Abstract

The advanced nanofluid with good stability is demand of industry as well as solar thermal systems. In industrial application, Graphene Oxide (GO) nanofluid formulated with Ethylene Glycol (EG): water (W) is usually known well for good stability along with high thermal conductivity. In this research, GO nanofluid is characterized for exploring thermal, optical, and suspension stability under certain conditions and then utilized as working fluid in photovoltaic thermal (PV/T) system. SEM, UV–vis, FTIR and TGA analysis are performed for morphology, optical and thermal stability characterization respectively. Thermal conductivity measurements of the GO/EG:W nanofluid revealed an enhancement of 9.5% at 40 °C compared to water. It also displayed good long-term stability, with a zeta potential of 30.3 mV. The long-term stability with time as well as stability at high temperature of GO nanofluid give a good room for future researchers to use it as coolant in solar PV panel. Because large increment in thermal conductivity of EG:W nanofluid of GO may act very amazing media for heat transport which resulted in enhancement of performance of PV solar panels. Therefore the electrical as well as thermal efficiencies of the PV/Thermal system improved.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The eighteenth century is the century of industrial revolution, so energy became one of the greatest challenges among all the challenges faced by mankind. Due to rapid growth of the world population, demand of energy has increased massively in last few decades. Hence to meet the demand of energy the rapid depletion in conventional sources of energy takes place. So the fossil fuel-based fuels such as petroleum, coal and natural gas have been depleting, which is very serious issue for the future development of the world. However, fossil fuel resources are rapidly depleting due to exploration to meet the energy demand of the countries. If these conventional sources of energy are exhausted, it is impossible to replenish them.

Photovoltaic-thermal collectors [1], a cogeneration technology, which combine the components of photovoltaic cell and solar thermal absorber, have been shown to be a viable solution because they maximize the use of netted heat inside the photovoltaic cell while also enhancing PV efficiency. Chow et al. [2] have investigated that every 10° rise in the solar cell temperature results in to decrease in conversion efficiency of Photo Voltaic cells by 5%. So if we combine the both, the photovoltaic panel with the thermal system so that both help each other and the combination is known as Photovoltaic-Thermal System.

The efficiencies of these energy harnessing technologies are observed usually in the range of approximately 50–70% [3] and 15–20% [4] respectively. At present, the hybrid photovoltaic thermal system (PV/T) developed by integrating both PV and solar thermal systems receives considerable attentions by the researchers as it improves the energy generation efficiency [4, 5]. The working fluid used in PV/T system plays key role in absorbing heat from solar module and transferring it to the collector. The thermal conductivity of commonly used base fluids such as water, oil or ethylene glycol is usually increased by colloidal mixing of nanoparticles (1–100 nm). The suspended nanoparticles in base fluid help improve its thermal properties and thus enhance the overall performance of the system [6]. The reported literature studies [3, 5] reveal that the commonly used metal-based nanoparticles in preparing nanofluids are either metals (Zn, Fe, Cu, Al) or metal oxides (Al2O3, ZnO, Cu2O, TiO2, etc.). Many researchers use carbon-based nanomaterials such as fullerenes (carbon molecule Cn where n > 20) [7], carbon nanotubes (carbon allotropes with cylindrical nanostructures) [6] and graphene (caron with two-dimensional allotropic form) [8]. Concerning PV/T system’s overall efficiency, thermal and electrical efficiency, surface temperature, entropy generation and energy loss, different researchers investigated various input parameters with nanofluids including types, size, shape and concentration of nanoparticles, types of base fluid, stability, viscosity and flow rate experimentally/numerically [9, 10].

Recently, the hybrid nano-fluids, composed of two distinct nanoparticles or amalgamated nano-powder suspended in a base fluid, increase capabilities in all domains of heat transfer and most notably in solar thermal collectors, including concentrating kinds and flat plate [11]. It has also been suggested that synthesis nanofluids are more effective as compared to mono nanofluids [12,13,14]. When combination of two nanoparticles is used in solar collectors the solar thermal efficiency of solar collectors improves significantly [15, 16]. The researchers have also reported the enhancement of effectiveness of parabolic solar collectors [17]. Due to the synergistic effect of nanoparticles, the good characteristics of traditional heat transfer fluids (like ethylene glycol, water, and oil) and the nano-fluids incorporating single nanoparticles can indeed be enhanced [18, 19]. The combined nano-fluids’ increased absorption capacities are enticing leading to a significant increase in solar thermal collector efficiency. Khan et al. evaluate the performance of water-based Fe3O4/SiO2 hybrid nano-fluid in PV thermal system [20].

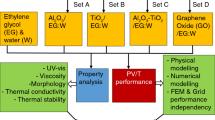

2 Materials and Methods

2.1 Preparation of Aqueous Ethylene Glycol Nanofluids

To prepare the nanofluids, the graphene nano-platelets were procured from SRL lab. These graphene nano-platelets dispersed with the water-ethylene glycol in a volumetric ratio of 60:40 and mass fractions were kept in range of 0.1–0.3%. The required mass of the graphene nano-platelets was weighed with the help of calibrated digital balance. One kilogram of water-ethylene glycol in the ratio of 60:40 by volume was prepared. To achieve maximum stability of nanofluid a surfactant (NPE 400) in volumetric ratio of 0.1% of the base fluid is added. A speed stirrer, which was running about 300 rpm, was used to disperse the graphene nano-platelets in water ethylene glycol. The stirrer run for about 20 min to achieve high level of stability of nanofluid. The nanofluid prepared by stirrer may have agglomerations of nano-particles. Hence to break these agglomerations, an ultrasonic homogenizer was used. There may be chances of damage of nano-platelets, so to minimize this damage, the sonication of nano-fluid was performed for 10 min at 20 kHz and 150 W.

2.2 UV–Vis Analysis of the Aqueous Ethylene Glycol Nanofluids

An Ultraviolet–visible spectroscopy (UV–Vis) of model: Perkin Elmer Lambda 750 was used to record the optical absorbance measurements. The absorption data was recorded at room temperature for the wavelength within 800 to 200 nm range. The adjusted scan speed was 266.75 nm/min with the 860 nm monochromatic.

2.3 Viscosity Measurement of Aqueous Ethylene Glycol Nanofluids

The measurement of viscosity was carried out by Rheometer Anton Paar model MCR92. T-Ramp measurement i.e. the investigation of variation of viscosity with temperature was carried out in the temperature range of 20–80 °C for all samples (60 mL). T-Ramp measurements for the pure aqueous ethylene glycol, aqueous ethylene glycol nanofluids including 4 different types of nanoparticles and in different concentrations were performed in identical condition to assure the uniformity of the measurements.

2.4 Microstructure and Morphological Analysis of Graphene

The morphology of the synthesized Graphene nanoflakes was monitored with a scanning electronic microscopy (SEM) of model; TESCAN, VEGA3 and energy-dispersive x-ray spectroscopy (EDX) model; OXFORD INSTRUMENT). A digital ion coater (COXEM Co, SPT-20) was utilized for Pt coating on the samples in the fixed current of 3 mA for 300 s for taking SEM images.

2.5 Thermal Conductivity Measurements

The thermal conductivity of synthesized aqueous ethylene glycol nano-fluids with different concentrations was measured with the help of thermal properties analyzer (Tempos) from Meter Group (USA) with improved proprietary algorithm. The sensor of the analyzer was KS-3 with the length of 60 mm and dimension of 1.3 mm. The selected sensor is able to measure the thermal conductivity in the range of 0.02–2 W/m K in the accuracy range of ±10%. Thermal conductivity measurements for all prepared samples were executed in 4 different temperatures including 25, 40, 55 and 70 °C. Firstly, the prepared samples were poured into a vial followed by locating the KS-3 sensor inside the sample. Then the vial was placed inside a water bath (MEMMERT, WNB22) for stabilizing the temperature to achieve accurate results. Thermal conductivity measurements for all samples in certain temperatures were repeated for 5 times to assure the accuracy of the obtained data.

3 Results and Discussion

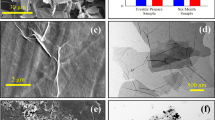

Figure 1a illustrates the FESEM image of Graphene Oxide nanoflakes, and FESEM and TEM images of GO-based aqueous nanofluids. Upon formulation of GO nanofluid with E:W, the GO particles show some surface wrinkling and well dispersed distribution in fluid.

a FESEM image of Graphene Oxide nanoflakes, b FESEM and c TEM images of Graphene Oxide -based aqueous nano-fluids (taken from Ref. [21])

Figure 1a presents a typical micrometer scale flake of GO, which displays some surface wrinkling. Figure 1c presents a representative TEM sample showing well dispersed and transparent sheets of GO [22]. Typically, suspensions with absolute zeta potential values greater than 30 mV are physically stable, while suspensions below 20 mV have limited stability, and suspensions below 5 mV experience rapid aggregation. Thus, the GO-based aqueous nanofluid is physically stable and it was only after 6 months its zeta potential dropped down to 30.3 mV.

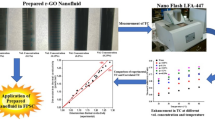

3.1 Thermal Conductivity Analysis

The thermal conductivities of different nanofluids such as Al2O3, TiO2, hybrid (Al2O3-TiO2) and Graphene in the aqueous EG:W at 0.1% concentrations and aqueous EG:W are presented in Fig. 4. Among others, the GO nanofluid shows higher thermal conductivity (Figs. 2 and 3).

The order of thermal conductivity as shown in Fig. 2 is GO/EG:W > TiO2 + Al2O3/EG:W > Al2O3/EG:W > TiO2/EG:W > EG:W. The thermal conductivity of EG:W is found to be increased from 0.32 to 0.44 W/m.K at 25 °C due to addition of graphene oxide. It is also seen from Fig. 4 that the thermal conductivity rises linearly with increasing the temperature. The thermal conductivity of GO nanofluid is found to be raised from 0.44 to 0.5 when temperature is increased from 25 to 70 °C. The temperature grows at the same rate of each of temperature step. The cause of this phenomenon can be related to the Brownian motion of the particles in the nanofluid [23,24,25,26]. When the temperature increases, the kinetic energy of the nanoparticle inside the nanofluid also increases leading to faster collision among the nanoparticles. Hence the thermal conductivity is enhanced as also reported by Chiam and Azmi [27], Esfe and Karimipour [28] and Sati and Shende [29]. These authors have also reported the linear enhancement in thermal conductivity with the increase of temperature.

3.2 Viscosity Analysis

In Fig. 3, the viscosity of the nanofluids with respect to temperature and wt.% concentration of the nanoparticles is depicted. The temperature is varied from 20 to 80 °C in 50 steps. The study of viscosity variation is very important as the nanofluids are under constant flow conditions. During such applications, the rheological properties must remain intact and should be in favor of pumping power required. From the figures, it is evident that the viscosity of the nanofluids is marginally affected by the concentration of the nanoparticles while the temperature has shown a promising effect. In Fig. 3, a comparative analysis of all four nanofluids with lowest viscosity in comparison to base fluid is depicted. The hybrid nanofluid has provided the lowest of all viscosity at almost same temperatures and TiO2 nanofluid has given a comparatively higher viscosity than others. The order of viscosity within 30–50 °C is TiO2/EG:W > Al2O3/EG:W > GO/EG:W > TiO2 + Al2O3/EG:W.

From an overall analysis of thermal and viscosity property of the nanofluids, the hybrid nanofluid has shown more promising results than the individual nanoparticles suspended in base fluid. It can also be inferred that irrespective of nanoparticle usage, at temperatures above the room temperature (here 50 °C) the increase/decrease in viscosity is found to seize and at the near boiling point of water the viscosity is same at all concentrations.

3.3 Performance of Nanofluid in PVT System

In this study, the temperature of PV panel is maintained in permissible limit by different coolants in the back of PV panel. Figures 4a and b present the electrical and thermal efficiencies of PV/T with different nanofluids having a nanoparticle concentration of 0.1% in the base fluid. The electrical efficiencies observed for the PV/T with TiO2/EG:W, Al2O3/EG:W, Al2O3-TiO2/EG:W and GO/EG:W are 12.2, 12.3, 12.5 and 13.5% respectively at the maximum flow rate of 0.07 kg/s. Similarly, at the same flow rate, the thermal efficiencies observed for those systems are 62, 64, 68 and 76% respectively. Both electrical and thermal efficiencies for GO/EG:W nanofluid are observed to be better than other tested fluids. The enhancement in thermal and electrical efficiency is due to the better heat removal capacity of the nanofluid as compared to other coolants. This also indicates the improvement in thermal conductivity of the nanofluid. Because almost same trend for the improvement of thermal conductivity of nanofluids is shown in above graph of thermal conductivity in Fig. 4.

4 Conclusions

4.1 The Following Conclusions Are Drawn from the Study:

-

(i)

Prior to processing, the FESEM image of GO nanoflakes shows an agglomeration of large micrometer scale sheets displaying surface wrinkling and folding. Upon formulation of GO nanofluid, the GO particles display some surface wrinkling and well dispersed distribution in fluid. It was physically stable as the zeta potential even after 6 months was around 30.3 mV which was greater than the required value (30 mV) assigned for stability.

-

(ii)

The order of thermal conductivity for the tested fluids is GO/EG:W > TiO2 + Al2O3/EG:W > Al2O3/EG:W > TiO2/EG:W > EG:W. The thermal conductivity of EG:W is found to be increased from 0.32 to 0.44 W/m.K at 25 °C due to addition of graphene oxide. The thermal conductivity of GO nanofluid is further found to be raised from 0.44 to 0.5 when temperature is increased from 25 to 70 °C.

-

(iii)

The thermal degradation for almost all the nanofluids is seen to begin in the range at nearly 55 to 70 °C. Approximately 3 to 10% of mass is lost in this temperature range. The viscosity is decreased with the increase of temperature and the order of viscosity within 30–50 °C is found be TiO2/EG:W > Al2O3/EG:W > GO/EG:W > TiO2 + Al2O3/EG:W.

-

(iv)

The electrical efficiencies observed for the PV/T with TiO2/EG:W, Al2O3/EG:W, Al2O3-TiO2/EG:W and GO/EG:W at 0.1% concentration level are observed by 12.2, 12.3, 12.5 and 13.5% respectively at the maximum flow rate of 0.07 kg/s. Similarly, at the same flow rate, the thermal efficiencies observed for those systems are 62, 64, 68 and 76% respectively. This demonstrates that both electrical and thermal efficiencies for GO/EG:W nanofluid are better than other tested fluids. Among others, the PV/T system with GO/EG:W system shows the highest electrical and thermal efficiencies. Both electrical and thermal efficiencies are found to be further increased when the concentration level is increased.

-

(v)

Both electrical and thermal efficiencies increase with the increase of mass flow rate. The electrical efficiency for Al2O3/EG:W, TiO2/EG:W, Al2O3-TiO2/EG:W increased from 11.65 to 12.5%, from 12 to 13% and from 12.25 to 14.10% respectively for the increase of mass flow 0.01 to 0.07 kg/s. Similarly, the thermal efficiencies of these working fluids are increased from 62 to 64%, from 64 to 68%, and from 68 to 81.5% respectively when the mass flow rate is increased from 0.01 to 0.07 kg/s. All the analyzed properties and performances of different nanofluids indicate GO/EG:W as better working fluid for PV/T compared to others.

5 Future Scope

The combination of two different nanoparticles in a base fluid improves system performance when compared to the mono-nanofluid. The performance of the system also improved when graphene is used as compared to hybrid nanofluid. Furthermore, hybrid nanofluid shows the better stability than mono-nanofluid. Future researchers may investigate the effect of cooling for high weight concentration of graphene and compare it with the others. Also, there is a need to evaluate the effect of nanoparticles on the cell temperature of PV panel. More comprehensive study can be started to acknowledge the overall performance of the system.

Abbreviations

- GO:

-

Graphene oxide

- EG:

-

Ethylene glycol

- W:

-

Water

- UV-vis:

-

Ultraviolet visual spectroscopy

- TEM:

-

Transmission electron microscopy

- FESEM:

-

Field emission scanning electron microscopy

- PVT:

-

Photo-voltaic thermal

References

Ahmed F, Al Amin AQ, Hasanuzzaman M, Saidur R (2013) Alternative energy resources in Bangladesh and future prospect. Renew Sustain Energy Rev 25:698e707

Chow TT, Hand J, Strachan P (2003) Building-integrated photovoltaic and thermal applications in a subtropical hotel building. Appl Therm Eng 23:2035–2049. https://doi.org/10.1016/S1359-4311(03)00183-2

Choudhary S, Sachdeva A, Kumar P (2020) Influence of stable zinc oxide nanofluid on thermal characteristics of flat plate solar collector. Renewable Energy 152:1160–1170. https://doi.org/10.1016/j.renene.2020.01.142

Bhakre S, Sawarkar P, Kalamkar V (2021) Performance evaluation of PV panel surfaces exposed to hydraulic cooling—a review. Sol Energy 224:1193–1209. https://doi.org/10.1016/j.solener.2021.06.083

Hossain F, Karim M, Bhuiyan A (2022) A review on recent advancements of the usage of nano fluid in hybrid photovoltaic/thermal (PV/T) solar systems. Renew Energy. https://doi.org/10.1016/j.renene.2022.01.116

Tembhare S, Barai D, Bhanvase B (2022) Performance evaluation of nanofluids in solar thermal and solar photovoltaic systems: a comprehensive review. Renew Sustain Energy Rev 153:111738. https://doi.org/10.1016/j.rser.2021.111738

Zaytseva O, Neumann G (2016) Carbon nanomaterials: production, impact on plant development, agricultural and environmental applications. Chem Biol Technol Agric 3:17

Wahab A, Khan M, Hassan A (2020) Impact of graphene nanofluid and phase change material on hybrid photovoltaic thermal system: exergy analysis. J Clean Prod 277:123370. https://doi.org/10.1016/j.jclepro.2020.123370

Qeays I, Yahya S, Asjad M, Khan Z (2020) Multi-performance optimization of nanofluid cooled hybrid photovoltaic thermal system using fuzzy integrated methodology. J Clean Prod 256:120451. https://doi.org/10.1016/j.jclepro.2020.120451

Parsa S, Yazdani A, Aberoumand H, Farhadi Y, Ansari A, Aberoumand S, Karimi N, Afrand M, Cheraghian G, Ali H (2022) A critical analysis on the energy and exergy performance of photovoltaic/thermal (PV/T) system: the role of nanofluids stability and synthesizing method. Sustain Energy Technol Assess 51:101887. https://doi.org/10.1016/j.seta.2021.101887

Sundara LS, Sharmab KV, Singha MK, Sousaa ACM (2017) Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor—a review. Renew Sustain Energy Rev 68:185–198

Yahya SM, Anwer SF, Sanghi S (2013) Enhance heat transfer and fluid flow in a channel behind photovoltaic panel in hybrid PV/T system. Indus Eng Chem Res 52:18413–18420

Gupta M, Singh V, Kumar S, Kumar S, Dilbaghi N, Said Z (2018) Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J Clean Prod 190(169):92

Ranga Babu JA, Kiran Kumar K, Srinivasa RS (2017) State-of-art review on hybrid nanofluids. Renew Sustain Energy Rev 77(551–56):5

Bellos E, Tzivanidis C (2018) A review of concentrating solar thermal collectors with and without nanofluids. J Therm Anal Calorim 1–24

Bellos E, Said Z, Tzivanidis C (2018) The use of nanofluids in solar concentrating technologies: a comprehensive review. J Clean Prod 196:84–99

Bellos E, Said Z, Tzivanidis C (2018) Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Renew Sustain Energy Rev 26:105–115

Minea AA, El-Maghlany WM (2018) Influence of hybrid nanofluids on the performance of parabolic trough collectors in solar thermal systems: recent findings and numerical comparison. Renew Energy 120:350–364

Azwadi CSN, Adamu IM, Jamil MM (2016) Preparation methods and thermal performance of hybrid nanofluids. J Adv Rev Sci Res. 24(1):13–23

Khan AA, Danish M, Rubaiee S, Yahya SM (2022) Insight into the investigation of Fe3O4/SiO2 nanoparticles suspended aqueous nanofluids in hybrid photovoltaic/thermal system. Clean Eng Technol 100572

Yu X et al (2018) Investigation on synthesis, stability, and thermal conductivity properties of water-based SnO2/reduced graphene oxide nanofluids. Materials 11(1):38

Chamsaard W (2019) Synthesis, Characterisation and thermo-physical properties of highly stable graphene oxide-based aqueous nanofluids for low-temperature direct absorption solar collectors and solar still desalination. Thesis of Doctor of Philosophy, Murdoch University

Chiam H et al (2017) Thermal conductivity and viscosity of Al2O3 nanofluids for different based ratio of water and ethylene glycol mixture. Exp Thermal Fluid Sci 81:420–429

Esfe MH et al (2017) Optimization, modeling and accurate prediction of thermal conductivity and dynamic viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids by NSGA-II using ANN. Int Commun Heat Mass Transfer 82:154–160

Manimaran R et al (2014) Preparation and characterization of copper oxide nanofluid for heat transfer applications. Appl Nanosci 4(2):163–167

Aslfattahi N, et al (2019) Experimental investigation of thermal stability and enthalpy of eutectic alkali metal solar salt dispersed with MgO nanoparticles. 10(6):1112–1119

Esfe MH et al (2015) Experimental study on thermal conductivity of ethylene glycol based nanofluids containing Al2O3 nanoparticles. Int J Heat Mass Transf 88:728–734

Sati P, Shende RC, Ramaprabhu S (2018) An experimental study on thermal conductivity enhancement of DI water-EG based ZnO (CuO)/graphene wrapped carbon nanotubes nanofluids. Thermochim Acta 666:75–81

Sunil J et al (2019) The thermal properties of CaO-Nanofluids. Vacuum 161:383–388

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Khan, A.A., Yahya, S.M. (2024). Development, Characterization and Performance Evaluation of Graphene Oxide Nanofluid in EG:Water-Based PV/Thermal System. In: Siddiqui, M.A., Hasan, N., Tariq, A. (eds) Advances in Heat Transfer and Fluid Dynamics. AHTFD 2022. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-7213-5_17

Download citation

DOI: https://doi.org/10.1007/978-981-99-7213-5_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7212-8

Online ISBN: 978-981-99-7213-5

eBook Packages: EngineeringEngineering (R0)