Abstract

Food scientists today are focused on the development of not only microbiologically safe products with a long storage life, but, at the same time, products that have fresh-like characteristics and a high quality in taste, flavor, and texture. This focus is based on the needs of the consumer, which is one of the main reasons for constant research in the so-called area of emerging technologies. Traditionally, thermal treatments have been used to produce safe food products. Pasteurization of juice, milk, beer, and wine is a common process in which the final product has a storage life of some weeks (generally under refrigeration). However, vitamins, taste, color, and other sensorial characteristics are decreased with this treatment. High temperature is responsible for these effects and can be observed in the loss of nutritional components and changes in flavor, taste, and texture, often creating the need for additives to improve the product.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

3.1 Introduction

Food scientists today are focused on the development of not only microbiologically safe products with a long storage life, but, at the same time, products that have fresh-like characteristics and a high quality in taste, flavor, and texture. This focus is based on the needs of the consumer, which is one of the main reasons for constant research in the so-called area of emerging technologies. Traditionally, thermal treatments have been used to produce safe food products. Pasteurization of juice, milk, beer, and wine is a common process in which the final product has a storage life of some weeks (generally under refrigeration). However, vitamins, taste, color, and other sensorial characteristics are decreased with this treatment. High temperature is responsible for these effects and can be observed in the loss of nutritional components and changes in flavor, taste, and texture, often creating the need for additives to improve the product. Thus, one of the challenges in food science today is to develop new technologies that can simultaneously ensure high-quality properties and long storage life. In recent years, the most popular emerging technologies being tested in food science labs have been high pressure, electric pulsed fields, ultraviolet light, irradiation, light pulses, and ultrasound, and some are already being used in the food industry, while other emerging technologies are still in the lab testing stage. Ultrasound technology is applied in the food industry mostly as a processing aid and for the cleaning/disinfecting of factory surfaces, but many of its uses are still being researched.

The majority of literature on processing foods by ultrasound, including its use to enhance other food technologies, is application-specific and reports process parameters and results for one type of experiment only. This chapter examines the process parameters across many experiments, as well as many applications in ultrasonic fields that have met with success. Discussion of the engineering principles behind the experimental results reported in literature is included. In order to show the differences between high- and low-frequency ultrasound, the parameters and applications of ultrasound will likewise be discussed. Special emphasis will be placed on food engineering applications as an update on microbial inactivation research, describing the types of experiments conducted, the basic theory about microbial inactivation, and the different processes involving the use of heat and pressure in combination with ultrasound. Uses in enzymatic inactivation will be addressed, although information is scarce, and applications of non-destructive ultrasound and high-frequency ultrasound will be reviewed in an attempt to show the broad applications of this technology in the field.

Thus, the overall goal of this chapter is to show the parameters, mechanisms, and results of different experiments around the world that have used low- and high-frequency ultrasound, so that readers can easily understand the fundamentals of this technology, which already has proven successful in many areas of food science and food processing technology.

3.2 General Principles

Ultrasound consists of a series of sound waves with high frequencies that begin at 16 kHz, which is near the upper limit of the human hearing range (Elmehdi et al., 2003; Hecht, 1996). When a given source radiates sound into a nearby medium that has mass (e.g., air, liquid, or solid), the sound propagates in sinusoidal waves. The medium responds to the propagation of these waves and also sustains them by vibrating elastically. The medium’s elastic vibrations take two forms: condensation and rarefaction (Hecht, 1996; Knorr et al., 2004). During condensation, the medium particles are compressed (i.e., the spacing between particles is condensed), causing the medium’s pressure and density to increase (Gallego-Juárez et al., 2003; Hecht, 1996). During rarefaction, the medium particles shift apart so that the medium’s density and pressure decrease (American Heritage, 2002; Hecht, 1996).

McClements (1995) describes ultrasonic wave behavior insightfully by viewing the wave from two perspectives, time and distance. At a fixed position in the medium, the sound wave behaves sinusoidally with respect to time. As shown in Fig. 3.1, the time span from one peak amplitude to another is the time period τ of the sinusoidal wave. This physically means that each particle at some depth in the medium (along some line of equidistance) must wait for time period τ before experiencing another sound wave equal to the one just experienced. The sinusoid frequency f represents how often (frequently) the sinusoid completes an oscillation (cycling from peak to peak) in one second duration and is mathematically given by the inverse of the time period as shown in Equation (3.1) (McClements, 1995):

Ultrasonic wave behavior (adapted from McClements, 1995)

The distance considers the effect of the sound wave at any fixed instant in time on particles that are successively deeper in the medium. At any time, the amplitude of the sound wave is felt strongly by particles near the sound wave source, but particles deeper in the medium experience the sound wave less strongly. This decrease in sound wave amplitude with distance is due to attenuation from the medium. The plot of sound amplitude versus distance is actually an exponentially decaying sinusoid, as shown in Fig. 3.2. The distance between successive amplitude peaks is the wavelength (λ). The wavelength relates to frequency through the velocity of the traveling wave c, as follows in Equation (3.2) (McClements, 1995):

Thus, sound waves travel through the medium with a measurable velocity by acting on the medium particles. The waves oscillate the medium particles about their equilibrium positions. At any moment in time, the particles shift toward or away from each other. This shifting causes alternate increases and decreases in medium density and pressure. Consequently, the only type of energy imparted into the medium from the ultrasound is mechanical, which is associated with the oscillation of medium particles (Hecht, 1996).

With respect to imparted energy, treatments using ultrasound differ from treatments using waves from the electromagnetic (EM) spectrum, such as ultraviolet (UV) light waves, radio frequency (RF) waves, and microwaves (MW) (Kardos and Luche, 2001), as well as pulsed electric fields (PEF). EM waves and PEF introduce electric and magnetic energy into a medium, which are absorbed by the medium particles. For example, UV light from the sun can impart enough atomic energy (4 eV) to break a carbon–carbon bond. EM waves occur when subatomic particles, having positive and negative charges, move freely in non-uniform motion. Between positive and negative charges, electric and magnetic fields radiate. These electric and magnetic fields enter the medium and interact with the atoms, ions, or molecules in the medium. For example, microwaves interfere with polar molecules (those with one positive end, one negative end) in a medium by causing them to rotate and align with the electric fields associated with the microwaves. Inside microwave ovens, the water molecules in foods absorb much microwave radiation, and their subsequent rotations are converted to heat energy (Hecht, 1996). Hence, EM waves impart electric and magnetic energy into the medium, while sound waves impart only mechanical energy.

Also important to note in comparing sound waves with light is that only sound waves contain no particles of their own. Sound waves merely interrupt the stillness of the medium to oscillate the particles belonging to the medium. Unlike sound, physicists consider light to be an unsolved mystery, propagating as both streams of particle-like “energy concentrations” and massless waves simultaneously. This difference becomes apparent in a vacuum. As vacuums contain no medium particles, massless sound waves cannot propagate because they cannot create condensations and rarefactions of particles.

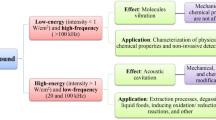

The pressure exerted on the human ear by loud sounds is very small (<10 Pa), but ultrasonic pressure in liquids can be high enough (several MPa) to help initiate a phenomenon called inertial cavitation, which can destroy the medium (Hecht, 1996; Povey and Mason, 1998). Inertial cavitation refers to bubble activity in a liquid and is produced by very high intensity ultrasonic waves, which can break apart the microstructures of a medium and generate free radicals. The cavitation ultimately leads to the destruction of microbiological cells and the production of free radicals and sonochemicals that react chemically with liquid media (Chemat et al., 2004; Knorr et al., 2004). Those ultrasonic applications concerned with detection of flaws, such as quality assurance in food processing, must be designed so that inertial cavitation cannot possibly occur. Other ultrasonic applications, however, rely directly on inertial cavitation to generate desired changes in foods. Changes produced by cavitation include the inactivation of microorganisms and the release of oils or nutritional compounds through the erosion of a food’s cellular structures (Knorr et al., 2004; Riera-Franco de Sarabia et al., 2000). Hence, cavitation is avoided in one branch of ultrasonic food processing and studied in the other branch as the mechanism responsible for all desired effects. In Table 3.1 there are some examples of the use of ultrasound in food applications, in both ranges, high and low frequencies.

3.2.1 Overview of Ultrasonic Equipment

No matter what industry or application involved, the same basic system components are needed to generate and transmit ultrasonic waves. Ultrasonic equipment consists of the electrical power generator, transducer(s), and emitter, which physically sends the ultrasonic waves into the medium (Povey and Mason, 1998). Exceptions include the “liquid whistle,” which uses purely mechanical energy without an electrical generator to generate ultrasound (Mason et al., 1996), and airborne systems, which do not require an emitter (Gallego-Juárez et al., 2003; Povey and Mason, 1998).

Two types of ultrasound systems are reported to be used in food industry, one using a horn as the sound emitter and the other using a bath. The bath has been traditionally used in food processing due to its early availability (Povey and Mason, 1998). In recent research, horn-based systems appear to be cited as often as baths (Aleixo et al., 2004; Duckhouse et al., 2004; Mason et al., 1996; Neis and Blume, 2003; Patrick et al., 2004; Tian et al., 2004). The horn-based system is employed equally well in many applications, from ultrasonic food processing to cleaning of food process plant surfaces to ultrasonic welding of metals.

3.2.1.1 Electrical Generator

The electrical generator is the source of energy for the ultrasonic system, which must drive the transducer (Povey and Mason, 1998). Generally, an electrical generator produces electrical current with a specified power rating. Most generators allow the power to be set only indirectly through voltage (V) and current (I) settings. The voltage represents the potential energy stored in the electrons (measured in volts); the current represents the net charge of electrons traversing an area over some time interval (measured in amps); and the power is the product of these two represented in Equation (3.3) (Hecht, 1996):

Electrical generators that are designed specifically for ultrasound mostly focus on industrial cleaning, and therapeutic, welding, and disinfecting applications, and operate in the lower frequency range (10–40 kHz). Low frequencies are not used in non-destructive testing of foods, but power ultrasound has many potential applications in food processing as will be shown in this chapter.

3.2.1.2 Transducer

All ultrasonic systems include a transducer as the central element, whose role is to generate the actual ultrasound. The transducer converts electrical energy (or mechanical energy, in the case of the liquid whistle) into sound energy by vibrating mechanically at ultrasonic frequencies (Povey and Mason, 1998). Lee et al. (2003) explain that a transducer attached to an electrical generator will transform, for instance, 20-kHz electrical energy from the generator into ultrasound energy of the same frequency by vibrating at 20,000 mechanical cycles per second.

Povey and Mason (1998) summarize three main types of transducers: liquid-driven, magnetostrictive, and piezoelectric (pzt). Liquid-driven transducers rely on purely mechanical energy to produce ultrasound, but magnetostrictive and piezoelectric transducers convert electrical and magnetic energy into mechanical, ultrasonic energy. While liquid whistles make excellent mixers and homogenizers, most power ultrasound equipment use piezoelectric or magnetostrictive transducers today (Knorr et al., 2004; Povey and Mason, 1998). The piezoelectric transducer (pzt) is the most common type and is used in most ultrasonic processors and reactors and cited often in literature (Aleixo et al., 2004; Gallego-Juárez et al., 2003; Povey and Mason, 1998). The pzt is also the most efficient, achieving better than 95% efficiency, and it is based on a crystalline ceramic material that responds to electrical energy.

3.2.1.3 Emitter (Baths, Horns, and Sonotrodes)

The purpose of the emitter, also called the reactor by some, and ultrasonic cell by others, is to radiate the ultrasonic wave from the transducer into the medium. Emitters may also fulfill the role of amplifying the ultrasonic vibrations while radiating them. The two main forms of emitters are baths and horns (i.e., probes); horns often require the attachment of a horn tip known as a sonotrode (Povey and Mason, 1998).

Baths usually consist of a tank to which one or more transducers have been attached. The tank holds a sample in solution and the transducers radiate ultrasound directly into the sample (Povey and Mason, 1998). In horn-based systems, a horn is attached to the transducer to amplify the signal and bring it to the sample. The tip of the horn, often a separate attachable device known as a sonotrode, radiates the ultrasonic wave into the sample. The shape of the horn determines the amount of amplification. Hence, the intensity of radiation can be controlled by selecting differently shaped horns. The main difference in equipment used in laboratories versus commercial processing plants is the type of emitter. More robust emitters that do not wear down after many hours of use are required in food manufacturing.

3.2.1.4 Examples of Ultrasound Systems in Food Processing

Many laboratory-scale and industrial food applications employ an integrated system called an ultrasonic processor. The ultrasonic processor is also called a reactor (e.g., the “probe reactor” or “bath reactor”) if the ultrasonic treatment is capable of producing chemical changes in the medium (Mason, 2003). Equipment manufacturers usually design the processor (or reactor) with the electrical generator and transducer contained in one housing (this is lightweight and portable) and offer several types of emitters as attachments, which are selected based on the application. Emitters are either horns (i.e., probes) or sonotrodes. A large number of companies in the world sell ultrasonic processors, among which are Hielscher, Branson, Undatim, Sonicmaster, Giken, Sonics & Materials, and Vibra Cell.

Food processing publications contain a number of examples of successfully custom-designed ultrasonic systems. For example, researchers Furuta et al. (2004), in a report on the inactivation of Escherichia coli cells, show a schematic of an apparatus containing a generator, transducer, and emitter. A function generator plus power amplifier is connected to an ultrasonic transducer, which uses a horn (i.e., probe) immersed in the sample. They also used a displacement meter for monitoring input/output vibrational amplitudes of the horn face to check the acoustic power introduced to the sample. Another custom system set up to inactivate E. coli, this time in liquid whole egg (LWE), is reported by Lee et al. (2003). Their laboratory-scale equipment included an electric generator (with adjustable power supply output), a transducer from Bandelin electronic, and a horn that both amplified the ultrasonic output and radiated it into the LWE.

Other researchers have successfully investigated ultrasonic thawing of meat and fish samples with transducers they constructed specially for their experiments (of diameters nearly equal to sample sizes). These custom transducers were powered by a sine-wave generator together with an RF power amplifier from ENI, Inc.; they also employed a Hewlett-Packard 5302A universal counter to monitor output frequency (Miles et al., 1999).

Gallego-Juárez et al. (2003) conducted airborne ultrasound experiments using a unique system in which an electrical generator was connected to a custom-designed stepped plate transducer. The ultrasound was emitted by an ultrasonic radiator and a flat plate parallel to it. The plate held the sample and acted as a reflector to help form a standing wave.

3.2.2 High-Versus Low-Intensity Ultrasound

Across the industry, engineering applications of ultrasound are separated into two distinct categories: low intensity (also called high frequency or “non-destructive” ultrasound) and high intensity (also called low frequency or “power” ultrasound) (Mason, 2003). These two categories differ in the goal to be achieved, the application, and the applied ultrasonic power and frequency. The goal of low-intensity ultrasound is usually to identify some unseen substance in a medium, while high-intensity ultrasound usually focuses on altering some part of a medium or promoting a chemical reaction. For instance, medical tomography applies low-intensity ultrasound to locate and outline (i.e., “image”) objects suspended in various media (Kennedy et al., 2004). Dolphins and bats likewise send out low-intensity ultrasonic waves to navigate by echoes; this phenomenon works similarly to SONAR (SOund NAvigation and Ranging) (Hecht, 1996). In contrast, high-intensity ultrasound is used to erode surface contaminations in welding and precision cutting of materials, and also to destroy tumors in therapeutic medical ultrasound (Kennedy et al., 2004; Krefting et al., 2004; Mason, 2003; Povey and Mason, 1998).

These differences are similar in food processing applications; while low-intensity ultrasound is applied non-invasively to locate flaws and foreign objects in foods during quality assurance testing, high-intensity ultrasound is applied for such manipulative purposes as damaging the cellular walls of microorganisms in foods, denaturing proteins, stimulating seed germination, and enhancing crystallization in foods (Knorr et al., 2004; Mason et al., 1996; Tian et al., 2004). The major process parameters differentiating the two types of ultrasound are ultrasonic energy and frequency. Low-intensity ultrasound is low energy, with power intensities below 1 W/cm2 and high frequency of 1–10 MHz. Hence, low-intensity ultrasound is also termed high-frequency ultrasound. High-intensity ultrasound is high energy with power intensities above 10 W/cm2 and low frequency of 10–100 kHz (Povey and Mason, 1998; McClements, 1995). High-intensity ultrasound likewise is referred to as low-frequency ultrasound.

3.2.2.1 Overview of Low-Intensity “Non-destructive” Ultrasound

Low-intensity (non-destructive, high-frequency) ultrasound is applied for detection purposes in general, and so it is utilized as a processing aid in the food industry to characterize food components, often on quality assurance lines. Aptly named non-destructive testing (NDT), this process sends ultrasonic waves through a medium without causing any permanent physical, chemical, or electrical change in the medium, because the ultrasonic intensity is too low \(( < 1\;{\textrm{W/cm}}^2 )\) to alter the material (Gestrelius et al., 1993; McClements, 1995). The medium particles oscillate in response to the low energy (purely mechanical) while exposed to the ultrasonic waves and simply return to their equilibrium position when the source of ultrasound is removed.

When acoustic waves pass through the medium, the waves are partially reflected or scattered wherever the medium changes from one material to another (Hecht, 1996). The distance to the reflection location can be calculated through measured ultrasonic properties like frequency (always higher than 1 MHz) and attenuation coefficient, to allow detection and location of the presence of foreign particles and compositional changes in foods (McClements, 1995).

Low-intensity ultrasound can invaluably aid quality control in food production, as well as monitor the changes that foods undergo as they are processed (freezing, emulsifying, drying, etc.). Food manufacturers use ultrasonic NDT to locate foreign bodies such as glass, organic residues, or bacterial infections in solids and liquids – even after foods are packaged (Gestrelius et al., 1993; Hæggström and Luukkala, 2001). Other examples include characterization of the cellular structure of pre-cooked dough to obtain predictions of cooked product quality (Elmehdi et al., 2003), and monitoring the movement of the ice front in a solid food (as the food slowly freezes) to determine the energy efficiency of the freezing process (Sigfusson et al., 2004).

3.2.2.2 Overview of High-Intensity “Power” Ultrasound

High-intensity (low-frequency, power) ultrasound is used either to destroy cellular structures or to enhance or inhibit activities within foods (Mason et al., 1996), and is characterized by power intensities generally ranging between 10 and 1,000 W/cm2. These intense acoustic waves can cause high pressures inside liquid foods, producing streams of fast-moving microbubbles and causing bubbles in liquids to collapse violently (Mann and Krull, 2004). These types of bubble activities in liquids, respectively termed non-inertial and inertial cavitation, are mechanisms that affect the physical and chemical properties of foods (Povey and Mason, 1998). The cavitation activities in liquids can be so intense that living cell walls are broken down, free radicals and sonochemicals are produced, and processes such as seed germination are enhanced whereas enzymatic activities are inhibited (Mason, 2003; McClements, 1995; Povey and Mason, 1998). Hence, Povey and Mason (1998) coin the term “material-altering” to describe high-power ultrasound, in parallel to the descriptor “non-destructive” for low-intensity ultrasound.

The material-altering applications of high-intensity ultrasound are numerous in the food processing arena. Major research schools working with power ultrasound in food processing mainly are studying extraction, emulsification, filtration, crystallization, producing of fine-particles, thawing, and freezing, while several research teams around the world are examining the inactivation of microorganisms and enzymes in foods (Mason, 2003).

When researchers analyze results from ultrasound experiments, they determine and use different process parameters for high-intensity applications than for low-intensity applications. The only parameters commonly used in both high- and low-intensity applications include frequency (f, or angular frequency \(\omega = 2\pi f\)) and power amplitude (denoted by A or P). These values are set or adjusted by the ultrasonic generation equipment and controlled by the experimenter based on the results desired. Parameters used extensively in low-intensity ultrasound include frequency, amplitude, velocity, time and distance of travel, attenuation coefficient, reflection coefficient, acoustic impedance, and density. High-intensity ultrasound parameters include power, frequency, treatment temperature, and treatment time.

3.3 Power and Energy

In general, power represents the strength of a treatment or, from another perspective, how much treatment a medium experiences. In ultrasound, the treatment is accomplished by passing an ultrasonic wave through the medium; therefore, the power of the treatment is determined by the power (or strength) of the ultrasonic wave.

Studies show that more power causes greater alterations in the material, at least up to some maximum power limit depending upon the properties of the medium in question (De Gennaro et al., 1999; Furuta et al., 2004; Joyce et al., 2003; Mason et al., 1996; Pagán et al., 1999; Povey and Mason, 1998; Riera-Franco de Sarabia et al., 2000; Sun and Li, 2003; Tian et al., 2004). Theoretically, high ultrasonic wave powers produce high pressures in the medium (Hecht, 1996). These high-acoustic pressures work to destroy microorganisms and enzymes in a food and break down microstructures, through cavitation (Povey and Mason, 1998). Of course, researchers aim to find the minimal power necessary to process the food as desired and yet preserve the vitamins, colors, textures, and flavors in foods (De Gennaro et al., 1999; McClements, 1995; Riera-Franco de Sarabia et al., 2000).

Power also relates to energy, and a few ultrasonic researchers prefer to measure the energy delivered to the medium rather than power. For example, researchers Duckhouse et al. (2004) measured the treatment time in seconds and multiplied these times by their power values to obtain the Joule-energy experienced by the medium. This method applies the basic physics relationship below in Equation (3.4) (Hecht, 1996):

In a similar vein, other researchers have reported energy density in W•s/m in place of power density.

3.3.1 Vibrational Amplitude

A traditional way to represent the power or strength of ultrasonic waves is to measure the amplitude of the mechanical vibrations. The vibrational amplitude is measured as the maximum displacement in micrometers (μm) of the vibrating tip of the sonotrode (i.e., horn) as it sends the acoustic waves into the medium. Generally, vibrational amplitude is specified by the equipment manufacturers. Furuta et al. (2004) and Tsukamoto et al. (2004a, b) preferred to use vibrational amplitude, from 1 to 7 μm, to represent the actual acoustic power that their custom-made system introduced to their cell samples. They implied that their amplitude measurements provided a more exact and stable indication of ultrasonic cavitation than a power parameter would have provided; they were able to measure the vibrational amplitude during ultrasonic irradiation (Tsukamoto et al., 2004a).

Vibrational amplitude is also reported as the ultrasonic parameter in two other articles on microbial inactivation, those of Pagán et al. (1999) and Vercet et al. (2002). Additionally, Mason et al. (1996) mention vibrational amplitude in their overview of ultrasonic uses in food processing, although they also refer to many other ways that ultrasonic power can be represented. Other ways to represent ultrasonic wave strength do not relate to the vibrations of the transducer, but rather to the electrical generator powering the ultrasonic equipment.

3.3.2 Power Intensity

Power intensity is a way to measure power transmitted to the medium from the sonotrode tip surface, rather than from the ultrasonic generator. In general, power intensity P i (also called power irradiance) represents power, P, distributed over surface area A as shown in Equation (3.5) (Hecht, 1996):

For ultrasonic systems, power intensity is calculated to obtain the power radiating from the sonotrode tip surface (Neis and Blume, 2003). This power intensity value is the actual power the medium experiences near the sonotrode surface, per unit area of the sonotrode tip. For a sonotrode that has a circular area, the power intensity becomes as shown in Equation (3.6):

Power intensity also enables relationships to be established between the dimensions of sonotrodes and the power. For example, if an ultrasonic generator has a power rating of 360 W and the sonotrode radius is 1 cm, then P i equals 114.59 W/cm2. For the same power of 360 W, if a smaller sonotrode of only half the radius (0.5 cm) is used, then P i is much greater at 458.37 W/cm2. This shows that the power is much more concentrated on the smaller sonotrode. Power intensity increases as sonotrode radius decreases.

Today so many different power and energy parameters are used in treating foods with ultrasound (parameters are too often unexplained in literature) that new researchers cannot always determine from reported data how much application of sonication is needed to build upon the published results. Hence, the use of one or two standard parameters, based on understood proven measurements and calculations of these parameters, could erase the current confusion.

3.3.3 Frequency

High-intensity ultrasound is accomplished with frequencies between 10 and 100 kHz. The frequency used mainly depends on process considerations related to equipment and the first consideration is the amount of power desired, for instance, transducers produce high-power radiations at low frequencies as the power changes inversely with the square of the frequency (Povey and Mason, 1998), as shown in Equation (3.7):

The second consideration is frequency dependence on emitter dimensions. Ultrasonic baths, which transmit ultrasound directly into the tank through bonded transducers, usually operate at 40 kHz. However, systems that attach a horn to the transducer for power amplification are able to achieve lower frequencies of 20 kHz. The lower frequency is achieved by the length extension the horn provides to the transducer: frequency is reduced by half when the emitter length doubles.

The frequency selected for the application will have a strong effect on cavitation activity. The degree of cavitation occurring in a liquid depends on the relationship between frequency and bubble size. High pressures from acoustic vibrations cause the bubbles in liquids to increase rapidly in size and to pulsate even between expanded and reduced sizes (Povey and Mason, 1998). When the bubble pulsations take on too much amplitude, the bubbles collapse violently, a phenomenon termed inertial cavitation that can change the physicochemical properties of food. The ultrasonic frequency helps to promote bubble collapse by driving the bubble into resonance.

3.3.4 Temperature

Ultrasonic treatments raise the temperature of the sample, even if no external heat is applied in addition to the ultrasound. When the transducer or horn sends ultrasonic vibrations into the medium, the responding oscillations of the medium particles generate heat over time. Acoustic radiation forces move the liquid media in waves, generating heat from this motion (Povey and Mason, 1998). More heat is generated when the ultrasonic waves encounter bubbles in liquids; as the bubbles are set into motion this activity is converted into heat by thermal and viscous damping mechanisms. Also, when the high-intensity ultrasound causes inertial cavitation in liquids, very high temperatures (up to 5,000 K) are generated in small areas (called hotspots) in the sample due to the collapse of bubbles in the liquid. In contrast, more cavitation bubbles are produced as the temperature of the sample increases, leading to yet more heat-generating bubble movements and collapses. The net result of these ultrasonic effects is a steady increase in temperature in an ultrasonicated sample over time.

Additionally, food researchers may choose to introduce moderate heat to the system in order to enhance the effects of ultrasound; the combined treatment is termed thermo-sonication (Povey and Mason, 1998). Some food plants thermally processing foods, today, might be able to incorporate transducers into their heat exchangers and heating systems in the future, so that ultrasonic treatment can precede thermal treatments with lower process temperatures (Povey and Mason, 1998). Sometimes thermo-sonication can be accomplished without adding heat, by controlling the rise of heat in the sample during ultrasonic treatment to achieve a steady value of temperature over time.

3.3.5 Effects of High-Power Sonication

The effects ultrasound produces in a medium depend on the solid, liquid, and gas phases in the medium (Povey and Mason, 1998). Mostly, solid media will undergo a “sponge” effect in response to the passage of sound waves, in which the condensations and rarefactions in the medium act upon the solid similar to the squeezing and releasing of a sponge (Riera-Franco de Sarabia et al., 2000). In liquid media, the condensations and rarefactions cause the liquid particles to accelerate in alternating (first forward, then reverse) directions, and any bubbles, i.e., gases entrapped in the liquid, accelerate as well (Povey and Mason, 1998). Ultimately, the pressures from the condensations/rarefactions can cause the bubbles in the liquid to collapse violently, a phenomenon called inertial cavitation (Piyasena et al., 2003).

3.3.6 Cavitation

Cavitation is the mechanism that enables the desired effects of high-intensity “power” ultrasound to occur in foods. The effects of cell killing, inhibition of enzyme activity, maturation of wines, cleaning of produce surfaces, extraction, filtration, emulsification, and crystallization all rely on the mechanism of cavitation (Mason et al., 1996; Povey and Mason, 1998).

The study of cavitation centers on the activity of bubbles in liquids (Povey and Mason, 1998). The activity of the bubbles determines which of the two types of cavitation occurs, inertial or non-inertial cavitation; both produce very different effects in the medium. When inertial cavitation occurs, the bubble dynamics are behind the activities produced in the food, for instance, whether free radicals are generated (or not) and to what degree erosion occurs in the food (Mason et al., 1996; Patrick et al., 2004). Yet, the bubbles cannot be controlled directly in experiments (Povey and Mason, 1998). Instead, the effects of other parameters on bubbles must be studied in depth if cavitation is to be optimized for the best effects. These parameters include the acoustic pressure amplitude (controlled by ultrasonic wave amplitude) and acoustic frequency.

3.3.6.1 Inertial Versus Non-inertial Cavitation

The two types of cavitation already mentioned, inertial (also called “transient”) and non-inertial (also called “stable”) (Povey and Mason, 1998), involve a sound field that drives the bubbles in a liquid into some kind of response. One response occurring in both cavitation cases is bubble growth; in a process called rectified diffusion, bubbles increase in size by drawing more gas from the surrounding liquid into the bubble. Bubbles also decrease in size by expelling the gas into the liquid. The pressure variations in the medium determine whether the gas will be drawn into the bubble (when the gas pressure inside the bubble happens to be less than the ambient liquid pressure) or released from the bubble into the liquid.

In non-inertial cavitation, the sound field causes bubbles either to increase in size and then dissolve or to pulsate between a smaller and larger size over many acoustic cycles. Because the bubbles never collapse or break into fragments, this form of cavitation was originally termed stable cavitation.

Inertial cavitation is characterized either by rapid growth followed by rapid collapse of the bubbles or by extremely high-amplitude pulsations in which bubbles greatly expand and greatly contract, continually and eventually collapsing (Povey and Mason, 1998). After a bubble collapses, it may fragment into much smaller bubbles or grow again to undergo more pulsations and/or collapses. Because first observations of inertial cavitation involved sonoluminescence from bubbles that fragmented after a few cycles, the phenomenon was termed transient cavitation.

The effects of cavitation can produce a number of desirable changes in foods, such as mechanical erosion and fracturing of food particles (for improved separation, mixing, and extractions), which are caused by the hydrodynamic shear stresses from high-amplitude pulsations, the rebound pressure pulse from a collapsed bubble; microstreaming; and jetting (Behrend and Schubert, 2001; Joyce et al., 2003; Li et al., 2004; Povey and Mason, 1998; Riera-Franco de Sarabia et al., 2000). Jetting in particular can dislodge dirt and bacteria from the surfaces of foods, such as eggs, and food processing plants (Povey and Mason, 1998). Other changes can be biological, such as stimulation of growth – seeds and hatching, for example; the hot spots created by bubble collapses can degrade hydrophobic pollutants in water (Mason, 2003). Changes also occur from chemical reactions, such as the decomposition of hydrophilic pollutants in water by hydroxyl radicals produced during inertial cavitation (Mason, 2003). The inactivation of microorganisms and enzymes in foods occurs from combinations of mechanical, chemical, and biological effects.

3.4 Microbial and Enzyme Inactivation in Food Using Ultrasound

As it was previously mentioned, depending on the frequency, ultrasound is used in two wide areas of food processing. In this section a more detailed view of some of its applications are described. First, high-intensity ultrasound is used for the degassing of liquid foods; the induction of oxidation/reduction reactions; the extraction of enzymes and proteins; the inactivation of enzymes and microorganisms; and the induction of crystallization processes. Sometimes ultrasound is combined with other types of treatments to enhance the effectiveness of the treatments. Inactivation of microorganisms by combining ultrasound treatments with antimicrobials, pressure, and heat is widely documented (Knorr et al., 2004). Low-intensity ultrasound is used in the stimulation of living cells and enzymes, surface cleaning of foods, ultrasonically assisted extraction, crystallization of fats and sugars, destruction of foams, extraction of flavorings, emulsification, filtration, drying, freezing and tenderization of meat (Chemat and Hoarau, 2004; Knorr et al., 2004), measurement of concentration of simple solutions and meat composition (Saggin and Coupland, 2001), mixing and homogenization, and precipitation of airborne powders (Mason, 1996).

Even so, applications of ultrasound in food processing are not limited to the process per se; in quality assurance, many applications of this novel technology are used as mentioned throughout this chapter. Food manufacturers can use ultrasonic non-destructive technique (NDT) to locate foreign bodies such as glass, organic residues, or even bacterial infections in both solid and liquid foods, even after foods are packaged (Gestrelius et al., 1993; Hæggström and Luukkala, 2000). Other applications include characterization of the cellular structure of pre-cooked dough to obtain predictions of the quality of the cooked product (Elmehdi et al., 2003) and monitoring the movement of the ice front in a solid food as it is slowly frozen to determine the energy efficiency of the freezing process (Sigfusson et al., 2004).

Some of these applications are described in detail in the following paragraphs. The initial focus will be on power or low-frequency ultrasound, which has been used for disruption purposes such as the inactivation of microorganisms or enzymes. In the following, low-intensity or high-frequency ultrasound will be covered according to some food industry applications.

3.4.1 Microorganisms

The goal of emerging technologies in food processing is to inactivate the initial population of microorganisms to a safe level with minimal damage to the product’s quality attributes. Nevertheless, with some emerging technologies, microorganisms become more resistant over time to the action of a specific factor such as pressure, electricity, or sound waves. In fact some microorganisms find that certain factors actually improve their growth during treatment. In the case of ultrasound, although it has been explored more deeply in recent years, some reports show that ultrasound exerts a positive effect, in combination with other preservation factors, on some microorganisms and enzymes.

Ultrasound treatments can have lethal effects on microorganisms when applied with sufficiently high intensity (e.g., frequencies above 18 kHz) (Rodríguez et al., 2003). Some reports in literature claim microbial inactivation with frequencies as low as 14 kHz, although the most common frequencies are 20 and 24 kHz. Nevertheless, it has been shown that ultrasound by itself is often not enough to reduce microbial populations. Sound waves should be applied with other preservation factors in order to increase the effectiveness of the treatment. The use of ultrasound in combination with heat, pressure, or both seems to be a good option. Raso and Barbosa-Cánovas (2003) reported that the use of ultrasound, pressure, and heat along with low water activity \((a_w )\) was a good combination for reducing microbial populations in foods. The effect of pH, however, seems to be less important when combined with ultrasound, and only a few reports are focused on its effect. Jiménez-Fernández et al. (2001) studied the effect of pH in Aspergillus flavus during thermo-ultrasonic treatments and, depending on the other conditions of the medium such as a w , the effect attributed to pH was found to be relevant in only some cases. When a w was constant and the pH was decreased, the D values were lower, but when pH was constant, lower D values were achieved with the highest a w (0.99). This is a logical result, considering some of the mechanisms of inactivation, and will be described in next sections. In another study the use of ultrasound to inactivate E. coli in acidic media (model orange and apple juice systems; pH 3) showed that at low intensities (20 kHz; 0.4 and 7.5 μm) the inactivation rate was affected because of the strain of microorganisms and the prior acid adaptation of the bacteria in the media; however, at higher intensities these factors were not important (Patil et al., 2009). Higher water activity means the presence of free water in the medium, which increases the production of free radicals because of the destruction of water molecules generated by the sound waves, increasing the lethality of the microorganisms. In the same study, hurdle technology was used with antimicrobials such as potassium sorbate and vanillin in addition to ultrasound, heat, pH, and water activity, showing good results according to the D values reported. Guerrero et al. (2001) reported no change in the sensitivity of Saccharomyces cerevisiae when ultrasound and heat were applied in broth with different pH values. But in Sabouraud broth, at pH 5.6, the addition of chitosan enhanced the inactivation of yeast under thermo-sonication (Guerrero et al., 2005).

Other reports on the use of ultrasound and heat (thermo-sonication) show how certain combinations of factors affect different microorganisms in different ways. For instance, Knorr et al. (2004) reported that inactivation of Bacillus stearothermophilus and E. coli K12 DH5α was improved with the use of direct steam injected into the ultrasound treatment, leading to reduced temperature and process time. This method was ultrasound-assisted thermal (UST) treatment. Nevertheless, a different type of microorganism, Lactobacillus acidophilus, was more resistant to the UST combination process.

From previous research, using high pressure to inactivate microorganisms appears to be a good alternative to the use of heat. For this reason, high pressures have been used in combination with other preservation factors such as temperature and antimicrobials. In ultrasound technology, a new area called mano-sonication is currently being tested, in which the use of moderate and high pressures in combination with ultrasound effectively reduces the initial level of microbial populations. Some of the most studied microorganisms in non-thermal technology research are the so-called emergent pathogens, such as E. coli, Salmonella, and Listeria monocytogenes, because of their new importance in food microbiology and impact on food safety. Reports show improvements in E. coli inactivation through combined ultrasound and high-pressure treatments, as well as through the combined use of heat, sound, and pressure, achieving important reductions in the enzymatic activity of some very heat resistant pathogens. Other hurdles used in combination with MTS are antimicrobials exhibiting good results in microbial inactivation (Knorr et al., 2004). Mano-sonication and heat treatment have also been reported to have an additive effect in achieving inactivation of L. monocytogenes. When the microorganisms were subjected to ultrasound energy at 20 KHz and 117 μm at ambient conditions, no important reductions were achieved; however, when pressure was added as a hurdle the microbial inactivation was significant. Using 200 kPa under the same ultrasound conditions described above, the D value was 1.5 min, lowering to 1 min when pressure was increased to 400 kPa. The experiment was conducted at different temperatures up to 50°C but the effect of this parameter was not significant at the studied levels (Piyasena et al., 2003).

Mathematical models have been developed to describe the resistance of different bacteria to mano-sonication treatments (Raso and Barbosa-Cánovas, 2003) as well. Dr. Javier Raso and his research team at the Universidad of Zaragoza in Spain are some of the pioneers currently combining pressure, heat, and sound to achieve microbial inactivation. Beginning in the late 1990s and in the last 5 years, ultrasound research from this university has achieved important relevance in the food engineering field worldwide.

In Table 3.2, the inactivation of some microorganisms is shown for different treatment media and operating conditions. With the combination of heat and ultrasound, substantial reductions in D values are obtained for Listeria innocua and Salmonella. Apparently, studies with Zygosaccharomyces bailii have shown that thermo-sonication is independent of the treatment medium, at least in this case. Good reductions in D values are obtained with the combination of temperature and sonication. Furthermore, the combination of ultrasound with pressure clearly improves the inactivation of microorganisms as Pagán et al. (1999) showed for L. innocua. An additive effect has been shown with MTS in vegetative cells, while for Enterococcus faecium and Bacillus subtilis spores, the effect was shown to be synergistic (Raso and Barbosa-Cánovas, 2003). Research by Guerrero et al. (2001) with S. cerevisiae showed good results, indicating a synergistic effect between heat and ultrasound in the inactivation of the yeast. Furthermore, when temperature is constantly maintained below lethal values, the increase in the intensity of the ultrasound wave is the most important value in the inactivation of microorganisms, but results are not as clear as in the previous example. Raso et al. (1998b) also showed that the use of pressure in combination with thermo-sonication enhanced the inactivation of B. subtilis spores, compared to thermal treatment. Results of thermo-ultrasonic treatments tested on molds like A. flavus and Penicillium digitatum showed the effect of adding antimicrobials on enhancing the inactivation. The use of low-weight chitosan (1000 ppm) as a natural antimicrobial in the medium under ultrasound treatment and heat (45ºC) enhanced the inactivation compared to just thermo-ultrasonic treatment (Guerrero et al., 2005). Nevertheless, pressure, ultrasound, heat, and other preservation factors do not have an additive or synergistic effect in all cases. Each microorganism should be studied under different treatments to know its response. For example, the response of spores to different technologies is always different from other types of cells, because of their unique, intrinsic characteristics. Results of mano-thermo-sonication applied on B. subtilis spores showed that when pressure was increased in combination with heat and ultrasound, inactivation was enhanced. Yet over 500 kPa, pressure was no longer an important factor because no matter how much it was increased past 500 kPa, there was no further effect on spore inactivation observed under the conditions tested (70°C, 117 μm, and 20 kHz) (Raso et al., 1998b). An interesting study on the use of ultrasound is application of this energy to delay fruit decay and to maintain fruit quality. For example, ultrasound was used at different frequencies (maximum 59 kHz) and temperature 20°C to process strawberries immersed in water. Decay was delayed and the number of microorganisms reduced. The firmness of the fruit and the levels of total soluble solids, titratable acidity, and vitamin C were also retained after processing (Cao et al., 2010).

An additional factor that should be studied is the treatment medium. As a novel technology, ultrasound is being tested under many different conditions, and some results have shown that inactivation of cells can be either increased or decreased depending on the medium’s composition. Comparison of the results of microorganisms under sonication treatment is difficult because of the non-uniform data of the operating conditions. As a novel technology, more homogeneity in some data is starting to be important because equipment is often different and some researchers do not report the full data. As authors of this chapter, and because literature is scarce, our aim is to summarize or draw general conclusions as to which microorganisms are more resistant (bacteria, yeasts, molds, or spores) and/or what are the best conditions for inactivation of specific organisms. Table 3.2 shows some of the relevant and most recent experiments that have been conducted with ultrasound. Target microorganisms under several conditions of sonication, temperature, pressure, and medium composition (among others) have been evaluated. Even so, more research and uniformity in experiment design and results could generate additional information to draw further conclusions. However, based on the information described above and in Table 3.2, ultrasound is clearly a potential technology for microbial inactivation.

3.4.1.1 Mode of Action of Ultrasound in Microorganisms

Ultrasound was studied as a microbial inactivation technique for the first time in the 1960s (Piyasena et al., 2003). The killing effect was first observed when ultrasonic waves were applied in a US army experiment to investigate their use in anti-submarine warfare, and fish died in large numbers. The effects of inactivation of cells by ultrasound have been attributed to shear disruption, heating, and free-radical production. In the 1970s, some cells showed a separation between the cytoplasmic membrane and cell wall after a short sonication (Earnshaw et al., 1995). However, the background of ultrasound technology reveals that development and research was temporarily halted due to a lack in the development of equipment (or specific parts) needed to generate good results, as well as greater interest in other emerging technologies by researchers, as in the case of ohmic heating. But gradually ultrasound is beginning to be explored by more researchers because of its effectiveness in inactivating bacteria. Due to this history, the main mechanisms of microbial inactivation are not totally understood, although there are several theories. Reports on ultrasound discussed previously were concerned with establishing how bacteria are inactivated with sound waves. The mode of action of ultrasonic inactivation is currently believed to be related to damage in the cell wall and cell wall structures, which is supported by the fact that some bacteria of specific species are more resistant to cavitation than to others under the same treatment conditions (Knorr et al., 2004). The thinning of cell membranes together with heating and free-radical production is essential in the inactivation. When ultrasonic waves pass through a liquid, some regions of compression and expansion are created. In these regions the physical phenomenon of cavitation starts and thousands of bubbles are formed. Bubbles are produced very rapidly and then hit each other inside the medium. Within the medium, very high localized temperatures (up to 5,500°C) and high pressures (50 MPa) are reached, and extremely violent implosions eventually occur; these conditions kill some bacteria (Piyasena et al., 2003). With cavitation, either cell wall structures are disrupted or particles are removed from surfaces (Earnshaw et al., 1995). Cavitation is associated with shear disruption, heating, and free-radical formation, which are considered the primary effects. Thinning of cells is caused by the ultrasound and the cell wall is broken, releasing the cytoplasm content (Earnshaw et al., 1995). A schematic view of this is shown in Fig. 3.3. Some microscopy studies after thermo-sonication treatments enable some of these previously mentioned effects to be observed. In Fig. 3.4, the use of scanning electron microscopy (SEM) is shown for L. innocua after 30 min of treatment at 24 kHz, 400 W, 120 μm and 63°C in milk (Bermúdez-Aguirre, D., and Barbosa-Cánovas G. V. (2008) “Unpublished data”). First, disruption of the cell wall can be observed in the damaged cells. Here, the cytoplasm content has been released outside of the cell, causing the death of the microorganism. A common characteristic observed in a high proportion of these cells is the formation of pores in the outer layer of the bacteria. These pores, in some cases appearing as big holes, are generated in the cell because of the high pressures in the medium and the violent implosions and explosions of the bubbles. Some thermo-sonicated cells are fragmented into smaller pieces, which look like smaller cells cut into unnatural shapes. The cell wall is not defined by one or more sides because of the breakage during sonication. Additionally, the cell walls probably are weaker due to thermal treatment, making the cell more sensitive to the formation of pores.

High-vacuum scanning electron microscopy (SEM) pictures of control (left top) and thermo-sonicated Listeria cells, showing the lethal effects of cavitation in cells such as pore formation, cell membrane disruption, and cell breakage. Magnification: (a) 150,000×, (b) 50,000×, (c) 50,000×, and (d) 50,000×. (Photos: Courtesy of the authors)

3.4.2 Enzymes

Enzymatic inactivation using different technologies is a widely studied field and much research has been conducted in order to achieve low residual enzymatic activities in several products. From the point of view of quality, enzymatic reactions produce undesirable changes in many foods during processing and storage. For this reason, non-thermal technologies are being tested as an option for reducing the enzymatic activities in foods.

The first studies in enzyme inactivation were conducted almost 60 years ago, in which pure pepsin was inactivated by ultrasound, probably due to cavitation. A more recent study shows that inhibition of sucrose inversion can also be achieved by cavitation. Since then the use of ultrasound in combination with heat and pressure has been proven effective in the inactivation of enzymes. Examples of these enzymes are soybean lipoxygenase, horseradish peroxidase, tomato pectic enzymes, orange pectin methylesterase (Vercet et al., 2002), watercress peroxidase (Cruz et al., 2006), PPO, lipase, and protease, among others (Raso and Barbosa-Cánovas, 2003). Some of these enzymes have been tested in a number of different food products, because, as in the case of microorganisms, the medium is an important factor affecting the level of inactivation of enzymes. In this book, an entire chapter is devoted to inactivation of food enzymes using ultrasound and because of that this topic is not covered in depth in this chapter.

Encouraged by the results of microbial inactivation using ultrasound, some researchers are now focused on enzyme inactivation with this technology. However, one of the big challenges of using ultrasound is again the heterogeneity of the food matrix, as it needs to achieve enzyme inactivation not only after processing but during food storage as well.

3.4.2.1 Mode of Action of Ultrasound in Enzyme Inactivation

Ultrasound’s mode of action in the inhibition of enzymes seems to be similar to its mode of action inactivating microorganisms. Mano-thermo-sonication is responsible for particle size reduction and molecular breakage. It has induced the breakage of pectin molecules in a purified pectin solution. It is also possible that ultrasound generates protein denaturation (Vercet et al., 2002). Changes in pressures generate stretching and compression in the cells and tissues. But as mentioned before free-radical production is promoted by ultrasound. Such free radicals as H+ and OH− could recombine with amino acid residues of the enzymes. These residues are associated with structure stability, substrate binding, and catalytic functions (Cruz et al., 2006). In the case of microorganisms, free-radical formation seems to be important to the main mechanism of inactivation, the disruption of the cell membrane. In the case of enzymes, the main mechanism is free-radical formation, which allows changing some characteristics of the enzymes. Disruption of tissue is mainly important because it generates better surface contact between the enzymes and free radicals. For example, oxidases are usually inactivated by sonication, while catalases are affected at low concentrations. Reductases and amylases are highly resistant to sonication (Mason, 1996). Mano-thermo-sonication has inactivated several enzymes at lower temperatures and/or in a shorter time than thermal treatments. Sensitivity of the enzymes to mano-thermo-sonication treatment is independent of the medium of treatment. In addition, the substrates, small co-solutes, and other proteins are unable to protect the enzymes during treatments (Vercet et al., 2001).

3.5 Other Applications of Ultrasound in Food Processing

In different areas of science, high-frequency ultrasound has many more applications than power ultrasound. In addition, low-intensity ultrasound has been used more in the food industry than power ultrasound due to its non-destructive, rapid, and convenient technique. It has been used to assess the quality of some foods such as meat, fish, beverages, oils, vegetables and fruits, and dairy products (Benedito et al., 2002). Yet ultrasound is a novel technology in many countries, and for this reason, Chemat and Hoarau (2004) suggest that ultrasound operations in food engineering require the establishment of a hazard analysis and critical control point (HACCP) program in which the critical control points of food processing are identified, so that potential hazards in producing a quality safe product can be controlled.

3.5.1 Quality Assurance

Quality assurance is an area that concerns food technologists because of the consumer’s desire for quality foods. Every food industry must have a quality assurance department for monitoring production, which requires testing of products. In some tests, long treatment times are required and destructive techniques are used. Ultrasound appears to be helpful in some of these tests, wherein low-intensity ultrasound has been used to assess the quality of avocados, mangos, and melons according to ripeness by evaluating ultrasonic parameters such as velocity and attenuation in relation to the physical characteristics of the medium. The quality of beef, chicken, cod, pork meat, milk, wine, sugar solutions, and oils has been evaluated with ultrasonic parameters (Benedito et al., 2002), by applying the theory of how wave behaviors (e.g., velocity and attenuation) relate to the physical composition of the medium. Textures of products like cheese and cooked vegetables and the ripeness of fruits have all been determined with the use of ultrasonic waves (Coupland, 2004).

3.5.1.1 Cheese and Tofu Manufacturing

In many countries cheese industry is one of the most important food industries as indicated in their sales reports of cheese products and high consumer demand. Depending on the place of manufacture and the type of cheese, cheese production can take several hours or several years to produce a final product. The specific characteristics desirable in cheese depend on the variety or type. Cheese manufacturing consists of various stages such as coagulation, drainage, salting, and ripening. Low-intensity ultrasound has been used to monitor different stages of the process, for example, in the evaluation of internal cracks due to bad fermentation and in the determination of the optimum rennet cut time; additionally, the compositions and textures of hundreds of cheeses around the world could be evaluated by this non-destructive technique to improve packaging and storage (Benedito et al., 2002). Along with monitoring the cheese as it is produced, ultrasound has been directly involved in the production of soft cheese by promoting the coagulation of proteins and oils (Mason, 1996).

High-frequency ultrasound has also been used to assess the quality of tofu during its manufacture. Tofu is a water-based gel composed mainly of soy protein; its quality is based a lot on the product’s final texture. Ultrasound can be used to monitor the development of texture during the gelation process of tofu. The propagation of ultrasonic waves through the structure of the tofu gel provides information about the entire process (Ting et al. 2009), as in the case of cheese making, in relating the ultrasound variables to the enzyme activity in milk during the coagulation process.

3.5.1.2 Beverages

Power ultrasound has been able to achieve pasteurization standards for some beverages such as milk, fruit juices, and ciders; but low-intensity ultrasound can also be useful for quality assessment purposes. Ultrasound has been used to degass (removing oxygen) orange juice, proving that the final vitamin A content in product is higher during storage in ultrasonicated juice than in conventionally heat-treated juice. In another study, limonin content, brown pigments, and color were evaluated in orange juice after sonication (500 kHz; 240 W; low temperature, 5 and 14°C), finding only minor changes in these characteristics in the product (Valero et al., 2007). Ultrasound has been used successfully to process strawberry and blackberry juice and apple cider as well. Enzymes such as pectin methylesterase and polyphenol oxidase were inactivated along with pathogenic bacteria. Minor changes in ascorbic acid and anthocyanins were also detected in sonicated juice (Valdramidis et al., 2010). Beer yield is also improved with ultrasound applied at the beginning of the mashing process (Knorr et al., 2004). This improvement in yield does not only occur with beer, but in cheese production as well, with yield increasing after the milk is pasteurized with power ultrasound, which represents economic benefits for the dairy and beer industries. Additionally, ultrasound can improve several characteristics of products such as color, texture, and storage life, as well as maintain some of the same nutritional values found in fresh products. One example is the oxidation process widely used in the alcoholic beverage industry. The process is assisted by ultrasound as it enhances oxidation in fermented products leading to characteristic flavor and early maturation. Ultrasound of 1 MHz alters the alcohol/ester balance producing an apparent aging in the product. It has been used for wines, whiskey, and spirits (Mason, 1996).

3.5.1.3 Bread

Bread quality is always a topic and a factor that food scientists are trying to innovate and improve. Now that different options like frozen and freeze-dried breads are available in the market, the texture of the final product is an important parameter. Traditional techniques to evaluate the texture are very often destructive to the sample. Ultrasound offers the advantage of being a non-destructive technique that enables knowing the texture of breads through acoustic parameters. Physical structure of foods is hard to study because of the non-homogeneity of foods, as with breads, but sound waves can provide information about the structure of bread crumbs. Gas cells determine the structural integrity of bread crumbs, and through some ultrasonic parameters, the physical structure can be evaluated. Velocity and attenuation of ultrasonic waves (at 54 kHz) have been used to describe certain quality factors of bread. For example, changes in the microstructure of freeze-dried bread crumbs due to density changes (100–300 kg/m3) have been evaluated, showing that size and shape of the gas cells in bread are sensitive to ultrasound measurements, whereas the signal amplitude was increased linearly with density (Elmehdi et al., 2003). This non-destructive technique is a very useful tool in the cereal industry throughout the world allowing manufacturers to understand the structure of end products without modifications.

3.5.1.4 Product Identification

One area in food quality assurance refers to the detection of foreign bodies in the final product. In an attempt to ensure the safety of foods, all food industries have specific detectors for metals, glass, bones, and other materials that could potentially enter the food in the processing plant. Animal bones in meat products, fragments of glass in glass jars, and metal swarf are among the materials sometimes detected in products due to poor manufacturing practices (Hæggström and Luukkala, 2001). Various researchers have focused their work on this subject alone. Knorr et al. (2004) showed that foreign bodies like glass and plastic pieces, and raw materials, can be detected in yogurt, fruit juices, and tomato ketchup by ultrasonic signals in a time–frequency analysis. Strange bodies of material such as stone, glass, wood, plastic, bone<comma> and steel spheres were detected in cheese and marmalade by means of ultrasound, showing that this non-destructive and highly sensitive method is viable for use in a homogeneous product with 20–75 mm of probing depth (Hæggström and Luukkala, 2001). Ultrasonic pulse compression (UPC) is used to detect variations in the consistency of some liquids, liquid leveling in polymer-based soft drink bottles, and foreign objects in containers. This is possible as changes in the acoustic properties of the medium, mainly propagation velocity and acoustic impedance, can be related to changes in food product composition. Air-coupled ultrasonics is a new technique used to estimate the level of water within a polymer drink bottle (Gan et al., 2002). The volume fraction of some components in foods such as syrups, fruit juices, and alcoholic beverages can also be determined by ultrasonic waves, and measurements of the solid content of semi-crystalline fats have also been tested successfully with ultrasound (Coupland, 2004). The thickness of some foods, including cheddar cheese, luncheon meat, and cranberry sauce, has been measured by ultrasonic techniques to measure the speed of sound in the product; this method produced results similar to the more difficult tests using calipers (Saggin and Coupland, 2001). In another example, demonstrating ultrasound’s effect on product quality, the concentration of solids is an important parameter in slurries processing industry; in this industry, the parameters density and attenuation of ultrasonic waves have proven useful as tools for quality assurance and process control of the thick slurry suspensions; both parameters are related to concentration of the medium (Bamberger and Greenwood, 2004). One direct application of this kind of ultrasound is during fermentation, wherein the concentration of sugars changes accordingly with the production of ethanol because of the yeast activity. The concentration of ethanol and sugar can be estimated based on the sound wave velocity traveling through the medium (Schöck and Becker, 2010). Here it is important to remark that specific characteristics of the ultrasonic wave, such as frequency and intensity, or acoustic parameters related to the material – whether attenuation coefficient, velocity, acoustic impedance, or density – must be selected wisely for evaluation in order to determine the specific properties of foods for which the researchers are looking. Ultrasound also is being tested in microbial quality control: some studies conducted on aseptically packaged milk show that the acoustic streaming induced by ultrasound in a liquid is affected by the microbial activity, and thus, those bacteria that alter physicochemical parameters can be detected (in quantity) through the use of ultrasonic waves (Gestrelius et al., 1993).

3.5.2 Thawing/Freezing/Crystallization

As in the case of high-pressure technology, ultrasound is not limited to the above-mentioned examples; every day new applications are being used and tested in the food industry, while an important number are still under research. One such application would be its use in thawing processes, where high-power ultrasound is used to assist the thawing of beef, pork, and fish, with frequencies and intensities around 500 kHz and 0.5 W/cm−2. With ultrasonic radiation, the common problem encountered in microwave thawing – surface heating – is minimized, in which samples have been thawed to a depth of 7.6 cm within about 2.5 h (Miles et al., 1999).

Power ultrasound, with frequencies in the range of 20–100 kHz, has proved useful in the formation of ice crystals during the freezing of water, since the rate is improved and cell damage reduced. The involved mechanism is acoustic cavitation, in which the acoustically generated bubbles act as nuclei for crystal growth (Sun and Li, 2003). Sonication is a highly useful tool in the control of crystallization processes because it enhances the nucleation rate and crystal growth rate, thus generating new and fresh nucleation sites. The freezing rate of potato assisted by ultrasound was very fast, with an output power of 15.85 W and a treatment time of 2 min; furthermore, a better microstructure was achieved under these freezing conditions due to the high rate of the process (Sun and Li, 2003). In some crystallization processes, as in the initial stage of freezing, ultrasound plays a very important role because it can accelerate the process. Thus the size of crystals is smaller than in conventional freezing, and for some products like strawberries, this fact results in important reductions in damage to the product’s microstructure. Some studies using ultrasound have been made on ice lollipops, and although a better adherence of the lollipop to the wooden stick was observed, the lollipop became harder than the common product (Mason, 1996). Ultrasound has been used to monitor the cooling processes of gelatin, chicken, salmon, beef, and yogurt by measuring the ultrasonic pulse time-of-travel to the cool surface. In the same products, the movement of the ice front was measured by the time of flight of an ultrasonic pulse, by recording echoes as a function of time, which correlated with the percentage of frozen food (Sigfusson et al., 2004).

3.5.3 Extraction

The use of ultrasound in extraction processes delivers benefits that include greater penetration of the solvent into cellular materials, improvement in mass transfer, and improved release of contents due to the disruption of cell walls. Some examples of ultrasound use are in the extraction of sugar from sugar beets, medicinal compounds (helicid, berberine hydrochloride, bergenin), and protein from defatted soybeans and tea. Through extraction of the enzyme rennin for cheese making, the use of ultrasound achieved a higher yield of the enzyme compared to normal extraction. The advantages of using ultrasound in extraction processes are the reduction of temperatures and the shortening of treatment times, resulting in a purer extract. Many of the ultrasonic extraction processes have been scaled up to industrial levels because of the above-cited advantages (Mason, 1996). An example of one specific advantage is in the extraction of tea solids from water, resulting in an increased yield of almost 20%. Another example is that reduction in maceration time was achieved with ultrasound in the extraction of alkaloid reserpine from Rauwolfia serpentina. Compounds from Salvia officinalis were also extracted faster, and the antioxidant carnosic acid extracted from the culinary herb Rosmarinus officinalis was increased even as extraction times were reduced. In the last example, ultrasound at 40 kHz was combined with temperature ranging from 47 to 53°C and evaluated for 15, 30, and 45 min; just 15 min was enough to extract most of the material, as the ultrasound enhanced the mass transfer, a result of cell breakage (Albu et al., 2004). In another example the use of power ultrasound in the extraction of sugar and protein from soy flakes showed excellent results after a few seconds (less than 120 s) of sonication, showing a total sugar and protein release of up to 50 and 46%, respectively, compared with untreated samples, enhancing the yield during extraction and reducing the cost of processing (Karki et al., 2010).

Other extraction processes reported in literature are the extraction of almond oils, herbal extracts (fennel, hops, marigold, mint), ginseng saponins, ginger, rutin, carnosic acid from rosemary, polyphenols, amino acid and caffeine from green tea, and pyrethrins from flowers. In general all of these processes have benefited from the use of ultrasound, showing higher extraction yields and rates, shorter processing times, and on the whole more efficient processing (Vilkhu et al., 2008).

Recently, study of the sonochemical reactions taking place during sonication showed that these reactions when successfully controlled could be an important tool for food extraction. The hydroxylation of some food chemicals plus some hydroxyl radicals generated during cavitation can enhance the functional properties of these chemicals; for example, the phenolic compounds can enhance their antioxidant properties under specified sonication conditions (Ashokkumar et al., 2008).

3.5.4 Cleaning

In addition to a myriad of other uses, ultrasound is a very efficient method for cleaning purposes. It can dislodge dirt and bacteria from surfaces and reach crevices that are difficult to access using conventional methods. Medical, surgical, dental, and food processing instruments and surfaces are cleaned with ultrasound. Recently, ultrasound has been applied in combination with a bactericide to clean the surfaces of hatchery eggs. The activities of chemical biocides are also enhanced with ultrasound (Mason, 1996). Furthermore, a number of studies reveal that ultrasound (40 kHz) can be used to remove biofilm, which occasionally is the cause of fouling in some food industry equipment. In the dairy industry, for instance, fouling of tubes used to pasteurize and process certain products is often the reason for contamination of milk, because some microorganisms can be added to the walls of these tubes. Ultrasound was twice as effective in removing the biofilm from some of the evaluated surfaces compared to the common method of swabbing to clean the equipment (Oulahal-Lagsir et al., 2000); likewise, ultrasound is very useful for cleaning in dairy membrane processes during ultrafiltration activities when applied at a constant low frequency (i.e., 50 kHz), as compared to intermittent use (Muthukumaran et al., 2007).

Ultrasound also is being studied as an alternative to chlorination processes for disinfection of water. Due to the production of free radicals in aqueous solutions during the ultrasound treatment, some studies carried out in water have focused on the emergent pathogen Cryptosporidium parvum. With ultrasound as a disinfectant technique, some of the problems related to carcinogenic products formed in chlorination processes could be avoided. Studies were performed with S. cerevisiae, which, according to the author, has a structure similar to the pathogenic microorganisms. With a sodium hypochlorite solution, ultrasound treatment at 27.5 MHz for longer treatment times yielded a better effect against the cells (Tsukamoto et al., 2004a, b).

3.5.5 Other Applications

Changes in ultrasonic parameters are often associated with changes in the different food products during processing. Transmission of ultrasound in minced beef during simulated automated roasting showed good results as an alternative technique in temperature and process control. Temperatures ranged from 45 to 74°C, with ultrasonic equipment set at 300 kHz, and only small pieces of minced beef were used with thicknesses between 7.15 and 15 mm (Hæggström and Luukkala, 2000).

Ultrasound has also been used to study changes in flow behavior and thermophysical properties of whey protein isolate (WPI) and whey protein concentrate (WPC). Water solubility of both WPI and WPC was significantly increased after sonication compared to control samples. As for flow behavior, the apparent viscosity and flow behavior index and consistency coefficient of WPI and WPC were significantly changed after sonication. The thermophysical properties, such as initial freezing and initial thawing temperatures, were also changed compared to control samples (Krešić et al., 2008). In addition, the effects of ultrasound on the solubility and foaming properties of whey proteins were studied; important effects on these properties were observed when whey proteins were exposed at low frequency (20 kHz) compared to high frequency (40 kHz); even higher frequencies (i.e., 500 kHz) did not have a significant effect. An important effect with temperature increase was also observed in sonicated samples after processing at low frequency (Jambrak et al., 2008).