Abstract

The merger of biology and modern microsystem technology bears challenges literally at the interface. Precise control of the interaction between an artificial surface and a biological environment is a prerequisite for a successful interplay of the “living world” with man-made technology. Any design of a chip for a spatially controlled attachment and outgrowth of living cells has to meet two fundamental yet apparently opposing requirements: it has to divide the surface into areas that favor cell adhesion and those that resist it. In the first part of this article, we provide a basis for an understanding of how to achieve both tasks by discussing basic considerations concerning cell adhesion to matrices in vivo and ways to control the interactions between biomacromolecules and surfaces. We also include an overview of current strategies for the integration of living cells on planar devices that aims to provide a starting point for the exploration of the emerging field of cell-chip technology.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Assay

- Bioactive surface

- Cell adhesion

- Cell chip

- Hydrogel

- Microengineering

- Micropattern

- Peptide

- Polymer brush

- Protein adsorption

1 Surface-Microengineering and Biology: A Challenge at the Interface

The progress over the past decades in the field of surface science and the development of several microengineering techniques for the precise deposition, manipulation, and characterization of ultrathin films will open new avenues for the design of novel types of medical devices [1–6]. The new devices will, for example, monitor the health-status of a person for extended time-periods, detect critical metabolic situations such as unusually elevated or strongly reduced levels of blood sugar, or recognize an unexpected, serious immune reaction. Although the two research areas (biomedicine and surface-microengineering) involved in these developments, particularly in the tailoring of functional surfaces for specific needs, are both at present highly advanced, the merger of both brings great challenges literally at the interface.

In the field of medical diagnostics, surfaces are required that allow a specific interaction with a particular environment (e.g., an analyte) and meanwhile suppress unspecific reactions. A well-established implementation of this kind of a “smart” biomaterial is the development of DNA-analyzing chips (also known as DNA-chips) [7, 8]. This successful application of a biomedical microengineered system also involves an important concept in microengineering in general – miniaturization. The reduction of dimensions together with an increased sensitivity of the sensorial sites, mainly achieved through a tailor-made bioactive surface, leads to a parallelization of the analytic process that allows tremendous reductions in cost, time, and amount of analyte necessary. In a next step, biochips for the analysis of proteins are of utmost interest in medical diagnostics and therapy. In contrast to DNA analysis, where the “sensors” are single-stranded DNA fragments, the detection of proteins (e.g., disease markers) requires the immobilization of specific proteins (or parts of such proteins), such as antibodies, on the artificial surface [9, 10]. With respect to successful surface-immobilization, however, one has to deal with a number of hurdles when using proteins: they have a complex structure and, hence are highly sensitive to conformational changes (i.e., denaturation) that might be induced upon interaction with a surface. Denaturation (i.e., any change of the natural protein structure) can lead to a reduction or even loss of the functionality and, consequently, to an altered, often poor and nonreproducible performance of the device. Looking at the family of biofunctional analysis chips, one can state that DNA-chips are already well established on the market, with protein-chips starting to follow in their footprints. However, for biomedical diagnostics and research, it would be of great interest to use even more complex systems as sensorial devices, i.e., living cells. The ability of living organisms (i.e., cells) to react to various environmental changes with a high specificity and sensitivity is as impressive as it is difficult to predict. Therefore, the search for substances that induce a certain (desired) cellular response either for medicinal purposes (drug-screening) or as coatings for medical implants (biocompatibility tests) is mainly done to date in extensive in vitro studies using cell culture assays. These assays require comparatively large volumes of the often very expensive substances to be tested. Here, the manipulation of living cells in microscale devices offers distinct advantages over conventional macroscale systems. Microscale devices have the ability to process small sample volumes rapidly and inexpensively, and thereby provide valuable information about important cell parameters such as gene expression and metabolic activity. Figure 1 hints at the vast potential a cell chip could offer to a number of biomedical research areas. Thus, an increasing amount of fundamental research in current bioengineering science is dedicated to the development of such cell chips.

Any successful attempt to create a cell chip has to meet important requirements with respect to the precise surface chemistry and physics that govern the interaction of the substrate with the living cells. Therefore, the quest for the development of a device for guided cell adhesion has to be preceeded by a study of the environment of living cells in vivo in order to understand the mechanisms and surrounding cirumstances of “normal” cell behavior. The key challenge in the development of such cell chips lies in the specific attachment of living cells in a spatially controlled manner. For this, a surface has to be designed that, on the one hand, prevents unspecific protein adsorption that can mediate cell adhesion and, on the other hand, simultaneously promotes specific cell attachment in a spatially resolved way. In this review, we focus on novel developments in the design of surfaces that guide a locally controlled adhesion of living cells at desired surface areas. In order to present related work in the context of modern bioengineering, we first review how cells adhere to their neighboring environment in nature (Sect. 2). Then, we briefly discuss strategies for design of surfaces that resist nonspecific interactions with proteins (Sect. 3). In Sect. 4, we then review the current state-of-the-art in confining cells to distinct lateral spots on various artificial surfaces, including those surfaces where surface-adsorbed proteins are used to mediate cell-adhesion, as well as surfaces that have been designed to expose bioactive ligand-modules that promote the adhesion of living cells.

2 Lessons for Surface Design: Cell Adhesion in Nature

Our understanding of the molecular mechanisms that underlie the adhesion of living cells in nature has improved tremendously over the past decades. Cell–cell adhesion, as well as the adhesion of living cells to an extracellular matrix (ECM), is governed by specific interactions between distinct “cell adhesion molecules” (CAMs) localized in the plasma membrane as transmembrane proteins (i.e., receptors) and their specific ligands in the ECM. Different major classes of such receptors have been identified [9, 11, 12]. Immunoglobulins and cadherins interact with their counterparts located in a neighboring cell membrane, and thus form cell–cell contacts. Selectins bind to glycosylated mucins, and vice versa, as well as to distinct growth factors. Finally, integrins comprise an important class of CAMs that mainly bind to ECM proteins and also interact with immunoglobulins (Fig. 2).

(a) The cell-membrane–ECM interface. Transmembrane integrins are composed of two subunits, α and β, which anchor the cell to ECM molecules, e.g., fibronectin. The extracellular binding of the integrins triggers the intercellular formation of the cytoskeleton through a highly organized aggregate of proteins, such as actin filaments and others. (b) Specific binding of integrins to recognition sites in the ECM proteins, here to fibronectin. (Figure reproduced in part with permission from [132])

Integrins consist of two noncovalently linked subunits (α- and β-subunits), i.e., they comprise a heterodimeric structure [13–15]. There are more than 20 different integrins known to date [12]. Most integrins are expressed on a variety of cells, and most cells express several different integrins, enabling them to bind to various matrix molecules. The most important of these matrix molecules are ECM proteins such as fibronectin, collagens, laminin, and vitronectin. The cell–ECM adhesion comprises a cascade of different, mainly consecutively occurring events, and is initiated by the interaction of the integrin receptors with small ligands (peptides) present in ECM proteins [12]. Once the ligand interacts with its specific receptor, the cell begins to flatten (i.e., it “spreads”) on the interface. The chemical information is “transmitted” into the cell by conformational rearrangements of the receptor at the cytosolic side, where it triggers the further organization of actin filaments, which are often called “stress fibers.” Finally, integrin molecules that are attached to both the peptide ligand outside of the cell and to the cytoskeleton inside (stress fibers and a number of other cell proteins, such as focal adhesion kinase, vinculin, talin, and tensin) cluster together in the plasma membrane, thereby forming “focal adhesion contacts” [16–19]. At first view, this scenario seems to be simple; however, it is important to note that from a molecular view, many different steps of the above-described cascade are not yet understood in detail. In addition, it is important to recognize that the interaction of the peptide ligands with integrins not only ensures the structural integrity of living cells, but also triggers a number of different events inside the cell that finally influence the metabolism, differentiation, and proliferation of the cell. The interaction also impacts the systemic responses of the immune system, and is involved in wound-healing cascades [20, 21].

A biomedical device that aims to provoke a normal cell behavior in vitro needs to “mimic” the ECM in a way that allows the initiation of the cell adhesion process. In principle, one can either modify a surface with ECM proteins that mediate the attachment of living cells, or one can engineer cell-adhesion-mediating small ligands into/onto appropriate surfaces. A well-known ligand is the minimal cell-recognition peptide sequence RGD (R = arginine, G = glycine, and D = aspartic acid) [22–27], which is found in many different ECM proteins. Although the RGD motif is by far not the only recognition sequence known today, it is of special interest due to its broad distribution and variability. The affinity to different integrins is mainly governed by its flanking amino acids, and a number of oligopeptides that include the RGD sequence have been identified as binding to specific members of the integrin family. For a more detailed overview on different bioactive peptide sequences that interact with various CAMs, the reader is referred to two excellent review articles [28, 29].

Note that the above-mentioned, rather simplified set of characteristics for a biomimetic strategy of “guided cell adhesion” were first developed for planar surfaces. For many cell-types, this accounts for an interesting model system with a sufficient relevance to the biological situation; however, there also exist a number of cell types that might behave differently with respect to surface attachment, growth, and differentiation if cultured in 2D (as opposed to the 3D biological environment) [30]. However, 3D artificial model systems are much more sophisticated with respect to matrix preparation, as well as peptide–ligand (or protein–ligand) presentation, and therefore studies using such systems are so far very rare. Thus, we restrict further discussions exclusively to planar surfaces.

3 Surfaces that Resist the Adsorption of Proteins and Cells

Throughout the last few decades, a number of interesting strategies have evolved that address the construction of both surfaces that resist the adsorption of proteins as well as surfaces that promote protein adsorption, and hence are either capable of suppressing or supporting protein-mediated cell adhesion. Protein adsorption is a crucial issue in the design and performance of materials in contact with living cells. And, perhaps, it is the surface chemistry and physics that govern any successful attempt to design a material that directs the controlled attachment and growth of cells, rather than the bulk properties of the material itself. Both, surfaces that allow the adsorption of proteins and surfaces that repel proteins are of the utmost interest for guiding cells, particularly if a spatially controlled attachment of cells is targeted, where these two properties have to be implemented onto the same substrate.

We will briefly outline the principle thermodynamic considerations that comprise the underlying key issues of protein adsorption on surfaces. Subsequently, we will describe strategies that have been followed for the design of protein-repellent surface coatings. For details on protein adsorption, as well as further discussion on this particular topic, the reader is referred to more comprehensive reviews [31, 32].

3.1 Thermodynamics

From a thermodynamic point of view, protein adsorption at a surface depends on the Gibb’s free energy of adsorption ΔG ads:

Here ΔH ads is the enthalpy of adsorption, T is the temperature, and ΔS ads is the entropy change associated with the adsorption of the protein onto the surface. Protein adsorption will take place if ΔG ads < 0. Considering a complex system, where proteins are dissolved in an aqueous environment, and are brought into contact with an artificial interface, there are a vast number of parameters that impact ΔG ads: due to their small size (i.e., large diffusion coefficient), water molecules are the first to reach the surface when a solid substrate is placed in an aqueous biological environment. Hence, a hydrate layer is formed. With some delay, proteins diffuse to the interface and competition for a suitable spot for adsorption starts. This competition is mainly governed by the surface properties of the material that influence the rate, amount, and conformation of the adsorbed molecules. The surface charge, the degree of swelling in water (if a water-swellable surface coating is considered), as well as the surface energy of the material are thus important parameters, which influence the kind and strength of interaction of proteins with the substrate. Table 1 summarizes phenomena accompanying protein absorption as well as their influence on the Gibb’s free energy.

Considering the polarity of a surface, water molecules will arrange themselves on hydrophobic surfaces in a highly ordered fashion, which decreases the overall entropy of the system (i.e., ΔS > 0). Adsorption of a protein replaces parts of the ordered water layer at the surface and thus can increase the entropy of the system. Because proteins carry both, hydrophobic as well as hydrophilic chemical groups, adsorption itself relies on the free energy change of the protein molecule during the surface attachment. If the loss in conformational entropy of the protein molecule due to fixation of some parts of it at the surface is compensated by the gain in enthalpy due to the interaction of distinct chemical groups with the hydrophobic surface, adsorption will occur. Proteins will thus mainly attach to hydrophobic interfaces via interactions between hydrophobic residues present in a number of different amino acids and the respective surface chemical groups. The complex structure of soluble proteins can be taken in a very simplified fashion as a “core–shell”-like object, i.e., hydrophobic parts are arranged “inside” the protein, and are covered by more hydrophilic modules that form a soft shell surrounding the hydrophobic core. If such proteins adsorb to a hydrophobic surface, the core of the protein has to turn towards the substrate. Simultaneously, the hydrophilic parts of proteins turn towards the aqueous environment upon adsorption. By this mechanism, the surface energy of the substrate may be significantly decreased. The process is often accompanied by a restructuring of the protein molecule. This “denaturation,” which is entropically unfavorable for the protein, is compensated by the gain of entropy of the system due to the release of the water molecules from the surface, as well as the gain in enthalpy of the protein molecule.

In contrast, protein adsorption to hydrophilic surfaces might be even more complex, and is still not completely understood. As will be shown, there exist a number of examples in which hydrophilic surfaces indeed successfully repel proteins; however, there also exist interesting examples in which attractive interactions between a strongly hydrophilic surface and proteins in solution can lead to an attachment of the protein to the substrate. In a textbook by Lanza et al. [33], cell adhesion on various polymeric substrates is discussed in the context of surface polarity, as measured by the water–air contact angle. Figure 3 shows the amount of adherent cells as a function of the water contact angle for various polymeric surfaces. The data were collected by Saltzman, and the reader is referred to the literature for details of the polymeric substrates studied [33]. Saltzman claims that surfaces with more hydrophobic properties (i.e., water contact angles greater than 60 ∘ ) will probably promote protein adsorption, and thus support protein-mediated cell adhesion. However, the guide to the eye, present as a solid line in the figure, is still questionable because the data scattering is tremendous. In our opinion, water contact angle measurements should not be taken as a measure for protein-repellent surface properties. Despite the surface polarity, protein adsorption will also be largely affected by further parameters such as surface charge, surface elasticity, and the morphological composition of the surface.

Relationship between cell adhesion and water–air contact angle for a variety of polymer surfaces. The data have been collected and plotted by Saltzman, and are summarized in a book by Lanza et al. (Figure reproduced, with permission, from [33])

Surface charge has been observed to impact protein adsorption significantly. The net charge of most proteins is negative and adsorption to positively charged surfaces can take place, e.g., by electrostatic, attractive interactions [34]. Negatively charged surfaces can still be subject to protein adsorption when a layer of counterions reverses the effective surface charge. The attraction for protein adsorption is furthermore influenced significantly by the degree of swelling of the surface-confined layers or bulk material in water. Considering a surface layer such as surface-confined hydrophilic polymer films, which are capable of swelling in an aqueous environment, any adsorption of protein molecules leads to a compression of the surface layer. The latter is always accompanied by a reduction of the conformational entropy of the surface-attached molecules due to the loss in the degree of conformational freedom and, as a result, elastic forces (i.e., excluded volume effects) will act against this compression. As a result, proteins will be pushed away from the surface, rendering water-swellable surface layers interesting candidates for the implementation of protein-repellent properties.

Following the above-outlined phenomenological considerations, scientists have studied various surfaces with respect to protein adsorption, and a number of different surface chemistries have been successfully applied to the design of surfaces that resist the adsorption of proteins.

3.2 Examples of Protein-Resistant Surface Coatings

Materials that have been used as surface-coatings for the design of protein-resistant surfaces include natural polymers such as heparin [35] or dextran [36] as well as synthetic polymers such as poly(ethyloxazoline) (PEtOx) [37, 38], poly(dimethylacrylamide) (PDMAA) [39, 40], poly(glycerols) [41], and poly (ethylene glycol) (PEG) [42]. Due to its availability, as well as biocompatible properties, PEG is perhaps the most common example of a polymeric material used to produce surfaces that are inert to nonspecific protein adsorption [43–45]. Despite PEG polymers, self-assembled monolayers (SAMs) presenting similar chemical surface-functionalities [i.e., oligo(ethylene glycol) groups] have been successfully used as protein-resistant surface-coating materials [46, 47]. Although PEG-based surface coatings are widely used, these materials also exhibit some severe limitations with respect to chemical and thermal stability. For example, Whitesides and coworkers have shown that PEG-based films can undergo autooxidative degradation in the presence of transition metals, or enzymatically in vivo [48]. In addition, from a mechanistic point of view, the protein resistance of PEG coatings is still controversially discussed in the literature. Nagaoke et al. proposed that the underlying mechanism governing the protein resistance of PEG coatings is the restriction of the mobility of PEG chains if protein molecules adhere to the surface. This accounts for the loss in conformational entropy of the surface-confined chains [49]. Other groups proposed the helical conformation of short PEG chains, as well as tightly bound water molecules, to be crucial for protein-resistant properties [50–52]. Based on extensive studies using short PEG segments anchored to a solid substrate via self-assembled monolayers (SAMs), Whitesides and coworkers concluded that hydrophilic surface chemistries with hydrogen-bond accepting rather than donating functionalities (i.e., acidic protons) exhibit protein-resistant properties [53]. However, to date it is not clear whether this finding holds for all kind of hydrophilic surface coatings. Mrksich and coworkers, for example, showed that surface-adsorbed monolayers exposing mannitol-groups, which offer a moiety with acidic protons, are inert to protein adsorption [54]. The latter finding is even more interesting because films consisting of different sugar derivatives do not resist the adsorption of proteins [48]. In addition to surface coatings consisting of linear PEG polymers and oligomers, branched polymeric systems, such as surface-attached PEG-derivatized poly(ethyleneimine) (PEI) [55], or dentritic polyglycerol layers [41] have also been shown to resist the nonspecific adsorption of proteins. Figure 4 schematically summarizes some of the hydrophilic surface coatings that have been shown to prevent nonspecific protein adsorption.

Examples (a) PEGylated monolayer; (b) Glucose-modified monolayer; (c) Surface-attached hyper-branched polyethylene imine; and (d) Surface-attached hyperbranched polyglycerols of surface-coatings that resist the nonspecific adsorption of proteins. (Figure reproduced in part with permission from [41])

An interesting class of surface coatings consists of so-called polymer brushes. These are polymer monolayers that are end-attached to a surface with a high grafting density, which leads to a stretching of the molecules normal to the surface (Fig. 5) due to strong excluded volume interactions. Polymer brushes can be prepared by either growing macromolecules in situ using surface-immobilized initiator groups (“grafting from”) or by grafting end-functional macromolecules onto a reactive surface-site (“grafting to”). Note that polymer brushes can also be prepared by physisorption of block copolymers onto solid substrates from selective solvents, or by using surface-immobilized monomers and a “grafting through” process, respectively. The preparation of polymer brushes, characterization of the physicochemical properties (e.g., swelling in solvents), and initial studies on interesting applications of such layers, including bioactive surfaces, are described in a comprehensive book by Advincula et al. [56], as well as in a recent review by Klok and coworkers that includes an impressive list of almost 1000 references [57].

Hydrophilic polymer brushes have been shown to resist the nonspecific adsorption of proteins. The underlying mechanism has been ascribed to a strong loss in entropy of the surface-attached chains if a protein attaches to a polymer brush; hence, protein attachment to a highly swollen polymer brush in an aqueous environment is thermodynamically unfavorable [57–59]. These brushes differ from the oligo-PEG SAM coatings described above in the sense that protein-resistancy might not be influenced by the chemistry of the surface-linked macromolecules as long as neutral, water-swellable chains of sufficient molar masses and high grafting densities are considered. Interestingly, attractive forces between a brush, swollen in water, and a protein can lead to strong protein-adsorption. This was shown in studies by Ballauff and coworkers in which charged polymer brushes (i.e., polyelectrolyte brushes) were used to confine protein molecules into/onto the brush via electrostatic interactions [34].

Similar to hydrophilic polymer brushes, surface-confined, cross-linked polymer films (i.e., surface-attached hydrogels) (Fig. 5), can prevent a nonspecific adsorption of proteins to the underlying substrate [60, 61]. The driving forces resisting protein-adsorption are again of thermodynamic nature, provided that attractive forces (e.g., electrostatic interactions or hydrogen bonding) can be neglected. Protein attachment onto the hydrogel leads to a decrease in the conformational entropy, and strong osmotic forces retain water molecules inside the gel, thus repelling proteins from the interface. Finally, hydrophilic polymer monolayers of just a few nanometers in thickness have been proven to be suitable for implementation of protein-repellent properties onto glass-substrates (Fig. 5 and Sect. 4.2) [40]. The underlying driving forces for resisting the nonspecific adsorption of proteins are probably of thermodynamic (i.e., entropic) nature, as for polymer brushes, and hydrogels.

4 Directed Cell Adhesion to Engineered Surfaces

Several routes have been followed to create a local environment suitable for the attachment of living cells on an artificial surface. On the basis of the insight that cell adhesion in vivo is based on the interaction of CAMs and proteins found in the ECM, an approach that utilizes locally deposited proteins from the ECM represents a suitable starting point for “successful” cell attachment. A close control over the local surface chemistry, on the other hand, is the decisive factor for a controlled placement of proteins on a surface, because of its influence on the whole adsorption process of the biomolecule. Although denaturation of the adsorbed proteins can significantly alter the biological functions of the protein, the degree of biomimicry of the ECM can be – in the best case – high, simply by employing the main building blocks (i.e., proteins) that constitute the extracellular space in vivo for applications in vitro. However, some restrictions apply for certain applications. The nonspecific adsorption of proteins is based on physisorption and can be altered or reversed by thermodynamic processes. For example, the cell-adhesion-mediating film can bleed off or can be replaced over time by other molecules with a higher enthalpy of adsorption. Consequently, the properties of the surface can be subject to a dynamic change in a biological environment unless the bioactive film is covalently immobilized on the surface. Furthermore, proteins are subject to proteolytic degradation and need to be replaced continuously to ensure a sufficient longevity.

Despite the problems mentioned, the passive control of protein adsorption is excellently suited for short-term applications and many situations in a controlled environment ex vivo.

As described in Sect. 2, the binding of CAMs is highly specific to certain peptide sequences present in the proteins of the ECM. The last few decades have seen a number of interesting approaches that employ the mere minimum binding sites for guided cell adhesion through surface modification, either by directly (e.g., through short linker molecules) placing the peptides on the substrate or by incorporation of the biomolecules into polymeric backgrounds. Although this strategy compromises on the degree of biomimicry as compared to the protein-based approach, it is able to offer unique advantages in terms of controllability of cell–substrate interactions.

In combination with the techniques for rendering a surface nonfouling (as discussed in Sect. 3), a powerful “box of building blocks” arose for the design of live-cell chips. The choice of cell- or protein-repellent components, in combination with a cell-adhesion-mediating entity, of course depends on the application. Important parameters that have to be taken into account are:

-

Degree of biomimicry

-

Control over the specific cell–surface interaction

-

Stability and longevity of the surface coating under cell culture conditions

-

Ease of synthesis and availability of components

-

Microstructuring method (which also depends on the application)

-

Instruments required for production and experiment

4.1 Protein-Decorated Surfaces for Spatially Guided Cell Adhesion

The deposition of proteins onto surfaces for the purpose of a guided cell adhesion requires two major prerequisites: first, the immobilized proteins have to exert their native biofunctionality towards cell binding, i.e., the specific recognition sites have to remain active and accessible for the cell. Second, the deposited protein layer has to be sufficiently stable under cell culture conditions in order to provide a controlled experimental setup. Both criteria have been the focus of extensive studies in the last two decades. As discussed, the driving forces for protein adsorption onto surfaces can be categorized into enthalpic (e.g., electrostatic interactions due to redistributions of charged groups at the interface, and hydrogen bonding, to name the most prominent kind of interactions) and entropic contributions. The latter include (partial) dehydration of the protein and/or the sorbent surface or a structural reorganization of the protein molecule [62].

For the preservation of a protein’s cell-binding ability (also termed “molecular potency”), unfolding (denaturation) can be a prohibiting factor and leads to a loss of the natural adhesion-mediating ability of the protein. Results by Norde and Giacomelli, who investigated a number of proteins and surfaces, suggest that at least some conformational changes occur with most protein adsorption processes [63–65]. Although these studies indicate that adsorbed proteins retain a major part of their secondary structure, other reports propose changes in protein folding as likely causes for enhanced or impaired protein activity towards cell adhesion [66–71]. In fact, the actual role a biomolecule plays in the cell–surface interaction can be dramatically altered by the adsorption process and the resulting conformational changes in the protein. Human albumin, the most abundant protein in blood, might serve as a good example. Although it is conventionally considered nonadhesive to platelets and therefore widely used as a surface-passivation against nonspecific platelet–surface interactions in platelet adhesion studies, Sivaraman and Latour reported that platelet adhesion can be substantially mediated by specific interactions with denaturated albumin, if the protein is adsorbed from low concentrations and/or onto hydrophobic surfaces [72]. Other examples for the close dependency of the biological function of a protein and its conformation include the enhanced adhesion of pre-osteoblastic cells on partially denaturated collagen type I as compared to its native form [70]; and the activation of low levels of adhesion proteins (too low to promote cell adhesion when deposited by themselves) for cell adhesion by co-adsorbtion with high concentrations of nonadhesion proteins (likely causes for enhanced or impaired protein activity towards cell adhesion) [70]. For a more detailed discussion on the unfolding of proteins on surfaces, the reader is referred to reviews by Horbett [73, 74].

Since the build-up of multilayers of proteins on a surface is thermodynamically unfavorable (parts of the protein layer exposed towards the ambient solution may act as a kind of a swollen hydrophilic layer, rendering the adsorption of other proteins to the surface thermodynamically unfavorable), competitive adsorption becomes a decisive factor in the cell’s response once the protein-coated surface is placed into contact with cell culture media, which is often enriched with a mixture of more than 400 different proteins from the serum supplement [12]. The surface concentration of adsorbed proteins from plasma or model protein mixtures depends on their relative abundance and affinity towards the surface [75–79]. Over time, the composition of the adsorbed protein layer is subject to a dynamic change. Initial coverage is dominated by smaller proteins with a faster diffusion (e.g., albumin), which are subsequently replaced by molecules with a higher affinity towards the surface (also known as Vroman effect [80–84]). On the other hand, cells actively remodel their extracellular environment by expression of proteins or their removal by proteolysis [85–88]. Although chemisorption of the proteins (e.g., through crosslinking the biomolecules to the matrix [89, 90]), might stabilize the adsorbed layer against competitive replacement in cell culture medium, proteolysis and a consequent degradation of the biofunctional surface coating remains an issue in the control of the cell–surface interaction.

For a more comprehensive treatment of the concepts discussed here, the reader is referred to an excellent review by Wilson et al. [91]. In summary, one has to keep in mind that the composition of a protein film interacting with cells in vitro (and more so in vivo) generally differs from the initially deposited physisorbed proteins, especially if long-term experiments are conducted. Nevertheless, protein-based surface films have often been shown to provide an excellent platform for cell adhesion experiments in which the precise control of the cell–surface interactions does not play a key role.

Most reports on protein-mediated cell adhesion can be categorized into one of two basic concepts for structuring the cell-adhesive islands:

-

1.

Indirect patterning: A protein repellent background is locally “opened,” rendering areas of the surface prone to protein adsorption. The patterning of cell-attractive areas is indirectly achieved by a subsequent deposition of proteins either by preincubation with a solution of proteins (most prominent are fibronectin, vitronectin, and laminin) or by adsorption from serum-supplemented cell culture media during cell seeding.

-

2.

Direct patterning: Cell-adhesion-mediating proteins are directly placed on a surface that is already protein-resistant or is later backfilled with a passivating film.

4.1.1 Indirect Patterning of Proteins

Whitesides and coworkers describe the use of an elastomeric membrane to pattern proteins and cells on bacteriological polystyrene (PS), glass, and poly(dimethyl-siloxane) (PDMS) substrates [92]. A patterned PDMS membrane was casted from lithographically structured photoresists and brought into close contact with the substrates (Fig. 6). When incubated with a solution of fibronectin (FN), adsorption of the cell-adhesion-mediating protein to the surface was restricted to the exposed areas. The membrane was peeled off and cells were seeded from a serum-free medium. Passivation to cell attachment of the untreated portions of the surface was achieved by adding 1% bovine serum albumin (BSA) to the cell-seeding medium, which can adsorb to areas not coated with FN. This easy-to-use strategy for passivating the surface against cell adhesion proved to be sufficient to limit the attachment of bovine adrenal capillary endothelial (BCE) cells selectively to the FN patterned areas. However, this approach is limited to short-term experiments or the use of serum-free medium because passivation with BSA is not stable in the presence of other proteins (e.g., those present in serum supplements in cell culture medium). In an interesting variation of this approach, the group seeded cells directly onto the membrane–substrate assembly. When the PDMS membrane was passivated by adsorption of BSA before cell seeding, BCE cell adhesion could be physically constrained to the patterned areas. Following the removal of the membrane after 7–24 h in culture, spreading of the cells to the unprotected areas could be analyzed.

(a) Micropatterning through the use of a “lift-off membrane”: PDMS prepolymer is poured on a silicon master featuring microstructures of photoresist, and then spin coated to produce a silicone film thinner than the photoresist structures. Following a thermal curing process, the PDMS membrane can be peeled off the silicon wafer and brought into conformal contact with a standard culture plate. In the next step, the protected surface is exposed to a protein solution to allow proteins to adsorb to the uncovered culture dish. After removal of the elastomeric membrane, the remaining areas are rendered protein-repellent by a treatment with a BSA-containing solution. Cells can be subsequently seeded on the chemically micropatterned surface. (b) Scanning electron micrograph of a PDMS membrane used as a stencil for protein patterning. (Figure adapted from [92])

Protein adsorption onto intrinsically repellent materials is enhanced by a brief plasma treatment that chemically and physically alters the surface properties. Stencil-assisted plasma oxidation of inherently hydrophobic polymers (e.g., PDMS or PS) increases the hydrophilicity of the surface and, more importantly, introduces charged groups into the substrate and produces a pronounced roughening of PDMS and PS, favoring the adsorption of proteins in their bioactive form [93–95]. As an alternative to modification of the bulk material, a protein-repellent surface coating can be selectively removed by plasma ablation, laying bare the protein-attractive bulk substrate (Fig. 7) [93, 96–98]. Stencils for plasma treatment are commonly prepared by molding of PDMS from photoresist masters using standard photolithography methods.

(a) Micropatterning by local photo-ablation of protein-repellent polymer hydrogel: A photo-crosslinkable prepolymer is coated onto a glass substrate bearing photoreactive groups. Simultaneous crosslinking and binding of the polymer film is achieved by illumination with UV light. The surface coating is subsequently micropatterned by UV ablation through a mask. Uncoated areas of the substrate mediate cell adhesion through unspecific adsorbtion of serum proteins from cell culture medium. (b) HUVEC growing on a glass surface coated with a cell-repellent PDMAA film. Microstructuring was achieved by local ablation of the protein-resistant PDMAA hydrogel. (Figure in part (b) Courtesy of Jürgen Rühe, University of Freiburg, Germany)

Microcontact printing (μCP, see Fig. 10 for an example) has been used for the spatially resolved modification of gold, silver, or titanium surfaces with SAMs of methyl-terminated alkanethiolates, which favor protein adsorption [99–101]. Backfilling around the patterned protein-attractive islands was performed by a subsequent self-assembly of an ethylene-glycol-terminated alkanethiol. In a next step, the hydrophobic methyl-terminated SAMs were covered by adsorbed FN or other cell-adhesion-mediating proteins.

Direct writing methods have also been proposed for the generation of high-resolution cell patterns. In one example, UV laser ablation was used to locally remove polyacrylamide and thus create areas for spatially controlled protein adsorption [102]. Pesen et al. modified a layer of physisorbed BSA through electron beam lithography (EBL), creating nanodots of fragmented BSA with radii as small as 100 nm (Fig. 8) [103]. The dissociated protein acts as a template for a selective adsorption of FN, allowing precise modulation of the cell–surface contacts. Robotically controlled pin-printing of diluted solutions of sodium hypochloride on poly(vinylalcohol) films or commercially available ultralow attachment dishes (from Corning) has been used to locally oxidize the surface, leaving it open for protein adsorption and cell adhesion [98].

(a) Nanopatterning by EBL: A silcion substrate is functionalized with an amino-silane and coated with BSA. A focused electron beam is employed to “write” nanopatterns into the BSA film. Proteins from solution can selectively adsorb into the nanopatterns and guide the formation of cell–substrate contacts. (b) Fibroblast on fibronectin 10 ×10 nanodot matrix created by electron beam lithography. Cells spread, and fluorescent staining of intracellular proteins shows that focal contacts are located on the nanodots: actin (green), fibronectin (red), and vinculin (blue). Areas a, b, and c are shown magnified. (Figure in part reproduced with permission from [103])

In a different approach, Bouaidat et al. adapted the lift-off technique to pattern a cell-repellent poly(ethyleneoxide)-like (PEO-like) coating on glass substrates [104]. In brief, a photoresist was microstructured using conventional photolithography, and a plasma polymerized protein-repellent film (plasma-polymerized hexene as adhesion layer and 1,4,7,10-tetraoxacyclododecane (12-crown-4)) was subsequently deposited on the substrate. Lift-off of the photoresist opened the cell-repellent PEO-like coating for a targeted adsorption of proteins (Fig. 9). The group of Chang and Sretavan also chose the lift-off technique to pattern the protein-attractive areas rather than the protein-repellent patches [105]. Again, a plasma-polymerized PEO-like film was grafted onto a surface and over-coated with a photoresist. The latter was microstructured using photolithography, and the underlying PEO activated for the adsorption of polylysine by a brief plasma treatment. After the lift-off of the photoresist, the adsorbed polylysine remained on the patterned areas, enabling a successful spatially resolved cultivation of mice embryonic hippocampus neurons. Polylysine (positively charged) adsorbed to plasma-activated PEO-like films can also be used as a template to selectively adsorb other molecules (e.g., laminin or immunoglobulin G) in order to make this approach compatible with other cell types.

(a) Micropatterning through the use of the lift-off technique: A photoresist is coated onto a glass substrate and patterned by illumination through a mask. In the case of a negative resist, shaded areas remain soluble in the developer-solution and can be removed. The substrate surface is then completely modified with a protein-repellent polymer. Using a good solvent for the patterned photoresist, the polymer layer is locally removed together with the underlying photoresist (“lift-off”). (b) Optical microscope image of HeLa cells adherent on untreated glass surrounded by a PEG-like film structured through a lift-off process. The surface was not rinsed to remove unadherent (round) cells prior to inspection. (Figure in part reproduced with permission from [104])

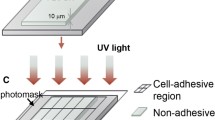

A way to pattern the protein-repellent background by lithography without the need for an intermediate overcoat is to incorporate a photoinitiator into the precursor solution of the polymer. For example, Revzin et al. used 1% 2, 2′-dimethoxy-2-phenylacetophenone (DMPA) in poly(ethylene glycol) diacrylate (PEG-DA) precursor solution to create microwells for cell culturing that had a glass base and PEG-DA side walls [106]. As an alternative to the widely used PEG as protein-resistant background, Rühe and coworkers copolymerized hydrophilic dimethylacrylamide (DMAA) and a photoreactive comonomer (benzophenone) to produce a directly photo-patternable polymer system that showed excellent protein-repellent properties [39, 107, 108]. In combination with photoreactive benzophenone-silane attached to the underlying glass substrate, polymer coatings that allow protein adsorption (e.g., PMMA) were copatterned with PDMAA hydrogel by standard mask lithography [109]. This approach allowed fine tuning of the surface-bound film to meet the specific requirements imposed by different cell types, e.g., human skin fibroblasts (HSF) and human umbilical vein endothelial cells (HUVEC) attached nicely to PMMA coating, whereas neuronal cells only adhered to PEI surfaces.

Similarly, Chien et al. used a poly(acrylic acid)/poly(acrylamide) (PAA/PAM) multilayer system in which PAA was replaced by PAA conjugated with photoreactive 4-azidoaniline (AZ) after several bilayers [110]. As a result, the polyelectrolyte multilayer could be covalently crosslinked by UV irradiation through a mask. For an enhanced cell repellence, poly(allylamine) was conjugated with poly(ethylene glycol methyl ether) and incorporated into the top layers of the film.

4.1.2 Direct Patterning of Proteins

For the direct placement of adhesion-mediating proteins onto surfaces, μCP is probably one of the most popular methods (Fig. 10). This technique offers great flexibility with respect to the molecules patterned as well as to the choice of substrate. Examples include the modification of glass, PS, BSA and biodegradable polyurethane or hydrogel-coated surfaces with proteins, commonly FN, laminin, or poly-l-lysine (PLL) [89, 111–117]. The transfer of the proteins in μCP is done in the dry state, opening the opportunity to physisorb molecules even to substrates that prevent the adsorption of material in the hydrated state (e.g., hydrogels). In this case, μCP allows single-step patterning of proteins on an otherwise protein-repellent background (i.e., no backfill is needed). The stability of the printed protein films, especially on protein-repellent backgrounds, has been assessed for different surfaces and the results indicate a more persistent protein immobilization with an increasing “softness” of the underlying substrate [89, 111, 113, 114]. Although a sometimes reduced transfer efficiency and denaturation of the stamped (dry) proteins causes a diminished protein activity towards cell binding on the surface, μCP has been reported to be a very robust method for protein patterning and thus cell patterning.

(a) Microstructuring by μCP: PDMS prepolymer is poured on a silicon master featuring microstructures of photoresist. After thermal curing, the PDMS stamp is peeled off the master structure and stamped into a protein-containing solution. After drying of the “ink solution” on the stamp, the attached proteins are transferred to another surface by placing the PDMS onto the target substrate for a short time (minutes). Uncoated areas can be backfilled with BSA, and cells are seeded onto the substrate. (b) Cell patterns produced by μCP on different surfaces (top row: untreated glass, middle row: tissue culture polystyrene (TCPS), bottom row: ibidi plastic). Printing efficiency was investigated using fibronectin-Cy3 (left column). Printing was followed by a backfill with PLL-g-PEG to prevent unspecific cell attachment. Cell patterns remain intact for 24 h in culture. (Figure reproduced in part with permission from [89])

Microfluidic patterning (μFP), a technique closely related to μCP, employs microfluidic channels to selectively deliver molecules on a surface (Fig. 11). Identically flexible as μCP with respect to choice of patterning solution and substrate, μFP is capable of depositing proteins in the wet state, thus reducing problems resulting from denaturation. Depending on the application, a subsequent backfill of uncoated areas after removal of the stamp material is, in most cases, mandatory. Another appealing property of μFP lies in its ability to pattern different binding proteins in a single step using separated microchannels [119]. A drawback of this technique is the geometric limitation to connected protein areas, although Folch and Toner reported the implementation of cell-adhesive islands by filling the microchannels with hot agarose [120]. After solidification of the agarose inside the channels, the PDMS stamp was removed from the support, turned upside-down and used as substrate for cell cultivation, the PDMS representing the protein- and cell-attractive spots. A combination of μCP and μFP was reported by Cuvelier et al. [121]. The group used a BSA-coated PDMS stamp to create the microchannels, which were filled with a biotin-containing solution, creating protein-repellent and protein-attractive areas simultaneously.

(a) Microstructuring by microfluidic printing (μFP): PDMS prepolymer is poured onto a silicon master featuring connected microstructures of photoresist. After thermal curing, the PDMS stencil is peeled off the master structure and brought into firm contact with a substrate (e.g., glass or Petri dish). The recesses in the PDMS stencil form a microfluidic network on the substrate that is subsequently filled with a protein-containing solution. After removal of the stencil, uncoated areas are backfilled with BSA. To enhance selective cell attachment, cell seeding is performed from serum-free medium. (b) Hepatocyte micropatterns on PS (a), and PMMA (b). Surfaces were structured by microfluidic printing of ECM proteins. Substrates were backfilled with BSA, and cells were seeded in serum-free culture medium to prevent unspecific adsorption of serum proteins onto uncoated areas. (Figure in part reproduced with permission from [118])

Direct printing techniques have become a standard tool in genomics and proteomics, where large-scale and high-throughput microarrays allow fast and easy detection of thousands of different elements in a single experiment. Among other applicable molecules for printing, protein microarrays have been studied for antibody–antigen, protein–protein, protein–nucleic acid, and protein–small-molecule interactions [122, 123]. Apart from its use in proteomics, printing of proteins has also been employed in cellomics, for example by printing cell-adhesion-mediating proteins onto glass [124], and printing polymers that contain photoreactive groups for subsequent covalent binding of proteins to the surface [90]. Folch and Toner reported the preparation of cocultures of hepatocytes and fibroblasts using printed collagen arrays with a preliminary backfill of BSA during the first seeding step of hepatocytes, which was done from serum-free medium to ensure a sufficient site-selectivity in cell attachment (Fig. 12) [120]. In a second step, BSA-covered areas were populated by fibroblasts, presumably through replacement of BSA by a competitive adsorption of serum proteins contained in the medium of the second seeding.

(a) Microstructuring through contact printing: A robotic microarrayer is used to print a protein-containing solution on an amino-silane functionalized substrate (e.g., glass). Surrounding areas can be backfilled with BSA and cells are seeded from serum-free medium to enhance the site-selective attachment. In a variation of this technique, cocultures of different cell types can be achieved through addition of serum proteins to the culture medium and (using a short incubation time for the first cell type) a subsequent seeding of a second cell type on the same surface. Attachment of the first cell type is restricted to the protein-coated areas by the adsorbed BSA. Over time, BSA is replaced by proteins from the culture medium, which provide adhesion sites for cells from a second seeding. (b) Microstructured coculture of hepatocytes and fibroblasts. Hepatocytes adhere to printed spots of collagen surrounded by BSA (top). After 24 h of incubation, a second cell type (fibroblasts) was added and cells attached in the formerly BSA-coated areas (middle). Co-culture after 5 days of incubation (bottom). (Figure in part reproduced with permission from [124])

4.2 Peptide-Decorated Surfaces for Spatially Guided Cell Adhesion

Another interesting way to guide the adhesion of living cells is to selectively present the recognition sites on the surface instead of whole proteins. It is self-evident that this “breaking-down” of ECM proteins into their functional components will offer only a minimalistic, and therefore limited, reproduction of the natural environment of cells in vivo. Nevertheless, the strategy to use distinct peptide moieties for a direct mediation of cell attachment has the potential to create highly defined model systems for cell adhesion that will, and indeed have already, elevate our understanding of basic mechanisms involved in cell–substrate interaction. Apart from the chemical identity (i.e., the amino acid sequence) of the peptide, the presentation of the binding ligands to the cell is a key parameter for such investigations. In the last three decades, model surfaces have been created that allow for different degrees of control over the presentation and surface density of the functional moieties, progressing from randomly distributed peptides in polymer matrices (e.g., hydrogels or monolayers) to highly ordered systems such as SAMs of peptide–amphiphiles or star-PEG assemblies (Fig. 13). Depending on the application, scientists can nowadays choose a system that meets their requirements in terms of control of interaction, long-term stability of the cell guidance, ease of synthesis, and coating technique.

Different strategies for immobilizing peptide moieties on solid surfaces. (a) Peptide–polymer hybrid copolymers are attached to the substrate, offering no direct control of the peptide orientation (scheme refers to surfaces introduced by [40, 135]). The peptide moieties are statistically distributed in the polymer film. (b) A polymerized monolayer of peptide–amphiphiles is immobilized on a planar substrate, giving control over peptide orientation and concentration on the surface through coattachment of a nonmodified polymerizable amphiphile (scheme refers to surfaces introduced by [134]). (c) Minimal integrin adhesion ligands (YGRGD) are attached to surface-immobilized star PEO tethers to allow control over spatial distribution (through the formation of clusters of more than one peptide per star molecule) and the total average concentration (through blending with unmodified star polymers) (scheme refers to surfaces introduced by [146]). (d) RGD moieties are attached to substrates using virtually no spacer, giving an excellent control over peptide concentration at the cost of limited flexibility for peptide clustering (scheme refers to surfaces introduced by [145])

Many approaches comprise some attractive features with respect to specific binding to certain integrins and long-term stability of the produced surface coatings. In order to ensure the exclusive interaction of the cells with the recognition sites presented (and not with unspecifically adsorbed proteins), the matrix (i.e., the background) must possess protein-repellent properties.

Moreover, a strong linkage of the adhesion moiety to the polymer matrix is the perquisite to supply a mechanically and chemically stable support for cell adhesion that withstands the considerable contractile forces exerted by many cell types [125–127]. Furthermore, cells can actively remodel their extracellular environment by redistribution or internalization of small and mobile ligands [68, 125, 127–131]. A number of chemistries are readily available for covalently attaching short peptide sequences to a polymeric background. For an in-depth discussion of this topic, the interested reader is referred to reviews by Tirrell et al. and by Hersel and Kessler [29, 132]. Most commonly, the peptide is grafted to an already protein-repellent surface in a postsynthetic modification step, either via its amine or carboxylic acid end-group, by bioconjugate chemistry means or through photoreactive linkers (e.g., benzophenone or aromatic azide functionalized peptides). The introduction of suitable functional groups into the polymeric background can be achieved by blending of polymers with functional groups with the base polymer, by copolymerization or through a chemical or physical treatment of the protein-repellent background, such as alkaline hydrolysis, reduction or oxidation, track-etching, or plasma deposition. As an alternative to the postsynthetic modification of a preformed polymeric background, the employment of so-called peptide–polymer hybrid materials was suggested [133–135]. Hereby, solid-phase organic synthesis is used to attach specific peptide moieties to synthetic polymers or amphiphiles, or vice versa. The resulting peptide–polymer hybrids are then self-assembled (in the case of peptide–amphiphiles) or chemically immobilized onto a surface.

The last three decades have seen great advances in the characterization of specific cell–substrate interactions through the use of peptide-containing surfaces [29]. Several parameters have been identified that influence the specificity and binding efficacy of synthetically formed biomimetic films. Among these, the conformation of the presented peptide ligand plays an important role. For example, if the RGD peptide is isolated from the context of the protein, it loses some specificity as well as binding affinity to integrins as compared to its native counterpart [24]. However, if the RGD sequence is presented in a “looped” conformation resembling its natural structure in FN more closely, the adhesion and spreading of cells is enhanced, as compared to the linear peptide, in a concentration-dependent manner [136, 137]. Cell attachment is also influenced by the presence of immediate side groups and short peptide sequences in close proximity (so-called synergy sites) to the integrin-binding motif RGD. Hirano et al. compared the binding affinity of different tetra-peptides comprising the RGD sequence derived from the ECM proteins FN (RGDS), vitronectin (RGDV), and collagen (RGDT) towards five cell types. They found a strong influence of the residue amino acid X in RGDX on the cell-binding activity [138]. The incorporation of the recognition site into its wider context in nature – instead of using the minimal recognition sequences – was also found to improve cell response. For example, in FN the peptide sequence PHSRN is found in the ninth type III module (FNIII9) and therefore in close proximity to the recognition motif RGD (FNIII10). When tested for its influence on cell attachment, the synergy site PHSRN in a defined distance to RGD was found to lead to an overall strengthening of the cell–substrate binding as compared to the minimal recognition motif RGD [139, 140]. However, whether PHSRN acts as a synergy site only, or binds to the integrin receptor in a competitive fashion, is still controversially discussed [141].

Apart from a favorable conformation and context of the peptide, the accessibility of the recognition motif for the integrin-binding site must be provided by the artificial synthetic background. A number of studies investigated the optimal spacer length between recognition site and polymeric support. Through systematic introduction of amino acids between the binding motif and the background, a spacer length of 3–4 nm was identified by several groups as optimal with regard to cell adhesion [142–144]. In other experiments by Massia and Hubbell however, although virtually no spacer between GRGDY and the anchoring group to a glass surface was used, satisfying adhesion of human foreskin fibroblasts could be observed (Fig. 13d) [145]. Although the question of whether a spacer is needed or not has not yet been fully resolved, most systems incorporate some form of soft polymeric matrix (e.g., hydrogels, brushes, or SAMs, as outlined in Sect. 3) for protein-repellent purposes as a background for peptide immobilization and thus provide at least some flexibility and mobility to the recognition motifs.

Another parameter that influences the ability of a bioactive surface coating to mediate cell adhesion is the surface concentration of the binding recognition site. Pioneer work on the question of minimal peptide concentrations for cell attachment was reported by Massia and Hubbell in 1991 [145]. Here, a functionalized peptide-ligand was directly immobilized onto glass substrates. The concentration of the peptide was varied by coimmobilizing an inert compound that does not support cell attachment. Using these substrates, a minimum surface concentration of GRGDY ligand of 1 fmol ∕ cm2 was sufficient to promote fibroblast cell spreading on an otherwise poorly adhesive glass substrate. However, a tenfold higher surface concentration (i.e., 10 fmol ∕ cm2) was needed to induce the formation of focal contacts.

Besides the overall concentration of the recognition motif on the surface, the lateral distribution of the presented peptides can also evoke different cellular responses, e.g., trigger the aggregation of integrins in the cell membrane to form focal adhesions [146–148]. For the investigation of the effects of peptide clustering in a polymeric film, star-like polymers were functionalized with a recognition motif (Fig. 13c) [146]. Nanoscale RGD clustering, for example, was found to result in a significantly higher stress resistance and in the formation of well-formed stress fibers and focal contacts in fibroblasts. Using block copolymer micelle nanolithography, Spatz and coworkers were able to control the lateral spacing of single integrin-receptor binding sites by a highly defined presentation of cyclic RGD peptide on a rather rigid support [149]. Their studies emphasize the importance of nanoscale integrin clustering over the macroscale peptide density for normal cell adhesion and cytoskeleton development.

Although the RGD motif is by far the most studied cell-binding moiety, other peptide sequences have been identified for specific cell binding [150, 151]. The exact peptide sequence presented has a significant influence on the selectivity towards certain integrins and thus different cell types [152–155]. This difference in affinity has been exploited by Plouffe et al. for the design of an adhesion-based cell separating system, embedded in a microfluidic device [154, 155]. Using three successive stages of different peptide coatings (REDV, VAPG, and RGDS) in a microchannel, a heterogeneous cell suspension of endothelial cells, smooth muscle cells, and fibroblasts could be successfully depleted. This could open the door to an automated cell-sorting device that selectively immobilizes cells on the basis of the expression level of certain integrins.

The deciphering of the fundamental mechanisms involved in integrin-mediated cell adhesion has come a long way since the discovery of the minimal recognition motif RGD(S) by Pierschbacher and Ruoslahti in 1984 [24]. Synthetic peptide–polymer model systems presenting biofunctional moieties in a highly defined context contribute an important tool to this quest. Although precise control over parameters such as peptide surface concentration and distribution (i.e., clustering), spacer length, and conformation of the binding motif often requires elaborate synthesis and coating protocols for the biofunctional conjugate, alternative approaches exist that provide for a more simple, versatile and chemically stable surface modification. Although compromising on the degree of control over the exact presentation of the peptide, these systems constitute an extremely defined environment for cell–matrix interactions. Moreover, well-designed setups (e.g., based on postsynthetically peptide-modified hydrogels or surface-bound peptide–polymer monolayers) often allow for long-term cell studies while preserving their comparatively high inertness towards changes in the experimental conditions (e.g., induced by protein adsorption/desorption, or proteolytic degradation).

Compared to systems that rely on protein adsorption for spatially guided cell adhesion, reports on cell chips based on peptide-mediated adhesion are less frequent, but emerging. In principle, identical methods to those used for the microstructuring of proteins can be employed for peptides, although reports on direct patterning (controlled deposition of peptides) prevail.

As for protein patterning, μCP of thiol-conjugated molecules onto gold surfaces was among the first methods used for locally resolved deposition of peptides. Zhang et al. used a combination of microcontact-printed ethylene glycol thiolate and self-assembled oligopeptides containing the cell adhesion motif (RADS) and a cysteine linker to guide the adhesion of cells onto gold substrates (Fig. 14) [156].

(a) Photolithographic lift-off process has been used to selectively deactivate a commercially available amine-reactive polymer coating (OptiChem, Accelr8 Technology, Denver, CO) (please refer to Fig. 8 for a process description). After removal of the photoresist, RGD peptide was immobilized in unreacted areas. NIH-3T3 fibroblasts follow the implemented structures for several days. (Figure in part reproduced with permission from [159]). (b) Human epidermal carcinoma cells on self-assembled monolayer of oligopeptides containing the cell-adhesion motif RADS. Microstructures were transferred onto gold-coated silicon surfaces by microcontact printing of ethylene glycol thiolate and a subsequent backfill with the thiolated oligopeptides (please refer to Fig. 10 for a process description). Note that the unpatterned round cells are not adherent not the surface, but free-floating. (Figure in part reproduced with permission from [156]). (c) PS-binding peptides were printed by an automated pin microarrayer on native PS (please refer to Fig. 12 for a process description). A subsequent backfill with BSA renders the remaining PS surface sufficiently protein repellent to confine HUVEC attachment to the peptide-coated areas. (Figure in part reproduced with permission from [157]). Scale bars: 100 μm

Grainger and coworkers used commercially available telechelic N-hydroxy succinimide (NHS)-terminated PEG to create a protein-resistant film containing reactive groups [157]. Microstructuring was achieved through a conventional photolithographic process based on microstructuring of a photoresist film deposited onto the hydrogel, which serves in a second step as a stencil for site-selective methoxylation of exposed areas. Following removal of the photoresist, the remaining NHS-capped regions were treated with a GRGDS peptide, allowing for covalent attachment of the adhesion-mediating ligand. Fibroblasts (NIH-3T3) adhered exclusively to the RGD-patterned areas and showed a “normal” behavior with respect to proliferation and spreading (Fig. 14). Our own group recently reported on the synthesis and spatially resolved surface immobilization of a peptide–polymer hybrid for the controlled adhesion of cells (Fig. 15) [40, 135]. The novel peptide–polymer hybrid was synthesized by a controlled radical polymerization of dimethylacrylamide (DMAA) from an initiator-modified RGD peptide [135]. Monolayers of hydrophilic peptide–PDMAA were shown to resist the unspecific adsorption of proteins and can be covalently bound and microstructured by lithography on surfaces modified with photoreactive benzophenone groups [40]. Peptide–PDMAA areas can be backfilled with (chemically almost identical) PDMAA and shown to be able to locally constrain the adhesion of human fibroblasts under serum conditions for more than 2 weeks.

(a) Microstructuring by photopatterning: A direct photoinduced structuring of surface chemistry has been employed by our own group to guide human skin fibroblasts on peptide–polymer monolayers. Here, we used a surface-bound photoreactive benzophenone-silane to covalently attach monolayers of a cell-attractive, yet protein-repellent RGD–polymer (GRGDSP–PDMAA) on glass using UV illumination through a mask. Polymer in the shaded areas can be extracted, and the peptide–polymer microstructures are backfilled with a protein-repellent polymer (PDMAA). (b) Human skin fibroblasts adhere to peptide–polymer spots implemented in a protein-repellent environment through direct photopatterning. Cells follow the implemented structures for more than 2 weeks in culture [40]

Printing of peptides, either using a contact pin microarrayer [124, 159] or noncontact printer (using ink-jet technology) [160, 161], was used as a versatile tool for delivery of cell-adhesive ligands onto protein-repellent surfaces (Fig. 14). An attractive property of this technique lies in the ability to simultaneously print different peptides in one step. For example, Monchaux and Vermette used a noncontact automatic dispensing robot to covalently graft three different bioactive peptides in combination with RGD on a protein-repellent carboxy-methyl-dextran (CMD) background [161]. Although RGD was necessary to initiate the adhesion of endothelial and fibroblast cells, the coimmobilization of SVVYGLR or VEGF enhanced endothelial cell adhesion, and coimmobilization of SVVYGLR and REDV caused a reduction of cell spreading. Combination of RGD with any of the three bioactive molecules interfered with the formation of stress fibers and caused a rearrangement of focal adhesions in endothelial cells. Interestingly, fibroblasts were not affected by spot composition. EBL, another direct writing technique, was employed in combination with block copolymer nanolithography of gold nanodots by Spatz and coworkers for the implementation of micro-nanostructured interfaces of cyclic RDGfK-thiols [149]. This approach allows a remarkable degree of control over the integrin–receptor interaction because it combines a defined presentation of the peptide (loop-type conformation), a precise control of the single peptide spacing (through block copolymer nanolithography and short thiol anchors), as well as an arbitrary distribution of the cell-adhesive spots on the surface (by electron beam patterning of the gold nanodots).

As reviewed in this chapter, surface chemistry plays a key role in the interaction between living cells and artificial substrates. However, reducing this complex interplay solely to the underlying chemistry would draw a too-simplified picture. Cells are also highly sensitive to other environmental cues such as surface topography and elasticity, which can influence almost any aspect of a cell’s life, from cell proliferation, contraction, migration, internal cytoskeleton organization, and even cell death [162]. A thorough discussion of these influences lies far beyond the scope of this article and the interested reader is referred to an interesting recent commentary as well as references therein [162]. Tables 2 and 3 summarize recent examples of bioactive, microengineered surfaces for the spatial control of the attachment and outgrowth of living cells, using protein- or peptide-decorated surfaces. We hope that they serve to outline recent trends and strategies in the implementation of cell chips (Tables 2 and 3).

5 Conclusions and Outlook

Precise control of the interaction between an artificial surface and the biological environment is the key challenge for any successful interplay of the biological world with man-made technology. Live-cell biochips are increasingly attractive to both academia and industry due to a large number of potentially interesting applications, progressing from pharmaceutical sciences to biosensor development, and to biophysical model systems.

The demands that are posed on the surface coating are challenging. The coating must provide areas that are inert to cell adhesion in the neighborhood of regions that allow, promote, and sustain the adhesion of living cells, all this in the context of a complex, changing and insufficiently defined environment, such as found in modern cell culture. Derived from nature, proteins or even short peptide-ligands, micropatterned on the surface, are used to guide cell adhesion in a spatially resolved manner. Both strategies, protein- and peptide-mediated cell adhesion, offer distinct advantages in terms of a high biomimicry for cell–matrix adhesion (as for proteins) or a precise control over integrin–ligand interactions (as for peptides). Restriction of cell adhesion to defined spots demands equally challenging properties, especially with respect to the longevity of cell- and protein-repellence in vitro. Scientists have gathered a toolbox of different surface-coating strategies that allow the engineering of surfaces that resist nonspecific protein-adsorption and thus prevent non-desired protein-mediated cell adhesion. Examples include polymer brushes, surface-attached hydrogels, and hydrophilic, noncharged polymer monolayers.

Eventually, the optimal combination of cell-attractive and cell-repellent surface modification depends on the application and, although we have witnessed a number of very promising design strategies, successful integration into technological microdevices is still to come. With respect to the latter, persistency of the coating in vitro, the exact control of the cell–surface interaction, and the ability to induce and understand “normal” cell behavior on-chip, are of utmost importance and need to be covered by extensive (comparative) studies in the future.

References

Goodsell DS (2004) Bionanotechnology – lessons from nature. Wiley, Hoboken, NJ

Staples M, Daniel K, Cima MJ, Langer R (2006) Application of micro- and nano-electromechanical devices to drug delivery. Pharmaceut Res 23:847–863

Santini JT, Cima MJ, Langer R (1999) A controlled-release microchip. Nature 397:335–338

Lee SJ, Lee SY (2004) Micro total analysis system (μ-TAS) in biotechnology. Appl Microbiol Biotechnol 64:289–299

Willner I, Willner B (2001) Biomaterials integrated with electronic elements: en route to bioelectronics. Trends Biotechnol 19:222–230

Voldman J, Gray ML, Schmidt MA (1999) Microfabrication in biology and medicine. Annu Rev Biomed Eng 1:401–425

Brown PO, Botstein D (1999) Exploring the new world of the genome with DNA microarrays. Nat Genet 21:33–37

Panda S, Sato TK, Hampton GM (2003) An arrays of insights: application of DNA chip technology in the study of cell biology. Trends Cell Biol 13(3):151–156

Norde W, Baszkin A (2000) Physical chemistry of biological interfaces. Marcel Dekker, New York

Templin MF, Stoll D, Schwenk JM et al (2003) Protein microarrays: promising tools for proteomic research. Proteomics 3:2155–2166

Lodish H, Berk A, Zipursky SL, Matsudaira P, Baltimore D, Darnell J (2000) Molecular cell biology, 4th edn. Freeman, New York

Alberts B, Bray D, Lewis J et al (2002) Molecular biology of the cell, 4th edn. Taylor & Francis, New York

Hynes RO (2002) Integrins: bidirectional, allosteric signaling machines. Cell 110:673–687

van der Flier A, Sonnenberg A (2001) Function and interactions of integrins. Cell Tissue Res 305:285–298

Humphries MJ (1990) The molecular basis and specificity of integrin ligand interactions. J Cell Sci 97:585

Zamir E, Geiger B (2001) Molecular complexity and dynamics of cell-matrix adhesions. J Cell Sci 114:3583–3590

Geiger B, Bershadsky A (2001) Assembly and mechanosensory function of focal contacts. Curr Opin Cell Biol 13:584–592

Petit V, Thiery JP (2000) Focal adhesions: structure and dynamics. Cell 92:477–494

Pande G (2000) The role of membrane lipids in regulation of integrin functions. Curr Opin Cell Biol 12:569–574

Albeda SM, Buck CA (1990) Integrins and other cell adhesion molecules. FASEB J 4: 2868–2880

Travis J (1993) Frontiers in biotechnology – biotech gets a grip on cell adhesion. Science 260:906–908

Giancotti FG, Ruoslahti E (1999) Transduction – integrin signalling. Science 285:1028–1032

Giancotti FG (2000) Complexity and specificity of integrin signalling. Nat Cell Biol 2:E13–E14

Pierschbacher MD, Ruoslahti E (1984) Cell attachment activity of fibronectin can be duplicated by small synthetic fragments of the molecule. Nature 309(5963):30–33

Pierschbacher MD, Ruoslahti E (1984) Variants of the cell recognition site of fibronectin that retain attachment-promoting activity. Proc Natl Acad Sci 81:5985

Ruoslahti E, Pierschbacher MD (1987) New perspectives in cell-adhesion – RGD and integrins. Science 238:491–497

Ruoslahti E (1996) RGD and other recognition sequences for integrins. Annu Rev Cell Dev Biol 12:697–715

Wintermantel E, Ha SW (2003) Medizintechnik mit biokompatiblen Werkstoffen und Verfahren. Springer, Berlin

Hersel U, Kessler H (2003) RGD modified polymers: biomaterials for stimulated cell adhesion and beyond. Biomaterials 24:4385–4414

Yamada KM, Clark K (2002) Survival in three dimensions. Science 419:790–791

Andrade JD, Hlady V, Jeon SI (1996) Poly(ethylene oxide) and protein resitance – principles, problems, and possibilities. Adv Chem Ser 248:51–59

Horbett TA, Brash JL (1995) Proteins at interfaces II: fundamentals and application. Adv Symp Ser 602. American Chemical Society, Washington

Lanza RP, Langer R, Vacanti V (eds) (1997) Principles of tissue engineering, 2nd edn. Academic, San Diego

Ballauff M (2007) Spherical polyelectrolyte brushes. Progr Polym Sci 32:1135–1151

Römpp H, Falbe J, Regnitz M (1995) Römpp Chemie Lexikon. Thieme, Stuttgart

Frazier RA, Matthijs G, Davies MC et al (2000) Ccharacterization of protein-resistant dextran monolayers. Biomaterials 21:957–966

Rabinow BE, Ding YS, Qin C et al (1994) Biomaterials with permanent hydrophilic surfaces and low-protein adsorption properties. J Biomater Sci Polym Ed 6:91–109

Lehmann T, Rühe J (1999) Polyethyloxazoline monolayers for polymer supported biomembrane models. Macromol Symp 142:1–12

Wörz A, Berchthold B, Kandler S et al (2007) Tailormade surfaces for a guided adhesion and outgrowth of cells. MikroSystemTechnik Kongress 2007 Dresden

Petersen S, Loschonsky S, Prucker O et al (2009) Cell micro-arrays from surface-attached peptide-polymer monolayers. Physica Status Solidi A 206(3):468–473

Siegers C, Biesalski M, Haag R (2004) Self-assembled monolayers of dentritic polyglycerol derivatives on gold that resist the adsorption of proteins. Chem Eur J 10:2831–2838

Harris JM, Zalipsky S (1987) Poly(ethylene glycol): chemistry and biological applications. American Chemical Society, Washington

Jenney CR, Anderson JM (1999) Effects of surface-coupled polyethylene oxide in human macrophage adhesion and foreign body giant cell formation in vitro. J Biomed Mater Res 44:206–216