tools involved in performing pressure technique increases together with the size (mainly width) of the products. Mode 2 requires a shoulder crutch and a set of grooved pieces or another device for squeezing and holding the core. Mode 3 sitting requires a similar crutch to mode 2, but a larger grooved piece or a notched piece and a distal support set in the ground. Mode 4 standing necessitates a longer crutch and a holding device (without the help of the left hand) possibly similar to that of mode 3 but adapted to larger cores. Mode 5 – pressing with a lever – presupposes knowledge of the lever principle itself and that of rather sophisticated implements (Fig. 18.24).

Consequently, we can propose a few postulates about the development of pressure techniques. It is highly improbable that an inexperienced community could have invented from scratch an advanced mode of pressure like mode 3 or higher. It is, however, conceivable that an inventor of mode 1 can very quickly develop modes 1b and 2, so that the very first step (mode 1) may in fact be archaeologically invisible. It is highly improbable, however, that a group will directly invent mode 3, and even more improbable mode 4, not to mention lever pressure (mode 5).

In addition, modes 4 and 5 presuppose the mastery of other techniques to achieve the pre-shaping of the core, as well as access to raw material with adequate size and homogeneity. If a mode 3, 4 or 5 is recognized within a lithic industry, one should first look for the same or preceding mode within the same geographic or cultural space. If none of these are present, a source has to be detected within another cultural complex more or less adjacent geographically, taking into consideration the whole of the typo-technological characters of each that may account for their ‘proximity’ or distinction. Once a candidate is detected or suspected, the modalities of transmission or diffusion can be considered.

Other assumptions regarding the question of transmission or diffusion emerge from our experimental reproductions and experiences. To those assumptions, we can add anecdotal exchanges between modern flintknappers and experiences during practical teaching events. These observations help us to envision the practical conditions and circumstances that might be sufficient or necessary for the transmission of a given mode of pressure technique.

I can easily believe that a Paleolithic hunter and producer of his own microblades by percussion, who heard that it was possible to detach a microblade by pressing instead of striking on a core, would be tempted to try it due to curiosity and emulation, and that he could succeed in detaching a few microblades by pressure with mode 1 from a core already started by percussion. Considering the thinness and regularity of the microblade product that percussion cannot easily produce, our hunter may thus train in this new ‘way of doing’, and on the basis of this acquired knowledge, he would potentially master it rather quickly so as to be able to perform it efficiently and thus adopt it, all the while raising the interest of his fellow knappers.

The acquisition of this new way of doing would be even easier if that man could watch, be it only once, an expert in action, perhaps on the occasion of a meeting of our hunter with another initiated group or of a visit of the expert to the hunter’s group. Through such a meeting, the transmission of the new technique does not even imply any description or explanation that would require a linguistic understanding, because the new ‘way of doing’ is essentially reducible to a knowledge that is visible and understandable in a few seconds (such as seeing someone using a bone needle).

The ‘new way’ can also be reported by miming it, and can thus be transmitted more quickly than by repeated meetings ‘down the line’ within related groups. It can even ‘jump’ over unrelated or scarcely related groups that would have little mutual linguistic understanding. In the context of groups and communities of hunter-gatherers that are already producers of microblades by percussion (assuming that the raw material(s) used would also be usable for pressure microblades), this elementary or basic mode 1 is susceptible to spreading quite quickly. Moreover, the greater productivity of the pressure technique mode would certainly stimulate the adoption of the ‘new way’ if suitable raw material is scarce or not available everywhere in the frequented territory.

In a context of ubiquitous raw material, permanent access to suitable raw materials allows for a more frequent and consumptive production by percussion, while in the first case of scarce or unevenly distributed raw material, the hunter-gatherer groups are used to managing raw material in a curated way, that is preparing cores in advance and transporting them for a later sequential reduction. In the opposite scenario, if the non-initiated groups are not microblade users, the transmission of the pressure mode of production can only accompany, and must rely upon, the adoption of those innovations that require microblades, such as the principle of fixing narrow lithic elements onto spearheads as a way to increase their haemorrhagic effect and the fabrication of adhesives. It would therefore mean much more to show and to explain, and might imply a mutual linguistic understanding.

The transmission of the modes 1b and 2 to inexperienced groups can be considered somewhat less easy because these modes require the fabrication of specific tool(s) (grooved piece +/− shoulder crutch), and some know-how for the use of them. Therefore a simple oral account has less chance of success in transmitting the technique. I presume that direct social contact, like meeting or visiting between experienced and non-initiated or inexperienced pressure knappers, would be necessary for the transmission of modes 1b and 2.

The transmission of modes 3, and above all 4 and 5, to a person ignorant of pressure technique would certainly require a demonstration including comments and explanations regarding the necessary morphology and regularity of the core, the platform preparation and setting of the tool including all critical details, the dynamic of the movement and the modalities of repair after accidents. All of these different conditions imply discrete knowledge and invisible know-how. The adoption of the ‘new technique’ by an inexperienced knapper would also imply, besides the access to adequate raw material, a respectable effort in the core shaping, the difficulty of which grows exponentially with the increasing dimensions of the blades being produced.

Conversely, the transmission of a mode X to a person who already practices the mode X-1 becomes relatively easy as, from one mode to the next, there are only one or two additional concepts to be mastered along with the improvement of some prior details. We have already assumed that it would be relatively ‘easy’ for a knapper to switch by himself from mode 1 to mode 2, that is, to replace his hand pressure tool by a shoulder crutch (possibly through an ‘arm crutch’ –or Ishi stick- step). Giving the knapper a short hands-on demonstration, or even simple indications, would certainly make it easier.

Switching from mode 2 to 3 is not that difficult either; the new concept is to steady the core on the ground, with the platform facing the knapper, through an easy adaptation of a larger but similar holding device (grooved piece or possibly another device). The very same shoulder crutch becomes useable by pressing it with the belly just under the belt, the knapper sitting low on some stone or piece of wood (a more refined adaptation of this is to dig out a little hole in the soil and/or use stones to stabilize the holding device). From mode 3 to 4, the adaptation consists in lengthening the crutch so as to employ it in a standing position, the holding device being again somewhat larger (a notch carefully carved on a superficial tree root can do as well, Pelegrin 2003).

So, from 1 to 2, 2 to 3 and 3 to 4, we assume that a brief demonstration, and possibly the narrative of an attentive observation, may well allow for a transmission of the innovation. That innovation should be of interest because each mode progressively gives the possibility of producing somewhat larger products with greater ease. However, the shaping of larger cores requires a qualitative improvement relating to the length of the expected products and the available raw material. From mode 4 to 5, which is from standing pressure to lever pressure, the innovations regarding the lever device are also rather understandable for an observer who is already an experienced knapper of pressure blades in a standing position.

If this knapper could attend a session of lever pressure blade production for a few hours, he or she would probably be able to reproduce blades on their own, especially if they were motivated (imagine what a master stroke in front of fellow knappers and for those who receive the products, staring with astonishment at such regular and huge blades). The report of an attentive observer, who could also mime the actions and draw some outlines on the ground, could easily motivate a knapper experienced in the standing pressure mode to try using a lever with success. I consider it highly improbable, however, that several inexperienced intermediaries might have transmitted, by word of mouth, sufficiently complete and precise information to be useful to a final receiver trying to replicate the pressure blade technique.

9 Conclusion: From Technical to Cultural Interest

We hope to have demonstrated in this chapter that pressure blade production involves much more than just one sole technique. Indeed, this peculiar mode of blade(let) production (mode in the sense of Newcomer 1975, p. 97) covers several ‘techniques’, or methods in the American sense: the particular mode of force application (each of them with their own range of products and dimensional limits), the way of holding or immobilizing the core, and two distinguishable types of material for the tip of the pressure tool (organic and metal). Furthermore, all of these techniques are visible on the archaeological material in the form of the platform preparation and detachment stigmata. The method of core shaping and the reduction sequence represent additional features.

Pressure blade production, from micro- to macroblades, constitutes a rich chapter of lithic technological evolution and opens up a wide field of cultural interpretation for archaeologists. In this chapter we chose not to consider the techno-economical and sociological aspects of pressure production, which are of great interest in Neolithic and later contexts as examples of specialized productions and exchange/diffusion mechanisms.

One of the more useful outcomes of this research is our postulate that the advanced ‘modes’ of pressure have very little chance (mode 3), or no chance at all (mode 4 and 5), to be invented de novo without the traditional knowledge base of less advanced modes and can hardly be transmitted by a casual contact from an experienced knapper to a knapper with no prior experience of pressure blade manufacture. As an example, consider the sudden appearance of pressure bladelets indicative of mode 3 in different regions of the western and southern Mediterranean basin during the seventh millennium (Chap. 4 by Rahmani and Lubell, this volume, Chap. 7 by Binder et al., this volume). This is indeed strongly evocative of the migration of some, possibly very few, experienced knappers of eastern Mediterranean origin.

The historical development of pressure techniques is not only interesting per se, regarding the amazing capacity of technical invention by prehistoric people, it is also relevant for the detection and interpretation of demographic events and social relations that made innovations spread over continents.

Notes

- 1.

In this chapter, ‘microblade’ refers to tiny bladelets generally less than 8 mm wide, such as those described in the Far East and Arctic regions. ‘Bladelet’ refers to small blades generally 8 to 12 mm wide. ‘Blade’, which is the general term for elongated flakes detached in parallel series, is expected here to be over 12 mm wide.

References

Alix, Philippe, Jacques Pelegrin, and Huguette Deloge 1995 Un débitage original de lamelles par pression au Magdalénien du Rocher-de-la-Caille (Loire, France). Paléo, No.7: 187–99.

Astruc, Laurence, Bernard Gratuze, Jacques Pelegrin, and Peter Akkermans 2007 From production to use: a parcel of obsidian bladelets at Sabi Abyad II. In Systèmes techniques et communautés du Néolithique précéramique. Technical systems and Near-Eastern PPN communities. (5 ème colloque international sur les industries lithiques du Néolithique précéramique), edited by Laurence Astruc, Didier Binder and François Briois, pp 327–341. Editions APDCA, Antibes.

Binder, Didier 1984 Systèmes de débitage laminaire par pression: exemples chasséens provençaux. In Préhistoire de la Pierre Taillée II, économie du débitage laminaire (Table ronde de technologie lithique 3; Meudon-Bellevue octobre 1982), edited by Jacques Tixier, pp. 71–94. CREP, Paris.

Binder, Didier 1991 Facteurs de variabilité des outillages chasséens dans le sud-est de la France. In Identité du Chasséen : actes du Colloque international de Nemours, 1989. (Mémoires du Musée de Préhistoire d’Ile-de-France 4) edited by Alain Beeching, Didier Binder, Jean-Claude Blanchet and Claude Constantin, pp. 261–272. APRAIF, Nemours.

Binder, Didier 2007 PPN Pressure Technology: Views from Anatolia. In Systèmes techniques et communautés du Néolithique précéramique. Technical systems and Near-Eastern PPN communities. (5 ème colloque international sur les industries lithiques du Néolithique précéramique) edited by Laurence Astruc, Didier Binder and François Briois, pp. 235–243. Editions APDCA, Antibes.

Binder, Didier, and Bernard Gassin 1988 Le débitage laminaire chasséen après chauffe: technologie et traces d’utilisation. In Industries lithiques, tracéologie et technologie, edited by Sylvie Beyriès, pp. 93–125. British Archaeological Reports International Series, No. 411, Archeopress John & Erica Hedges Ltd, Oxford.

Binder, Didier, and Nur Balkan-Atli 2001 Obsidian exploitation and blade technology at Kömürcü-Kaletepe (Cappadocia, Turkey). In Beyond tools: redefining the PPN lithic assemblages of the Levant, SENEPSE 9, edited by Isabella Caneva, Christina Lemorini, Daniella Zampetti and Paolo Biagi, pp. 1–16. Ed. ex oriente, Berlin.

Bordes, François 1969 Reflexions on typology and techniques in the Palaeolithic. Arctic Anthropology, Vol. VI, 1: 1–29.

Bordes, Jean-Guillaume, and Arnaud Lenoble 2002 La « lamelle Caminade » : un nouvel outil lithique aurignacien ? Bulletin de la Société Préhistorique Française 99(4): 735–749.

Bricker, Harvey M. (editor) 1995 Le Paléolithique supérieur de l’abri Pataud (Dordogne): Les fouilles de H.-L. Movius jr. Suivi d’un inventaire analytique des sites aurignaciens et périgordiens de Dordogne, (Document d’Archéologie Française, No. 50). Maison des Sciences de l’Homme, Paris.

Briois, François, Fabio Negrino, Jacques Pelegrin, and Elizabetha Starnini 2005 Flint exploitation and blade production during the Harappan period (Bronze Age): testing the evidence from the Rohri Hills flint mines (Sindh-Pakistan) throughout an experimental approach. In Stone Age – Mining Age (actes du VIIIth International Flint Symposium Bochum 13–17 Sept. 1999). Der Anschnitt, Beiheft 19: 185–191.

Callahan, Errett 1985 Experiments with Danish mesolithic microblade technology. Journal of Danish Archaeology 4: 23–39.

Chabot, Jacques 2002 Tell’Atij, Tell Guded : Industrie lithique; Analyse technologique et fonctionnelle. Avec une annexe de Jacques Pelegrin (CNRS, France) sur la reconnaissance du débitage par pression au levier. (Cahiers d’archéologie du CELAT, No. 13, Série archéométrie, No. 3). Université Laval, Québec.

Clark, John E. 1982 Manufacture of Mesoamerican Prismatic Blades: An Alternative Technique. American Antiquity 47: 355–376.

Costa, Laurent, and Jacques Pelegrin 2004 Une production de grandes lames par pression à la fin du Néolithique dans le nord de la Sardaigne (Contraguda, Perfugas). Bull. de la Société Préhistorique Française 101(4): 867–873.

Crabtree, Donald E. 1967 Notes on experiment in flintknapping: 4. Tools used for making flaked stone artifacts. Tebiwa 10(1): 60–73.

Crabtree, Donald E. 1968 Meso-American polyhedral cores and prismatic blades. American Antiquity 33(4): 446–478.

Flenniken, Jeffrey J., and Kenneth G. Hirth 2003 Handheld prismatic blade manufacture in Mesoamerica. In Experimentation and Interpretation in Mesoamerican Lithic Technology, edited by Kenneth G. Hirth, pp. 98–107. The University of Utah Press, Salt Lake City.

Gallet, Michel 1998 Pour une technologie des débitages laminaires préhistoriques. (Dossier de documentation archéologique du CRA, No. 19). CNRS Editions, Paris.

Guilbeau, Denis 2010 Les grandes lames et les lames par pression au levier du Néolithique et de l’Enéolithique en Italie. Thèse de Doctorat de l’Université Paris Ouest, Ethnologie préhistorique, Vol. 3. MAE, Nanterre.

Hirth, Kenneth G. 2003 The Kaminaljuyu Production Sequence for Obsidian Prismatic Blades: Technological Characteristics and Research Questions. In Experimentation and Interpretation in Mesoamerican Lithic Technology, edited by Kenneth G. Hirth, pp. 170–181. The University of Utah Press, Salt Lake City.

Inizan, Marie-Louise 1991 Le débitage par pression: des choix culturels. In 25 ans d’études technologiques en Préhistoire. Bilan et perspectives. Actes des XIe Rencontres Internationales d’Archéologie et d’Histoire d’Antibes 18–20 Octobre 1990, pp 367–377. Editions APDCA, Juan-les-Pins.

Inizan, Marie-Louise 2002 Tailler des roches par pression: émergence d’une technique et étapes de sa diffusion dans le monde. In Matériaux, productions, circulation, du Néolithique à l’âge du Bronze, edited by J. Guilaine, pp. 27–40. Errance, Paris.

Inizan, Marie-Louise, Hélène Roche, and Jacques Tixier 1975–76 Avantages d’un traitement thermique pour la taille des roches siliceuses. Quaternaria, XIX: 1–18.

Inizan, Marie-Louise, Michèle Reduron-Ballinger, Hélène Roche, and Jacques Tixier 1999 Technology and Terminology of Knapped Stone, followed by a multilingual vocabulary Arabic, English, French, German, Greek, Italian, Portuguese, Spanish. (Préhistoire de la Pierre Taillée 5). CREP, Nanterre (on line on the ARKEOTEK web site).

Inizan, Marie-Louise, and Jacques Tixier 2001 L’émergence des arts du feu: le traitement thermique des roches siliceuses. Paléorient 26(2): 23–36.

Inizan, Marie-Louise, and Jacques Pelegrin 2002 Débitage par pression et expérimentation : une question de méthodologie. Paléorient 28(2): 105–108.

Kelterborn, Peter 2003 Measurable flintknapping. In Experimentation and Interpretation in Mesoamerican Lithic Technology, edited by Kenneth G. Hirth, pp 120–131. The University of Utah Press, Salt Lake City.

Léa, Vanessa 2004a Les industries lithiques du Chasséen en Languedoc oriental : caractérisation par l’analyse technologique. British Archaeological Reports International Series, No. 1232, Archeopress John & Erica Hedges Ltd, Oxford.

Léa, Vanessa 2004b. Centre de production et diffusion des silex bédouliens au Chasséen. Gallia-Préhistoire 46: 231–250. (CNRS Editions, Paris).

Manolakakis, Laurence 1996 Production lithique et émergence de la hiérarchie sociale: l’industrie lithique de l’Enéolithique en Bulgarie (première moitié du IVème millénaire non cal.). Bull. de la Société Préhistorique Française 93(1): 119–123.

Manolakakis, Laurence 2005 Les industries lithiques énéolithiques de Bulgarie. Coll. Internationale Archäologie, Bd 88. Leidorf, Rahden/Westf.

Manolakakis, Laurence 2006 Les très longues lames de Varna, quelle fonction? In La fin de l’Age de Pierre en Europe du Sud, actes de la table-ronde de l’EHESS Carcassonne 5–6 Septembre 2003, edited by Jean Vaquer and François Briois, pp. 5–23. Editions des Archives d’Ecologie Préhistorique, Toulouse.

Méry, Sophie, Patricia Anderson, Marie-Louise Inizan, Monique Lechevallier, and Jacques Pelegrin 2007 A pottery workshop with flint tools on blades knapped with copper at Nausharo (Indus civilisation, ca. 2500 BC). Journal of Archaeological Science 34: 1098–1116.

Michel, Alexandre 2010 L’Aurignacien récent (post-ancien) dans le sud-ouest de la France: variabilité des productions lithiques. Thèse de Doctorat de l’Université de Bordeaux I, Préhistoire et Géologie du Quaternaire, 599 p.

Morgado, Antonio, Jacques Pelegrin, Gabriel Martinez-Fernandez, and José Afonso Marrero 2008 La production de grandes lames dans la Péninsule ibérique (IVe – IIIe mil. av.JC. cal.). In Les industries lithiques taillées des 4e et 3e millénaires en Europe occidentale edited by Marie-Hélène Dias-Meirinho, Vanessa Léa, Karim Gernigon, Pierrick Fouéré, François Briois and Maxence Bailly, pp. 309–330. British Archaeological Reports International Series, No. 1884, Archeopress John & Erica Hedges Ltd, Oxford.

Newcomer, Mark 1975 “Punch technique” and Upper Paleolithic blades. In Lithic Technology: making and using stone tools, edited by Earl Swanson, pp. 97–102. Mouton, La Haye.

Ohnuma, Katsuhiko 1993 Experimental studies in the determination of manners of micro-blade detachment. AL-RAFIDAN XIV: 153–181 (The Institute for cultural studies of Ancient Iraq, Kokushikan University, Tokyo).

Pelegrin, Jacques 1984a Approche technologique expérimentale de la mise en forme de nucléus pour le débitage par pression. In Préhistoire de la Pierre Taillée II, économie du débitage laminaire (Table ronde de technologie lithique 3; Meudon-Bellevue oct. 1982) pp. 93–104. CREP, Paris.

Pelegrin, Jacques 1984b Systèmes expérimentaux d’immobilisation du nucléus pour le débitage par pression. In Préhistoire de la Pierre Taillée II, économie du débitage laminaire (Table ronde de technologie lithique 3; Meudon-Bellevue oct. 1982) pp. 105–116. CREP, Paris.

Pelegrin, Jacques 1984c. Débitage par pression sur silex : nouvelles expérimentations. In Préhistoire de la Pierre Taillée II, économie du débitage laminaire (Table ronde de technologie lithique 3; Meudon-Bellevue oct. 1982) pp. 117–127. CREP, Paris.

Pelegrin, Jacques 1988 Débitage expérimental par pression; “du plus petit au plus grand”. In Technologie préhistorique (Notes et Monographies Techniques du CRA, No. 25), edited by Jacques Tixier, pp. 37–53. Editions du CNRS, Paris.

Pelegrin, Jacques 1994 Lithic technology in Harappan times. In South Asian Archaeology 1993, edited by Asko Parpolla and Petteri Koskikallio, Vol. 2, pp. 585–598. Annales Academiae Scientiarum Fennicae B 271, Helsinki.

Pelegrin, Jacques 2003 Blade making techniques from the Old World: insights and applications to Mesoamerican obsidian lithic technology. In Experimentation and Interpretation in Mesoamerican Lithic Technology, edited by Kenneth G. Hirth, pp. 55–71. The University of Utah Press, Salt Lake City.

Pelegrin, Jacques 2006 Long blade technology in the Old World: an experimental approach and some archaeological results. In Skilled production and social reproduction – aspects on traditional stone-tool technology, edited by Jan Appel and Kjel Knutsson, pp. 37–68. Societas Archeologica Upsaliensis, Upsalla.

Pelegrin, Jacques in press. Grandes lames de l’Europe néolithique et alentour. In Sur quatre centres de production de grandes lames en Europe néolithique (Actes de la table ronde internationale de Tours, sept. 2007), edited by Jean-Claude Marquet and Christian Verjux, Supplément à la Revue Archéologique du Centre.

Perlès, Catherine 1984 Débitage laminaire de l’obsidienne dans le Néolithique de Franchthi (Grèce): techniques et place dans l’économie de l’industrie lithique. In Préhistoire de la pierre taillée 2. Economie du débitage laminaire: technologie et expérimentation (IIIe table ronde de technologie lithique, Meudon-Bellevue, Oct. 1982), edited by Jacques Tixier, pp. 129–137. CREP, Paris.

Perlès, Catherine 2001 The early Neolithic in Greece; the first farming communities in Europe. (collection Cambridge World Archaeology). Cambridge University Press, Cambridge.

Perlès, Catherine 2004 Les industries lithiques taillées de Franchthi (Argolide, Grèce): tome III ; Du Néolithique ancien au Néolithique final. (collection Excavations at Franchthi cave, Greece). Indiana University Press, Bloomington & Indianapolis.

Rankama, Tuija, and Jarmo Kankanpää 2008 Eastern arrivals in post-glacial Lapland: the Sujala site 10,000 cal BP. Antiquity 82(318): 884–899.

Renault, Stephane 1998 Economie de la matière première. L’exemple de la production, au Néolithique final en Provence, des grandes lames en silex zoné oligocène du bassin de Forcalquier (Alpes-de-Haute-Provence). In Production et identité culturelle. Actualité de la recherche. Actes de la deuxième session des Rencontres méridionales de Préhistoire récente (Arles, 1996), edited by André D’Anna and Didier Binder, pp. 145–161. Editions APDCA, Antibes.

Renault, Stephane 2006 La production des grandes lames au Néolithique final en Provence: matériaux exploités, multiplicité des productions, aspects technologiques et chrono-culturels. In La fin de l’Age de Pierre en Europe du Sud. actes de la table-ronde de l’EHESS Carcassonne 5–6 Septembre 2003, edited by Jean Vaquer and François Briois, pp. 139–164. Editions des Archives d’Ecologie Préhistorique, Toulouse.

Renault, Stephane, Gérard Poupeau, and Stephan Dubernet in press. Reconnaissance de l’emploi d’un compresseur de cuivre pour la production de lames de la fin du Néolithique: le dépôt de lames de Sainte-Cécile-les-Vignes (Vaucluse).

Tabarev, Andrei V. 1997 Paleolithic wedge-shaped microcores and experiments with pocket devices. Lithic Technology 22(2): 139–149.

Titmus, Gene L., and John E. Clark 2003 Mexica Blade technique with wooden tools: recent experimental insights. In Experimentation and Interpretation in Mesoamerican Lithic Technology, edited by Kenneth G. Hirth, pp. 72–97. The University of Utah Press, Salt Lake City.