Abstract

Electrospinning is a simple and versatile method to produce fibers using charged polymer solutions. As drug delivery systems, electrospun fibers are an excellent choice because of easy drug entrapment, high surface area, morphology control and biomimetic characteristics. Various drugs and biomolecules can be easily encapsulated inside or on fiber surface either during electrospinning or through post-processing of the fibers. Multicomponent fibers have attracted special attention because new properties and morphologies can be easily obtained through the combination of different polymers. The factors that affect the drug release such as construct geometry and thickness, diameter and porosity, composition, crystallinity, swelling capacity, drug loading, drug state, drug molecular weight, drug solubility in the release medium, drug–polymer–electrospinning solvent interactions are discussed. Mathematical models of drug release from electrospun fibers are reviewed and strategies to attain zero-order release and control of burst stage are considered. Finally, some results concerning release control in bicomponent fibers composed of poly(\(\varepsilon\)-caprolactone) and Lutrol F127 (poly(oxyethylene-b-oxypropylene-b-oxyethylene) are presented. The properties of the bicomponent fibers were studied in order to determine the effect of electrospinning processing on crystallinity, hydrophilicity and degradation. Acetazolamide and timolol maleate were loaded in the fibers in different concentrations in order to determine the effect of drug solubility in polymer, drug state, drug loading and fiber composition on morphology, drug distribution and release kinetics. Such electrospun drug eluting fibers can be used as basic elements of various implants and scaffolds for tissue regeneration.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 What is Electrospinning?

Electrospinning is a method of producing fibers with diameters ranging from micrometer to nanometer scale by accelerating a jet of charged polymer solution/melt in an electric field. Recently, this technology has been expanding due to the simplicity of the process and the various materials that can be used. Fibers can be produced from either natural or synthetic polymers. Such fibers have diverse applications including filtration, catalysis, textiles, composite materials, biomedicine (wound dressings, drug delivery, tissue engineering, cosmetics), sensors, electronic devices, liquid crystals, photovoltaic cells and much more [1, 2].

Usually, the experimental set-up consists of a high voltage power supply connecting an electrode with needle-like geometry (through which the polymer solution is ejected) to the collector electrode. The polymer solution is pumped at the desired flow rate using a syringe pump. A diagram presenting the most common electrospinning set-up is shown in Fig. 1.

Recent works suggest that the most important mechanism of electrospinning is a rapidly whipping/bending fluid jet [3]. The jet instability is produced by the competition between surface tension and charge repulsion, in which the destabilizing effect of charge repulsion is responsible for the stretching of the fluid jet and simultaneous decrease in the jet diameter. Surface tension has a stabilizing effect leading to the cessation of stretching and attaining a limiting terminal jet diameter. The process can be decomposed into five components: fluid charging, formation of the cone-jet, thinning of the steady jet, onset and growth of jet instabilities and fiber collection [4]. Several process parameters (voltage, nozzle to collector distance, polymer flow rate, spinning environment) and solution parameters (concentration–viscosity, conductivity, surface tension, solvent volatility) can be manipulated in order to obtain the desired properties of the fibers such as fiber diameter and morphology. Moreover, the fibers can be collected with a multitude of collectors producing fiber mats that contain either aligned or unoriented fibers [5].

2 Electrospun Fibers as Drug Delivery Systems

Electrospun fibers have been shown to function as drug delivery systems because of high surface area (which enhances mass transfer), similar topography and porosity to the extracellular matrix making them ideal candidates as active implants/scaffolds. The easy control of the macrostructure (oriented or arranged randomly, fiber mat porosity) and the microstructure (individual fiber porosity) will determine both the bulk physico-chemical properties and the biological response to the implant/scaffold. Variuos drugs ranging from low molecular agents to proteins and even cells [6] can be easily encapsulated inside or on the surface of the fibers depending on the application. Some disadvantages include drug loading that is limited by the drug solubility in the electrospining solution or burst effect due to surface deposited drug.

Drug delivery systems can be classified according to different criteria [7, 8]. The most common one is to classify with respect to the rate control mechanism. These classifications may also be applied to drug-containing polymeric fibers:

-

Drug diffusion controlled systems: diffusion can take place either through the bulk polymer as in bicomponent mixed fibers or through a barrier as in core–shell fibers

-

Solvent diffusion controlled systems: drug release is determined by the rate of polymer swelling

-

Chemically controlled systems: either polymer erosion or enzymatic/hydrolytic polymer degradation control the drug release rate

-

Regulated systems: the application of a magnetic field or another external stimulus can trigger the release (as in composite fibers containing magnetic particles)

The active ingredient can be loaded either during electrospinning or during post-processing of the electrospun fibers. In the former case, the drug is either co-dissolved with the polymers in the electrospinning solution or the drug is loaded in particles that will be co-electrospun with the polymers [9–11]. The later case includes various modalities of drug loading: fiber soaking in the drug solution, drug impregnation using supercritical fluids technology [12], loading in previously molecular imprinted fibers [13, 14], functionalization of the fiber surface through grafting copolymerization [15] and subsequent drug/protein binding [16, 17].

By electrospinning, the drug is usually entrapped as solid particles inside or on the surface of the fibers. According to the type of solid–solid or polymer–drug mixture, the drug loaded fibers can be classified as:

-

Solid solutions: the drug is dissolved at molecular level in the polymer

-

Solid dispersions: the drug is distributed in the polymer as either crystalline or amorphous aggregates

-

Phase-separated systems or reservoir systems: the drug is contained inside the core of the fiber or encapsulated in particles, that are surrounded by a polymer shell (as in core–shell constructs or composite fibers, see Sect. 2.1)

2.1 Multicomponent Fibers

Multicomponent fibers have attracted special attention because new properties can be obtained through the combination of different materials. Synthetic polymers with good processability and good mechanical properties can be mixed with natural hydrophilic polymers producing an increase in cellular attachment and biocompatibility [5]. Unfortunately, sometimes the solvent that is used to dissolve both polymers can damage the structure of the natural polymer or phase separation can worsen the mechanical properties. One possible solution is to incorporate function-regulating biomolecules (DNA, growth factors) in synthetic polymers to increase bioactivity [17] or to modify the structure of the polymer before electrospinning [18].

Multicomponent fibers can be obtained mainly by two techniques [19, 20] as shown in Fig. 2: electrospinning of polymers solution in a single-needle configuration (if a mixture of polymers is co-dissolved in the electrospinning solution) or a multi-needle configuration (in which the polymer solutions are separated in parallel or concentric syringes) and post-treatment of the electrospun fibers (which can include either coating with other inorganic/polymer layers [16, 21], grafting [15], crosslinking [22], chemical vapour deposition [23] or functionalization with other (bio)polymers [17]).

In addition to the combination of physico-chemical properties that arise from using various components, there can be obtained a variety of fiber morphologies as presented in Fig. 3 such as core–shell fibers, micro/nanotubes, interpenetrating phase morphologies (matrix dispersed or co-continuous fibers) [24, 25], nanoscale morphologies (spheres, rods, micelles, lamellae, vesicle tubules, and cylinders) obtained by self-assembly of block copolymers [26], multilayers (either with different composition or different fiber diameter) [27, 28]. Moreover, the fiber morphology can be further controlled after electrospinning by selective removal of one component using thermal treatment [29] or dissolution [30].

Many of the fiber constructs are supposed to work as implants/tissue scaffolds besides functioning as drug delivery devices. Good mechanical properties are required in order to preserve the structural integrity of the implant. Crosslinking [31], thermal interfiber bonding (accomplished near the melting temperature of the electrospun polymer and impregnated with a hydrogel that maintains the structure of the scaffold against shrinkage) in order to improve biomechanical properties [32] or continuous alignment of electrospun fiber yarn obtained by self-bundling electrospinning and further treated by drawing and annealing to improve tensile strength [33] are just some of the available post-processing techniques.

2.2 Release Control of Drug Loaded Fibers

Fibers can be easily loaded with drug in a similar fashion as multicomponent fibers (Sect. 2.1), the drug being an extra component. By blend electrospinnning, the drug or drug vehicle (such as microspheres [9], nanoparticles [10, 11]) is mixed or phase-separated with the polymer phase and by coaxial electrospinnning, the drug is contained either in the core or in the shell. The advantage of encapsulating the drug in the core or in a vehicle is that usually burst release is minimized/avoided since the drug has longer diffusional paths [11] and the protection of active agents (such as proteins) that are sensitive to organic solvents can be achieved. Moreover, it does not require good interaction between the polymer and drug, but it must show sufficient interfacial compatibility in order to prevent delamination [34]. In contrast, for the cases of drugs loaded by blend electrospinning, poor interaction between the drug and polymer affects the drug distribution in the polymer matrix and consequently the release behavior [35, 36]. Incorporation of bioactive agents that are usually water soluble and can not be dissolved in the same solvent as the polymer (usually organic solvents) can be performed by emulsion electrospining [35, 37].

Various post-treatment modalities exist in order to further control the fiber drug release. These can be grouped in two main categories: physical and chemical. The first category includes functionalization of electrospun fibers with biomolecules using coating [16], subcritical carbon dioxide impregnation of electrospun fibers with which it is possible to load drugs and obtain more sustained release profiles in comparison to loading through soaking in drug solution [12]. The second category consists of coating electrospun fiber by chemical vapour deposition in order to prolong the release and avoid burst effect [23], molecular imprinting of fibers (either by loading the template molecule [13] or by loading molecularly imprinted particles [14] inside the fibers during electrospinning) that can selectively rebind the target molecule (biological receptor molecule) and produce targeted drug delivery.

Drug delivery systems are intended to deliver well controlled amounts of drug between the minimum effective level and the toxic level during a predetermined time interval [7]. Control of burst effect is essential either to avoid toxicity or to ensure immediate action at the targeted location (as in the case of antibiotics [38]). These are the reasons why the factors that affect the release rate should be considered when designing a new fiber drug delivery system:

-

Fiber construct geometry (fiber mats or multilayers) and thickness: the drug deposited in single layers is released faster than from multilayers either because the drug layers are intercalated with non-drug layers that function as barrier to drug release [39] or because the inner layers are not equally exposed to the release medium [40]

-

Fiber diameter and porosity: a thinner or more porous fiber implies a bigger surface and consequently accelerates the release [41]. However, thicker, but more porous fibers release drug faster than thinner, less porous fibers [42]

-

Fiber composition: the choice of a degradable polymer will allow release control through a hydrolytic [40] or enzymatic mechanism [36]. Besides, blending various components leads to modulating release capacity [42] either by improving fiber wetting properties (using hydrophilic polymers [43, 44]) or aiding incorporation of drug. In this case, it is possible to avoid burst effect by blending polymers with amphiphilic copolymers which can be compatible with both the drug and the initial incompatible polymer [38]

-

Fiber crystallinity: initial polymer crystallinity influences the drug release (it blocks the release of the drug from the crystalline domains due to limited water uptake). When the release of drug from the amorphous domains or from the fiber surface is finished, no more drug is released [45]. Moreover, there is an increase in crystallinity during drug release (the drug works as a plasticizer, the polymer chains gain more mobilility and as it is leached out, they crystallize), which decreases the release of residual drug [46]

-

Fiber mat swelling: water uptake by fibers or by the (macro)pores created between fibers will speed up drug release [47] as the dissolution of drug molecules is the initial step in the release process [48]

-

Drug loading: higher loadings will produce faster release ([41, 46, 47, 49, 50]); on one hand, at high loadings, there is more surface segregated drug that dissolves fast and on the other hand, there is an increase in porosity during drug elution proportional to the initial amount of drug [46, 41]

-

Drug state: in general, drug release was shown to be more sustained, when drug is incorporated in amorphous state [50, 51], than when drug is loaded in crystalline state [52]. Moreover, it was shown that, even when the drug is in amorphous state, the drug release was faster from the solid solution than from the amorphous dispersion [53]

-

Drug molecular weight: drugs with smaller volumes will be released faster since they diffuse faster through the aqueous pores created by the water uptake in the fiber [42, 54]

-

Drug solubility in the release medium: usually, the higher drug solubility, the faster the release [42]

-

Drug–polymer–solvent interaction: solubility and compatibility of drugs with the polymer and/or the electrospinning solvent is essential since it ensures proper drug incorporation inside the fibers and not on the fiber surface [35, 47, 36]. Phase separation between the drug and polymer will produce amorphous or crystalline drug at the fiber surface leading to faster release [55]. Moreover, the interaction between drug and the polymer can block the crystallization of the drug in the fibers, if so desired [53] and can even determine sustained release of drugs that are present in crystalline state because of hydrogen bonding to the polymer [54]

However, in order to predict the outcome of drug release from fibers, it is important to consider the interaction among the various factors in such a complex system. We have already discussed how the drug state controls drug release. However, sometimes high drug loadings are needed for long term applications. Usually, at high loads, the drug will crystallize and/or phase-separate from the polymer and form conglomerates that will produce a heterogeneous distribution of the drug inside the fibers [35, 56] or deposition on the fiber surface [55]. Thus, in long term release applications where high amounts of loaded drug are required, a compromise must be found between loading and release rate that change in contrary directions [57]. Careful consideration should also be paid when selecting best pair of polymer and drug, although some applications require material properties that may not match in terms of compatibility the drugs used in the treatment of the targeted diseases.

2.3 Release Modeling

As summarized in Table 1, a multitude of drug/biomolecules loaded fibers have already been produced. They have been produced either from polymers (synthetic and natural) or inorganic compounds. Most of the release mechanisms were attributed to drug diffusion (as it is the case for most non-biodegradable, non-erodible polymers), solvent diffusion (as in the case of natural polymers that are usually hydrophilic [58]), polymer erosion (as in the case of erodible (bio)polymers [53, 54]), polymer degradation (as for hydrolytic or enzymatic degradable polymers) or external triggers (like a magnetic field). In the release system governed by drug diffusion, one has to consider two cases, one in which the diffusion takes place through the bulk of polymer (bulk diffusion) or through a membrane/layer (barrier diffusion, similar to the reservoir devices as in the case of core–shell fibers, composite fibers or multilayered constructs). There are cases in which several mass transport mechanisms superpose. However, in most cases, there is only one that is the “rate-limiting” step. For example, in the case in which diffusion is coupled with chemical reaction (in most cases, hydrolysis), if diffusion is faster than the chemical reaction, then mass transfer is controlled by the polymer degradation [59] and when diffusion is not much faster than reaction, then diffusion and degradation superpose [40]. In some systems, the release process is composed of sequential stages, with each stage being controlled by a different phenomenon. For example, in the first stage you can have the drug release controlled by the polymer erosion and subsequent diffusion, followed by polymer degradation control stage [60].

Related to core–shell fibers, we can consider two controlling phenomena: diffusion through the polymer shell (barrier diffusion) or partition of the drug from the core to the shell. The diffusion through the shell polymer should not be too slow, otherwise this diffusion will be rate-limiting step. In this instance, the system behaves as monolith fibers and not core–shell fibers (reservoir system). Shell porosity must also be carefully controlled since the drug from the core will be released through water-filled channels rather than through the barrier/shell polymer [34]. Composite fibers that contain drug vehicles such as microspheres and nanoparticles (see Sect. 2.2) are also a type of reservoir system (double barrier system) in which the drug molecules have to diffuse through longer pathways: the polymer comprising the vehicle and the “shell" polymer [11].

Drug diffusion (more precisely solid state diffusion) was mentioned earlier as one of the most common mechanisms of drug release. There are models that consider diffusion of solutes in polymers insignificant in comparison with diffusion in water-filled spaces in between polymer chains, so they assume that water uptake and subsequent solubilization of the drug is an important step in the release process and it is the solvated molecule that is actually diffusing [61]. This is the assumption behind biphasic diffusion that includes an initial diffusion phase through the polymer (either amorphous or semi-crystalline) and a second diffusion phase through water-filled pores formed in the fiber due to polymer swelling/chain rearrangement or polymer recrystallization [55, 62].

The power law equation, which was developed considering that the main mechanism for drug release is drug diffusion through the polymer or solvent diffusion inside the polymer that produces polymer relaxation/chain rearrangement (Eq. 1) is the most widely used equation in works concerning drug release:

where \(m_{t}/m_{\rm tot}\) is the fractional release of the drug at time \(t,\) \(a_0\) is a constant, representing the percentage of burst release, \(k\) is the kinetic constant and \(n\) is the release exponent, indicating the mechanism of drug release (which can either be Fickian drug diffusion or polymer relaxation or an intermediate case combining the two [63]).

Other models consider different phenomena that control the release such as desorption due to the fact that under the assumption of diffusion control, 100% release of the drug is expected, but this was not verified experimentally. In the desorption model, the release is not controlled by diffusion, but by the desorption of the drug from fiber pores or from the fiber surface. Thus, only the drug on the fiber and pore surfaces can be released, whereas the drug from the bulk can only be released when the polymer starts to degrade. These assumptions are similar to the theory of mobile agent, that can be released by diffusion and the immobilized agent, that can be released through degradation [59].

The Eq. 2 is based on a pore model, in which the effective drug diffusion coefficient, \(D_{\rm eff}\) is considered and not the actual diffusion coefficient in water, \(D\) (with \(D_{\rm eff}/D \ll 1\)) because desorption from the pore is the rate limiting step and not drug diffusion in water, which is relatively fast.

where the porosity factor \(\alpha=m_{s0}/(m_{s0}+ m_{b0})< 1,\) with \(\hbox{m}_{s0}\) and \(\hbox{m}_{b0}\) being the initial amount of drug at the fiber surface and the initial amount of drug in the fiber bulk, respectively; \(m_t\) is the drug amount released at time t, while the total initial amount of drug in the fiber is \(m_{\rm tot}=m_{s0}+m_{b0}\) and \(\tau_r\) is the characteristic time of the release process [73].

Various release kinetics exist and the most desirable one is the zero-order kinetics in which the drug is released at constant rate, independent of concentration gradient (see Fig. 4). Usually, zero-order kinetics is achieved for reservoir systems such as core–shell fibers or composite fibers (see Table 1) in which the drug is properly encapsulated in the core of the fiber or in other vehicles (micro/nanopartilces). Burst stage in this kind of system is diminished (or non-existent) because there is no drug deposited on the surface of the fibers. As the controlling release phenomena is drug partition from one phase to another and not diffusion, there is no decrease in release rate over time as expected in a diffusion-controlled system (the release rate depends on the concentration gradient and on the length of diffusion path; as release proceeds, the concentration gradient decreases and the diffusion length increases and both contribute to slowing down the release rate).

Other strategies to attain zero-order release include polymer degradation controlled release (either accompanied by erosion or not) because then drug is released due to polymer chain cleavage [36, 40]. The drug is released either because the diffusion paths are shortened as degradation takes place (surface degradation) or because porosity is increased due to the leaching of degradation products (bulk degradation) [7]. Another strategy to obtain constant release rate is the use of multilayered constructs [39], in which sequential electrospinning is used to obtain drug loaded layers surrounded by barrier layers.

Burst effect can be determined by fiber porosity [34], poor drug solublity in electrospinning solvent [47], poor drug solubility in polymer [36], high drug solubility in release medium [42], heterogeneous drug distribution [35] or surface segregated drug [45]. Most of the times, the selection of the polymer and of the drug depends on the properties of the fiber mat and the targeted disease. Thus, the burst stage can only be controlled in unicomponent/monolith fibers by manipulating the process parameters and not by the material choice. Ensuring a homogeneous drug distribution [49] (usually by encapsulating drug in amorphous state [50, 46]), low drug loadings [50], or coating the drug loaded fibers [16] are some simple techniques to diminish burst if so desired.

3 Results

In this chapter we are presenting some results concerning release control in bicomponent fibers composed of poly(\(\varepsilon\)-caprolactone), PCL and Lutrol F127 (Lu, poly(oxyethylene-b-oxypropylene-b-oxyethylene)), both semi-crystalline (co)polymers. The properties of the bicomponent fibers were studied in order to determine the effect of electrospinning processing on crystallinity, hydrophilicity and degradation. As both polymers are semi-crystalline, we could test the effect of such organization on the loading and release of drugs. Acetazolamide and timolol maleate were loaded in the fibers in different concentrations (below and above the drug solubility limit in polymers) in order to determine the effect of drug solubility in polymer, drug state, drug loading and fiber composition on fiber morphology, drug distribution and release kinetics. A diffusion model and a desorption model (see Sect. 2.3) were fit to the release data in order to determine the release mechanism.

3.1 Fiber Mat Degree of Crystallinity, Drug Solubilitity in Polymer and Drug State

Solid-state drug polymer solubility and miscibility were shown to influence the drug encapsulation and correlate to drug release [74]. Timolol maleate (experimental water solubility =2.74 mg/ml [75]) and acetazolamide (experimental water solubility =0.98 mg/ml [76]) were chosen because of different hydrophilic/hydrophobic character that would allow us to understand how the interactions between the drug and polymers contribute to drug release. The drug solubility is expected to influence the loading and the state of the drug in the fibers as a higher solubility ensures higher loading of drugs in amorphous state. Thus, fibers with low and high drug loadings were prepared corresponding to drug percentages below and above the drug solubility limit, respectively. As a measure of drug–polymer interaction [77], the drug solubility in polymers was determined by differential scanning calorimetry (DSC) method and the obtained results are presented in Table 2. Acetazolamide had higher solubility than timolol maleate in all fiber compositions probably because of enhanced interaction with the hydroxyl/carboxyl groups of the polymers. Furthermore, a tendency of increase in solubility was noticed when PCL ratio was increased. An opposite trend was observed for timolol maleate when an increase in solubility was obtained with decrease in PCL content. We will discuss in Sect. 3.4 how the solubility affects the drug release.

The polymer degree of crystallinity is known to play an important role in determining water uptake and drug release. Drug release is faster from amorphous than from crystalline regions for semi-crystalline polymers because the lamellae behave as barriers to the diffusion of water and drug [45, 79]. In the case of amorphous polymers, the drug can act as a plasticizer and as it is leached out, the mobile polymer chains rearrange themselves and crystallize [46]. The crystallized matrix becomes microporous [78] and the subsequent drug diffusion takes place through water-filled pores. The polymers used in this work are semi-crystalline and the obtained fibers are expected to be semi-crystalline too. DSC analysis confirmed this hypothesis showing a single or two melting peaks corresponding to the melting of either PCL or Lu. The relative degree of crystallinity of drug loaded fibers is presented in Table 2, where it can be seen that the fibers showed similar degrees of crystallinity regardless the type of loaded drug. The drug appeared to be in amorphous state in fibers with low drug loadings as proven by the absence of drug melting peak (images not shown). In fibers with high loadings, part of the drug was in crystalline form as confirmed by morphological analysis (Sect. 3.2), while the DSC scans of these sample were not conclusive because the peak corresponding to drug melting was masked by fiber degradation process (that starts at around \(250\deg \hbox{C}\)).

3.2 Morphological Analysis and Drug Mapping

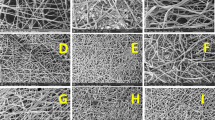

Morphological differences between samples loaded with the two drugs above or below the solubility limit were assessed by scanning electron microscopy (Fig. 5). In Fig. 5a and b surface images of fibers that contain acetazolamide above solubility limit are shown. As the loaded mass of drug was above the solubility limit in the polymer, the drug was expected to be in crystalline form as confirmed by the images where drug crystals were visible outside or inside the fibers. On the other hand, no crystals were observed in the fibers that contain drug in low loadings (Fig. 5c) suggesting that the drug was in amorphous state in the fibers in agreement with DSC analysis results (Sect. 3.1).

Electron probe microanalysis was performed in order to assess the drug distribution inside the fiber mats. The surface mapping of timolol loaded fibers (Fig. 6b, c) showed relatively homogeneous drug distribution regardless of composition, while the surface mapping of acetazolamide fibers (Fig. 6a) indicate the presence of drug conglomerates probably due to higher loading. When the drug is above the solubility limit, it will phase-separate and crystallize [56, 35].

3.3 Water Contact Angle, Swelling Capacity and Mass Loss

Water contact angle is determined by both chemical composition and surface morphology [80]. The surface roughness of the fibrous mat results in air entrapment between fibers, and as such the fiber mats usually present higher contact angle than films with the same composition [81]. Swelling takes place in two different regions of porosity (Fig. 7): water diffuses first in the pores between fibers and later in the fibers themselves.

In a fiber mat there are regions in between the fibers that can be occupied by water molecules, while in films or compacts these regions have significantly smaller surface. PCL fibers were highly hydrophobic (a water contact angle of 123.18 (0.98)), while the bicomponent fibers were highly hydrophilic (25/75 Lu/PCL had a water contact angle of 18.28 (4.07), while 50/50 Lu/PCL had one of 16.25 (2.16)). These results were surprising since in a previous work films with the same compositions presented contact angles in the range 50 to 62° [82]. In bicomponent fibers, the trapped air between the fibers and pores at the fiber surface is easily removed by the incoming water molecules because the water soluble component (Lu) is leaching out. In PCL fibers that showed an increase in water contact angle from 62 (for films) to 123, probably the hydrophobic nature of surface chemical groups (PDLLA was shown to enrich its fiber surface with hydrophobic groups [80]) and the trapped air create a barrier to water penetration. Consequently, PCL fibers absorbed water gradually (see Fig. 8a, while the bicomponent fibers presented a sudden increase in water content during the first day (79.0% for 50/50 Lu/PCL and 68.5% for 25/75 Lu/PCL), followed by a constant value thereafter as Lu content in the fiber was diminished due to dissolution.

The mass loss plot (Fig. 8b) showed an initial increase in mass loss for bicomponent fibers (42.5% for 50/50 Lu/PCL and 16.6% for 25/75 Lu/PCL), while PCL fibers presented insignificant mass loss (0.45%). Mass loss of PCL is detectable only after the molecular weight reaches a value of 10,000 g/mol [83] and thus the initial high mass loss of the bicomponent fibers can only be attributed to the dissolution of Lu as the sample with higher Lu content had the highest mass loss.

The morphology of aged fibers (immersed in PBS during 3 days) was also investigated in order to determine the change in fiber structure. In Fig. 9a, it can be noticed the smooth surface of the fibers, while in Fig. 9e pores were observed that were formed due to the dissolution and leaching of Lu. A different appearance was shown by 25/75 Lu/PCL fiber mat (Fig. 9f), where the fibers appeared more wrinkled in comparison with the initial ones and no pores were visible, probably because of lower Lu content.

3.4 Drug Release

We previously showed how the fiber morphology and drug deposition were affected by the drug state in the fibers: when drug was in amorphous state, it was incorporated inside the fibers, while the drug present in amounts above the solubility limit crystallized inside and on the fiber surface (as shown in Fig. 5b). In Fig. 10a and b, the cumulative percentage of released acetazolamide and timolol maleate from fibers with low drug content is presented, while in Fig. 11a, the released drug for fibers with high loadings is shown. It was noticed that fibers with high drug loading presented burst release in contrast with low drug content fibers that showed a more sustained release. The former contained drug crystals at the fiber surface or inside the fibers that were not totally encapsulated and were instantaneously “released”, suggesting that the predominant mechanism of release was drug dissolution. On the other hand, in the low loadings fibers, the drug was amorphous and dissolved in the fiber, and as such the release was governed by diffusion.

Cumulative release of high loadings fibers a from black square 25/75 Lu/PCL with acetazolamide, blacklozenge PCL with timolol, blacktriangledown 25/75 Lu/PCL with timolol and cumulative release of low loadings fibers and curves corresponding to non-linear fit of Eq. 2) b from blacksquare PCL with acetazolamide, blacklozenge PCL with timolol, blacktriangledown 25/75 Lu/PCL with timolol

Drug solubility in polymer as well as drug solubility in solution are important as they control the partitioning of the drug from the polymer toward the elution medium [48]. For the same type of fibers, higher percentages of timolol maleate were released in comparison with acetazolamide (for example, in the case of PCL fibers, \(\alpha=45.96\) (2.92) for timolol and \(\alpha=35.14\) (1.43) for acetazolamide). This can be explained by the combined effect of lower polymer solubility and higher water solubility of timolol maleate in contrast with acetazolamide that has higher polymer solubility and lower water solubility. High drug loading and sustained release were observed for formulations using drugs with higher solubility in the polymer [74]. The compatibility between drug and polymer is indeed important as it ensures sustained release when the drug is completely encapsulated and dissolved in the fiber [45].

Fiber composition influenced the release kinetics as drug was slowly released from PCL fibers when compared to bicomponent fibers regardless of the drug type (lower \(\alpha\) and k for PCL fiber with timolol than for 25/75 Lu/PCL and 50/70 Lu/PCL fibers with timolol, see Table 3). Certainly, as erosion was very fast (see Sect. 3.3), various pores were created and the drug was released through water-filled pores much faster than from amorphous and crystalline regions of PCL fibers that presented lower porosity [34, 55, 62].

A steady state was attained (after approximately 10 days for bicomponent fibers and after 20 days for PCL fibers) without total release of loaded drug (cumulative release percentages smaller than 100%). A fraction of the drug was desorbed from the pores surface and then it diffused through water filled pores, while another portion of the drug was trapped between crystalline areas [49, 50] (and inaccessible to water) and can only be released by polymer degradation (which is insignificant during the time scale of release experiment) [73, 59]. This was not the case for the high drug loading fibers where release was almost complete in the time frame of the experiment. At high loadings, only a small portion of drug was trapped (approximately 10% in the case of PCL, see Fig. 11a). As drug was in higher amount, additional regions of porosity were created after drug dissolution and diffusion besides those created by water uptake and polymer erosion, increasing surface area and enhancing drug release [46, 41].

The release kinetics and regression analysis results suggested a three stage release mechanism, with different steps depending on fiber composition. Dissolution of the surface deposited drug (this stage triggered burst release) was followed by drug desorption and subsequent diffusion through water-filled pores (created either due to Lu leaching or polymer recrystallization [78]), while the last stage was controlled by polymer degradation. In bicomponent fibers, the polymer erosion stage was dominant during the initial part of the drug release and it was replaced by the above-mentioned three stage mechanism as soon as Lu was leached out from the fibers.

4 Summary and Conclusion

Electrospinning is a method of obtaining fibers by stretching a polymer droplet using an electrical field. This technology has being expanding due to its simplicity and versatility. In the field of drug delivery, electrospun fibers are an excellent choice because of easy drug entrapment, high surface area, morphology control and biomimetic characteristics. Multicomponent fibers have attracted special attention because new properties can be obtained through the combination of different materials. There are several factors that can be manipulated in order to control the drug release from electrospun fibers. Fiber construct geometry and thickness, fiber diameter and porosity, fiber composition, fiber crystallinity, fiber swelling capacity, drug loading, drug state, drug molecular weight, drug solubility in the release medium, drug–polymer–electrospinning solvent compatibility are some of the process variables that can be optimised during method development.

We presented in this chapter how drug release control can be achieved in bicomponent fibers through the manipulation of drug solubility in polymer, drug state and loading. The restraint of burst stage is essential in order to avoid toxicity at the implantation site and to ensure long-term delivery. Fibers were obtained by electrospinning of two semi-crystalline (co)polymers, PCL and Lu, and were loaded with two drugs, acetazolamide and timolol maleate, in concentrations below and above the drug solubility limit in polymer. Morphological analysis showed that fibers with high drug loadings (above solubility limit) had drug crystals inside and outside the fibers, while fibers with low drug content (below solubility limit) had drug encapsulated in amorphous form.

The high loadings fibers showed higher extent of burst and shorter periods of release than low drug content fibers, suggesting that loading and drug encapsulation in either crystalline or amorphous form are interrelated and control the release rate, especially in the burst stage. Thus, in long term release applications where high amounts of loaded drug are desirable, a compromise must be found in order to balance the loading and release rate that seem to vary in opposite directions according to the present study. Timolol maleate was released faster than acetazolamide in the same type of fibers and at similar loadings, indicating that drug solubility in polymer influenced the partition of drug between polymer and elution medium. The fiber composition also controlled drug release, since release was slower from PCL fibers than from bicomponent fibers regardless of the drug type. By choosing the polymers making up the bicomponent fibers and their ratio, the magnitude of the various release stages can be controlled, attaining the desired release kinetics.

References

Fridrikh, S.V., Yu, J.H., Brenner, M.P., Rutledge, G.C.: Controlling the fiber diameter during electrospinning. Phys. Rev. Lett. doi:10.1103/PhysRevLett.90.144502 (2003)

Huang, Z.-M., Zhang, Y.-Z., Kotaki, M., Ramakrishna, S.: A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Comp. Sci. Tech. (2003). doi:10.1016/S0266-3538(03)00178-7

Hohman, M.M., Shin, M., Rutledge, G., Brenner, M.P.: Electrospinning and electrically forced jets. I. Stability theory. Phys. Fluids. (2001). doi:10.1063/1.1383791

Rutledge, G.C., Fridrikh, S.V.: Formation of fibers by electrospinning. Adv. Drug Deliv. Rev. (2007). doi:10.1016/j.addr.2007.04.020

McClure, M.J., Sell, S.A., Ayres, C.E., Simpson, D.G., Bowlin, G.L.: Electrospinning-aligned and random polydioxanone-polycaprolactone-silk fibroin-blended scaffolds: geometry for a vascular matrix. Biomed. Mater. (2009). doi:10.1088/1748-6041/4/5/055010

Lopez-Rubio, A., Sanchez, E., Sanz, Y., Lagaron, J.M.: Encapsulation of living bifidobacteria in ultrathin PVOH electrospun fibers. Biomacromolecules (2009). doi:10.1021/bm900660b

Heller, J.: Drug delivery systems. In: Ratner, B.D., Hoffman, A.S., Schoen, F.J., Lemons, J.E. (eds.) Biomaterials Science: An Introduction to Materials in Medicine, 1st edn. Academic Press, London (1996)

Cussler, E.L.: Diffusion Mass Transfer in Fluid Systems. Cambridge University Press, New York (1997)

Qi, H., Hu, P., Xu, J., Wang, A.: Encapsulation of drug reservoirs in fibers by emulsion electrospinning: morphology characterization and preliminary release assessment. Biomacromolecules (2006). doi:10.1021/bm060264z

Liang, D., Luu, Y.K., Kim, K., Hsiao, B.S., Hadjiargyrou, M., Chu B.: In vitro non-viral gene delivery with nanofibrous scaffolds. Nucl Acids Res. (2005). doi:10.1093/nar/gni171

Wang, Y., Wang, B., Qiao, W., Yin T.: A novel controlled release drug delivery system for multiple drugs based on electrospun nanofibers containing nanoparticles. J. Pharm. Sci. (2010). doi:10.1002/jps.22189

Ayodeji, O., Graham, E., Kniss, D., Lannutti, J., Tomasko, D.: Carbon dioxide impregnation of electrospun polycaprolactone fibers. J Sup Fluids. (2007). doi:10.1016/j.supu.2006.09.011

Chronakis, I.S., Milosevic, B., Frenot, A., Ye, L.: Generation of molecular recognition sites in electrospun polymer nanofibers via molecular imprinting. Macromolecules (2006). doi:10.1021/ma052091w

Chronakis, I.S., Jakob, A., Hagstrom, B., Ye, L: Encapsulation and selective recognition of molecularly imprinted theophylline and 17\(\beta\)-estradiol nanoparticles within electrospun polymer nanofibers. Langmuir (2006). doi:10.1021/la0613880

Ma, Z., Kotaki, M., Ramakrishna, S.: Surface modified nonwoven polysulphone (PSU) fiber mesh by electrospinning: a novel affinity membrane. J. Membr. Sci. (2006). doi:10.1016/j.memsci.2005.07.038

Casper, C.L., Yang, W., Farach-Carson, M.C., Rabolt, J.F.: Coating electrospun collagen and gelatin fibers with Perlecan domain I for increased growth factor binding. Biomacromolecules (2007). doi:10.1021/bm061003s

Casper, C.L., Yamaguchi, N., Kiick, K.L., Rabolt, J.F.: Functionalizing electrospun fibers with biologically relevant macromolecules. Biomacromolecules (2005). doi:10.1021/bm050007e

Skotak, M., Leonov, A.P., Larsen, G., Noriega, S., Subramanian, A.: Biocompatible and biodegradable ultrafine fibrillar scaffold materials for tissue engineering by facile grafting of l-lactide onto chitosan. Biomacromolecules (2008). doi:10.1021/bm800158c

Sawicka, K.M., Gouma, P.: Electrospun composite nanofibers for functional applications. J. Nanopart. Res. (2006). doi:10.1007/s11051-005-9026-9

Liang, D., Hsiao, B.S., Chu, B.: Functional electrospun nanofibrous scaffolds for biomedical applications. Adv. Drug Deliv .Rev. (2007). doi:10.1016/j.addr.2007.04.021

Lee, J.A., Krogman, K.C., Ma, M., Hill, R.M., Hammond, P.T., Rutledge, G.C.: Highly reactive multilayer-assembled TiO2 coating on electrospun polymer nanofibers. Adv. Mater. (2009). doi:10.1002/adma.200802458

Lee, S.J., Yoo, J.J., Lim, G.J., Atala, A., Stitzel, J.: In vitro evaluation of electrospun nanofiber scaffolds for vascular graft application. J. Biomed. Mater. Res A. (2007). doi:10.1002/jbm.a.31287

Zeng, J., Aigner, A., Czubayko, F., Kissel, T., Wendorff, J.H., Greiner, A: Poly(vinyl alcohol) nanofibers by electrospinning as a protein delivery system and the retardation of enzyme release by additional polymer coatings. Biomacromolecules (2005). doi:10.1021/bm0492576

Bogntizki, M., Frese, T., Steinhart, M., Greiner, A., Wendorff, J.H.: Preparation of fibers With nanoscaled morphologies: electrospinning of polymer blends. Polym. Eng. Sci. (2001). doi:10.1002/pen.10799

Wei, M., Kang, B., Sung, C., Mead, J.: Core–sheath structure in electrospun nanofibers from polymer blends. Macromol. Mater. Eng. (2006). doi:10.1002/mame.200600284

Kalra, V., Kakad, P.A., Mendez, S., Ivannikov, T., Kamperman, M., Joo, Y.L.: Self-assembled structures in electrospun poly(styrene-block-isoprene) fibers. Macromolecules (2006). doi:10.1021/ma052643a

Vaz, C.M., van Tuijl, S., Bouten, C.V.C., Baaijens, F.P.T.: Design of scaffolds for blood vessel tissue engineering using a multi-layering electrospinning technique. Acta Biomater. (2005). doi:10.1016/j.actbio.2005.06.006

Pham, Q.P., Sharma, U., Mikos, A.G.: Electrospun poly(E-caprolactone) microfiber and multilayer nanofiber/microfiber scaffolds: characterization of scaffolds and measurement of cellular infiltration. Biomacromolecules (2006). doi:10.1021/bm060680j

Hong, C.K., Yang, K.S., Oh, S.H., Ahn, J.-H., Cho, B.-H., Nah, C.: Effect of blend composition on the morphology development of electrospun fibres based on PAN/PMMA blends. Polym. Int. (2008). doi:10.1002/pi.2481

You, Y., Youk, J.H., Lee, S.W., Min, B.-M., Lee, S.J., Park, W.H.: Preparation of porous ultrafine PGA fibers via selective dissolution of electrospun PGA/PLA blend fibers. Mater. Lett. (2006). doi:10.1016/j.matlet.2005.10.007

Sisson, K., Zhang, C., Farach-Carson, M.C., Chase, D.B., Rabolt, J.F.: Evaluation of cross-linking methods for electrospun gelatin on cell growth and viability. Biomacromolecules (2009). doi:10.1021/bm900036s

Lee, S.J., Oh, S.H., Liu, J., Soker, S., Atala, A., Yoo, J.J.: The use of thermal treatments to enhance the mechanical properties of electrospun poly(\(\varepsilon\)-caprolactone) scaffolds. Biomaterials (2008). doi:10.1016/j.biomaterials.2007.11.024

Wang, X., Zhang, K., Zhu, M., Hsiao, B.S.., Chu, B.: Enhanced mechanical performance of self-bundled electrospun fiber yarns via post-treatments. Macromol. Rapid Commun. (2008). doi:10.1002/marc.200700873

Tiwari, S.K., Tzezana, R., Zussman, E., Venkatraman, S.S.: Optimizing partition-controlled drug release from electrospun core–shell bers. Int. J. Pharm. (2010). doi:10.1016/j.ijpharm.2010.03.021

Chew, S.Y., Wen, J., Yim, E.K.F., Leong, K.W.: Sustained release of proteins from electrospun biodegradable fibers. Biomacromolecules (2005). doi: 10.1021/bm0501149

Zeng, J., Yang, L., Liang, Q., Zhang, X., Guan, H., Xu, X., Chen, X., Jin, X.: Influence of the drug compatibility with polymer solution on the release kinetics of electrospun fiber formulation. J. Con. Rel. (2005). doi:10.1016/j.jconrel.2005.02.024

Xu, X., Yang, L., Xu, X., Wang, X., Chen, X., Liang, Q., Zeng, J., Jing, X.: Ultrafine medicated fibers electrospun from W/O emulsions. J. Con. Rel. (2005). doi:10.1016/j.jconrel.2005.07.021

Kim, K., Luu, Y.K., Chang, C., Fang, D., Hsiao, B.S., Chu, B., Hadjiargyro, M.: Incorporation and controlled release of a hydrophilic antibiotic using poly(lactide-co-glycolide)-based electrospun nanofibrous scaffolds. J. Con. Rel. (2004). doi:10.1016/j.jconrel.2004.04.009

Okuda, T., Tominaga, K., Kidoaki, S.: Time-programmed dual release formulation by multilayered drug-loaded nanober meshes. J. Con. Rel. (2009). doi:10.1016/j.jconrel.2009.12.029

Ranganath, S.H., Wang, C.-H.: Biodegradable microfiber implants delivering paclitaxel for post-surgical chemotherapy against malignant glioma. Biomaterials (2008). doi:10.1016/j.biomaterials.2008.04.002

Cui, W., Li, X., Zhu, X., Yu, G., Zhou, S., Weng, J.: Investigation of drug release and matrix degradation of electrospun poly(D,L-lactide) fibers with paracetanol inoculation. Biomacromolecules (2006). doi:10.1021/bm060057z

Buschle-Diller, G., Cooper, J., Xie, Z., Wu, Y., Waldrup, J., Ren, X.: Release of antibiotics from electrospun bicomponent fibers. Cellulose (2007). doi:10.1007/s10570-007-9183-3

Nie, H., Soh, B.W., Fu, Y.-.C, Wang, C.-H.: Three-dimensional fibrous PLGA/HAp composite scaffold for BMP-2 Delivery. Biotech. Bioeng. (2007). doi:10.1002/bit.21517

Maretschek, S., Greiner, A., Kissel, T.: Electrospun biodegradable nanofiber nonwovens for controlled release of proteins. J. Con. Rel. (2008). doi:10.1016/j.jconrel.2008.01.011

Kenawy, E.-R., Bowlin, G.L., Manseld, K., Layman, J., Simpson, D.G., Sanders, E.H., Wnek, G.E.: Release of tetracycline hydrochloride from electrospun poly(ethylene-co-vinylacetate), poly(lactic acid), and a blend. J. Con. Rel. (2002). doi:10.1016/S0168-3659(02)00041-X

Xu, X., Chen, X., Xu, X., Lu, T., Wang, X., Yang, L., Jing, X.: BCNU-loaded PEG-PLLA ultrafine fibers and their in vitro antitumor activity against glioma C6 cells. J. Con. Rel. (2006). doi:10.1016/j.jconrel.2006.05.031

Xie, Z., Buschle-Diller, G.: Electrospun Poly(D,L-lactide) fibers for drug delivery: the influence of cosolvent and the mechanism of drug release. J. Appl. Polym. Sci. (2009). doi:10.1002/app.31026

Chien Y.W. (1992) Novel Drug Delivery Systems. Marcel Dekker, New York

Luong-Van, E., Grndahl, L., Chua, K.N., Leong, K.W., Nurcombe, V., Cool, S.M.: Controlled release of heparin from poly(\(\varepsilon\)-caprolactone) electrospun fibers. Biomaterials (2006). doi:10.1016/j.biomaterials.2005.10.028

Zamani, M., Morshed, M., Varshosaz, J., Jannesari, M.: Controlled release of metronidazole benzoate from poly(\(\varepsilon\)-caprolactone) electrospun nanobers for periodontal diseases. Eur. J. Pharm. Biopharm. (2010). doi:10.1016/j.ejpb.2010.02.002

Xie, J., Wang, C.-H.: Electrospun micro- and nanofibers for sustained delivery of paclitaxel to treat C6 glioma in vitro. Pharm. Res. (2006). doi:10.1007/s11095-006-9036-z

Thakur, R.A., Florek, C.A., Kohn, J., Michniak, B.B.: Electrospun nanobrous polymeric scaffold with targeted drug release proles for potential application as wound dressing. Int. J. Pharm. (2008). doi:10.1016/j.ijpharm.2008.07.033

Yu, D.-G., Shen, X.-X., Branford-White, C., White, K., Zhu, L.-M., Annie Blig S.W.: Oral fast-dissolving drug delivery membranes prepared from electrospun polyvinylpyrrolidone ultrafine fibers. Nanotechnology, (2009). doi:10.1088/0957-4484/20/5/055104

Taepaiboon, P., Rungsardthong, U., Supaphol, P.: Drug-loaded electrospun mats of poly(vinyl alcohol) fibres and their release characteristics of four model drugs. Nanotechnology (2006). doi:10.1088/0957-4484/17/9/041

Verreck, G., Chun, I., Rosenblatt, J., Peeters, J., Van Dijck, A., Mensch, J., Noppe, M., Brewste, M.E.: Incorporation of drugs in an amorphous state into electrospun nanofibers composed of a water-insoluble, nonbiodegradable polymer. J. Con. Rel. (2003). doi:10.1016/S0168-3659(03)00342-0

Huang, Z.-M., He, C.-L., Yang, A., Zhang, Y., Han, X.-J., Yin, J., Q.W Encapsulating drugs in biodegradable ultrafine fibers through co-axial electrospinning. J. Biomed. Mater. Res. (2005). A. doi:10.1002/jbm.a.30564

Natu, M.V., de Sousa, H.C., Gil, M.H.: Effects of drug solubility, state and loading on controlled release in bicomponent electrospun fibers. Int. J. Pharm. (2010). doi:10.1016/j.ijpharm.2010.06.045

Sikareepaisan, P., Suksamrarn, A., Supaphol, P.: Electrospun gelatin fiber mats containing a herbal—Centella asiatica—extract and release characteristic of asiaticoside. Nanotechnology, (2008). doi:10.1088/0957-4484/19/01/015102

Tzafriri, A.R.: Mathematical modeling of diffusion-mediated release from bulk degrading matrices. J. Con. Rel. (2000). doi:10.1016/S0168-3659(99)00174-1

Kim, T.G., Lee, D.S., Park, T.G.: Controlled protein release from electrospun biodegradable fiber mesh composed of poly(\(\varepsilon\)-caprolactone) and poly(ethylene oxide). Int. J. Pharm. (2007). doi:10.1016/j.ijpharm.2007.01.040

Perale, G., Arosio, P., Moscatelli, D., Barri, V., Mller, M., Maccagnan, S., Masi, M.: A new model of resorbable device degradation and drug release: transient 1-dimension diffusional model. J. Con. Rel. (2009). doi:10.1016/j.jconrel.2009.02.014

Zong, X., Ran, Sh., Kim, K.-S., Fang, D., Hsiao, B.S., Chu B.: Structure and morphology changes during in vitro degradation of electrospun poly(glycolide-co-lactide) nanofiber membrane. Biomacromolecules (2003). doi:10.1021/bm025717o

Peppas, N.A., Brannon-Peppas, L.: Water diffusion and sorption in amorphous macromolecular systems and foods. J. Food Eng. (1994). doi:10.1016/0260-8774(94)90030-2

Zeng, J., Xu, X., Chen, X., Liang, Q., Bian, X., Yang, L., Jin, X.: Biodegradable electrospun fibers for drug delivery. J. Con. Rel. (2003). doi:10.1016/S0168-3659(03)00372-9

Qi, M., Li, X., Yang, Y., Zhou, S.: Electrospun fibers of acid-labile biodegradable polymers containing ortho ester groups for controlled release of paracetamol. Eur. J. Pharm. Biopharm. (2008). doi:10.1016/j.ejpb.2008.05.003

Taepaiboon, P., Rungsardthong, U., Supaphol, P.: Vitamin-loaded electrospun cellulose acetate nanober mats as transdermal and dermal therapeutic agents of vitamin A acid and vitamin E. Eur. J. Pharm. Biopharm. (2007). doi:10.1016/j.ejpb.2007.03.018

Suwantong, O., Opanasopit, P., Ruktanonchai, U., Supaphol, P.: Electrospun cellulose acetate ber mats containing curcumin and release characteristic of the herbal substance. Polymer (2007). doi:10.1016/j.polymer.2007.11.019

Verreck, G., Chun, I., Peeters, J., Rosenblatt, J., Brewste, M.E.: Preparation and characterization of nanofibers containing amorphous drug dispersions generated by electrostatic spinning. Pharm. Res. (2003) doi:10.1023/A:1023450006281

Kenawy, E.-R., Abdel-Hay, F.I., El-Newehy, M.H., Wnek, G.E.: Processing of polymer nanobers through electrospinning as drug delivery systems. Mater. Chem. Phys. (2009). doi:10.1016/j.matchemphys.2008.07.081

Jiang, H., Hu, Y., Li, Y., Zhao, P., Zhu, K., Che, W.: A facile technique to prepare biodegradable coaxial electrospun nanofibers for controlled release of bioactive agents. J. Con. Rel. (2005). doi:10.1016/j.jconrel.2005.08.006

Tammaro, L., Russo, G., Vittoria, V.: Encapsulation of diclofenac molecules into Poly(\(\varepsilon\)-caprolactone) electrospun fibers for delivery protection. J. Nanomater. (2009). doi:10.1155/2009/238206

Abidian, M.R., Kim, D.-H., Martin, D.C.: Conducting-polymer nanotubes for controlled drug release. Adv. Mater. (2006). doi:10.1002/adma.200501726

Srikar, R., Yarin, A.L., Megaridis, C.M., Bazilevsky, A.V., Kelley, E.: Desorption-limited mechanism of release from polymer nanofibers. Langmuir. (2008). doi:10.1021/la702449k

Panyam, J., Williams, D., Dash, A., Leslie-Pelecky, D., Labhasetwar, V.: Solid-state solubility influences encapsulation and release of hydrophobic drugs from PLGA/PLA nanoparticles. J. Pharm. Sci. (2004). doi:10.1002/jps.20094

Drug card for timolol (DB00373), DrugBank database. http://www.drugbank.ca/drugs/DB00373. Cited 27 May 2010

Drug card for acetazolamide (DB00819), DrugBank database. http://www.drugbank.ca/drugs/DB00819. Cited 27 May 2010.

Marsac, P.J., Li, T., Taylor L.S.: Estimation of drug–polymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharm. Res. (2009). doi:10.1007/s11095-008-9721-1

Miyajima, M., Koshika, A., Okada, J., Ikeda, M., Nishimura, K.: Effect of polymer crystallinity on papaverine release from poly(L-lactic acid) matrix. J. Con. Rel. (1997). doi:10.1016/S0168-3659(97)00081-3

Jeong, J.-C., Lee, J., Cho, K.: Effects of crystalline microstructure on drug release behavior of poly(\(\varepsilon\)-caprolactone) microspheres. J. Con. Rel. (2003). doi:10.1016/S0168-3659(03)00367-5

Cui, W., Li, X., Zhou, S., Weng, J.: Degradation patterns and surface wettability of electrospun brous mats. Polym. Degrad. Stab. (2008). doi:10.1016/j.polymdegradstab.2007.12.002

Kang, M., Jung, R., Kim, H.-S., Jin, H.-J.: Preparation of superhydrophobic polystyrene membranes by electrospinning. Colloids Surf. A Physicochem. Eng. Asp. (2008). doi:10.1016/j.colsurfa.2007.04.122

Natu, M.V., Gil, M.H., de Sousa, H.C.: Supercritical solvent impregnation of poly(\(\varepsilon\)-caprolactone)/poly(oxyethylene-b-oxypropylene-b-oxyethylene) and poly(\(\varepsilon\)-caprolactone)/poly(ethylene-vinyl acetate) blends for controlled release applications. J. Sup. Fluids (2008). doi:10.1016/j.supflu.2008.05.006

Hglund, A., Hakkarainen, M., Albertsson, A.-C.: Degradation profile of poly(\(\varepsilon\)-caprolactone)-the influence of macroscopic and macromolecular biomaterial Design. J. Macromol. Sci. A. doi:10.1080/10601320701424487 (2007)

Acknowledgments

FCT (Fundação para a Ciência e a Tecnologia) financial support is acknowledged by Mădălina V. Natu (SFRH/BD/30198/2006).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Natu, M.V., de Sousa, H.C., Gil, M.H. (2011). Electrospun Drug-Eluting Fibers for Biomedical Applications. In: Zilberman, M. (eds) Active Implants and Scaffolds for Tissue Regeneration. Studies in Mechanobiology, Tissue Engineering and Biomaterials, vol 8. Springer, Berlin, Heidelberg. https://doi.org/10.1007/8415_2010_56

Download citation

DOI: https://doi.org/10.1007/8415_2010_56

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-18064-4

Online ISBN: 978-3-642-18065-1

eBook Packages: EngineeringEngineering (R0)