Abstract

The coalescence of two disc-shaped droplets falling under the effect of gravity inside a quiescent liquid medium is studied using particle image velocimetry (PIV). A smaller droplet, followed by a larger droplet, falls from a rest position inside a confined channel. The larger droplet with the higher terminal velocity collides with the smaller droplet and merges to form a single droplet that continues to fall. Here, three stages of coalescence (film drainage between droplets, film rupture, and growth of connection) of the droplets are shown qualitatively. The glycerol-water mixture is used as a droplet and silicon oil as a continuous surrounding liquid. The droplet is seeded with a 40 μm PMMA particle, which is neutrally buoyant and faithfully follows the flow. Images are recorded and processed at different time intervals to capture the droplet coalescence. It is shown that larger droplet approaches smaller droplet due to higher terminal velocity resulting in movement or leakage of surrounding liquid away from the droplets. Distance between droplets keeps reducing to zero where film rupture occurs. Reshaping of a larger diameter disc-shaped droplet is observed at the end, which keeps falling with a new higher terminal velocity.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Droplet coalescence is an important phenomenon observed in nature as well as in industries, where two miscible droplets come into contact and form a single droplet. [1] Many scientific studies have been done in the past to investigate the different variety of coalescence, such as a single droplet to bulk liquid, two drops in the air [2], two droplets in another liquid media present in the surrounding, etc. [3, 4] Total interfacial area reduces during coalescence, and it is governed by interfacial tension between fluids. High-speed flow visualization and analytical and numerical investigation of coalescence of droplets in different environments are rich in literature [5].

Confined droplets, due to their high interfacial area density, have shown tremendous application in emulsion, droplet microreactor, liquid–liquid contactors, underground oil, and gas reservoir multiphase flow, etc. Droplet coalescence also occurs in such confined channels, which affects the heat and mass transfer rate, mixing, and reaction rates. [6] Droplets acting as a reactor are commonly known as droplet microreactors. A series of droplets are introduced into the microreactor, having a continuous fluid stream. In such fluids, the mixing inside the droplets is important, e.g. to determine the kinetic rate of reaction accurately in flow chemistry. Droplet coalescence can occur in such droplet reactors, which affects the design aspects of the reactors. Therefore, studying the flow physics of such confined droplet coalescence is important.

Numerous investigations into droplet coalescence over liquid surfaces and droplet coalescence in surrounding gaseous media are well-documented in the literature, but little is known about the flow physics inside the droplet during coalescence in surrounding liquid media. In this study, due to the confinement of the channel in one direction, disc-shaped droplet coalescence inside another liquid medium is investigated using the particle image velocimetry technique. Flow physics of film drainage, film rupture, and connection growth is shown qualitatively.

2 Objective

This study investigates the physics of disc-shaped droplet coalescence falling under the effect of gravity inside continuous liquid media using particle image velocimetry. It investigates the movement of liquid film between droplets when the large droplet approaches the smaller drop, merging of interface and then the growth of the connection of droplet interface till a new larger droplet of circular disc shape forms and continues to fall. Recirculation inside the droplets during coalescence is also observed qualitatively.

3 Materials and Methods

A syringe pump (Holmarc HO SPLF 2) is used to inject droplets of different sizes by controlling their volume at different time intervals. After sufficient time, a large droplet is injected after a small droplet to ensure that coalescence occurs only after the droplets achieve their respective terminal velocities. A high-intensity non-flickering continuous LED light is used for illumination. A schematic diagram of the flow loop of the experiment is shown in Fig. 1. Confinement of the channel is achieved by using two glass slides (76.2 mm × 25.4 mm × 1 mm) attached to two 1 mm thick glass slides using UV super glue (Excel Impex). Silicone sealant is used at one opening to close the channel. The confined channel used in the experiment is shown in Fig. 2.

A superhydrophobic coating of 0.2% by vol. of octadecyltrichlorosilane (OTS) in toluene is applied to the front and back glass walls to minimize the wall resistance that prevents the drop from falling but at the same time enable us to visualize the 2D motion of a disc-shaped droplet. Glass slides are first cleaned with acetone and isopropyl alcohol followed by nitrogen wash and then treated with the ozone before the coating of OTS to make homogeneous coating throughout the glass surface. Silicone oil is used as a continuous phase and glycerol-water mixture for the dispersed phase. The density of aqueous glycerol solution (74% glycerol) is 1200 kg/m3 and viscosity is 0.035 Pa s. The density of silicon oil is 971 kg/m3, and viscosity at 25 °C is 0.0371 Pa s. Silicon oil is a more viscous fluid, due to which the circular shape of the droplet is maintained.

At first, a drop of 18 µl volume was injected, followed by a second drop of 12 µl volume. Spherical droplets become disc-shaped inside the confined channel. Starting from the rest position at the top of the channel, droplets slowly fall under the effect of gravity surrounded by silicon oil. Terminal velocity is achieved after falling some distance due to buoyancy and drag forces acting in an upward direction and gravitational force in the downward direction. Due to the higher terminal velocity of the larger diameter droplet, it approaches the smaller drop and collides to form a new bigger drop.

Poly Methyl Methacrylate (PMMA) particles (Dynoseeds Ltd.) are used as seeding particle for droplet, which is neutrally buoyant and follows the flow faithfully. Images are captured at 150 fps with a resolution of 1280 × 1024 using a high-speed camera (Photron UX50).

4 Results and Discussion

Seeded droplets falling through silicon oil inside a confined channel under the effect of gravity achieve terminal velocity well before merging. Two droplets of different sizes dropped from rest position at the top of the channel and central location from side walls. Larger diameter droplet will achieve higher terminal velocity than smaller droplet. The higher terminal velocity of larger droplets causes the collision and merging with the smaller droplet. Spacing between the droplet injection kept such a way that coalescence occur after both the droplets achieve their respective terminal velocities.

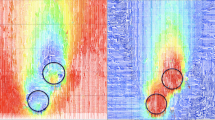

Figure 3 shows the time evolution of the coalescence phenomenon of two disc-shaped droplets where both have achieved their terminal velocities. Figure 3i indicates that a larger droplet is approaching towards smaller droplet due to its higher terminal velocity. Figure 3ii shows the film rupture between droplet interfaces and surrounding liquid drain away from the coalescence as the distance between droplets keeps reducing, causing the liquid between the droplets to move out.

Figure 3iii and iv shows that oil drain away from the merging point and the growth of connection of the newly formed interface. After the merging of droplets, the newly formed interface connection starts to reshape due to surface tension force acting at the interface. Figure 3v and vi shows the end of oil drainage from the merging point and maximum growth of the interface, resulting in a circular interface boundary of the new droplet. Reshaping occurs until the balance of interfacial tension force at the interface is established. Yellow colour marking lines show the flow direction near the merging point of the droplets.

5 Conclusions

The coalescence of two disc-shaped droplets falling inside liquid media under the influence of gravity was studied in a one-way confined channel using particle image velocimetry. The larger droplet, due to its higher terminal velocity, approached the smaller droplet, collided, and merged to form a new droplet. Time evolution images of the coalescence recorded and analysed. Images show that coalescence occurred in three stages. As the larger droplet reached the smaller droplet, the liquid film between the droplets leaked outside till the merging point. Furthermore, interface rupture occurred, and a new interface appeared. The newly formed interface grew, pushing the liquid outside till the shape of the droplet became circular. A new larger droplet was also disc-shaped due to the confinement of the channel. Qualitative images were shown only to depict coalescence, and further processing will be done to generate velocity vectors inside the droplet during coalescence.

References

Aarts DGAL, Lekkerkerker HNW (2008) Droplet coalescence: drainage, film rupture and neck growth in ultralow interfacial tension systems. J Fluid Mech 606:275–294

Pak CY, Li W, Steve Tse YL (2018) Free energy and dynamics of water droplet coalescence. J Phys Chem C 122:22975–22984

Rahman MM, Lee W, Iyer A, Williams SJ (2019) Viscous resistance in drop coalescence. Phys Fluids 31:1–10

Basheva ES, Gurkov TD, Ivanov IB, Bantchev GB, Campbell B, Borwankar RP (1999) Size dependence of the stability of emulsion drops pressed against a large interface. Langmuir 15:6764–6769

Saifi AH, Tripathi MK (2020) Distinct coalescence behaviors of hot and cold drops in the presence of a surrounding viscous liquid. Phys Fluids 32:1–10

Deka H, Biswas G, Sahu KC, Kulkarni Y, Dalal A (2019) Coalescence dynamics of a compound drop on a deep liquid pool. J Fluid Mech 866:1–11

Acknowledgements

We gratefully acknowledge the FIST Grant SR/FST/ETII-071/2016(G) from Department of Science and Technology, Government of India.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mishra, D.K., Gupta, R., Singh, A. (2024). Coalescence of Disc-Shaped Falling Droplets Inside Quiescent Liquid Media. In: Singh, K.M., Dutta, S., Subudhi, S., Singh, N.K. (eds) Fluid Mechanics and Fluid Power, Volume 5. FMFP 2022. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-6074-3_7

Download citation

DOI: https://doi.org/10.1007/978-981-99-6074-3_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6073-6

Online ISBN: 978-981-99-6074-3

eBook Packages: EngineeringEngineering (R0)