Abstract

Carbon materials are essential for a wide variety of electrochemical utilisations due to the fact that their electron-transfer and charge-storage capabilities may be tuned. In order to rationally build various high-performance electrochemical devices, it is essential to engage in careful structural manipulation of carbon in order to control its chemical, electrical, and crystalline properties. This study focuses on three different forms of carbon nanomaterials that have recently gained interest in the field of electrochemistry. These are carbon nanofibres, carbon nanotubes (CNTs), and graphene. The focus of this chapter is on the ways in which the structural differences among these carbon nanomaterials influence the electrochemical activities they exhibit. In this Chapter, after providing a brief summary of the recent developments in the fields of Nano carbon and nanofibres, Nano carbon and composites for energy applications, and the future perspectives of Nano carbon electrochemistry, this study will move on to discuss these topics in more depth. Focus is placed on delineating the ways in which the electrical structure of carbon affects the electrochemical activity of the element. Notice some of the modification approaches applicable to over one utilization area through the examination of various electrochemical devices; as a result, structural manipulation approaches utilized in one class of electrochemical devices can be extended to other types of electrochemical devices.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

It is necessary to do research into the ever-evolving landscape of nanotechnology in order to acquire a comprehension of the current standing of these technologies. One subfield of nanotechnology, known as nanocarbons, is undergoing continuous development and expansion in search of applications that are not only effective but also novel, robust, and efficient and have the potential to fill the gaps left by newer technologies. In this context, the status of various nanocarbons should be evaluated on a frequent and ongoing basis so that the current condition can be observed and the outcomes of the future may be anticipated. Enhanced electrical and thermal conductivity, mechanical strength and transmissivity are some of the qualities that have been reported in these nanocarbons. These properties provide these nanocarbons applications in electronic devices, energy storage, drug carriers, biosensors, biomedicine, aerospace, and thermal management, amongst other fields.

This chapter primarily focused on the Class of Nano carbons, nanofibres and their associated electronic structures and properties, 3D composite foams, Current Progress in the Fields of Nano carbon and nanofibres, Graphene, CNTs, Carbon Nanoparticles, Nano carbon and Composites for Energy Applications, Super capacitors, Future Perspectives of Nano carbon Electrochemistry, and finally, Conclusions.

1.1 Nanocarbons

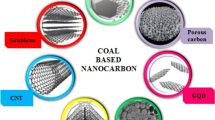

The term “nanocarbons” is utilised to describe a wide variety of carbon-based materials that have dimensions, structures, and textures on the nanoscale [1]. Because of the dimensional constriction of the electronic structures, nanocarbons have physicochemical characteristics that are entirely their own. When compared to ceramics or synthetic organics, nanocarbons have several advantages, including being abundant, flexible, versatile, lightweight, and environmentally beneficial for a variety of applications (Fig. 1) [2, 3].

Overview of nanocarbons. Adapted with permission [4], Copyright 2018, Elsevier

Nanocarbons, in general, exhibit outstanding intrinsic features (such as surface chemistry and electrical structures, for example), as well as extrinsic properties (such as specific surface area and shape, for example), which are imparted by the nanoscale confinement of their structures. As a result, synergistic catalytic performance can be achieved with better thermal and chemical stabilities, enhanced activity, and superior reusability by painting active catalyst (such as metal, oxide, and sulfide) onto nanocarbon. This will result in the catalyst having a longer lifespan. These nanocarbon composites have a wide variety of potential applications, some of which include photonics, nanomedicine, environmental remediation, energy storage, and industrial catalysis [5, 6].

1.2 Carbon Nanotubes (CNTs)

CNTs are one-dimensional, cylindrically rolled, solitary layers of carbon. The creation of ‘needle-like tubes’ of limited carbon structures is done by using an arc discharge evaporation technique. The generated carbon structures were eventually characterized as ‘multi-walled CNTs’. On the negative side of the electrode that was participating in the arc discharge, the creation of needle-like tubes was observed [2]. CNTs are essentially tubular structures that are manufactured by rolling up hexagonal sheets of carbon atoms or graphene. This process results in the formation of CNTs. These structures are only able to maintain their alignment and cohesion thanks to the presence of sp2 bonds and the force of van der Waal. They can also be covered with half fullerene molecules on each end, which makes them even stronger than the sp3 bonds despite the fact that their structure is completely unique [5].

Types of Carbon Nanotubes:

CNTs can be categorized into two distinct categories as shown in Fig. 2.

Types of CNTs. Adapted with permission [7], Copyright 2023, Springer Nature

-

Single-walled CNTs (SWCNT): Nanotubes made of single-walled carbon existing in a one-dimensional (1-d) configuration. Armchair and zig-zag shapes are two examples of SWCNTs.

-

Multi-walled CNTs (MWCNT): It is made up of multiple CNTs arranged in a nesting pattern. This particular variety of nanotubes possesses two diameters: the first one is referred to as the outer diameter, while the second one is referred to as the inner diameter. Chiral multi-walled CNTs are a type of multi-walled CNTs [7].

The following Table 1 can be utilised to provide an explanation of the characteristics of CNTs.

2 Nanofibers Electronic Structure and Properties, Class of Nano Carbons

In 1879, Thomas Edison was the first to successfully carbonise cotton and bamboo strands to create carbon fibres, which were then utilised in energy conversion and also storage, along with sensing devices, and also the reinforcing of composites. Hughes and Chamber [8] filed for a patent on gas pyrolysis to create nanofilaments of carbon in 1889. Carbon fibres were utilised in the areas of energy conversion and also storage, along with sensing devices, and also composite reinforcement. Tables 2 and 3 defines the properties of Nanofibers [6] and characteristics of different nanocarbon. When compared to conventional carbon fibre, the architectures of carbon nanofibres as shown in Fig. 3 can be described as having a few minor distinctions. These are renowned for their mechanical, along with electromagnetic shielding, as well as electrical, and also thermal stability with their existence at the nanoscale scale. Additionally, they are quite adaptable [9].

Structure of nanofibres. Adapted with permission [10], Copyright 2011, Elsevier

2.1 3D Composite Like Foams

Closed cell foams made of thermoplastics are traditionally produced using compression or injection moulding techniques. These processes call for tooling, which can be costly and time-consuming, to fabricate complicated parts. However, studies on additive manufacturing (AM) show that fused filament fabrication (FFF) is one of the methods most frequently employed to produce intricate functional parts [11, 12]. Additionally, additive manufacturing (AM) overcomes the conventional limitations on component size and may produce extremely complicated parts with no tooling expenses and minimal energy and also material usage [13]. Even though most polymers are already used in FFF-based 3D printing (3DP), the development of lightweight thermoplastic filaments for specialised applications remains in its early stages [14]. Due to its versatility in processing and ability to be employed in various engineering utilisations, thermoplastic composites are utilised in semi-structural and also many other engineering utilisations. Industrial 3D printers employ thermoplastic polymers as feedstock, such as polymethylmethacrylate, polylactide, acrylonitrile butadiene styrene, polycarbonate, and polyetherimide filaments made from their respective mixes [15, 16]. There have been few studies on 3D Graphene Foam-Reinforced Polymer composites as shown in Fig. 4 along with polymers like HDPE with polypropylene, and also polyamide along with polycaprolactone, and also polybutylene terephthalate, and others due to problems with warpage and delamination that can be resolved by using compounding techniques to add various inorganic/organic fillers [17, 18].

3D composite foam. Adapted with permission [18], Copyright 2018, Elsevier

3 Current Progress in the Fields of Nanocarbon and Nanofibers

For creating an eco-friendly society within the biosphere, the development of environmentally friendly, non-harmful materials that are also capable of keeping pace with technological progress is not only extremely important but has also become a difficult undertaking. Therefore, green chemistry plays a significant role in achieving these goals, which are essential for a healthy society. For businesses, the number one concern is zero waste creation, waste avoidance, and effective resource utilisation. By reducing the use of harmful chemical substances in the development of beneficial chemical products [19], green chemistry is widely acknowledged to be a safer alternative to conventional chemical synthesis techniques.

Nowadays, due to the of carbon-based nanomaterials’ unique properties like good electrical conductivity, along with ease in surface functionalization, as well as high mechanical strength, and also good thermal stability of carbon-based fullerenes CNTs, along with carbon fibres, as well as carbon quantum dots, and also graphene, they have attracted a lot of interest towards research and are utilised widely in a variety of utilisations. Therefore, within published literature, carbon nanomaterials are utilised directly or even modified for the aforementioned purposes [19]. These materials have been referred to as wonder materials. Despite this, other synthesis pathways, such as chemical vapor deposition (CVD), along with plasma CVD, and also laser ablation, which are utilized for the synthesis of various carbon-based nanomaterials, are not exactly the easiest things to work with because they require the employment of complex procedures and pricey hydrocarbons, as well as other specific dangerous sources. It has been demonstrated experimentally that carbon-based nanoparticles have usefulness in remediation and sensing applications [20, 21]. There have been a few reports published in academic journals that describe a technique to recovering carbon-based nanomaterials that is both economical and kind to the environment. The creation of nanocomposites plays a key role in the advanced applications that are being utilised today for things like energy storage, electronic parts, environmental remediation, biomedicine, and so on [22]. Some of the applications are listed below [23].

Catalyst Support of Hydrogen Fuel Cells and Two-Electron ORR: As the demand for energy continues to rise, more and more people are becoming interested in the study of fuel cells. The major reactions that take place in hydrogen fuel cells are the hydrogen evolution reaction (HER)/oxygen evolution reaction (OER) and also the hydrogen oxidation reaction (HOR)/oxygen reduction reaction (ORR). A two-electron oxygen reduction reaction (ORR) also is vitalin the creation of hydrogen peroxide (H2O2). In typical circumstances, the reaction that occurs when oxygen and hydrogen combine to form water is spontaneous, although the process itself is somewhat slow. As a result, the reactions require a catalyst in order to proceed more quickly.

Sensor Material of Wearable Devices: Real-time monitoring of the human body is possible with wearable electronics, which can provide information on the heart rate, sleep activities, calories burned, and stress level. These benefits have made wearable technology desirable and encouraged a variety of study. For the sensor materials, a thin, stretchable, flexible, and affordable material is crucial. Due to their exceptional conductivity, mechanical characteristics, etc., carbon-based materials, like CNFs and also CNTs have been researched as very stable and sensitive sensors.

Direct Contact Membrane Distillation: Researchers have been looking towards making freshwater from salt or contaminated water due to the lack of freshwater. Reverse osmosis is a traditional technology that uses a lot of energy but has limited uses. Due to its simple operating conditions (low temperature and pressure) and superior capabilities (high solute rejection, little mechanical needs), membrane distillation (MD) has become a viable alternative. With the simplest MD arrangement, direct contact membrane distillation (DCMD) is utilised extensively in the food and desalination processes.

Sensor Applications: Nanomaterial biosensor research is popular. Stacking, along with hydrogen bonding, and also hydrophobic interactions, along with Van der Waals, and also electrostatic forces allow these nanomaterials to interact non-covalently with organic molecules. These interactions and hollowness make them good analytical candidates. Carbon nanoparticle electrodes are highly electrocatalytic. Nano-biosensors benefit from their high surface area and volume ratio. Its chemical stability and biocompatibility make it a preferred sensor material.

3.1 Fullerenes

Fullerenes are spheroidal molecules that are comprised entirely of carbon. The most well-known fullerene is C60, which has 60 individual carbon atoms in its structure. Because of their nanoscale size and unusual electronic properties, they have been the focus of numerous investigations into their possible use in nanomedicine [24]. These applications include medication delivery, photodynamic therapy, antioxidant treatment, and even antiviral treatment.

Fullerenes can be manufactured by a variety of processes, the majority of which require the vaporization of graphite or other similar carbon sources. These processes include arc-evaporation, along with pyrolysis, as well as radio-frequency plasma, and also laser ablation, among others. In addition, the relatively low solubility of fullerenes necessitates the use of substantial amounts of organic solvents throughout the purifying process. As a result, the creation of environmentally friendly processes for their preparation is not at all a straightforward endeavour [25, 26]. The utilization of microwaves, on the other hand, can be advantageous in terms of reducing reaction times and also temperatures; nevertheless, even this practical advancement has not resolved the numerous issues that the industry faces in terms of producing fullerenes at minimal cost. One must keep in mind that fullerenes need to be derivatized in order for them to be water-soluble in concentrations that are significant for use in biomedical utilisations. As a result, chances for the environmentally friendly production of fullerenes may lie in the development of such derivatives. For example, hydrophilic polydopamine and also glutathione was utilised to solubilize fullerenes by simply mixing them in water. This was followed by dialysis and also freeze-drying so that the antioxidant activity of the fullerenes could be investigated [27]. A mixture containing fullerene and gallium oxide was subjected to a sonochemical treatment in water, which resulted in the production of nanostructured hybrids with possible uses in sensing. Without considering how to synthesise the fullerene core structure, these approaches just concentrate on derivatization. However, in a recent breakthrough, plastic trash was catalytically converted into a magnetic fullerene-based composite. The catalyst and precursor of magnetic nanoparticles, along with ferrocene, played a crucial role in this [28].

3.2 Graphene

As the class of graphene-based materials is so large and varied, it is essential to have a thorough understanding of the particular sort of structure that is being investigated and how it may be unique in comparison to previously published research on the subject [29, 30]. Although graphene has captivated the imagination of scientists for a number of applications in the medical field, unsolved difficulties exist in its extensive deployment on a worldwide industrial scale in order for it to widely reach the market. Nevertheless, significant work is being made in this area. There are several uses, but the ones relating to antibacterial properties are the ones that have received the most attention [31, 32]. When it comes to sensing applications, the one-of-a-kind features that graphene-based materials possess because of their two-dimensional structure are of utmost relevance. The biocompatibility of these materials has been the subject of extensive research, and the findings obtained so far are encouraging; nonetheless, because to the great variety of graphene-based materials, it is preferable to transition from descriptive to predictive toxicology [33].

In particular, the reviews [32] looked at the creation of a biomolecular corona on given graphene-based materials and also its implications for biodistribution and also cytocompatibility. Exfoliating graphite in the presence of a variety of dispersants is one of the many methods that may be utilised to make graphene; nonetheless, this method is now the most widely used. Graphene, on the other hand, is commonly oxidized to graphene oxide (GO) in order to provide good water dispersibility. This is a process for which environmentally friendly solutions are being researched. So, for instance, graphite’s electrochemical oxidation in acidic water was successful in producing GO-based conductive materials in a matter of seconds [31]. Taking use of synergy with photochemistry could result in further improvements to the process. Figure 5 depicts different structures of graphene [31].

Adapted from Ref. [31]. Copyright The Authors, some rights reserved; exclusive licensee Elsevier. Distributed under a Creative Commons Attribution License 4.0 (CC BY) https://creativecommons.org/licenses/by/4.0/

Different structures of graphene.

3.3 Diamane

The structural structure of diamane, a nano-allotrope of carbon, includes the presence of bilayer graphene that experiences sp3 hybridization. The creation of covalent bonds between the carbon atoms and hydrogen atoms of the two sub-lattices during the hybridization is confirmed, resulting in the synthesis of a C2H layer on one side and the formation of the diamane structure on the other side of the carbon layer [34]. In 2009, Chernozatonskii et al. [35] utilised theoretical simulation studies (Vienna Ab Initio Simulation Package (VASP)) to examine the synthesis, characteristics, and structure of diamane for the first time. They discovered that diamane, a diamond nanofilm, is created by hydrogenating bilayer graphene and has exceptional mechanical and electrical properties [35, 36].

Although the term “diamane” is frequently utilised by researchers, the diamane structure is also referred to by other names, including bilayer graphene, hydrogenated bilayer graphene, hydrogenated few-layer graphene, and interlayer-bonded bilayer graphene [37]. Diamane is categorized as either Bernal stacking (the AB stacking sequence of diamane) or Lonsdaleite stacking (the AA stacking sequence of diamane) based on its shape. The most stable form of diamane in this situation is represented by Lonsdaleite stacking, and under pressure, 3D graphene crystals can also be created from them [35].

3.4 Carbon Nanotubes (CNT)

CNTs are essentially single-walled or multi-walled sheets of graphene, depending on how many sheets make up their walls. They can be considered graphene sheets that have been rolled up into a tube. They are identified as prospective materials to innovate inside the biochemical field, much like the other nanostructures. Despite the fact that functionalization can reduce nanostructures’ toxicity, their physical resemblance to asbestos fibres has created many obstacles for their applications [38]. The academic community engaged in CNT research responded strongly, fearing additional barriers to innovation. The biocompatibility profiles of these nanomaterials vary widely depending on a number of criteria such as functionalization and also route of administration, and it was discovered that one specific form of CNT proved hazardous [39, 40].

The following Table 4 can be utilised to provide an explanation of the characteristics of CNT.

3.4.1 CNT with Metal-Oxides

Recently, numerous types of research is done looking at whether or not CNTs may be utilised as adsorbents. Research has been done looking into how CNTs can be utilised to filter contaminants out of water-based systems. Numerous laboratory investigations on the adsorption of dangerous chemical compounds and heavy metals have already been conducted out [41].

Purification and also activation or even functionalization of CNTs is needed and can be accomplished through oxidation treatment [42]. These processes are necessary for further enhancing the adsorption ability of CNTs. It is required to purify CNTs in order to get rid of the impurities that can frequently be found mixed in with them. Some examples of these impurities include catalyst particles, along with soot, as well as amorphous carbon, and also other forms. As a result of their coating on CNTs’ surfaces, impurities can lower the amount of adsorption that takes place, which in turn influences the amount of adsorption that takes place on the exterior surface of the nanotubes. Treatment of CNTs with an oxidising agent (like nitric acid, along with hydrogen peroxide, and also potassium permanganate, or even a mix of nitric acid and also sulfuric acid) results in an increase in hydrophilicity, which likely accounts for the improved adsorption ability. This is because the oxidation treatment increases the hydrophilicity of the CNTs. When CNTs are subjected to oxidation treatment, new functional groups are created on nanotubes’ surface.

Recently, metal oxide nanoparticles supported by CNTs are the subject of intensive research. This research has revealed that these nanoparticles are an excellent adsorbent for removing heavy metal ions and harmful organic compounds from water, and that they can also function as catalysts.

3.4.2 Synthesis of CNT/Metal Sulfide Composites

CNTs’ combination with metal sulphides is done in order to boost the electrocatalytic activity of CEs as well as their conductivity. CNTs’ combination and metal sulphides (metals) produce a remarkable electron channel due to the CNT network’s high electrical conductivity and the fact that metal sulphides improve electrochemical performance due to the electrocatalytic behavior that they exhibit [41, 43].

The Ni foam was cleaned with acetone, along with ethanol, and also deionized water (DI) for 10 min each, followed by ultrasonic etching with a 2 M HCl solution for 30 min, before the synthesis could begin. We mixed 0.05 g of MWCNT powder with 0.1 g of PVDF in 2 ml of N-Methyl-2-pyrrolidone (NMP) to make the counter electrode. Coating a piece of Ni foam (1.31.6 cm2) with the slurry required first thoroughly mixing the ingredients utilising a mortar and pestle. Sintered at 150 °C for 30 min, the resulting thin film is the carbon nanotube (CNT) electrode [3].

Figure 6a illustrates CNT/metal-sulfides. The electrons in CNT/metal-sulfides find the shortest path to accelerate charge transport and facilitate reduction of the polysulfide electrolyte compared to the bare CNT network, which encourages the enhanced electrocatalytic activity of the composite electrode material to enable higher QDSSC and SC performance (Fig. 6b). To deposit metal sulphides on the Ni-foam based CNT electrode, the simple solution method of chemical bath deposition (CBD) was utilised. Metal sources of 0.1 M CuSO4·5H2O (or NiSO4·6H2O, along with Pb(NO3)2, and also CoCl2·6H2O) and also sulphur sources of 0.4 M C2H5NS in 50 ml deionized water were used to create CuS, along with NiS, as well as PbS, and also CoS deposition solutions. The CuS and NiS solutions were next treated with 0.6 M C2H4O2 while the CoS and also PbS solutions were treated with 0.4 M CH4N2O, both added drop by drop. CNT electrodes were dipped vertically into CuS, along with NiS, as well as PbS, and also CoS solutions for 90 min at 90 °C to create composite electrodes. The electrodes were taken out of the oven after deposition and washed with DI water and also ethanol. When everything was ready, it was dried at 100 °C overnight. The solutions of PbS, along with CuS, as well as CoS, and also NiS were used to make the CNT/PbS, along with CNT/CuS, as well as CNT/CoS, and also CNT/NiS samples.

Adapted from Ref. [3]. Copyright The Authors, some rights reserved; exclusive licensee Springer Nature. Distributed under a Creative Commons Attribution License 4.0 (CC BY) https://creativecommons.org/licenses/by/4.0/

a Schematic representation and b electron transfer process of CNT/metal sulphides.

3.4.3 CNT with Chalcogenides

The chemistry behind CNTs’ functionalization is well understood due to the high level of interest and research activity, which, along with their special characteristics, makes them ideal templates for assembling with other functional nanomaterials. Increasing the tunability of CNTs’ physical, electrical, and optical characteristics has been shown to be possible by adding various organic or inorganic species to their surface. Nanocomposites and functional CNTs with novel or even tunable features may play a critical part in the miniaturisation procedure for nanoengineering and nanotechnology as the need for smaller, along with quicker, and also more efficient electronic devices increases. This covers the research and creation of novel catalyst materials, along with solar cell sensitization, and also nanobatteries, etc. Nanocomposites with semiconductor QDs covalently bound to CNTs have recently gained significant attention for use in these areas. In many applications, the unique ability of QDs to be tuned for key optical and electrical characteristics by changing their size is of tremendous importance. As promising semiconductors for utilisation in optoelectronic devices, multinary chalcogenide materials such as CuInS2 (CIS), Cu(In,Ga)S2 (CIGS), and Cu(In,Ga)Se2 (CIGSe) are of great interest due to their exceptional electronic and also optical properties (due to their characteristics as a direct band-gap semiconductor), precise control of these by straightforward modification of the preparation conditions (size, along with surface chemistry, and also composition), and also cost-effective [44].

3.4.4 CNT with HTS

High-temperature superconductors (HTS) feature layers that are extremely anisotropic, and their critical current density, Jc, is influenced by microstructural characteristics like connection between the grains and grain borders. Numerous researchers investigated the improvement of Jc using a variety of techniques, one of the most widely utilised being the substitution or addition of various nanomaterials. Due to the improved connectivity of the grain boundaries and an increase in their flux pinning capacities, the addition of nanomaterials enhances the electric transport parameters of HTS materials, such as the critical current density. It has been discovered that nanoparticles fill the spaces between the grains and have an impact on superconductivity through mechanisms that strongly bind the grain borders. While acting as impurities, these nanoparticles don’t alter the structure of HTS materials [45].

Many researchers have also looked at the possibility of using carbon-based nanomaterials to enhance HTS performance, especially with regard to critical current density. Recently, there has been a surge of interest in increasing the Jc of these HTS materials by adding CNTs. It has been claimed that the vital current density increases by a factor of 10 when CNTs are added to YBa2Cu3O7. These nanostructure phases are excellent traps for preventing flux mobility. Jc under the applied magnetic field likewise rises as a result. The addition of the CNT increases the electric transport capabilities between the grains without altering the materials’ structural makeup by creating electrical networks between grains, as seen in the SEM image [45].

4 Nanocarbon and Composites for Energy Applications

Due to its unconventional characteristics, like their high power density, quick charging time, and also high cycling stability, super capacitors are employed as energy storage devices in electric vehicles, along with hybrid electric vehicles, as well as backup power cells, and also portable electronic gadgets. Pseudo capacitance and electrochemical double-layer capacitance are the two basic methods of energy storage in super capacitors. The mechanisms of faradic reactions are in charge of charge transfer in a pseudo capacitor. Pseudo capacitance can be seen in several metals, oxides, and conducting polymers. In contrast, inside electrochemical double-layer capacitance procedures, charges are always accumulated at the interface by the mechanism of electrolyte ion adsorption/desorption on electrode materials with a wide surface area. Therefore, carbon-based nanomaterials can be crucial in the creation of super capacitors. Super capacitors made of Nano carbon are superior to conventional (metal-based) super capacitors in several ways, including high cycling stability, along with high power density, and also lower energy density requirements for battery use [46].

CNTs, which have excellent mechanical and electrical properties, have an exposed surface that can be functionalized to make them appropriate for energy storage. However, it has significant drawbacks, namely a moderate capacitance brought on by the low density of the nanomaterials. A different kind of energy-storing material is the lithium-ion battery, which stores energy as chemical energy. It is superior to capacitors in several ways, including high power density and reduced potential for greenhouse gas emissions. Since the structure of Nano carbon-based materials typically expresses some common factors, like the lithium amount reversibly incorporated into the carbon lattice, along with the faradic losses throughout the initial charge–discharge cycle, and also the voltage profile throughout charging and discharging, Nanocarbon materials and composites are utilised in lithium batteries [47]. Table 5 displays some Nano carbon-based compounds utilised in environmental and energy applications.

Supercapacitors:

To make super capacitors, electro spun carbon nanofibres are used, and they do so quite effectively. Electro spun CNFs can be produced with a variety of fibre diameters, porosities, and surface chemistries, which has several advantages for improving capacitor performance. Increasing the electrochemical capacitance of electrospun carbon nanofibres has been achieved through the manipulation of fibre morphology and also degree of graphitization via control of heat treatment conditions, utilisation of catalysts throughout carbonization and/or activation, and also selection and even combination of various polymer precursors like PAN/CA, along with PAN/PVP, and also PAN/pitch [48].

Electrospun carbon fibres’ electrochemical capacitance may be greatly increased by the insertion of redox-active species due to the simultaneous use of two charge storage processes, along with electrical double layer and also redox reactions. Ruthenium-embedded carbon nanofibres were made by electrospinning fibres made of ruthenium(III) acetylacetonate and PAN in dimethylformamide (DMF), then stabilizing, carbonizing, and activating those fibres. After adding Ru nanoparticles to the carbon fibres, the specific capacitance significantly increased. Carbon nanofibres without Ru had a capacitance of 140 F/g, whereas an electrode with 7.31 wt% Ru had a capacitance of 391 F/g. The enlargement of the average pore diameter and the additional pseudo capacitance made available by the well-dispersed Ru nanoparticles were credited as having synergistic effects that increased electric double-layer capacitance [8, 48]. Additionally, the pseudo capacitive contribution from the electrochemically active polymer PPy led to a further increase in capacitance when polypyrole (PPy) was coated on the MWCNT-loaded fibres. Another strategy for improving the electrochemical performance of electrospun CNFs is the encapsulation of many highly conductive components like CNTs and also metallic nanoparticles to increase electrical conductivity [8].

5 Future Perspectives of Nanocarbon Electrochemistry

Due to the one-of-a-kind characteristics, carbon nanomaterials have made significant contributions to the research, development, and advancement of electrochemical sensors and biosensors. When compared to traditional, non-nanostructured electrochemical systems, the innovative as well as the modified carbon-based probes frequently demonstrate significantly improved analytical performance. Electroanalytical approaches incorporating sensing and biosensing devices employing carbon nanostructure modified electrodes are displaying potential for utilisation in real-life analytical detection. Particularly useful as electrode materials for electrochemical detection of a wide variety of analytes have been CNTs and diamond. Because of their one-of-a-kind characteristics, CNTs, diamonds, and diamond-like films have made significant contributions to the development of innovative nanostructured electrochemical sensors and biosensors. These sensors have improved analytical performance in comparison to conventional electrochemical sensing systems. In addition, before any prospective commercialization can take place, more accurate assessments of certain performance characteristics along with their application for sensing analytes inside samples taken from the actual world are required [49].

The boosted active surface area of CNTs and also the anti-fouling capability of diamond and also diamond-like surfaces are two examples of the novel properties of carbon nanomaterials that contribute to their impact in modern electrochemical systems beyond their analytical superiority. These properties help make diamond and diamond-like surfaces resistant to fouling. In addition, the authors expect that the continued development of novel, adaptable methodologies for the synthesis and functionalization of carbon nanomaterial will soon lead to an increasing number of significant electroanalytical applications in a variety of fields of interest, including rapid and also sensitive medical analyses, along with drug quality monitoring, ad also food and environment security.

6 Conclusion

In conclusion, carbon-based sensors, along with electrocatalyst, as well as supercapacitors, and also LIBs share some electrochemical characteristics; some ways of manipulating carbon’s structural properties apply generically to each application area. For example, one way to modulate electrochemical activity is to disturb the electronic structure of the material. This can be done through covalent (e.g., controlled oxidation, along with doping with heteroatoms, and also alteration of synthesis conditions) or even noncolvent (adsorption of surfactants or even polyelectrolytes) approaches. on addition to this, the architectural design plays a vital effect on the electrochemical performance as a whole. For instance, substrate-supported continuous carbon nanotube arrays (CNFs) that have outstanding mesh integrity demonstrate wide-range sensing capabilities. Also, vertically aligned carbon nanotube arrays along with graphene sheets offer both good rate performance and also high sensitivities.

References

Nayak, A.K., Tiwari, S.K. (eds.): Nanocarbon Allotropes Beyond Graphene. IOP Publishing (2023). https://doi.org/10.1088/978-0-7503-5177-5.

Talebian, S., Rodrigues, T., Das Neves, J., Sarmento, B., Langer, R., Conde, J.: Facts and figures on materials science and nanotechnology progress and investment. ACS Nano 15, 15940–15952 (2021). https://doi.org/10.1021/acsnano.1c03992.

Muralee Gopi, C.V.V., Ravi, S., Rao, S.S., Eswar Reddy, A., Kim, H.J.: Carbon nanotube/metal-sulfide composite flexible electrodes for high-performance quantum dot-sensitized solar cells and supercapacitors. Sci. Rep. 7, 1–12 (2017). https://doi.org/10.1038/srep46519.

Liang, Y.N., Oh, W.-D., Li, Y., Hu, X.: Nanocarbons as platforms for developing novel catalytic composites: overview and prospects. Appl. Catal. A Gen. 562, 94–105 (2018). https://doi.org/10.1016/j.apcata.2018.05.021

Pandey, R., Tiwari, S.K.: Recent advances in nanocarbons: status and prospect. In: Nanocarbon Allotropes Beyond Graphene, pp. 1-1–1-57. IOP Publishing (2023). https://doi.org/10.1088/978-0-7503-5177-5ch1

Astié, V., Millon, C., Decams, J.-M., Bartasyte, A.: Direct liquid injection chemical vapor deposition. In: Chemical Vapor Deposition for Nanotechnology. IntechOpen (2019). https://doi.org/10.5772/intechopen.80244

Gautam, R., Sahoo, A., Pant, K.K., Mohanty, K.: Graphene nanoparticles and their derivatives for oil spill treatment. In: Materials Horizons: From Nature to Nanomaterials, pp. 229–249. Springer Nature (2023). https://doi.org/10.1007/978-981-99-4382-1_11

Mao, X., Rutledge, G.C., Hatton, T.A.: Nanocarbon-based electrochemical systems for sensing, electrocatalysis, and energy storage. Nano Today 9, 405–432 (2014). https://doi.org/10.1016/j.nantod.2014.06.011

Kim, S.K., Mao, A., Sen, S., Kim, S.: Fast Na-ion conduction in a chalcogenide glass-ceramic in the ternary system Na2Se–Ga2Se3–GeSe2. Chem. Mater. 26, 5695–5699 (2014). https://doi.org/10.1021/cm502542p

Palmeri, M.J., Putz, K.W., Ramanathan, T., Brinson, L.C.: Multi-scale reinforcement of CFRPs using carbon nanofibers. Compos. Sci. Technol. 71, 79–86 (2011). https://doi.org/10.1016/j.compscitech.2010.10.006

Yilmaz, A.C., Ozen, M.S., Sancak, E., Erdem, R., Erdem, O., Soin, N.: Analyses of the mechanical, electrical and electromagnetic shielding properties of thermoplastic composites doped with conductive nanofillers. J. Compos. Mater. 52, 1423–1432 (2018). https://doi.org/10.1177/0021998317752503

Luo, J., Fang, C.-C., Wu, N.-L.: High polarity poly(vinylidene difluoride) thin coating for dendrite-free and high-performance lithium metal anodes. Adv. Energy Mater. 8, 1701482 (2018). https://doi.org/10.1002/aenm.201701482

Jayavardhan, M.L., Bharath Kumar, B.R., Doddamani, M., Singh, A.K., Zeltmann, S.E., Gupta, N.: Development of glass microballoon/HDPE syntactic foams by compression molding. Compos. Part B Eng. 130, 119–131 (2017). https://doi.org/10.1016/j.compositesb.2017.07.037

Bharath, H.S., Bonthu, D., Prabhakar, P., Doddamani, M.: Three-dimensional printed lightweight composite foams. ACS Omega 5, 22536–22550 (2020). https://doi.org/10.1021/acsomega.0c03174

Gama, N., Ferreira, A., Barros-Timmons, A.: 3D printed cork/polyurethane composite foams. Mater. Des. 179, 107905 (2019). https://doi.org/10.1016/j.matdes.2019.107905

Chatkunakasem, P., Luangjuntawong, P., Pongwisuthiruchte, A., Aumnate, C., Potiyaraj, P.: Tuning of HDPE properties for 3D printing. Key Eng. Mater. 773, 67–71 (2018). https://doi.org/10.4028/www.scientific.net/KEM.773.67

Wang, S., De Clerck, K., Cardon, L.: Polylactic acid poly-3-hydroxybutyrate applications in extrusion based additive manufacturing. In: International Conference on Polymers and Moulds Innovations, pp. 1–5 (2018)

Idowu, A., Boesl, B., Agarwal, A.: 3D graphene foam-reinforced polymer composites—a review. Carbon N. Y. 135, 52–71 (2018). https://doi.org/10.1016/j.carbon.2018.04.024

Khare, P., Singh, A., Verma, S., Bhati, A., Sonker, A.K., Tripathi, K.M., Sonkar, S.K.: Sunlight-induced selective photocatalytic degradation of methylene blue in bacterial culture by pollutant soot derived nontoxic graphene nanosheets. ACS Sustain. Chem. Eng. 6, 579–589 (2018). https://doi.org/10.1021/acssuschemeng.7b02929

Gao, X., Han, S., Zhang, R., Liu, G., Wu, J.: Progress in electrospun composite nanofibers: composition, performance and applications for tissue engineering. J. Mater. Chem. B. 7, 7075–7089 (2019). https://doi.org/10.1039/C9TB01730E

Wang, Y., Ding, Y., Guo, X., Yu, G.: Conductive polymers for stretchable supercapacitors. Nano Res. 12, 1978–1987 (2019). https://doi.org/10.1007/s12274-019-2296-9

Kausar, A., Ahmad, I., Maaza, M., Eisa, M.H.: State-of-the-art of polymer/fullerene C60 nanocomposite membranes for water treatment: conceptions, structural diversity and topographies. Membranes (Basel) 13, 27 (2022). https://doi.org/10.3390/membranes13010027

Wang, T., Chen, Z., Gong, W., Xu, F., Song, X., He, X., Fan, M.: Electrospun carbon nanofibers and their applications in several areas. ACS Omega 8, 22316–22330 (2023). https://doi.org/10.1021/acsomega.3c01114

Wang, H., Wang, H.S., Ma, C., Chen, L., Jiang, C., Chen, C., Xie, X., Li, A.-P., Wang, X.: Graphene nanoribbons for quantum electronics. Nat. Rev. Phys. 3, 791–802 (2021). https://doi.org/10.1038/s42254-021-00370-x

Kim, W.Y., Kim, K.S.: Prediction of very large values of magnetoresistance in a graphene nanoribbon device. Nat. Nanotechnol. 3, 408–412 (2008). https://doi.org/10.1038/nnano.2008.163

Chen, Z., Narita, A., Müllen, K.: Graphene nanoribbons: on-surface synthesis and integration into electronic devices. Adv. Mater. 32, 1–26 (2020). https://doi.org/10.1002/adma.202001893

Llinas, J.P., Fairbrother, A., Borin Barin, G., Shi, W., Lee, K., Wu, S., Yong Choi, B., Braganza, R., Lear, J., Kau, N., Choi, W., Chen, C., Pedramrazi, Z., Dumslaff, T., Narita, A., Feng, X., Müllen, K., Fischer, F., Zettl, A., Ruffieux, P., Yablonovitch, E., Crommie, M., Fasel, R., Bokor, J.: Short-channel field-effect transistors with 9-atom and 13-atom wide graphene nanoribbons. Nat. Commun. 8, 633 (2017). https://doi.org/10.1038/s41467-017-00734-x

Koch, M., Ample, F., Joachim, C., Grill, L.: Voltage-dependent conductance of a single graphene nanoribbon. Nat. Nanotechnol. 7, 713–717 (2012). https://doi.org/10.1038/nnano.2012.169

Li, Y., Liu, Q., Li, W., Meng, H., Lu, Y., Li, C.: Synthesis and supercapacitor application of alkynyl carbon materials derived from CaC2 and polyhalogenated hydrocarbons by interfacial mechanochemical reactions. ACS Appl. Mater. Interfaces 9, 3895–3901 (2017). https://doi.org/10.1021/acsami.6b13610

Cui, W., Zhang, M., Wang, N., He, J., Yu, J., Long, Y., Yan, S., Huang, C.: High-performance field-effect transistor based on novel conjugated P-o-Fluoro-p-alkoxyphenyl-substituted polymers by graphdiyne doping. J. Phys. Chem. C 121, 23300–23306 (2017). https://doi.org/10.1021/acs.jpcc.7b07364

Tiwari, S.K., Sahoo, S., Wang, N., Huczko, A.: Graphene research and their outputs: status and prospect. J. Sci. Adv. Mater. Devices 5, 10–29 (2020). https://doi.org/10.1016/j.jsamd.2020.01.006

Zhu, M.J., Kretinin, A.V., Thompson, M.D., Bandurin, D.A., Hu, S., Yu, G.L., Birkbeck, J., Mishchenko, A., Vera-Marun, I.J., Watanabe, K., Taniguchi, T., Polini, M., Prance, J.R., Novoselov, K.S., Geim, A.K., Ben Shalom, M.: Edge currents shunt the insulating bulk in gapped graphene. Nat. Commun. 8, 14552 (2017). https://doi.org/10.1038/ncomms14552

Li, J., Xie, Z., Xiong, Y., Li, Z., Huang, Q., Zhang, S., Zhou, J., Liu, R., Gao, X., Chen, C., Tong, L., Zhang, J., Liu, Z.: Architecture of β-graphdiyne-containing thin film using modified Glaser-Hay coupling reaction for enhanced photocatalytic property of TiO2. Adv. Mater. 29, 1700421 (2017). https://doi.org/10.1002/adma.201700421

Li, J., Gao, X., Jiang, X., Li, X.-B., Liu, Z., Zhang, J., Tung, C.-H., Wu, L.-Z.: Graphdiyne: a promising catalyst-support to stabilize cobalt nanoparticles for oxygen evolution. ACS Catal. 7, 5209–5213 (2017). https://doi.org/10.1021/acscatal.7b01781

Chernozatonskii, L.A., Demin, V.A., Kvashnin, D.G.: Fully hydrogenated and fluorinated bigraphenes–diamanes: theoretical and experimental studies. C 7, 17 (2021). https://doi.org/10.3390/c7010017

Li, H., Li, Q., Wen, P., Williams, T.B., Adhikari, S., Dun, C., Lu, C., Itanze, D., Jiang, L., Carroll, D.L., Donati, G.L., Lundin, P.M., Qiu, Y., Geyer, S.M.: Retracted: colloidal cobalt phosphide nanocrystals as trifunctional electrocatalysts for overall water splitting powered by a zinc–air battery. Adv. Mater. 30 (2018). https://doi.org/10.1002/adma.201705796

Gao, X., Ren, H., Zhou, J., Du, R., Yin, C., Liu, R., Peng, H., Tong, L., Liu, Z., Zhang, J.: Synthesis of hierarchical graphdiyne-based architecture for efficient solar steam generation. Chem. Mater. 29, 5777–5781 (2017). https://doi.org/10.1021/acs.chemmater.7b01838

Chen, L., Hernandez, Y., Feng, X., Müllen, K.: From nanographene and graphene nanoribbons to graphene sheets: chemical synthesis. Angew. Chem. Int. Ed. 51, 7640–7654 (2012). https://doi.org/10.1002/anie.201201084

Hou, C., Wang, J., Du, W., Wang, J., Du, Y., Liu, C., Zhang, J., Hou, H., Dang, F., Zhao, L., Guo, Z.: One-pot synthesized molybdenum dioxide–molybdenum carbide heterostructures coupled with 3D holey carbon nanosheets for highly efficient and ultrastable cycling lithium-ion storage. J. Mater. Chem. A 7, 13460–13472 (2019). https://doi.org/10.1039/C9TA03551F

Liu, X., An, Y., Feng, J., Zhu, X., Li, F.: Preparation and properties of carbon nanofiber modified emulsified asphalt based on ultrasonication and surfactant and the impact of SBR and NH4Cl. Front. Mater. 7, 1–9 (2020). https://doi.org/10.3389/fmats.2020.00209

Pandit, B., Pande, S.A., Sankapal, B.R.: Facile SILAR processed Bi2S3:PbS solid solution on MWCNTs for high-performance electrochemical supercapacitor. Chinese J. Chem. 37, 1279–1286 (2019). https://doi.org/10.1002/cjoc.201900222

Muralee Gopi, C.V.V., Ravi, S., Rao, S.S., Eswar Reddy, A., Kim, H.-J.: Carbon nanotube/metal-sulfide composite flexible electrodes for high-performance quantum dot-sensitized solar cells and supercapacitors. Sci. Rep. 7, 46519 (2017). https://doi.org/10.1038/srep46519

Pande, S.A., Pandit, B., Sankapal, B.R.: Facile chemical route for multiwalled carbon nanotube/mercury sulfide nanocomposite: high performance supercapacitive electrode. J. Colloid Interface Sci. 514, 740–749 (2018). https://doi.org/10.1016/j.jcis.2017.12.068

Voigt, D., Primavera, G., Uphoff, H., Rethmeier, J.A., Schepp, L., Bredol, M.: Ternary chalcogenide-based quantum dots and carbon nanotubes: establishing a toolbox for controlled formation of nanocomposites. J. Phys. Chem. C 126, 9076–9090 (2022). https://doi.org/10.1021/acs.jpcc.2c01142

Chong, T.V., Loh, S.K., Liow, C.H., Abd-Shukor, R.: Effects of carbon nanotubes addition on the superconducting properties and critical current density of NdBa2Cu3O7−δ. Appl. Phys. A 128, 740 (2022). https://doi.org/10.1007/s00339-022-05877-3

Banerjee, R., Gebrekrstos, A., Orasugh, J.T., Ray, S.S.: Nanocarbon-containing polymer composite foams: a review of systems for applications in electromagnetic interference shielding, energy storage, and piezoresistive sensors. Ind. Eng. Chem. Res. 62, 6807–6842 (2023). https://doi.org/10.1021/acs.iecr.3c00089

Radwan, A., Jin, H., He, D., Mu, S.: Design engineering, synthesis protocols, and energy applications of MOF-derived electrocatalysts. Nano-Micro Lett. 13, 132 (2021). https://doi.org/10.1007/s40820-021-00656-w

Zhong, M., Zhang, M., Li, X.: Carbon nanomaterials and their composites for supercapacitors. Carbon Energy 4, 950–985 (2022). https://doi.org/10.1002/cey2.219

Wang, Q., Zhou, Y., Zhao, X., Chen, K., Bingni, G., Yang, T., Zhang, H., Yang, W., Chen, J.: Tailoring carbon nanomaterials via a molecular scissor. Nano Today 36, 101033 (2021). https://doi.org/10.1016/j.nantod.2020.101033

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Pande, S., Pandit, B., Shaikh, S.F., Ubaidullah, M. (2024). Electrochemical Properties of Nanocarbon. In: Gupta, R.K. (eds) NanoCarbon: A Wonder Material for Energy Applications. Engineering Materials. Springer, Singapore. https://doi.org/10.1007/978-981-99-9935-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-99-9935-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-9934-7

Online ISBN: 978-981-99-9935-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)