Abstract

Barefoot slips are most common in bathrooms, resulting in over 30% fall related injuries in older adults. Studies related to slip testing methods using footwear are widely conducted, but there is a lack of biofidelic testing framework for characterizing such types of slips in barefoot condition. In the present study, a human heel surrogate was prepared in order to study the slip safety of flooring tiles which were employed in the bathrooms and were subjected to different bathroom contaminants. Eight different floorings were tested in dry, soap, shower gel, and shampoo applied contaminant situation. The coefficient of friction was measured using the heel surrogate across the eight flooring tiles employing the bathroom contaminants. The developed human heel surrogate exhibited high repeatable (R2 > 0.80) nature across all the different contaminated conditions. The ACOF in this barefoot scenario was found to be low in the wet condition (less than 0.15), and much lower and generalizable for shampoo and shower gel contaminated conditions (less than 0.10). Such results with barefoot slip testing have not been reported to date and are anticipated to provide general guidelines in the selection of suitable bathroom floorings.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The bathroom region of a residential housing is considered one of the hazardous areas for slip related accidents for the older adults. Falls occurring in the bathrooms and its adjacent areas are more than twice as likely to result in a serious injury, compared to falls in other areas of the housing [1]. Movements involving motion from inside and outside of the bathtubs are also a leading cause of slip and fall accidents in older adults [1] and account for more than 70% of fall related injuries [1, 2]. Injuries leading to hospitalization, mainly from bathroom falls negatively affect the mobility, independence, and quality of life, and also induce fear, especially for older adults [3, 4]. The fear of falling, another grave consequence of falls, affects up to 85% of older adults [5] which can lead to avoiding the tendency of daily social and fundamental activities [6, 7]. A vast majority of elderly people encounter slip related accidents in the bathrooms of their respective homes. The extent of these accidents can be so severe, that it restricts the normal movement of the limbs be it the upper limbs or the lower limbs. The people who are affected by such slip related accidents are unable to bathe by themselves and require the assistance of nurses in hospitals and attendants in residences to properly perform the bathing activity. Injuries caused due to bathroom slip related accidents are associated with many adverse consequences, including increased visits to hospitals, home care services and long-term nursing home admissions [8]. Thus, evaluating the slip risk of such bathroom flooring tiles is imperative in reducing the possibility of fall related accidents.

Evaluation of barefoot slip risk till the present date was performed by employing human volunteers in a lab environment. In a previous study, the possibility of slips in barefoot condition in two age groups, mainly middle-aged and older adults, were quantified [9]. The friction at the foot-floor interface was measured as the volunteers manoeuvred on several dry floorings. Friction at the shoe-floor contact is quantified by dividing the forces that oppose slipping (i.e., shear forces) by the vertical force (i.e., body weight) and is typically stated as the available coefficient of friction (ACOF) [10,11,12,13]. Hence, ensuring adequate friction over common floorings is essential for the well-being of workers.

The surface roughness of the flooring was found to significantly affect the friction of the middle-aged group and was slightly higher than the older adults group, which showed minimal effect of the gender. Derler et al. [14] studied the relationship between coefficient of friction (COF) with the flooring surface roughness by performing barefoot slip simulations in wet contaminant scenarios. Fourteen individuals participated in the slip risk assessment study involving several floorings. The average ACOF measured on the floorings ranged from 0.012 to 0.50. The correlation of the floor roughness with the ACOF was found to be very low. The deviation of ACOF values was maximum on the same flooring tile was measured as 0.04, showing insignificant variability. Li et al. [15] had found out that the ACOF of different material floorings such as porcelain and ceramic floorings on the application of slippery contaminants. The floorings were substantially reported to affect the friction, while the foot slipping velocity was found to have no relation. Nagata et al. [16] investigated the effect of slip speed in barefoot condition and vertical forces in 15 older adult participants. Slip testing in a randomized way was conducted on dry, wet and soap applied flooring tiles. Siegmund et al. [17] attempted to find out the ACOF for participants moving around a shower chamber part of the bathroom consisting of the flooring tile adjacent to the bathtub in dry and water applied situations. Sixty healthy participants were selected for this study. Ten females and ten males were recruited into each of three age groups of twenty to thirty years, forty to fifty years and sixty to seventy years. The main selection criterion when recruiting volunteers for any human slip testing experiment is that the volunteers do not have any medical history of neurological disorders. Neurological disorders affect the natural gait of an individual and hence the human slip test results would not be reliable. Apart from neurological disorders, the volunteers or participants of the human slip testing experiments are also tested to make sure that they do not suffer from any physiological and musculoskeletal disorders, such as high blood pressure and muscle weakness which in turn can affect the walking pattern of the participants eventually leading to faulty data recording. Thus, the term physiologically effective implies to those participants who do not have a history of neurological, physiological and musculoskeletal disorders and whose gait cycles are normal. Force plates were placed below the bathroom flooring tile to record the vertical forces generated by the foot contact of the different participants. The friction estimated for the participants were in the range of 0.16 to 0.44. Overall barefoot friction was reported to be lower under wet conditions and in older subjects, with minimal effect of gender.

The limitations in human slip testing experiments are denoted here as the shortcomings. Various factors such as the process of getting ethical clearance for the human participants is a time-consuming process which can lead to delays in performing the slip testing experiments. The physiological and psychological parameters of the participant during a particular event of slip are not repeatable and a large number of trials as a result has to be conducted to properly understand the slip biomechanics. The human slip testing experiments are performed in a lab environment in which there are limited floorings to be tested. The variation in slip risk among larger number of floorings cannot be explored with human slip testing methodologies. The overall cost of the setup of the lab to monitor actual human slips is quite high, which is a throwback in performing greater number of human slip testing experiments. In light of these shortcomings, Nagata et al. [18] fabricated a mechanical slip risk assessment device. Barefoot COF measurement was performed by employing the flat rubber slider, across floorings with a range of surface roughness and with application of varying normal forces and sliding speeds. Barefoot COF was observed to be unaffected with variations in normal forces and sliding speeds, consistent with literature findings [9]. To date, just a handful of studies have focused on using slip testing to characterize barefoot friction. The rubber-based heel simulants not only lack in simulating the human heel’s mechanical properties, but also its structural, surface, and interfacial contact properties. These shortcomings do not allow the slip testing with existing heel simulants to replace human slipping studies [19] and inhibit accurate measurement of barefoot slip risk.

In order to perform biofidelic barefoot slip testing experiments, a novel heel surrogate was developed and slip testing experiments were conducted across different bathroom flooring tiles in the presence of contaminants such as soap, shower gel, and shampoo. The second section presented the materials and methods which were employed in this study. The third section upholded the results obtained from the barefoot slip testing experiments on different floorings in the presence of different bathroom contaminants. The fourth section discussed about the conclusions obtained from the study. The primary objective of this study was to see that if the occurrence of contaminants like water, liquid soap, shower gel and shampoo had affected the barefoot slip risk probability and secondly to identify if there was any generalizable trend in the barefoot ACOF values among the different bathroom flooring tiles.

2 Materials and Methods

2.1 Design of Barefoot Surrogate

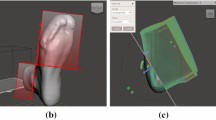

The replication of original biological appendages of human body parts is usually performed by employing a 3D scanner [20,21,22,23,24,25,26]. 3D scanning is also implemented to record the features of different types of footwear [27]. To replicate the slipping in barefoot condition, a laser based 3D scanner (Intel, USA) was implemented to capture the structural attributes of the human foot. After the scanning was completed, the raw data points of the foot model were transformed into a solid model by implementing a software, namely 3D Sense (3D Systems, USA). Only the heel portion was selected to mimic the realistic slipping biomechanics as it is the initial contact zone during the event of unintentional slips [28, 29]. By using a mesh editing software, namely Meshmixer (Autodesk, USA), the heel part was extracted from the overall scanned foot. The cutting plane was inclined at an angle of 17 ± 2.5 degrees based on the average slip angle observed in the previous study [29]. Figure 1 shows the consolidated steps to prepare the heel geometry. A wall thickness of 1.5 mm was applied to generate the mold which was further used for casting the heel surrogate. 3D printing using an Ender 3 printer (Creality, China) was employed for fabricating the heel mold. An adaptor mold was further 3D printed to attach the heel surrogate with the skid tester. Polylactic Acid (PLA) filament having a diameter of 1.75 mm was employed as the material for printing the molds. The molds for 3D printed heel and adaptor are shown in Fig. 2a, b.

2.2 Fabrication of Heel Surrogate

Application of polymeric based materials such as silicone in fabricating soft tissue surrogates and orthoses is increasing [30,31,32,33,34,35,36,37]. For this study, two-part Silicone mixture (LSR 130, Chemzest, India) was mixed and fabricated to ensure similar shore hardness (i.e., 30A) as that of the plantar foot skin, in-line with the study conducted by Chanda et al. [36]. The combination mixture of Silicone was stirred for one minute and then transferred to the heel and adaptor molds (Fig. 2c). During the curing process (Fig. 2d), the partially dry molded adaptor was placed over the heel mold and was allowed to fully dry and bond adhesively with each other for 8 h. In order to perform the repeatability tests in the different slip testing situations, two heel surrogates were fabricated (Fig. 3) and slip tested on dry, water, and soap, shampoo and shower gel contaminants on eight different floorings (Table 1).

2.3 Slip Testing Experiments

In order to perform human slip testing experiments, certain factors play a pivotal role. Firstly, the setup of the experiment which involves a walking platform with force plates to measure the ground force reaction at the moment of slips is required. In order to protect the participants from experiencing fall related accidents, a safety harness system is also required which will protect the participants from fall related injuries. These are the experimental considerations for human slip testing experiments. Apart from this, proper screening of the participants to ensure that they do not suffer from any neurological and musculoskeletal conditions also has to be ensured for appropriate data collection during the slip testing experiments. These considerations for performing human slip testing experiments can be collectively termed as ethical considerations. Several slip risk assessment experiments involved the usage of the British pendulum skid tester. The reason for which this slip tester was used for artificial slipping experiments was due to its ease of portability, and the sliding distance of the British Pendulum Skid Tester was in accordance to that of human slips [38,39,40,41,42]. The heel surrogate was connected to the rectangular bottom part of the rubber slider. The connector of the heel surrogate was so prepared to enable easy attachment of the heel surrogate to the rubber slider. On attaching it to the rubber slider, the bottom portion of the heel surrogate made the required contact with the flooring tile surface. The available coefficient of friction (ACOF) was determined from the British Pendulum Number (BPN) obtained during the tests. BPN was used to calculate the ACOF by using the formula (ACOF = 0.01xBPN). ASTM E303-96 standard was used for performing the experiments using the skid tester. Prior to starting any experiments, the leveling of the tester was done by turning the leveling screws until the tester was leveled with the flooring tile. The pendulum was adjusted to such a position so that the heel surrogate just contacted the flooring tile. Five swings of the pendulum were performed on any test flooring tile surface, and the average BPN was estimated. The strike angle or the heel angle was 17 ± 2.5 degrees between the heel and the ground and was maintained during all the slip tests (Fig. 4a) based on the previous studies [29, 43, 44].

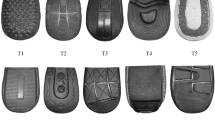

A total of eight commonly used bathroom flooring tiles were chosen for this current slip risk assessment study. Different types of tiles such as porcelain tiles, ceramic tiles, vitrified tiles, glossy tiles and super glossy tiles (Table 1) were included in the eight flooring tiles selected for study. The bathroom flooring tiles were fabricated by similar flooring tile manufacturing company known as Kajaria, India. It was found that these eight-bathroom flooring tiles were mainly being used throughout the country. The average surface roughness (Ra) of flooring tiles was focused because flooring tiles are manufactured and classified based on this parameter. The average surface roughness (Ra) was considered in the previous research by Taylor et al. [43] in which the average surface roughness (Ra) of three different vinyl composite flooring tiles was recorded before the slip testing of 12 formal shoes. The surface roughness was evaluated using a digital surface profilometer (Sudershan Measuring Instruments, India). Apart from dry condition, contaminants such as water, liquid soap (Dettol, Reckitt, UK), shower gel (Nivea, Beiersdorf, Germany) and shampoo (Sunsilk, Unilever, UK) were tested. Considering each contaminant condition in a particular flooring, ten repeated tests were performed, and the averaged ACOF was quantified. The risk of slip was assessed by the ACOF value obtained after each slip testing experiment. If the ACOF value recorded was below 0.3, then the probability of barefoot slip increased but there is a significant possibility of recovery. In the case of a reduction of ACOF below 0.1, there is a determined chance of slipping [43, 45]. Also, the developed heel surrogates were tested for their repeatable nature on the floorings.

2.4 Data Analysis

Evaluation of the frictional values among the floorings in different contaminated scenarios was performed. Repeatability of the surrogates and the association between floorings were evaluated with the help of the coefficient of determination (R2). Values more than 0.7 were designated as strong, and below 0.5 were designated to have insignificant contribution. The values varying from 0.5 to 0.7 were regarded as moderate [46, 47]. The coefficient of determination (R2), instead of the correlation coefficient (R), was used to estimate the percentage variability of the multiple parameters on the ACOF in terms of regression. The flooring surface roughness with the varying ACOF values was quantified in dry and the other considered contaminated floorings. Also, the association of ACOF was explored across flooring conditions to establish the generalizability of barefoot slip risk.

3 Results and Discussions

3.1 Repeatability Nature of Heel Surrogate

After dry slip testing on the various bathroom flooring tiles, employing two heel surrogates, the ACOF values were recorded and eventually compared (Fig. 5). High correlation (R2 = 0.81) was reported, which supported the repeatable nature of the ACOF values when the heel surrogates were used for slip risk assessment on similar bathroom floorings. The observable variations in ACOF values were recorded for tiles F3 and F4, which amounted to 0.05. Slightly lower variations among the ACOF values were noticed for F1 and F6 which was reported to be 0.01. The lowest differences in the ACOF values were recorded for the tiles F2, F5, F7 and F8 which amounted to 0.01. It was also seen that for ACOF values above 0.25 exhibited high difference in the ACOF values across heel surrogates. The similarity in the traction performance of the two heel surrogates which is in terms of the similar ACOF values recorded in each flooring tile indicates the quantitative comparison between the ACOF values recorded. The differences between the ACOF values of the two developed heel surrogates are low and are found to support the repeatable nature of the heel surrogate [37].

3.2 Barefoot ACOF Outcomes with Different Contaminants on Different Floorings

It was observed that the ACOF values recorded during dry slipping were the highest among all the different slip testing scenarios in this present study (Fig. 6). The variation of the ACOF values in the dry slip testing ranged from 0.17 to 0.31. The flooring tile designated as F6 showed the greatest ACOF value (i.e., 0.31) and the flooring tile designated as F8 showed the lowest ACOF value (i.e., 0.17). In the condition for wet slipping, there was a decrease in the ACOF values as compared to that of dry slip testing. The variation of the ACOF values in the wet slip testing ranged from 0.05 to 0.10. It was observed in this wet slip testing scenario, the ACOF value (i.e., 0.10) exhibited by the tile F2 was the highest and the flooring tile designated as F8 exhibited the lowest ACOF value (i.e., 0.05). There was a further decrease in the ACOF values when soap was employed as the contaminant. The range of ACOF values was from 0.05 to 0.07. Similar to that of the wet slip testing scenario, the flooring tile designated as F2 showed the greatest ACOF value (i.e., 0.07) and the flooring tile designated as F8 showed the lowest ACOF value (i.e., 0.05). The ACOF values for the soap and shower gel contaminants were in a similar range (i.e., 0.05 to 0.06). The lowest ACOF values were recorded for the shampoo contamination, varying from 0.03 and went upto 0.06. Across the floorings, the tile designated as F5 displayed the highest ACOF (i.e., 0.06) and the tile F8 exhibited the lowest ACOF (i.e., 0.03) in shampoo contaminated condition. The main information obtained from this graph is that how the traction barefoot performance decreased when transitioning from dry slip testing to wet and subsequently bathroom contaminant applied slip testing conditions. The slip probability increased when transitioning from wet to soap, shampoo and shower gel applied condition as evident from the decrease in ACOF values. Similarity in the traction performance in shampoo and shower gel applied conditions were observed in the F1, F4 and F5 bathroom flooring tiles.

3.3 Variation of Barefoot ACOF with Surface Roughness

An important observation was made when dry slipping was performed on the bathroom flooring tiles specifically F1, F2, F3, F4 and F8 showed a direct trend among the surface roughness and the ACOF (Fig. 7a). The bathroom flooring tiles F5 and F6 had almost similar and high ACOF values, but with wide variation in the surface roughness values. Considering the slip testing in wet condition (Fig. 7b), a decrease in the barefoot traction was observed. Some particular bathroom flooring tiles such as F3, F4, F7 and F8 showed a positive correlation among the barefoot ACOF, and the surface roughness values. The bathroom flooring tiles F1, F7, F4, and F6 had similar ACOF values but different surface roughness values. Specifically, two bathroom flooring tiles F3 and F5 had similar high ACOF values but there was a substantial difference in the surface roughness between them. The number of flooring tiles exhibiting similar ACOF values increased when soap was adopted as the contaminant (Fig. 7c). The flooring tiles F1, F4, F7 and F8 showed similar ACOF values but widely different surface roughness values. The highest ACOF values obtained in this case were that of the flooring tiles F2 and F3, which had a wide variation in their surface roughness values. The lowest obtained ACOF values were from slip testing with the shampoo (Fig. 7d). The flooring tiles F1, F6 and F7, and similarly the tiles F2, F3 and F4 exhibited similar ACOF values but there were wide differences in the surface roughness values. There was a similarity between the ACOF variation trend with the shower gel (Fig. 7e) and the liquid soap applied condition. The flooring tiles F2, F3, F5, F6 and F7 exhibited similar ACOF values but with different surface roughness values.

3.4 Correlation Between Barefoot ACOF and Surface Roughness

It was observed that the overall correlation among the ACOF and surface roughness was poor, an attempt was made to isolate at least five floorings for each contaminated condition, for which meaningful correlations existed. The main focus of this part of the study was to find the relation between the surface roughness of the bathroom flooring tiles and the traction performance recorded by the heel surrogate on these flooring tiles. Initially, the analysis was performed for all the eight flooring tiles but an attempt was made to identify the results of those floorings which had high correlation between the surface roughness and the ACOF values. On the basis of this classification, minimum 5 floorings were considered as the threshold for the correlation analysis for which the term “isolating at least five floorings” were used. This exercise was specifically conducted to study the possibility of barefoot ACOF prediction from known surface roughness of floorings, in the presence of different contaminants. During the process of forming these different flooring combinations, two floorings which negatively affected the correlation were removed. In dry slip testing (Fig. 8a), the flooring tiles F1, F2, F3, F4, F7 and F8 displayed moderate correlation (R2 = 0.62) between the surface roughness values and the ACOF values. In the wet condition (Fig. 8b), the bathroom flooring tiles F3, F4, F5, F6, F7 and F8 showed moderate correlation (R2 = 0.65) among the ACOF and the surface roughness values. For slip testing with the liquid soap (Fig. 8c), the same set of flooring tiles exhibited moderate correlation (R2 = 0.57) amongst the ACOF and the surface roughness. In case of the shampoo applied condition (Fig. 8d), the flooring tiles F2, F3, F4, F7 and F8 showed moderate correlation (R2 = 0.55) among the ACOF and the surface roughness. For the shower gel applied condition (Fig. 8e), the flooring tiles F1, F2, F4, F5, F6, and F7 showed a reasonable correlation (R2 = 0.61) between the ACOF and the surface roughness.

Surface roughness was not found to be a determining factor in estimating the ACOF values on the bathroom flooring tiles when liquid soap, shower gel and shampoo like high contaminants were considered. The phenomenon in which two contact surfaces are kept apart by a thin film of lubricant is designated by the term hydrodynamic lubrication. Hydrodynamic lubrication is also termed as fluid-film, thick-film or flooded lubrication. A film of lubricant is accumulated between the surfaces of the contacting bodies in relative motion. It was found that with the same load, the pressure developed in the film increases as the viscosity of the fluid increases [48]. The film formation might have reduced the effect of the valleys and ridges present on the topography of the flooring tiles. The surface film formation occurs due to the presence of slippery contaminants such as water, liquid soap, shower gel and shampoo resulting in lower correlation values between the barefoot ACOF and surface roughness. Reduction of the effect of surface roughness occurs due to the formation of the surface film and with increasing viscosity of the contaminant, the correlation between the barefoot ACOF and surface roughness decreases. The high viscous fluid film diminishes the effect of the surface roughness of the bathroom flooring tiles used. The surface irregularities of the flooring tiles are completely submerged in the viscous fluid film. The moment when the heel surrogate comes in contact with the flooring tile, the viscous fluid film prevents the actual heel strike contact. Thus, the ACOF decreases with increasing ACOF, as the surface roughness effect is completely diminished by the presence of the viscous shower gel contaminant.

3.5 Generalizable Barefoot ACOF Across Floorings and Contaminants

The traction performance of the heel surrogate varied across the different bathroom flooring tiles in the presence of different bathroom contaminants. It was observed that on comparing the trend in the variation of the traction performance of the heel surrogate among the different bathroom flooring tiles, a certain degree of similarity in the variation of traction performance was observed. This similarity in the variation of the barefoot traction performance among the different bathroom flooring tiles is referred to as the generalizability of barefoot slip risk. The generalizability of barefoot slip risk among the eight different bathroom flooring tiles was observed to increase as the viscosity of the contaminant increased. Thus, the generalizable trend increased from transitioning from water to shower gel contaminant. Slip testing was performed across different flooring tiles in the presence of different contaminants and the correlation analysis among the barefoot ACOF values for the different flooring tiles considering each contaminant scenario was performed accordingly. In the case of the dry slip testing (Fig. 9a), one flooring combination F4-F7 exhibited moderate correlation (0.5 < R2 < 0.7) and five flooring groups F2-F3, F1-F5, F1-F6, F2-F7 and F3-F7 showed high correlations (R2 > 0.7). In wet condition (Fig. 9b), majority of the combinations showed low correlation (R2 < 0.7) and just three flooring groups F1-F3, F1-F4, and F3-F4 showed high correlation. With soap as the contaminant, all the flooring combinations were found to have low correlations (Fig. 9c). With shampoo as the contaminant (Fig. 9d), five flooring combinations F2-F3, F5-F6, F2-F7, F3-F7 and F1-F8 exhibited high correlations. Six flooring combinations F1-F2, F5-F6, F5-F7, F6-F7, F1-F8, and F2-F8 exhibited high correlations in the shower gel contaminated condition (Fig. 9e). Overall, the most generalizable flooring combinations were identified from barefoot slip testing with shower gel contamination, followed by shampoo, dry, and wet conditions. No generalizability was observed across any floorings for the most common soap contaminated condition. These findings indicate the need to test only a few floorings for barefoot slip risk assessment in dry and majority of the slippery conditions, except in the case of soap, where all floorings need to be tested at least once to estimate the slip risk.

4 Conclusions

In this work, the barefoot slip risk quantification was performed by utilizing a biofidelic and as well as a tribofidelic human heel surrogate, which was fabricated by the process of 3D scanning and 3D printing. Eight bathroom flooring tiles were employed for slip risk assessment study in certain contaminant conditions which included dry, wet, soap, shower gel, and shampoo conditions. The friction in the barefoot condition was observed to substantially decrease on transitioning from dry to contaminated conditions. The floorings exhibiting meaningful correlations were estimated for all the contaminants. There were some particular flooring tiles specifically in dry, wet, shampoo and shower gel contaminant conditions which exhibited similar trends in traction performance. Slip risk assessment in these flooring tiles yielded similar trend in variation of the ACOF values also. These observations clarify the barefoot slip risk probability in different bathroom flooring tiles in the presence of commonly availed bathroom contaminants. The main focus of this present study was to understand the barefoot traction performance in dry and viscous contaminant scenarios for bathroom flooring tiles. Future studies will focus on a larger number of bathroom flooring tiles so that more detailed statistical analysis can be performed.

References

Stevens JA, Haas EN, Haileyesus T (2011) Nonfatal bathroom injuries among persons aged ≥15 years-United States, 2008. J Safety Res 42:311–315. https://doi.org/10.1016/j.jsr.2011.07.001

Yiannakoulias N, Rowe BH, Svenson LW, Schopflocher DP, Kelly K, Voaklander DC et al (2008) The epidemiology of bathing disability in older persons. J Am Geriatr Soc 5:311–315. https://doi.org/10.5249/jivr.v5i1.177

Scheffer AC, Schuurmans MJ, Van dijk N, Van der hooft T, De rooij SE (2008) Fear of falling: measurement strategy, prevalence, risk factors and consequences among older persons. Age Ageing 37:19–24. https://doi.org/10.1093/ageing/afm169.

Vellas BJ, Wayne SJ, Romero LJ, Baumgartner RN, Garry PJ (1997) Fear of falling and restriction of mobility in elderly fallers. Age Ageing 26:189–193. https://doi.org/10.1093/ageing/26.3.189

Howland J, Lachman ME, Peterson EW, Cote J, Kasten L, Jette A (1998) Covariates of fear of falling and associated activity curtailment. Gerontologist 38:549–555. https://doi.org/10.1093/geront/38.5.549

Deshpande N, Metter EJ, Lauretani F, Bandinelli S, Guralnik J, Ferrucci L (2008) Activity restriction induced by fear of falling and objective and subjective measures of physical function: a prospective cohort study. J Am Geriatr Soc 56:615–620. https://doi.org/10.1111/j.1532-5415.2007.01639.x

Brouwer B, Musselman K, Culham E (2004) Physical function and health status among seniors with and without a fear of falling. Gerontology 50:135–141. https://doi.org/10.1159/000076771

Brody KK (1997) Evaluation of a self-report screening instrument to predict frailty outcomes in aging populations. Gerontologist 37:182–191. https://doi.org/10.1093/geront/37.2.182

Rozin Kleiner AF, Galli M, Araujo do Carmo A, Barros RML (2015) Effects of flooring on required coefficient of friction: Elderly adult vs. middle-aged adult barefoot gait. Appl Ergon 50:147–52. https://doi.org/10.1016/j.apergo.2015.02.010.

Hemler SL, Pliner EM, Redfern MS, Haight JM, Beschorner KE (2020) Traction performance across the life of slip-resistant footwear: preliminary results from a longitudinal study. J Safety Res 74:219–225. https://doi.org/10.1016/J.JSR.2020.06.005

Gupta S, Sidhu SS, Chatterjee S, Malviya A, Singh G, Chanda A (2022) Effect of floor coatings on slip-resistance of safety shoes. Coatings 12:1455. https://doi.org/10.3390/COATINGS12101455

Gupta S, Chatterjee S, Malviya A, Chanda A (2022) Traction performance of common formal footwear on slippery surfaces. Surfaces 5:489–503 2022. https://doi.org/10.3390/SURFACES5040035.

Gupta S, Malviya A, Chatterjee S, Chanda A (2022) Development of a portable device for surface traction characterization at the shoe–floor interface. Surfaces 5:504–520. https://doi.org/10.3390/SURFACES5040036

Derler S, Huber R, Feuz HP, Hadad M (2009) Influence of surface microstructure on the sliding friction of plantar skin against hard substrates. Wear 267:1281–1288. https://doi.org/10.1016/j.wear.2008.12.053

Li KW, Wen HC (2014) Friction between foot and floor under barefoot conditions: a pilot study. IEEE Int Conf Ind Eng Eng Manag 1651–5. https://doi.org/10.1109/IEEM.2013.6962690

Nagata H, Kato M, Watanabe H, Inoue Y, Kim IJ (2008) A preliminary study on slip potentials of stepping barefoot on slippery floors. Contemp Ergon 2008:710–716

Siegmund GP, Flynn J, Mang DW, Chimich DD, Gardiner JC (2010) Utilized friction when entering and exiting a dry and wet bathtub. Gait Posture 31:473–478. https://doi.org/10.1016/j.gaitpost.2010.02.003

Nagata H, Watanabe H, Inoue Y, Kim I (2008) Development of a slip-resistance meter for evaluating fall risk on slippery floors covered with soapsuds

Iraqi A, Cham R, Redfern MS, Vidic NS, Beschorner KE (2018) Kinematics and kinetics of the shoe during human slips. J Biomech 74:57–63. https://doi.org/10.1016/J.JBIOMECH.2018.04.018

Wan FKW, Yick KL, Yu WWM (2017) Validation of a 3D foot scanning system for evaluation of forefoot shape with elevated heels. Meas J Int Meas Confed 99:134–144. https://doi.org/10.1016/j.measurement.2016.12.005

Yamashita T, Yamashita K, Sato M, Kawasumi M, Ata S (2021) Foot-surface-structure analysis using a smartphone-based 3D foot scanner. Med Eng Phys 95:90–96. https://doi.org/10.1016/j.medengphy.2021.08.001

Chen LH, Chang CC, Wang MJ, Tsao L (2018) Comparison of foot shape between recreational sprinters and non-habitual exercisers using 3D scanning data. Int J Ind Ergon 68:337–343. https://doi.org/10.1016/j.ergon.2018.08.006

Chanda A, Unnikrishnan V (2018) Novel insole design for diabetic foot ulcer management. Proc Inst Mech Eng Part H J Eng Med 232:1182–1195. https://doi.org/10.1177/0954411918808330

Singh G, Gupta S, Chanda A (2021) Biomechanical modelling of diabetic foot ulcers: a computational study. J Biomech 127:110699. https://doi.org/10.1016/J.JBIOMECH.2021.110699

Gupta S, Singh G, Chanda A (2021) Prediction of diabetic foot ulcer progression: a computational study. Biomed Phys Eng Express 7:065020. https://doi.org/10.1088/2057-1976/AC29F3

Irzmańska E, Okrasa M (2018) Evaluation of protective footwear fit for older workers (60+): a case study using 3D scanning technique. Int J Ind Ergon 67:27–31. https://doi.org/10.1016/j.ergon.2018.04.001

McGorry RW, DiDomenico A, Chang CC (2010) The anatomy of a slip: kinetic and kinematic characteristics of slip and non-slip matched trials. Appl Ergon 41:41–46. https://doi.org/10.1016/j.apergo.2009.04.002

Grönqvist R, Hirvonen M, Rajamäki E, Matz S (2003) The validity and reliability of a portable slip meter for determining floor slipperiness during simulated heel strike. Accid Anal Prev 35:211–225. https://doi.org/10.1016/S0001-4575(01)00105-1

Chanda A, Jones TG, Beschorner KE (2018) Generalizability of footwear traction performance across flooring and contaminant conditions. IISE Trans Occup Ergon Hum Factors 6:98–108. https://doi.org/10.1080/24725838.2018.1517702

Singh G, Chanda A (2021) Mechanical properties of whole-body soft human tissues: a review. Biomed Mater 16:062004. https://doi.org/10.1088/1748-605X/AC2B7A

Singh G, Gupta V, Chanda A (2022) Mechanical characterization of rotating triangle shaped auxetic skin graft simulants. Facta Univ Ser Mech Eng. https://doi.org/10.22190/FUME220226038S

Singh G, Gupta V, Chanda A (2022) Artificial skin with varying biomechanical properties. Mater Today Proc. https://doi.org/10.1016/J.MATPR.2022.03.433

Makode S, Singh G, Chanda A (2021) Development of novel anisotropic skin simulants. Phys Scr 96:125019. https://doi.org/10.1088/1402-4896/AC2EFD

Chanda A, Chatterjee S, Gupta V (2020) Soft composite based hyperelastic model for anisotropic tissue characterization. J Compos Mater 54:4525–4534. https://doi.org/10.1177/0021998320935560

Chanda A, Callaway C, Clifton C, Unnikrishnan V (2018) Biofidelic human brain tissue surrogates. Mech Adv Mater Struct 25:1335–1341. https://doi.org/10.1080/15376494.2016.1143749

Chanda A, McClain S (2019) Mechanical modeling of healthy and diseased calcaneal fat pad surrogates. Biomimetics 4:1. https://doi.org/10.3390/biomimetics4010001

Chatterjee S, Chanda A (2022) Development of a tribofidelic human heel surrogate for barefoot slip testing. J Bionic Eng. https://doi.org/10.1007/s42235-021-00138-0

Nagata H, Watanabe H, Inoue Y, Kim I (2016) Fall risks and validities of various methods to measure frictional properties of slippery floors covered with soapsuds θ.

Terjék A, Dudás A (2018) Ceramic floor slipperiness classification—a new approach for assessing slip resistance of ceramic tiles. Constr Build Mater 164:809–819. https://doi.org/10.1016/j.conbuildmat.2017.12.242

Sudoł E, Szewczak E, Małek M (2021) Comparative analysis of slip resistance test methods for granite floors. Materials (Basel) 14:1–15. https://doi.org/10.3390/ma14051108

Gupta S, Chatterjee S, Chanda A (2022) Effect of footwear material wear on slips and falls. Mater Today Proc. https://doi.org/10.1016/J.MATPR.2022.04.313

Chatterjee S, Gupta S, Chanda A (2022) Barefoot slip risk assessment of Indian manufactured ceramic flooring tiles. Mater Today Proc. https://doi.org/10.1016/J.MATPR.2022.04.428

Jones T, Iraqi A, Beschorner K (2018) Performance testing of work shoes labeled as slip resistant. Appl Ergon 68:304–312. https://doi.org/10.1016/j.apergo.2017.12.008

Iraqi A, Vidic NS, Redfern MS, Beschorner KE (2020) Prediction of coefficient of friction based on footwear outsole features. Appl Ergon 82:102963. https://doi.org/10.1016/j.apergo.2019.102963

Hemler SL, Charbonneau DN, Iraqi A, Redfern MS, Haight JM, Moyer BE et al (2019) Changes in under-shoe traction and fluid drainage for progressively worn shoe tread. Appl Ergon 80:35–42. https://doi.org/10.1016/J.APERGO.2019.04.014

Chanda A, Jones TG, Beschorner KE (2018) Generalizability of footwear traction performance across flooring and contaminant conditions. 6:98–108. https://doi.org/10.1080/24725838.2018.1517702

Chanda A, Reuter A, Beschorner KE (2019) Vinyl composite tile surrogate for mechanical slip testing. 7:132–41. https://doi.org/10.1080/2472583820191637381

Gohar R, Safa MMA (2010) Fluid film lubrication. Tribol Dyn Engine Powertrain Fundam Appl Futur Trends 132–70. https://doi.org/10.1533/9781845699932.1.132

Acknowledgements

No funding was received for this work.

Statements and Declarations

The authors declare no conflict of interest with respect to the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Chatterjee, S., Gupta, S., Chanda, A. (2023). Traction Performance of Barefoot Heel Simulant in Contaminated Bathroom Flooring Tiles. In: Chanda, A., Sidhu, S.S., Singh, G. (eds) Materials for Biomedical Simulation. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-99-5064-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-99-5064-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-5063-8

Online ISBN: 978-981-99-5064-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)